Method for welding pile leg and pile shoe of drill platform

A welding method and drilling platform technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as difficult welding, achieve cost saving, avoid material waste, and facilitate construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below through embodiments in conjunction with the accompanying drawings.

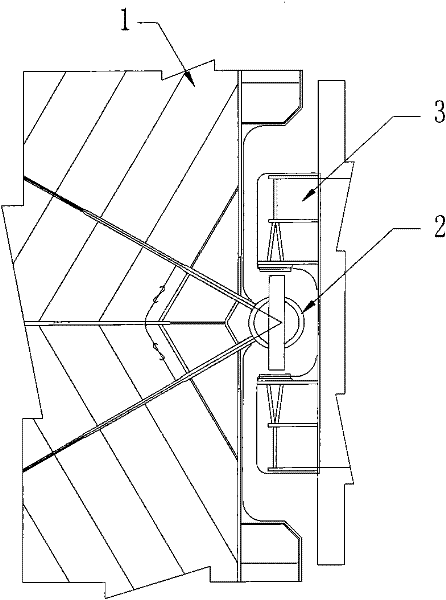

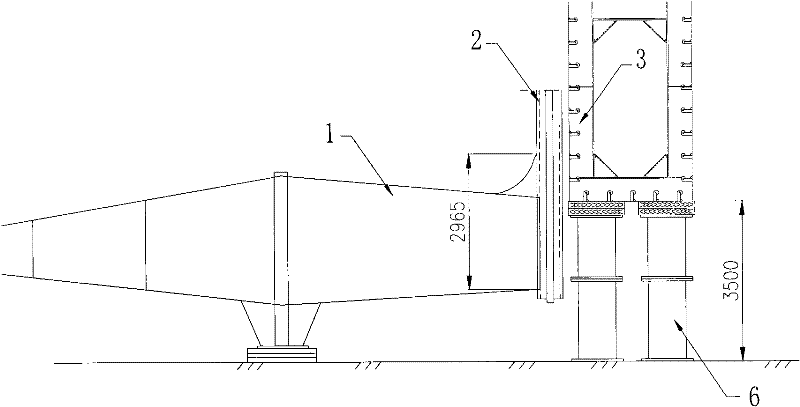

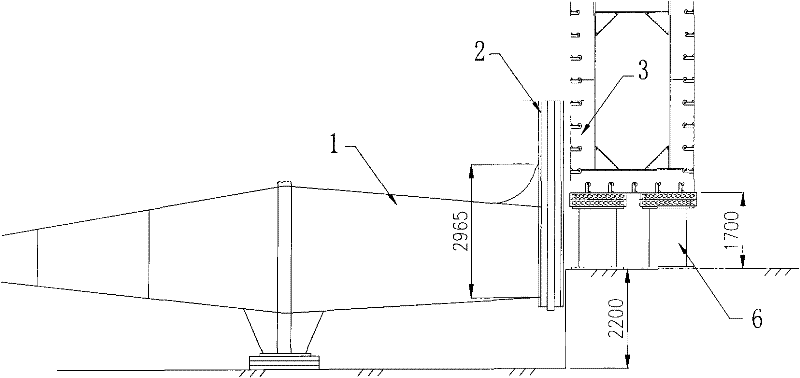

[0033] Please refer to Figures 4a-4d , in one embodiment, the drilling platform includes a spud can and a spud leg 2, the spud can includes a spud can body 1 and a vertical plate member, the position of the spud can body 1 opposite to the spud leg 2 is open, and the vertical plate member has two groups ( Not shown respectively) the first vertical plate 4 (model can be EQ63-Z) and the second vertical plate 5 (model can be EH36-Z), the first vertical plate 4 is rectangular, and described second vertical plate 5 is in A shape with a large curved cutout in a rectangular outline.

[0034] Please refer to Figure 4a-Figure 5 , in a preferred embodiment, the welding method of spud can and spud leg comprises the following steps:

[0035] Step S1. Butt the short side of the first vertical board 4 and the non-arc side of the second vertical boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com