Speed monitoring and braking device for vertical lifting equipment

A vertical lifting and speed monitoring technology, applied in the direction of hoisting devices, lifting frames, elevators, etc., can solve the problems of brake failure, increase the use cost, occupy a large space, etc., and achieve the effect of convenient and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

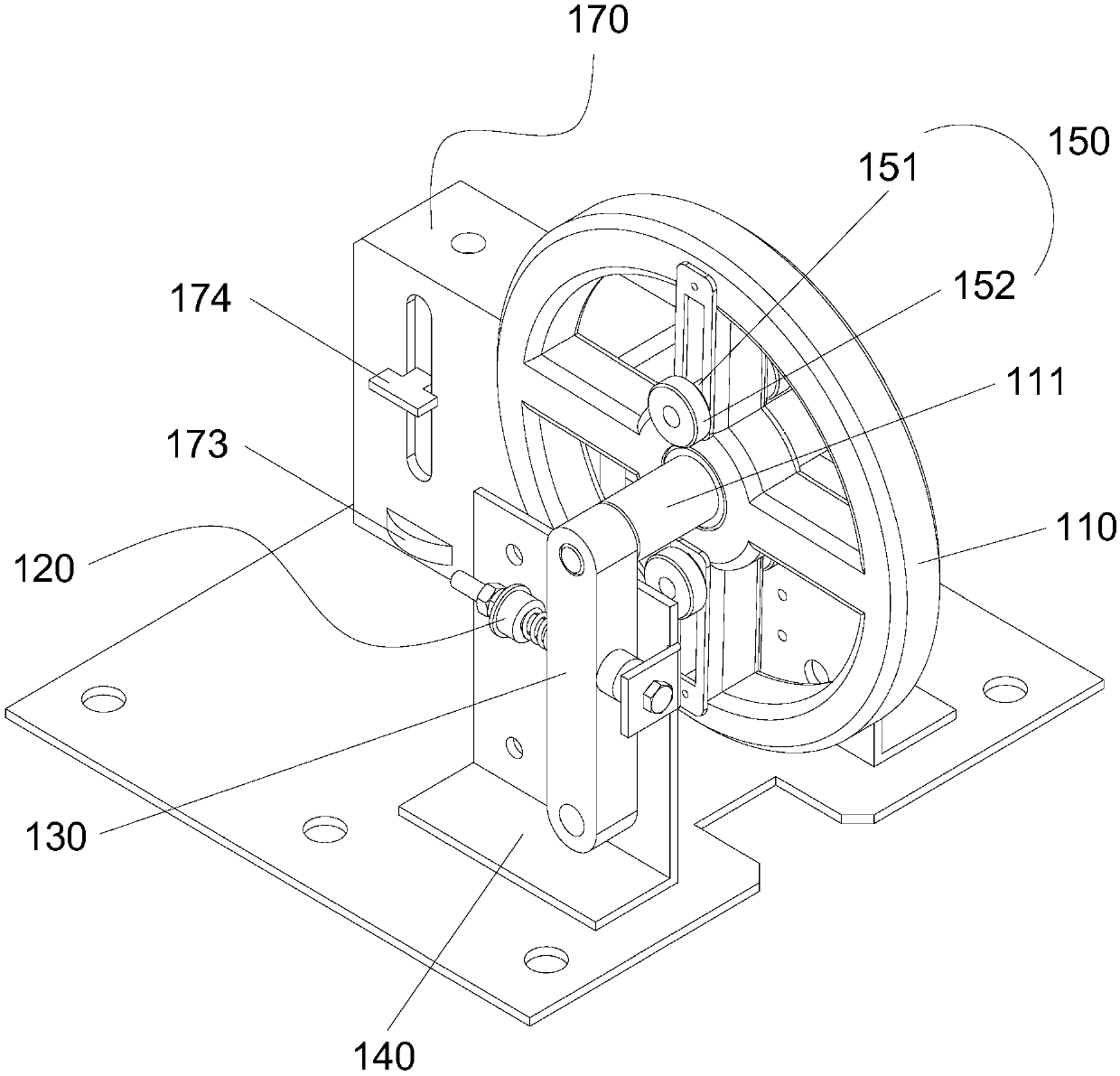

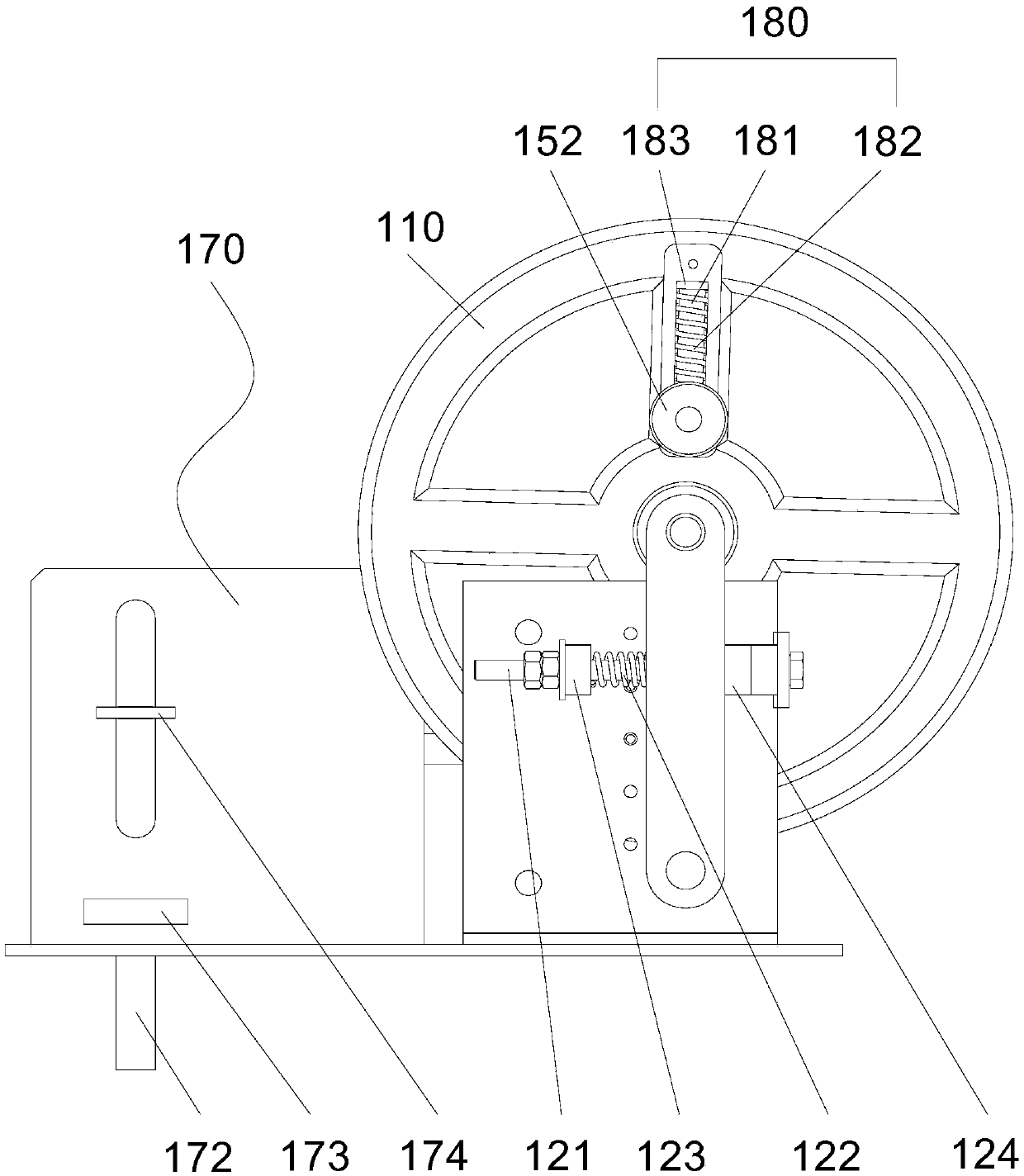

[0044] see figure 1—4, a speed monitoring and braking device 1 of a vertical lifting device, which includes: a roller 110, whose wheel circumference is pressed on the guide rail 4 of the vertical lifting device; The car body 2 of the vertical lifting device is connected; the centrifugal block 150 is movably arranged on the roller 110 along the radial direction of the roller 110; the centrifugal block balance mechanism 180 includes a compressible elastic member, preferably a compressible elastic member It is stage clip 182; stage clip 182 is arranged between the wheel circumference of centrifugal block 150 and roller 110; main engine safety switch 160, it comprises the first trigger mechanism that disconnects main engine safety switch 160 after feeling centrifugal block 150, preferably Specifically, the first trigger mechanism is the shift lever 161; the brake trigger device 170 includes: a pull rod 172, which is connected with the safety gear pull device 3; after the centrifug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com