A filter and filter element assembly thereof

A filter and filter element technology, applied in fixed filter element filters, filtration separation, chemical instruments and methods, etc., can solve problems such as damage to parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

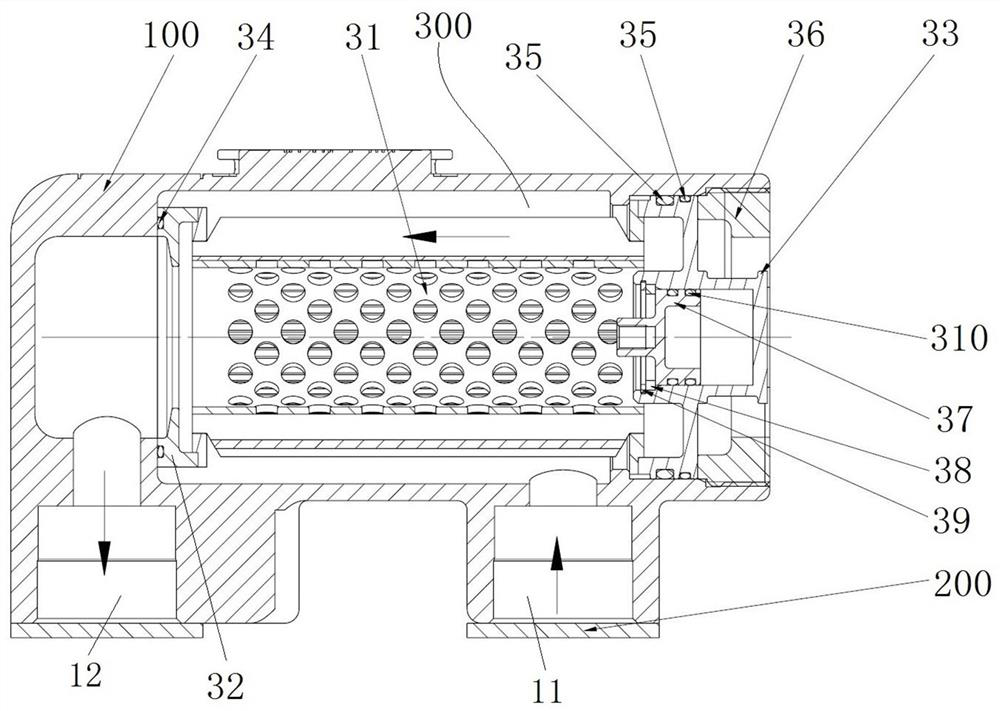

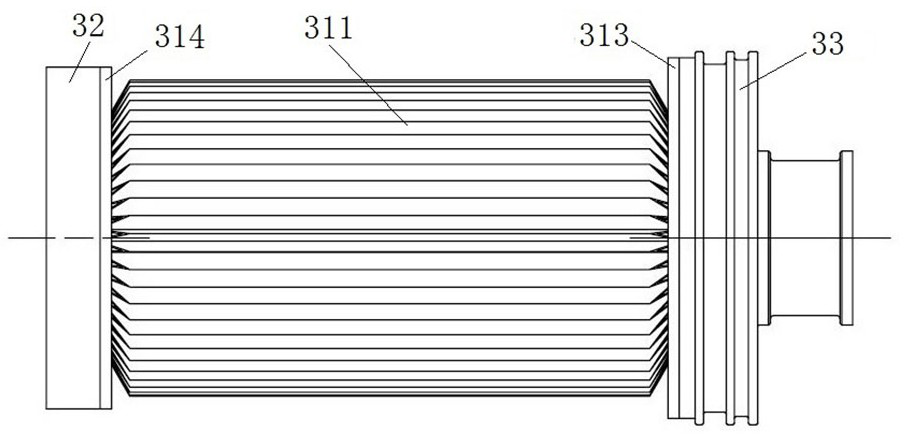

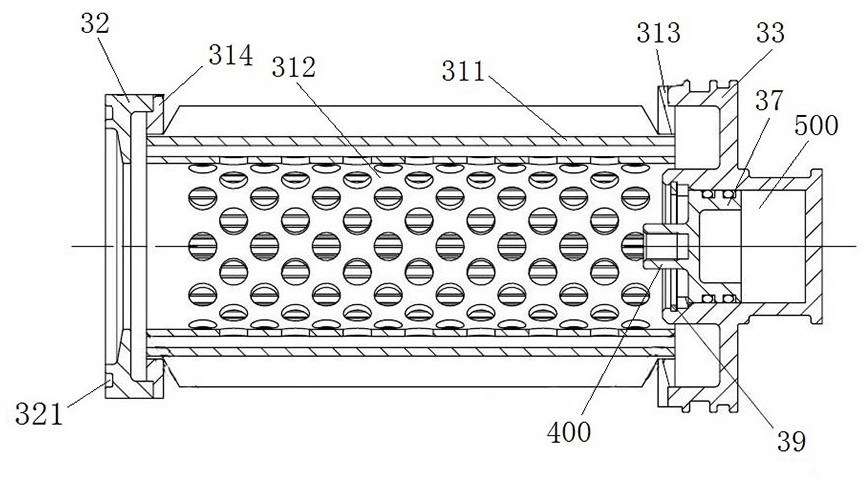

[0031] Specific embodiments of the filter of the present invention, such as Figure 1 to Figure 3 shown. Such as figure 1 As shown, the filter includes a housing 100, and the housing 100 is provided with a media inlet 11 and a media outlet 12. In this embodiment, the media inlet 11 and the media outlet 12 are arranged on the same side of the housing 100. Form return channels for liquid flow. A protective cover 200 is mounted on the medium inlet 11 and the medium outlet 12 . Of course, in other embodiments, the specific location of the medium inlet and the medium outlet can be selected according to the actual situation, for example, the medium inlet and / or the medium outlet can be arranged at one end of the housing. In the present invention, the two ports on the shell are the medium inlet and the medium outlet, and the medium inlet and the medium outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com