Aluminum wire straightening method of enamelling machine annealing furnace and mechanism of enamelling machine annealing furnace

An annealing furnace and enamelling machine technology, applied in the field of enameled wire manufacturing, can solve the problems of scratches on the surface of bare aluminum wires, continuity of paint film, and unstable breakdown voltage, etc., and achieve the effects of improving annealing effect, simple structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

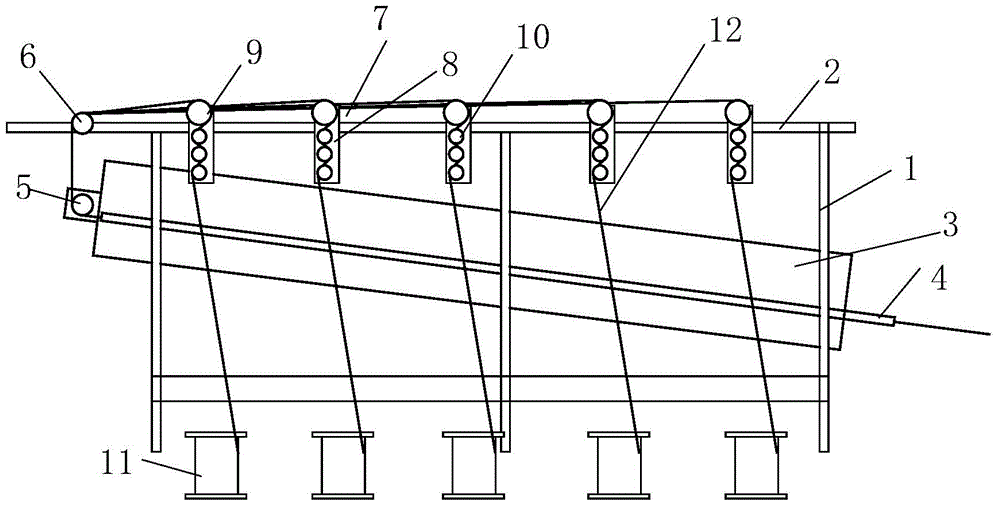

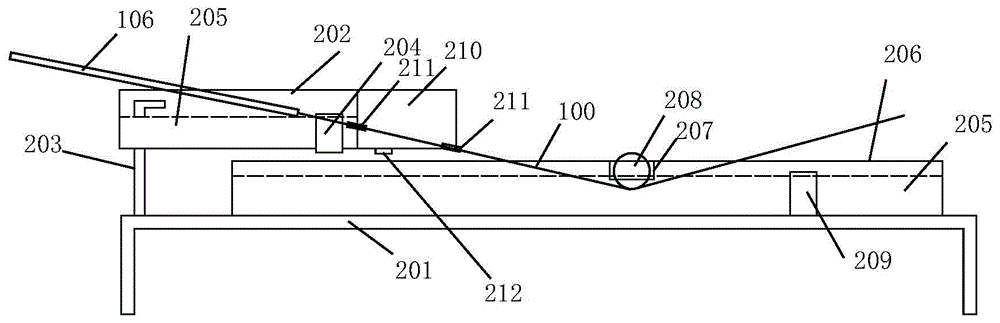

[0013] Embodiment: a method for straightening aluminum wires in an annealing furnace of an enamelling machine. The method is to pass the aluminum wires around two or more straightening wheels successively after entering the annealing furnace body for straightening, thereby improving the straightness of the enameled wires after annealing. The aluminum wire straightening mechanism of the enamelling machine annealing furnace that realizes the method includes a heating part and a cooling part, and the heating part is as attached figure 1 As shown, a bracket 1 is included, a crossbeam 2 is fixed above the bracket 1, an annealing furnace body 3 is fixed on the bracket 1, and the furnace body has a heating tube. Since the annealing furnace body is conventional equipment in this field, it will not be described in detail here. A group of wire conduits 4 are arranged in the stove body 3, and the wire conduits can be an iron pipe. The front portion of the wire conduit 4 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com