Thermoplastic carbon fiber prepreg tape laminated plate sample preparation device

A carbon fiber prepreg and thermoplastic technology, applied in the field of thermoplastic carbon fiber prepreg tape laminate sample preparation device, can solve the problem that it is difficult to effectively ensure the safety of prepreg tape laminate fiber tension and the consistency of the limit direction, and achieve Improve the safety of sample preparation, improve the efficiency of sample preparation, and ensure the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

[0031] The specific embodiment of the thermoplastic carbon fiber prepreg tape laminate sample preparation device of the present invention:

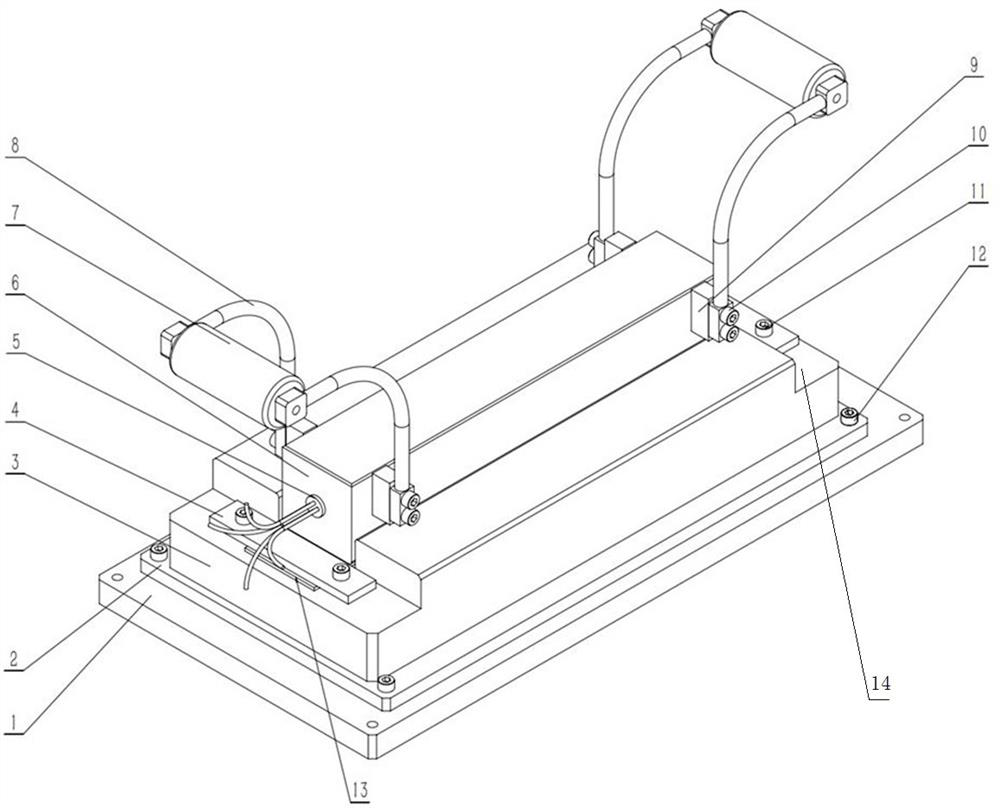

[0032] like figure 1 As shown, the thermoplastic carbon fiber prepreg tape laminate sample preparation device includes: a mounting base 1 , a sample preparation mold 3 , a hot pressing block 6 , a pressing component and a pressing sheet 4 .

[0033] Define the length direction of the mounting base 1 as the left-right direction, and the thickness direction as the up-down direction. The sample making mold 3 is made of mold steel, which is suitable for processing various resin substrates, such as PA, PPS, PEEK, etc. The bottom surface of the sample preparation mold 3 is integrally formed with a thermal insulation layer 2 with an area larger than the bottom area of the sample preparation mold 3. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com