Novel wire-type crank structure

A crank and line type technology, applied in the field of new linear crank crank structure, can solve the problem that the brake wire cannot completely fall into the wire pressing groove, easy to produce sliding wire, easy to press and break the brake wire and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

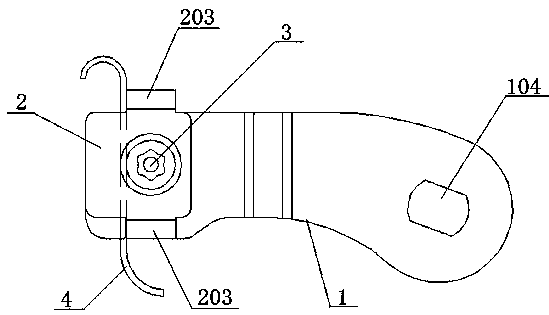

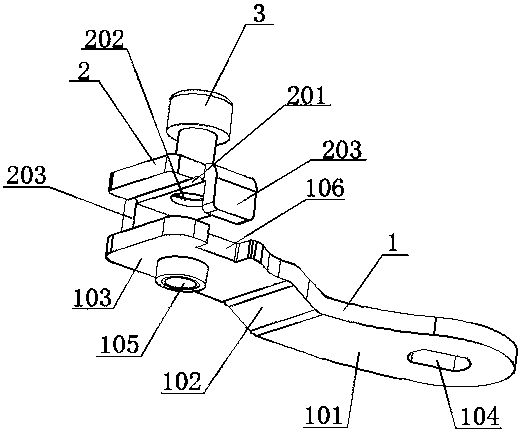

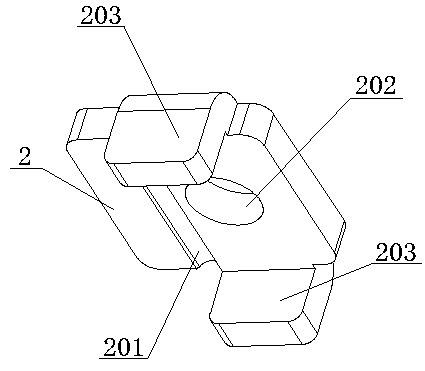

[0013] like Figure 1-Figure 3 As shown, a novel line bellcrank structure includes a line bellcrank body 1, a pressure plate 2 and an anti-theft bolt 3. The brake line positioning plate 103 constitutes an integral part, and one end of the crank throw body plane plate 101 is connected to the brake line positioning plate 103 through a shaped curved plate 102, and the other end of the crank throw body plane plate 101 is provided with a camshaft mounting hole 104, so that The brake wire positioning plate 103 is provided with a first threaded hole 105 compatible with the anti-theft bolt, and the pressure plate 2 is provided with a crimping groove 201 and a second threaded hole 202 adapted with the anti-theft bolt, and Limiting flanges 203 are provided on both sides of the wire crimping plate 2, the crimping groove 201 is located at one side of the limiting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com