Pressure-adjustable steering gear rack compaction structure

A technology of pressing structure and steering gear, which is applied in the direction of steering gear, steering mechanism, mechanical steering gear, etc., can solve the problems of reducing the service life of the steering gear, the pressing force cannot be adjusted, and the contact area is small, so as to reduce friction , increase the contact area, reduce the effect of wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

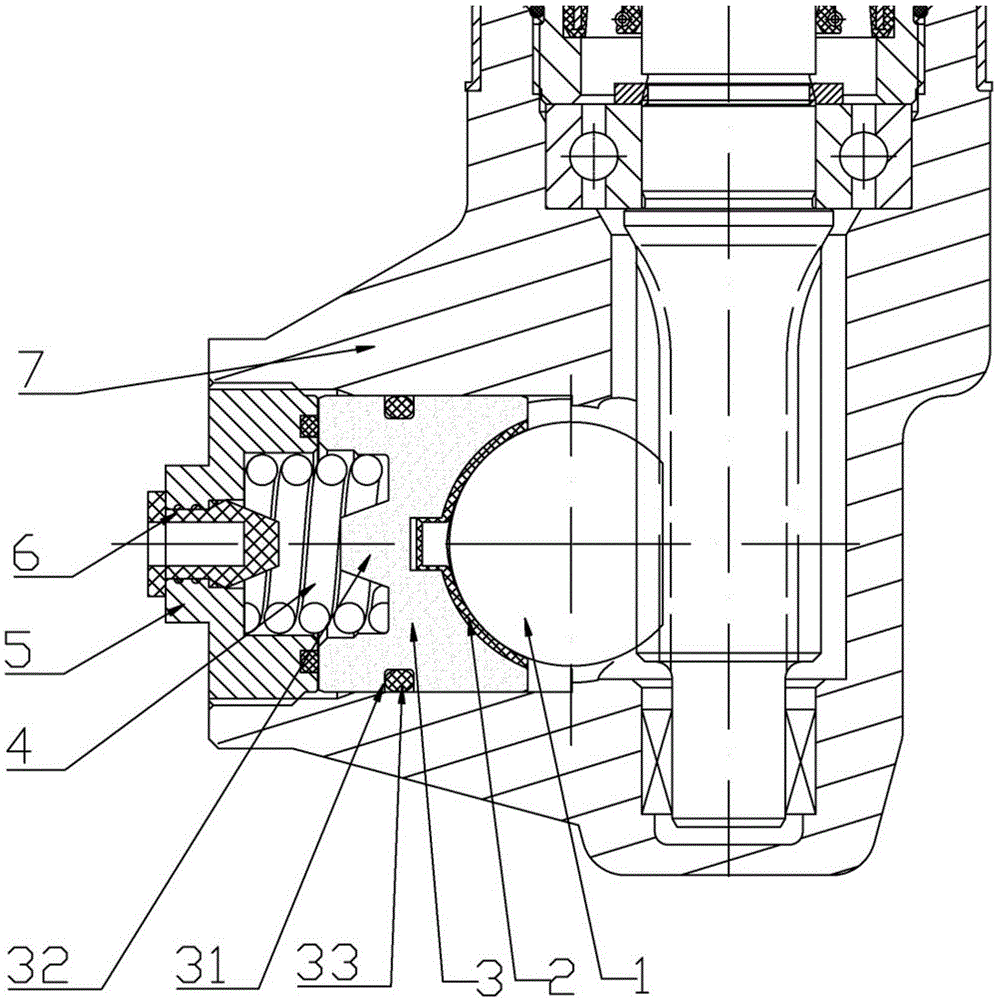

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0025] see figure 1 , a pressure-adjustable steering gear rack pressing structure, has:

[0026] Intermeshing gear and rack 1 installed in housing 7;

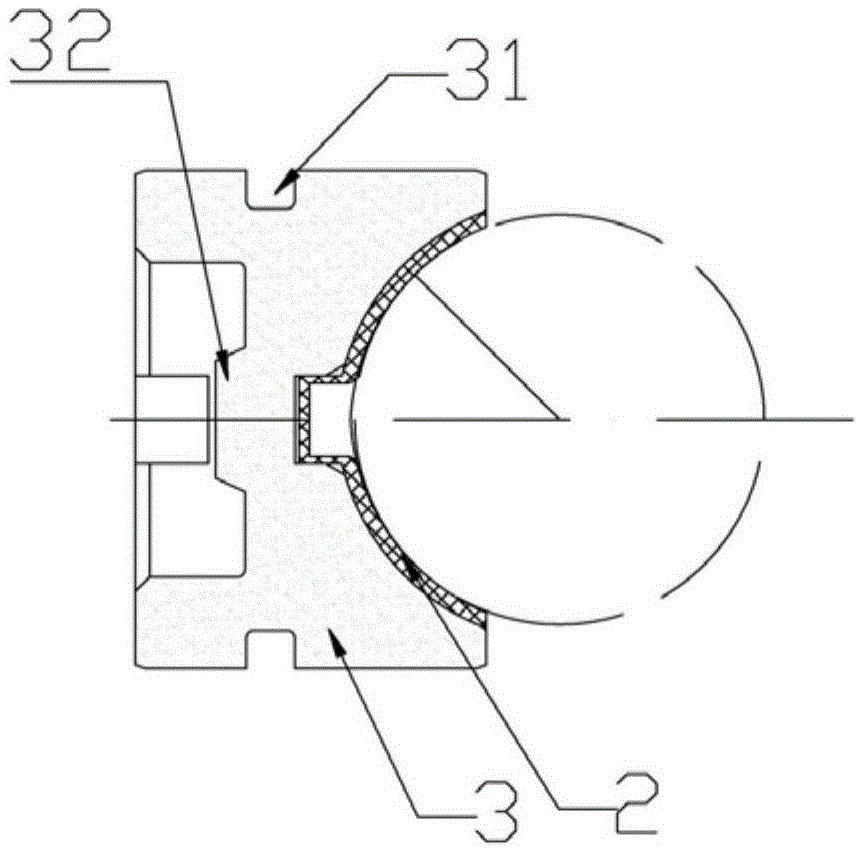

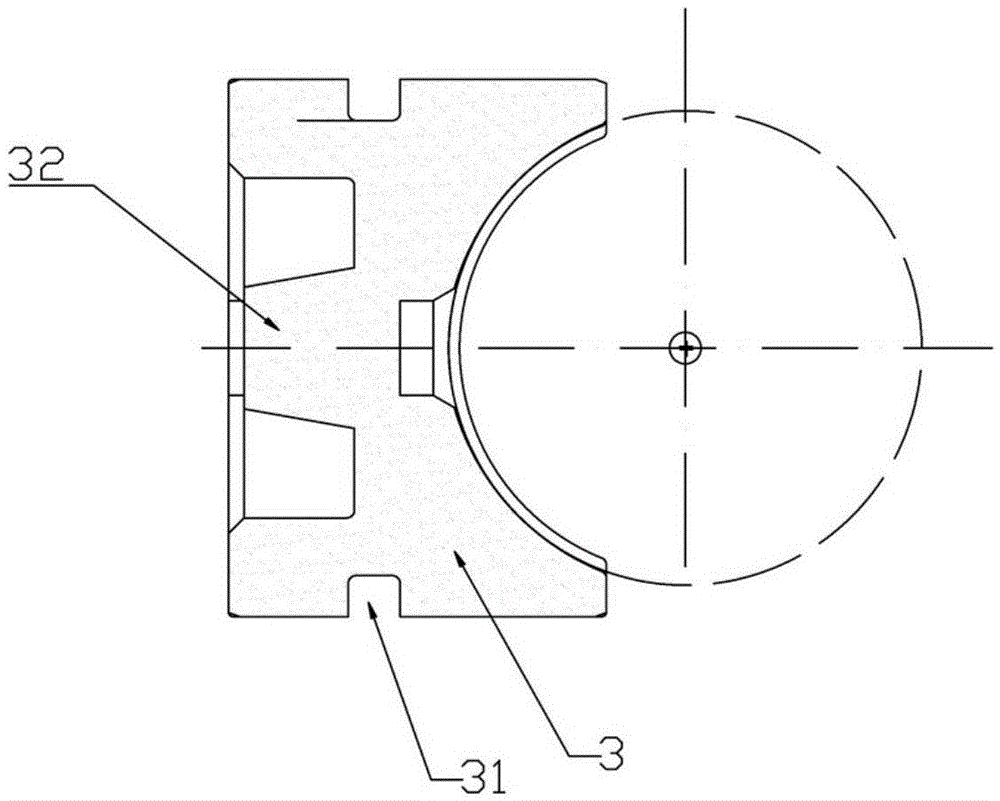

[0027] Press the support block 3 of the rack 1, and the end of the support block 3 opposite to the rack 1 is arc-shaped;

[0028] The arc-shaped pressing piece 2 arranged between the supporting pressure block 3 and the rack 1, such as Figure 6 As shown, the side of the pressing piece 2 in contact with the rack 1 is provided with an oil groove storing a lubricating medium; the lubricating medium is lubricating oil or grease.

[0029] The gland 5 is provided with a sealing screw 6 penetrating through the gland 5, and the sealing screw 6 is made of rubber to prevent dust and water.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com