Sewing anti-thread-breakage device of sewing machine

An anti-sewing device and technology for sewing machines are applied in sewing machine control devices, sewing machine components, and thread cutting mechanisms in sewing machines. The effect of hooking and returning the thread, not easy to jump off the thread, and reasonable space arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

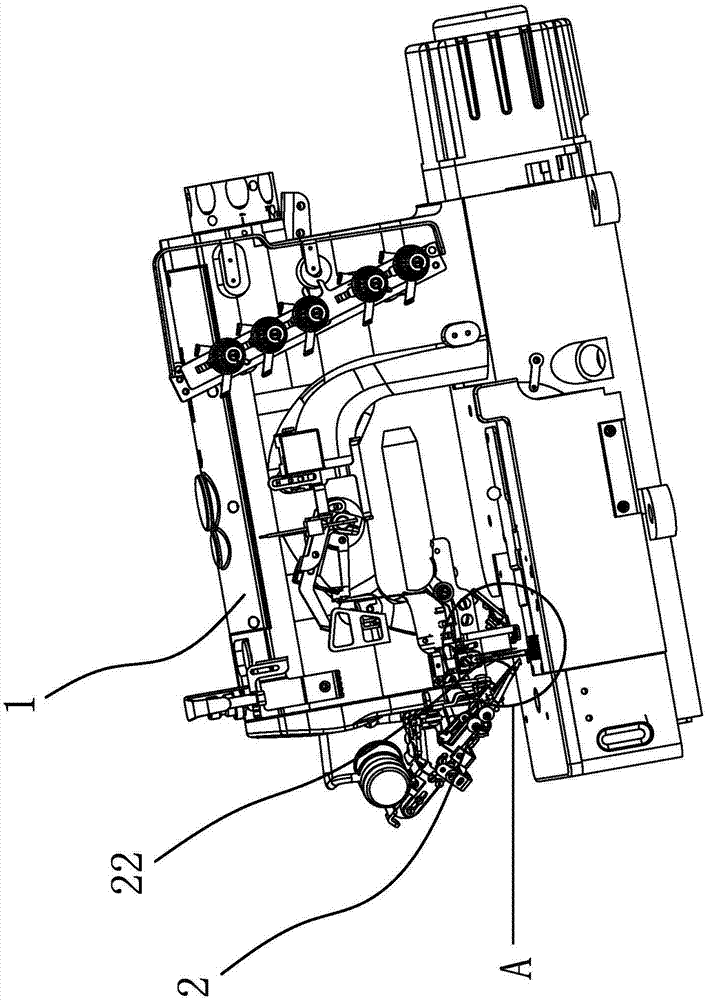

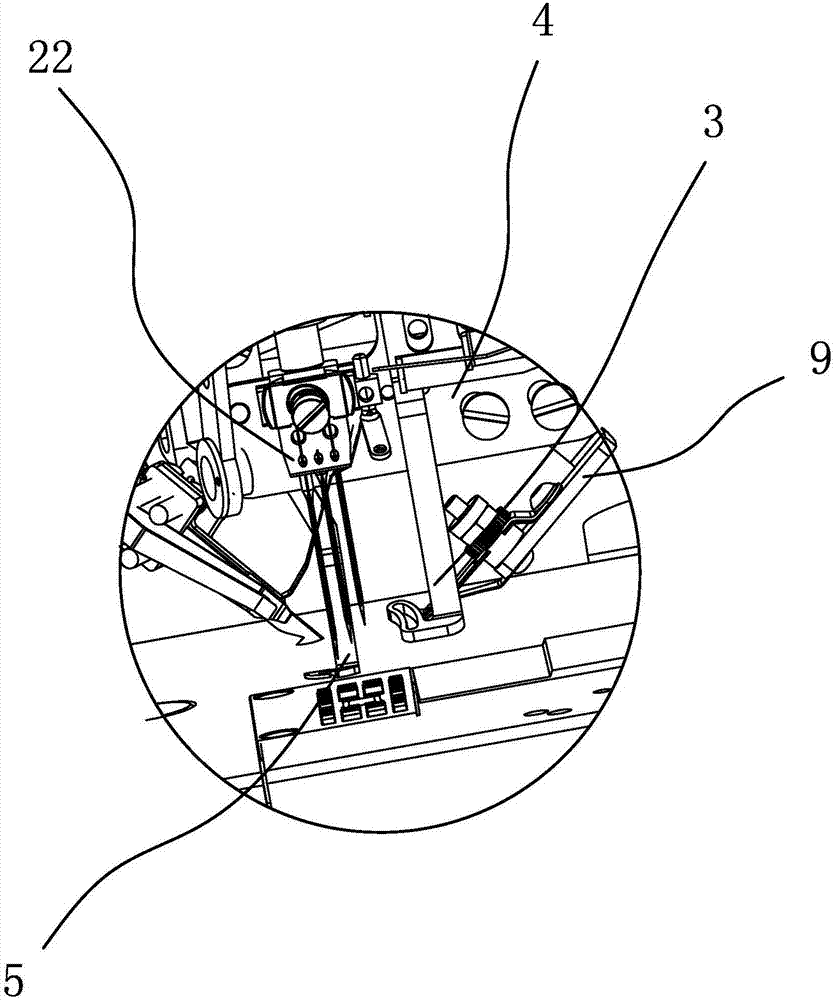

[0027] like figure 1 and 2 As shown, the sewing machine includes a casing 1, a decorative thread knife assembly 2, a needle feeding hook, a needle feeding frame 22 and a needle feeding thread plate 3. The seam prevention device includes a mounting plate 4, a wire pulling assembly and a thread clamping assembly. The mounting plate 4 is in the shape of a long strip. rear side.

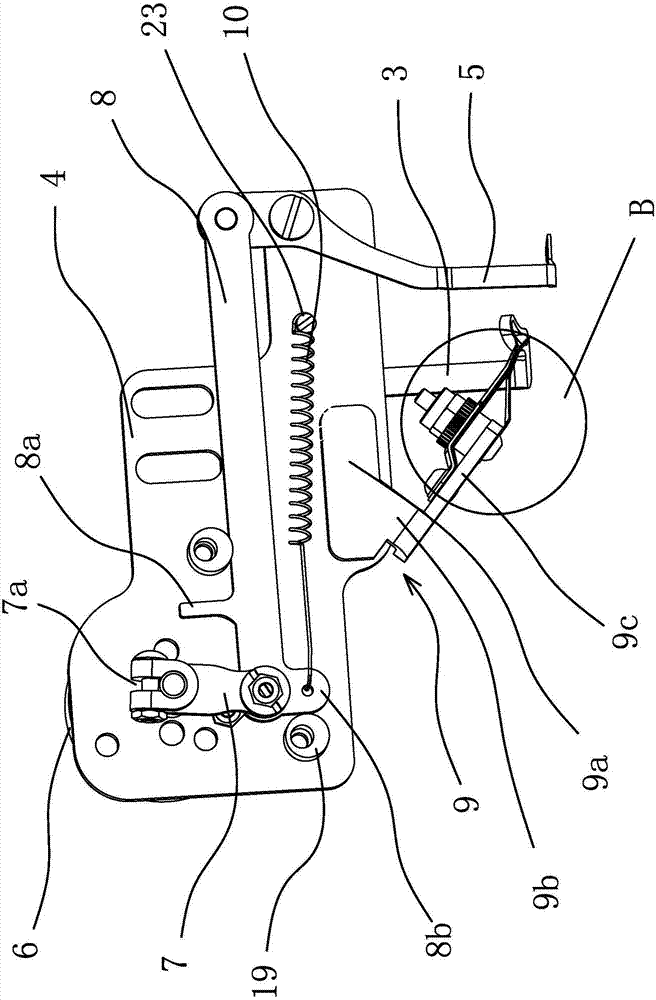

[0028] The wire pulling assembly includes a driving part and a wire pulling knife 5 with a pull hook at one end, and a driving crank 7 and a transmission connecting rod 8 are also arranged between the driving part and the wire pulling knife 5 of the driving part. like image 3 As shown, in the present embodiment, the driving part is a rotating electromagnet 6, and the rotating electromagnet 6 is fixed on one end of the mounting plate 4, and the middle part of the wire pulling knife 5 is hinged on the other end of the mounting plate 4 through a rotating shaft, and the rotating electromagnet 6 and Wiri...

Embodiment 2

[0034] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is: Figure 5 As shown, the driving part is a linear electromagnet 20, the linear electromagnet 20 is fixed on the mounting plate 4, the iron core of the linear electromagnet 20 is fixed with a connecting pin 21, and one end of the driving crank 7 is provided with a strip-shaped sliding hole 7b. The connecting pin 21 slides through the sliding hole 7 b, the middle part of the driving crank 7 is hinged on the mounting plate 4 , and the other end of the driving crank 7 is hinged with the transmission connecting rod 8 . The mounting plate 4 also has a fixed column 23 , one end of the return spring 10 is fixedly sleeved on the fixed column 23 , and the other end is fixedly mounted on the driving crank 7 . The movement of the iron core of the linear electromagnet 20 drives the connecting pin 21, and the connecting pin 21 slides in the sliding hole 7b of the driving crank 7, and dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com