Vertical magnetron sputtering coating device for long outer cladding tube

A magnetron sputtering coating, cladding tube technology, applied in sputtering coating, ion implantation coating, vacuum evaporation coating and other directions, to achieve the effect of improving processing efficiency, ensuring uniformity and flexible rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further explained below in conjunction with the drawings.

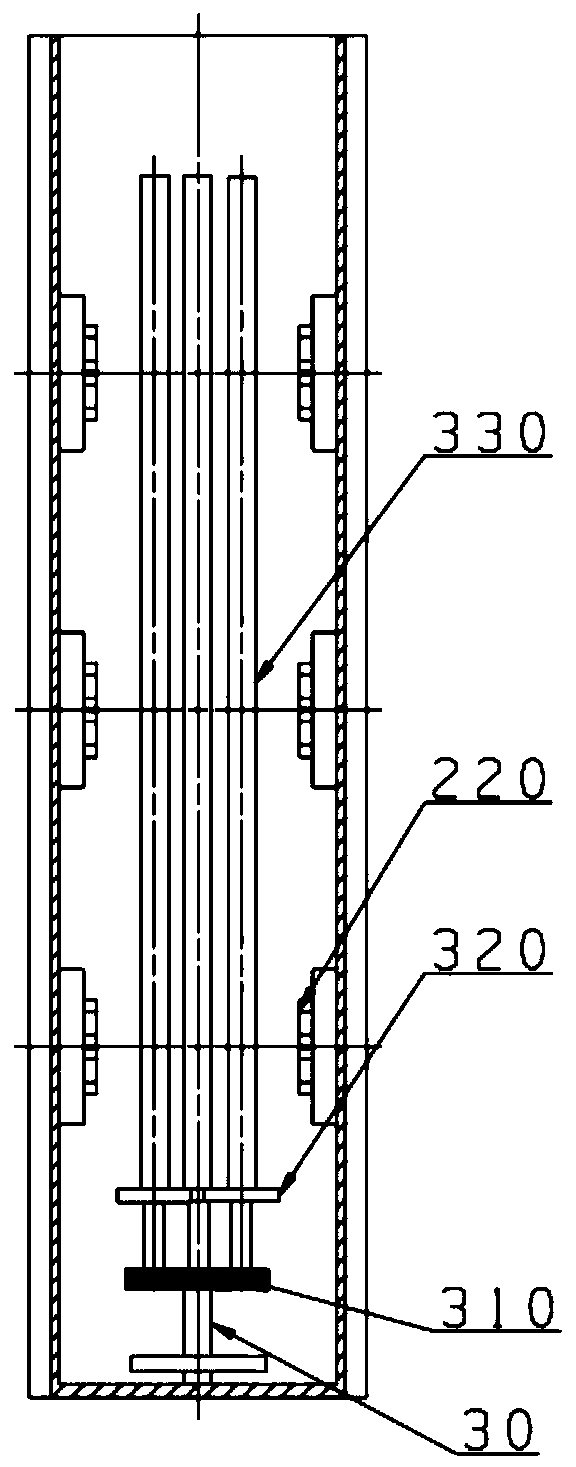

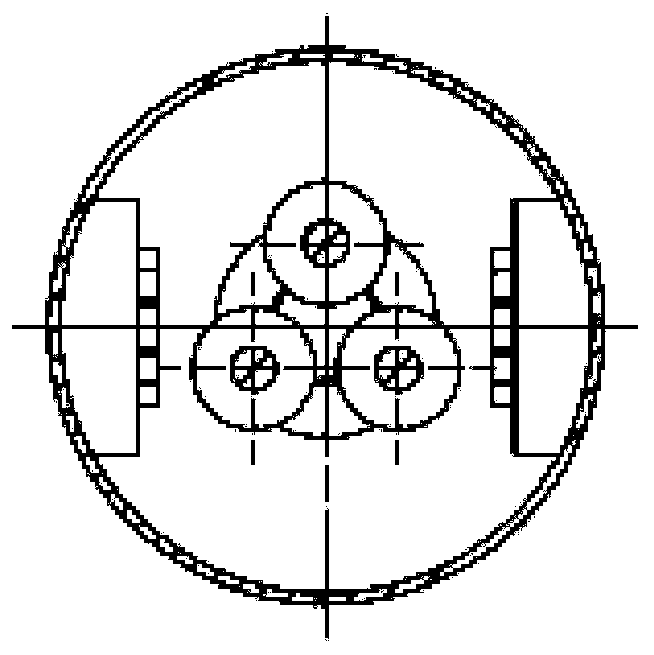

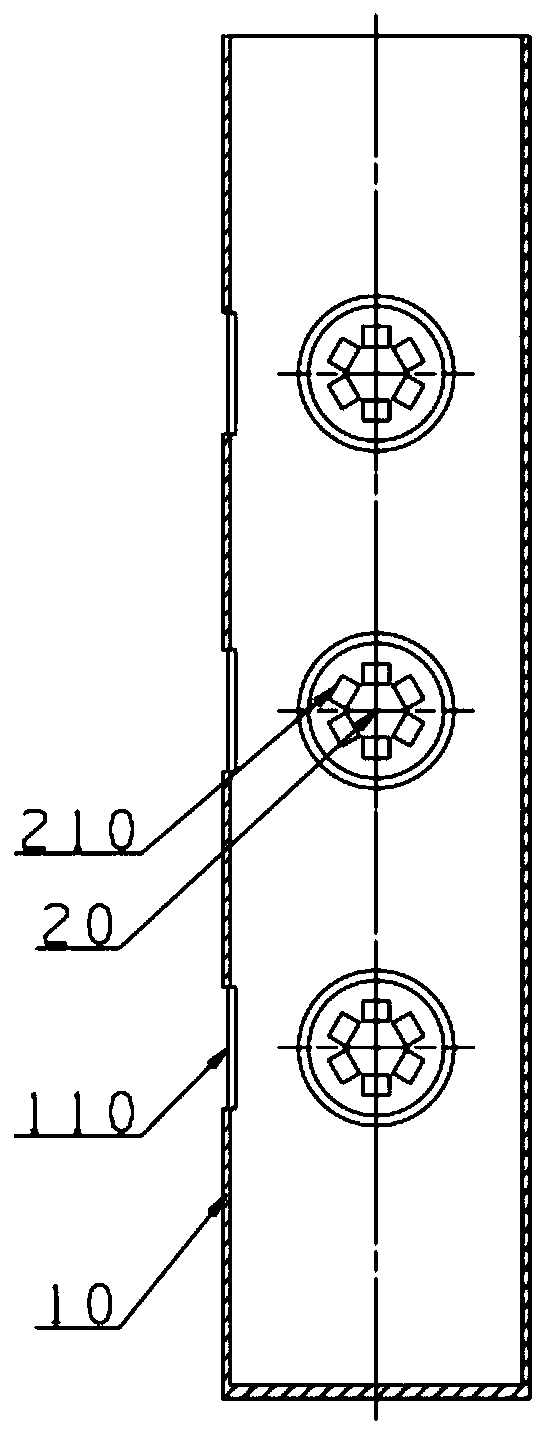

[0028] The present invention provides a vertical magnetron sputtering coating device for a long outer shell tube. The device is based on a cylindrical shell, which is the cavity 10, which is composed of three layers and has a hard protective outer shell. A metal layer, an insulating middle ceramic layer, and an inner metal layer that closes the magnetic lines of force and blocks energy-rich particles; the cavity 10 is directly above the cavity door 110; the cavity 10 is embedded with an observation window in the middle cavity On the door; a total of 3 pairs of target base chassis 20 are installed symmetrically on the inner metal surface of the cavity 10, each target base chassis 20 has 6 symmetrically distributed target bases 210, and each target base 210 is equipped with a cylindrical metal Target. The standard tooling size of the target material is Φ1.5m×5m. The metal target materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com