Novel pay-off non-return device

A new type of anti-reverse technology, applied in the direction of overhead lines/cable equipment, etc., can solve problems such as hidden safety hazards, large site impact, reverse slippage of cables, etc., to prevent continued retreat, prevent reverse slippage, and eliminate potential safety hazards. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

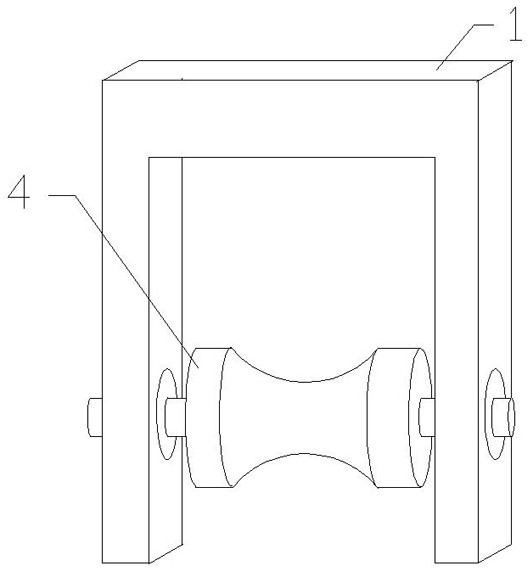

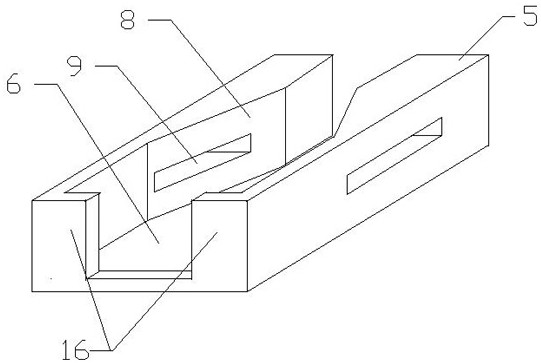

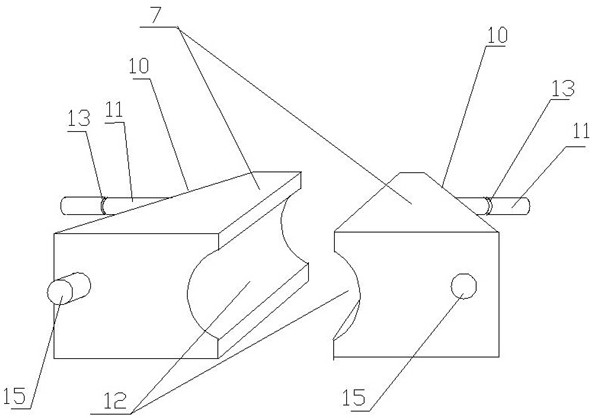

[0026] Such as Figure 1 to Figure 9 As shown, the new pay-off anti-reverse device of the present invention includes a base, and the base is sequentially provided with a first guide seat 1, a first anti-reverse structure 2, The non-return trigger structure 3 and the second guide seat, the first guide seat 1 and the second guide seat are all rotatably provided with guide rollers 4 matching the outer diameter of the cable, the first guide seat 1 and the second guide seat The structure is the same, and the guide roller 4 guides the cable to run in a straight line to ensure that the cable passes through the first non-return structure 2 and the non-return trigger structure 3 in a correct posture.

[0027] The existing anti-reverse device for paying off wires partly uses the eccentric balance wheel 34 to realize the anti-reverse action, but because the contact area b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com