Thread pulling device

It is a technology of pulling thread knife and clamping thread, which is applied in the field of thread threading device, which can solve the problems of easy thread removal, long distance, and large space occupation, and achieve the effect of not easy thread thread removal, stable seam start, and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

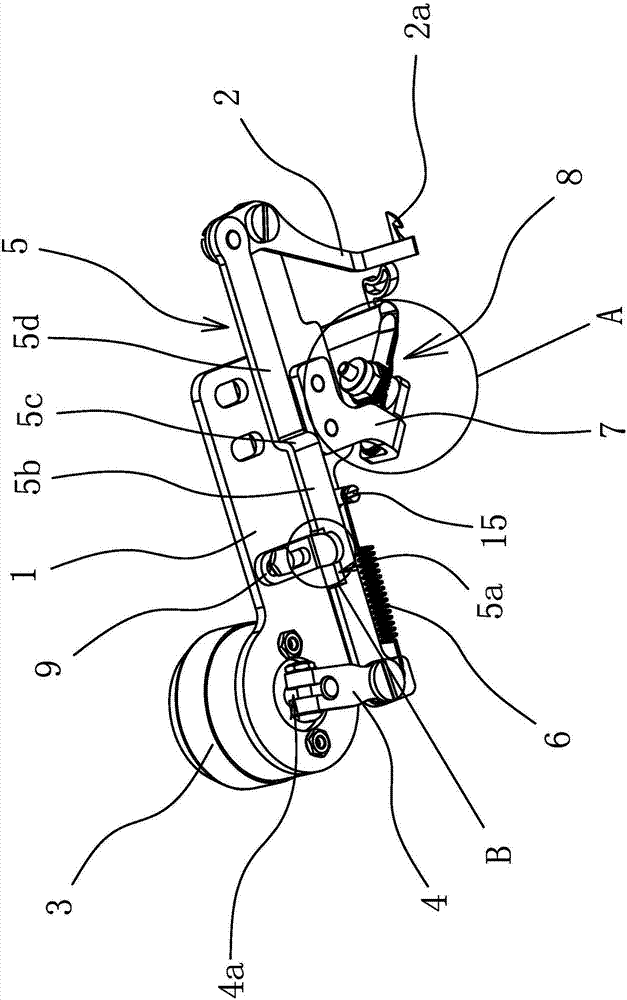

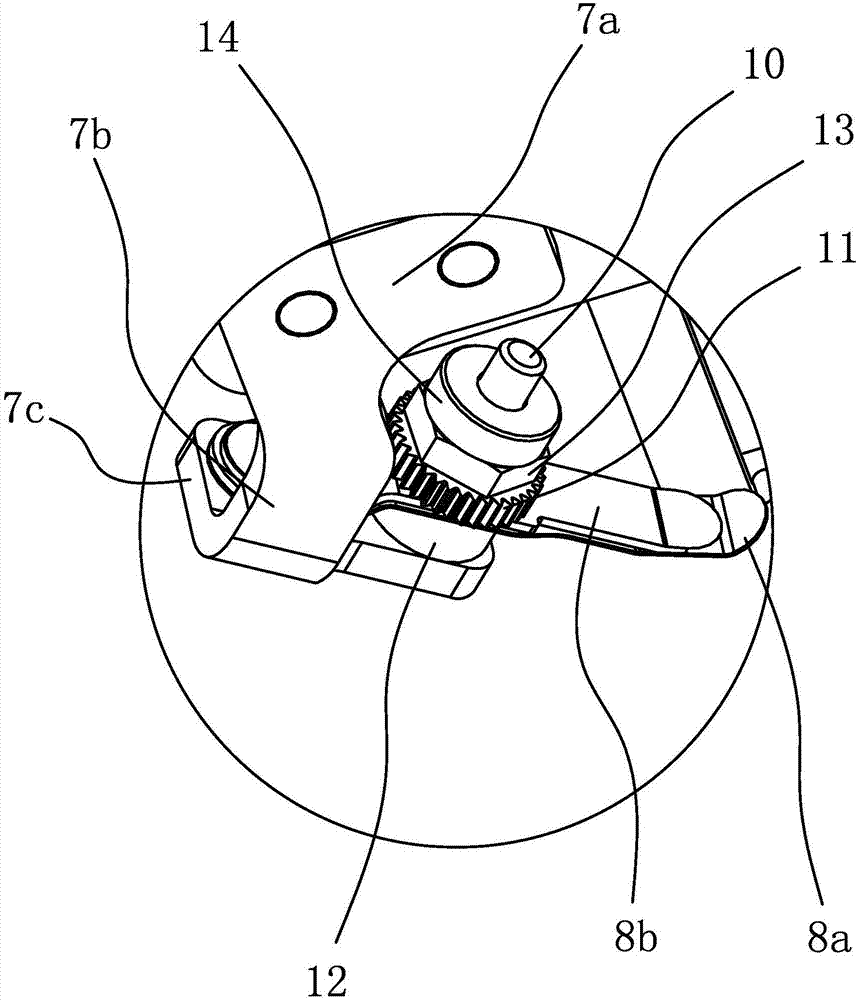

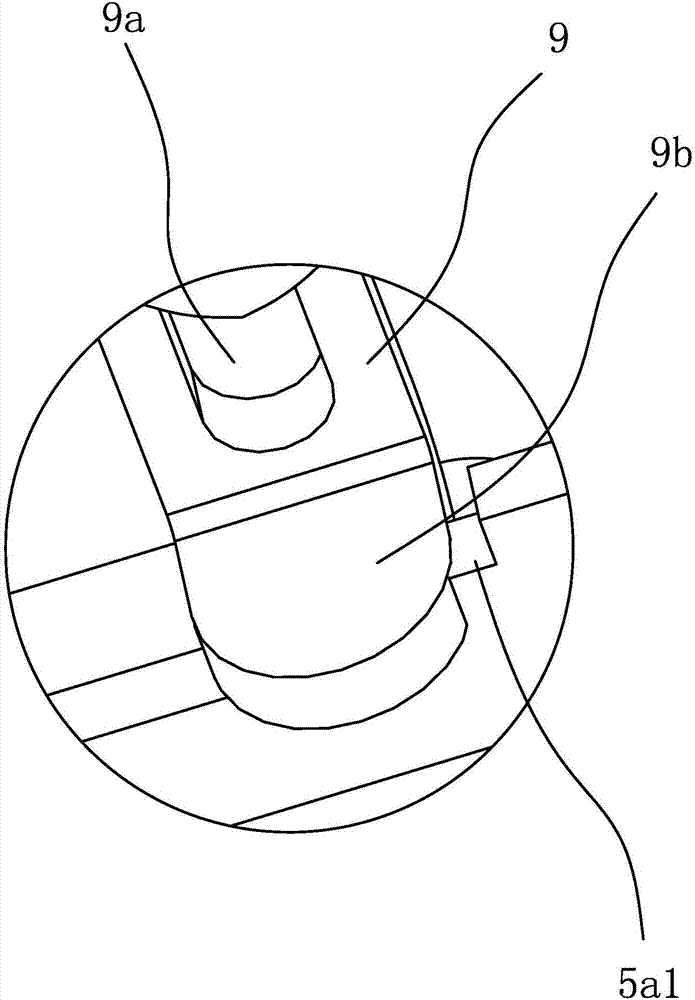

[0026] Such as figure 1 As shown, the wire pulling device is used to be installed on a sewing machine, and includes a mounting plate 1, a thread pulling knife 2 with a hook 2a at one end, a thread clamp assembly 8, a driving member and a mounting piece 7 detachably connected to the mounting plate 1 . The mounting plate 1 is in the shape of a long strip, the driving part is fixed on one end of the mounting plate 1, the middle part of the wire pulling knife 2 is hinged to the other end of the mounting plate 1 through a rotating shaft, and the driving part and the wire pulling knife 2 are respectively located on both sides of the mounting plate 1 , the mounting piece 7 and the wire wiper 2 are located on the same side of the mounting plate 1, and a drive crank 4 and a transmission connecting rod 5 are also arranged between the driver and the wire wiper 2 of the driving part.

[0027] Specifically, the driving part is a rotating electromagnet 3, and the rotating electromagnet 3 i...

Embodiment 2

[0033] The structure and features of this implementation are basically the same as in Embodiment 1, the difference is that: Figure 4 As shown, two eccentric shafts 16 are fixed on the mounting plate 1, and one end of the transmission connecting rod 5 hinged with the driving crank 4 has a downward bending baffle 5f, and the middle part of the transmission connecting rod 5 has a protruding limit The stop bar 5e, the baffle plate 5f and the stop bar are located between the two eccentric shafts 16, the baffle plate 5f can abut against one of the eccentric shafts 16 when the rotating electromagnet 3 drives the driving crank 4 to swing, and the stop bar 5e is on the drive crank. 4 can abut against another eccentric shaft 16 when returning to its position. The matching structure design of the two eccentric shafts 16 and the baffle plate 5f and the limit rod 5e respectively can limit the movement and the return stroke of the transmission connecting rod 5, thereby realizing the limit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com