Inflation/deflation type air bag unfolding and coiling device

An inflatable, inflatable and unfolding technology, which is used in ground installations, transportation and packaging, and aircraft component testing, etc. Difficulties and other problems, to achieve the effect of solving the difficulty of folding and unfolding control, simple structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

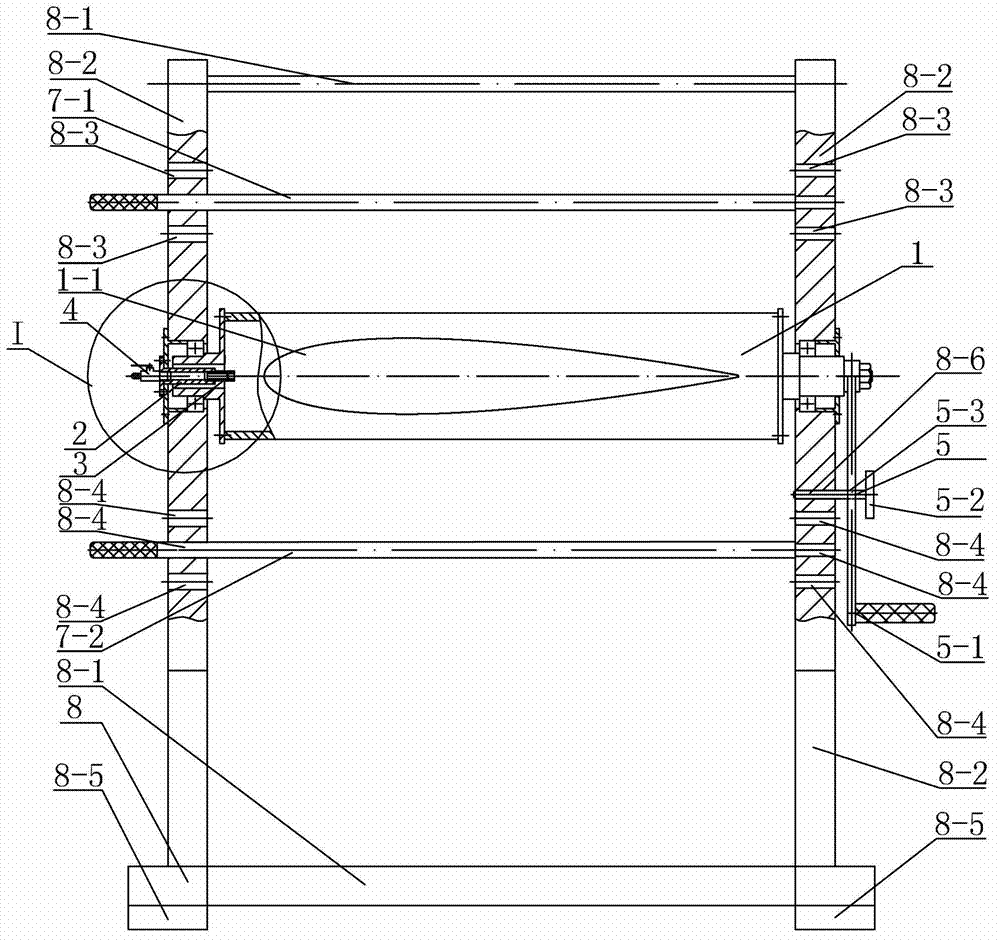

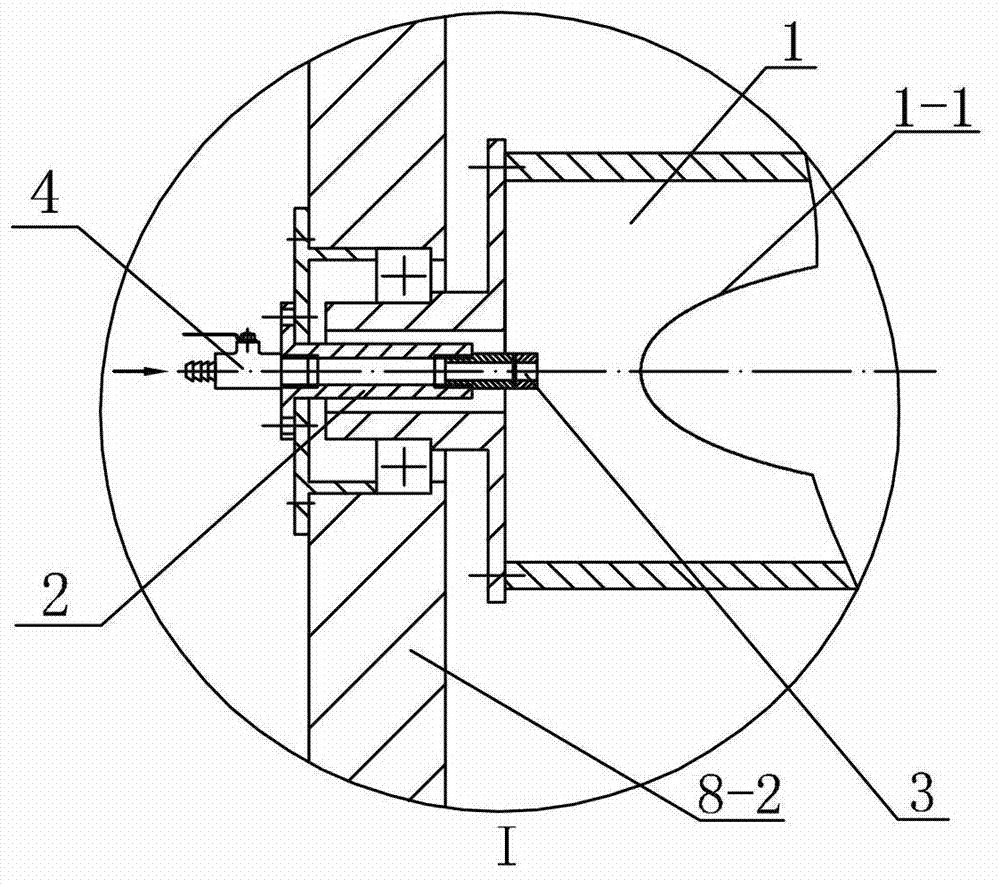

[0007] Specific implementation mode one: combine Figure 1-Figure 7 Describe this embodiment. An inflatable and deflated airbag unwinding device in this embodiment includes a center shaft 1, a drive lock mechanism 5, a support 8, an upper limit gear lever 7-1, a lower limit gear lever 7-2 and a ventilator. Mechanism, the ventilation mechanism includes a ventilation pipe 2, a rotary joint 3 and an air valve 4, and the support 8 includes a base 8-5, two beams 8-1 and two vertical beams 8-2, and two vertical beams 8- 2 is fixed on the base 8-5, two vertical beams 8-2 are arranged side by side, and the upper and lower ends of the two vertical beams 8-2 are respectively provided with cross beams 8-1 connected with the two, and the central axis 1 It is a hollow shaft, and the opposite side walls of the central shaft 1 are respectively provided with holes 1-1 in the same cross-sectional shape as the airbag 9 along its length direction, and the two holes 1-1 are oppositely arranged, a...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 Describe this embodiment, the drive locking mechanism 5 described in this embodiment includes a rocker arm 5-1 and a pin 5-2, the other end of the central axis 1 is connected to the rocker arm 5-1, and the lower side of the central axis 1 and the center The vertical beam 8-2 connected to the other end of the shaft 1 is provided with a first through hole 8-6, and the rocker arm 5-1 is provided with a second through hole 5-3, and shaking the rocker arm 5-1 can drive the axis 1 to rotate , when the second through hole 5-3 on the rocker arm 5-1 coincides with the first through hole 8-6 on the vertical beam 8-2, the first through hole 8-6 and the second through hole 5- 3. The pin 5-2 is pierced, which is used to control the rotation of the central shaft 1 and keep the inflated and deployed airbag 9 pierced on the central shaft 1 parallel to the ground. Such setting can realize the manual power input of the rotation of t...

specific Embodiment approach 3

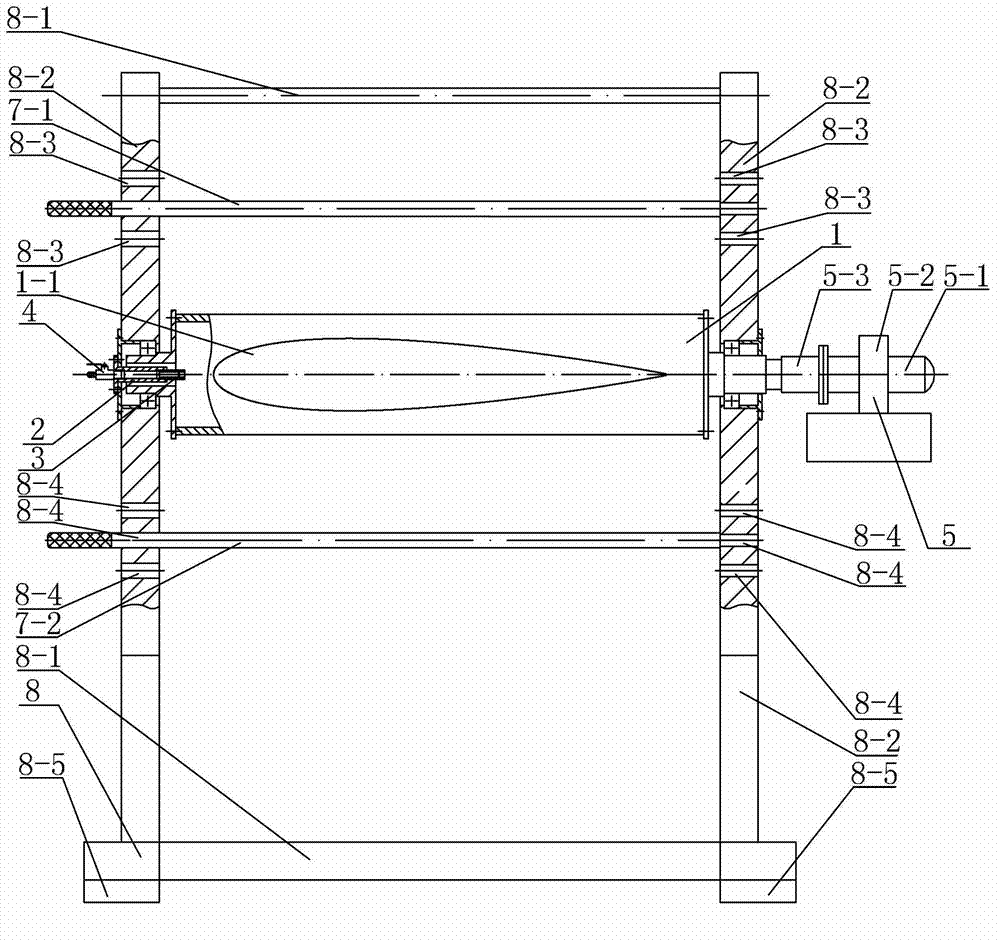

[0009] Specific implementation mode three: combination image 3 Describe this embodiment, the drive locking mechanism 5 described in this embodiment includes motor 5-1, speed reducer 5-2 and coupling 5-3, motor 5-1 and speed reducer 5-2 are connected, speed reducer 5-2 The other end of the central axis 1 is connected through the coupling 5-3, and the start and stop of the motor 5-1 is used to control the start and stop of the central axis 1, thereby keeping the inflated and deployed airbag 9 pierced on the central axis 1 in contact with the ground. parallel. Such setting can realize the automatic control of the rotation of the central axis, and can ensure that the air bag filled with gas passing through the central axis is parallel to the ground, which meets the design and actual needs. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com