Clamp and method for single surface electroplating of substrates

A substrate and single-sided technology, applied in the field of microelectronics, can solve the problems of difficult removal of adhesive, hidden dangers of sintering process, adhesive residue, etc., achieve low cost, avoid changes in plating area, and stabilize the substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment

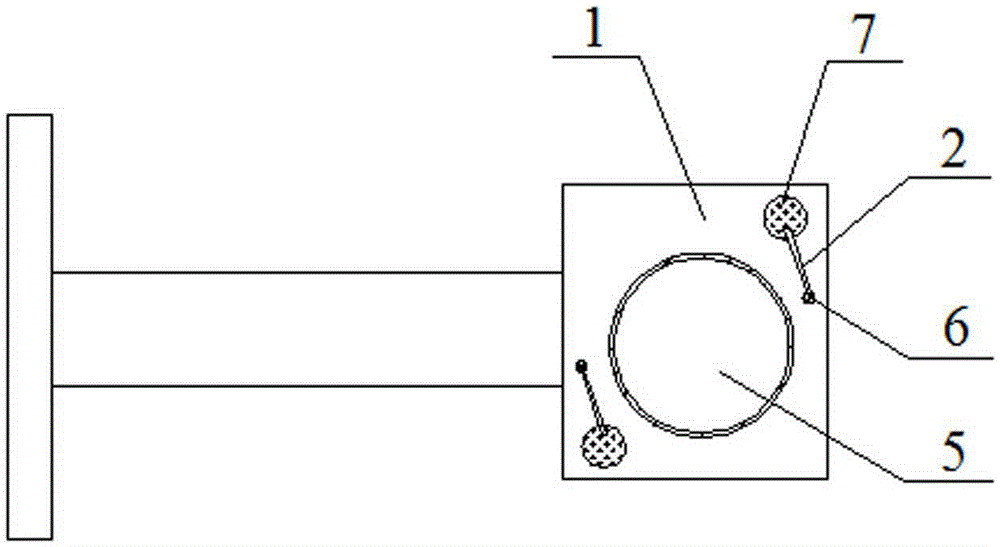

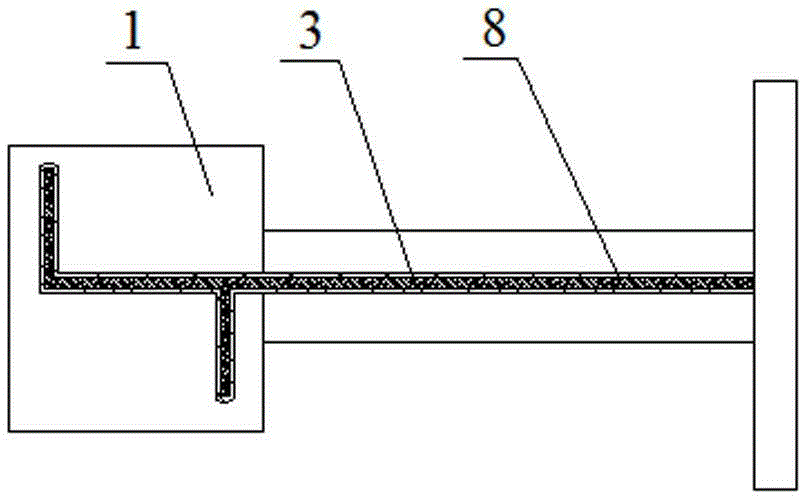

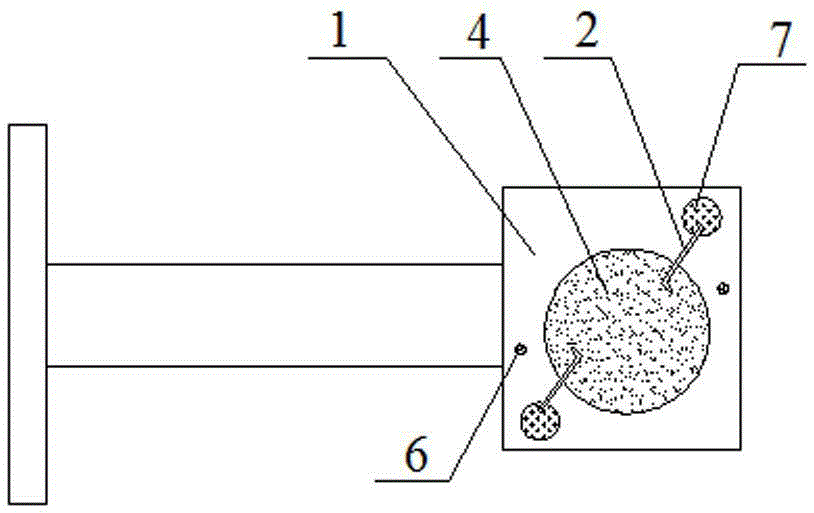

[0021] like figure 1 As shown, a fixture for single-sided electroplating of a substrate includes a support plate 1, two probe electrodes 2, and electrode leads 3 connected to the probe electrodes 2, wherein the support plate 1 is provided with a Groove 5, one end of the probe electrode 2 is fixed on the support plate 1 by means of a stud 7, and the probe of the probe electrode 2 is placed in the placement hole 6 on the support plate 1. like image 3 As shown, the back of the support plate 1 is provided with a lead groove, and the electrode lead 3 is located in the lead groove. The electrode lead 3 is a rubber wire and the electrode lead 3 is fixed in the lead groove with silica gel 8 . like figure 2 As shown, the substrate is put into the groove 5 during electroplating, and the probe of the probe electrode 2 is rotated onto the substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com