Flat pressing type upper tobacco leaf harvesting machine

A harvester and tobacco leaf technology, which is applied to harvesters, agricultural machinery and implements, agriculture, etc., can solve the problem of high damage rate of upper tobacco leaf harvesting, and achieve the effects of improving quality and work efficiency, avoiding accumulation and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

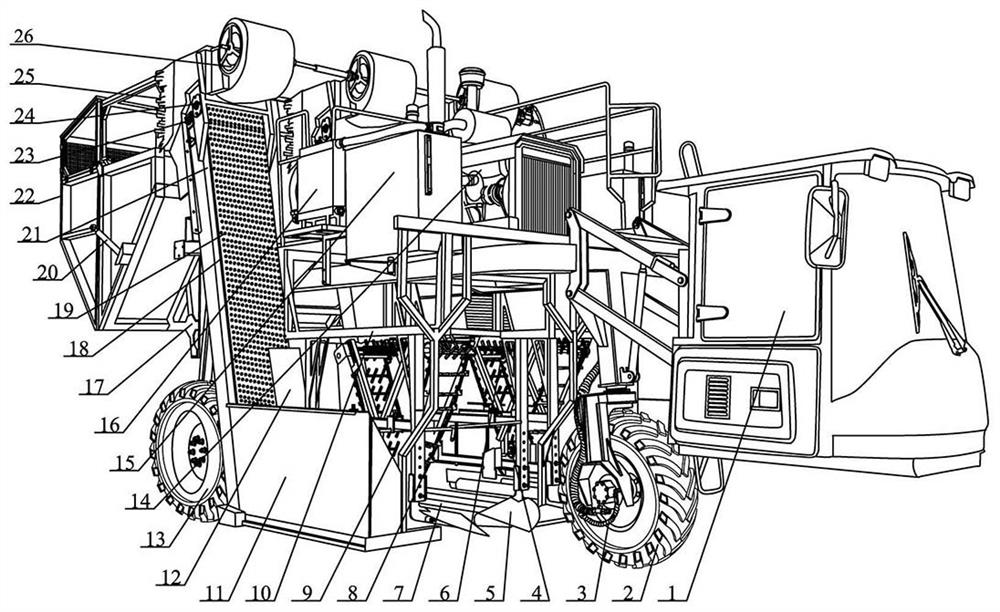

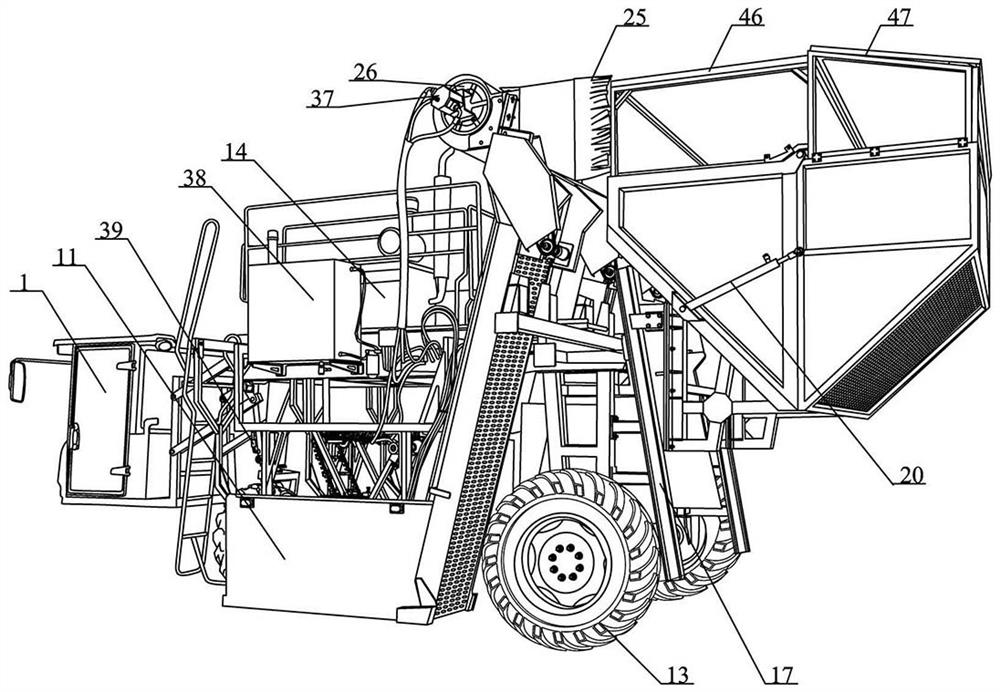

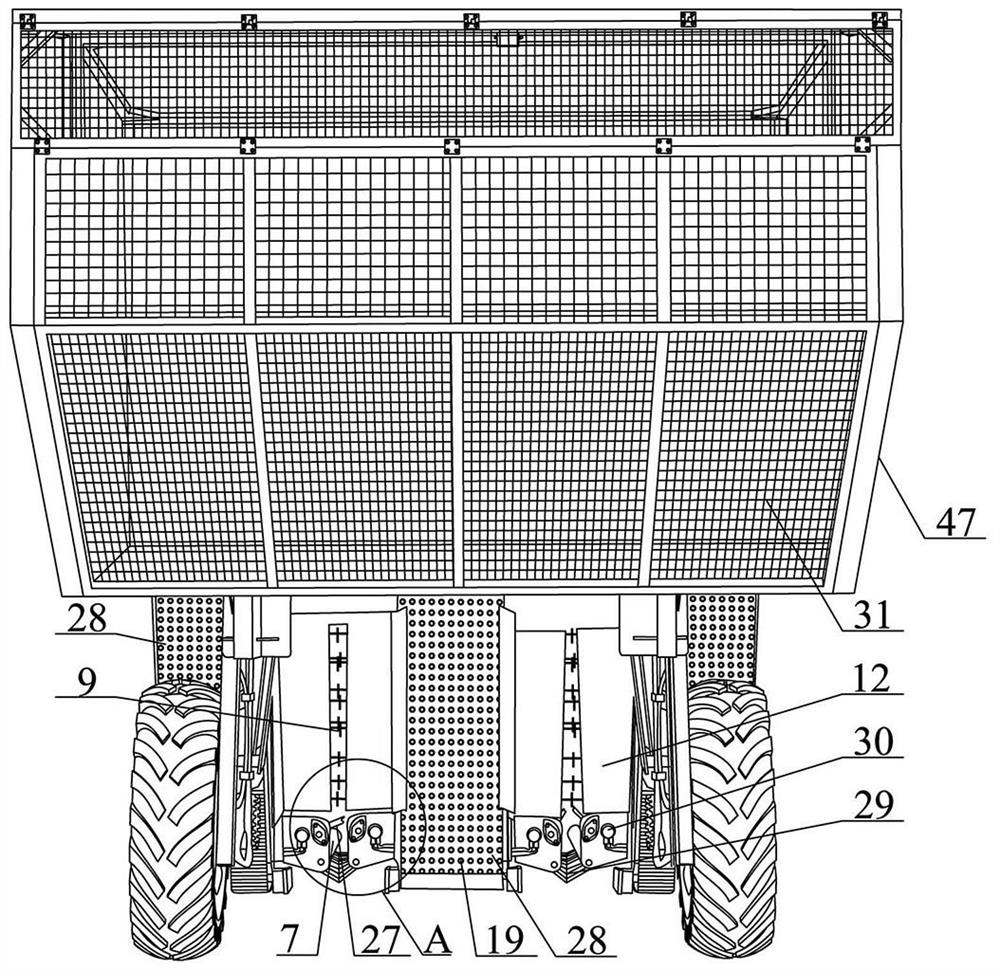

[0032] See attached Figure 1-8 As shown, a flat pressing type upper tobacco leaf harvester includes a frame 10, a power control system, a driving system, a harvesting system, a transmission system and a boxing system.

[0033] The frame 10 of this harvester is an internal hollow frame structure, and the power control system includes a diesel engine 14, a hydraulic oil tank 15, a hydraulic power conversion device 16 and an oil tank 38 installed on the upper end surface of the frame 10, and the power control system is used for Power the harvester and control the hydraulic drives. The driving system includes a driver's control room 1 installed in front of the frame 10 through a hinge structure, driving front wheels 2, front wheel hydraulic control drivers 3, front wheel steering power devices 39, and rear wheels 13, and the driver controls in the driver's control room 1 The power control system of the harvester makes the power control system drive the front wheel hydraulic cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com