A LED miniaturized power supply

A technology of power supply and power management, applied in the field of power supply, can solve the problems of large heat generation, unstable output, and rising heat generation of IC chips, and achieve the effects of stable power supply performance, cost reduction, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing of description:

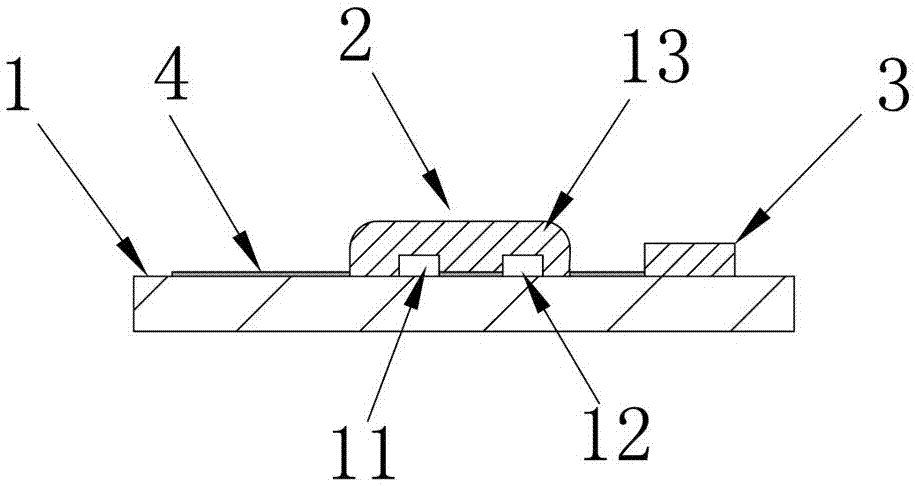

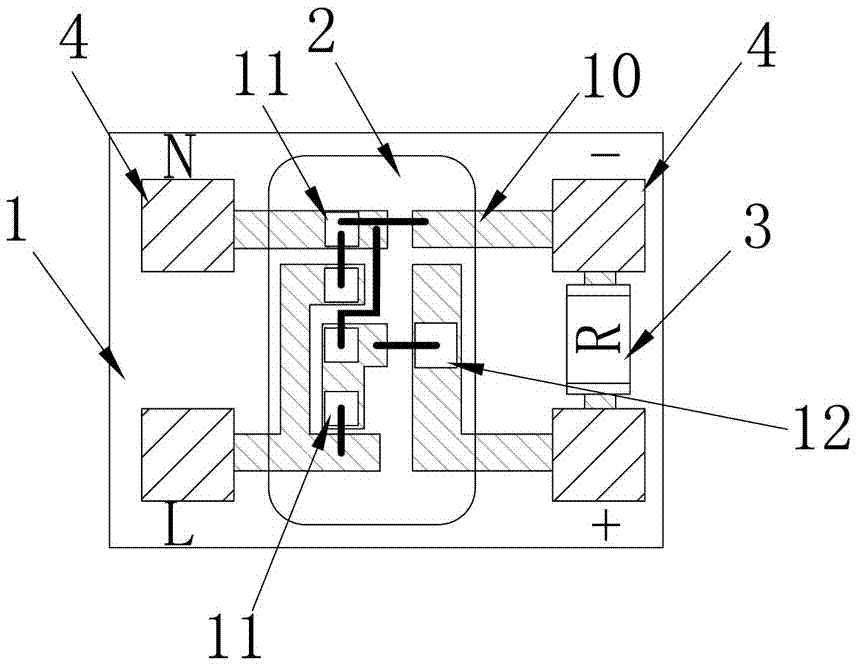

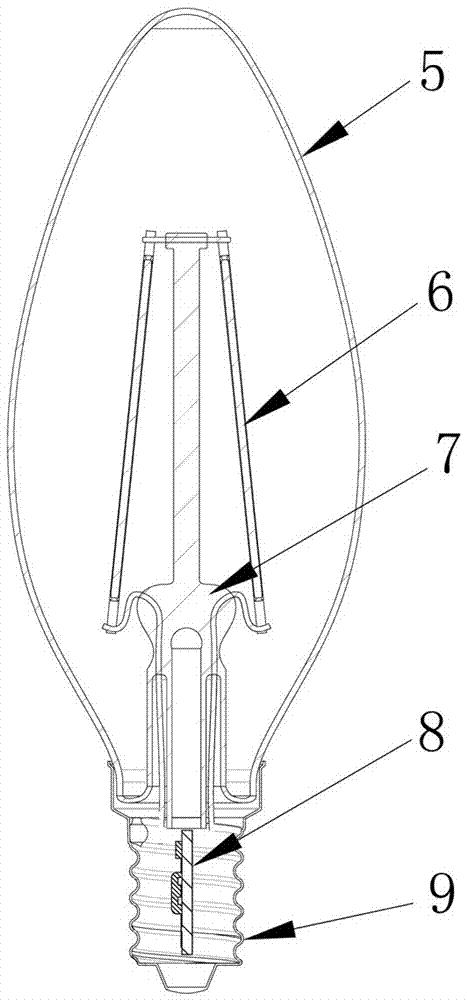

[0022] as attached Figure 1~2 As shown, the present invention discloses a LED miniaturized power supply, comprising a ceramic PCB substrate 1 and a silver paste circuit 10 sintered on the ceramic PCB substrate 1, the ceramic PCB substrate 1 is provided with a power management IC module 2, and the power supply In the management IC module, there are wafers with linear constant current function and auxiliary function devices directly packaged on the ceramic PCB substrate 1, and electronic components 3 are arranged on the periphery of the power management IC module 2, and the power management IC module 2 Input and output pads 4 are provided on both sides of the ceramic PCB substrate 1, silver paste lines are sintered on the ceramic PCB substrate 1, and the power management IC module 2 includes a wafer 11, an auxiliary function device 12 and a wafer 11 covered T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com