Novel electroplating barrel plating device

A new type of barrel plating technology, applied in the electrolytic process, electrolytic components, cells, etc., can solve the problems of limited number of small parts, unsuitable installation and hanging, poor electroplating effect of small parts, etc., to improve work efficiency, save manpower, electroplating uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

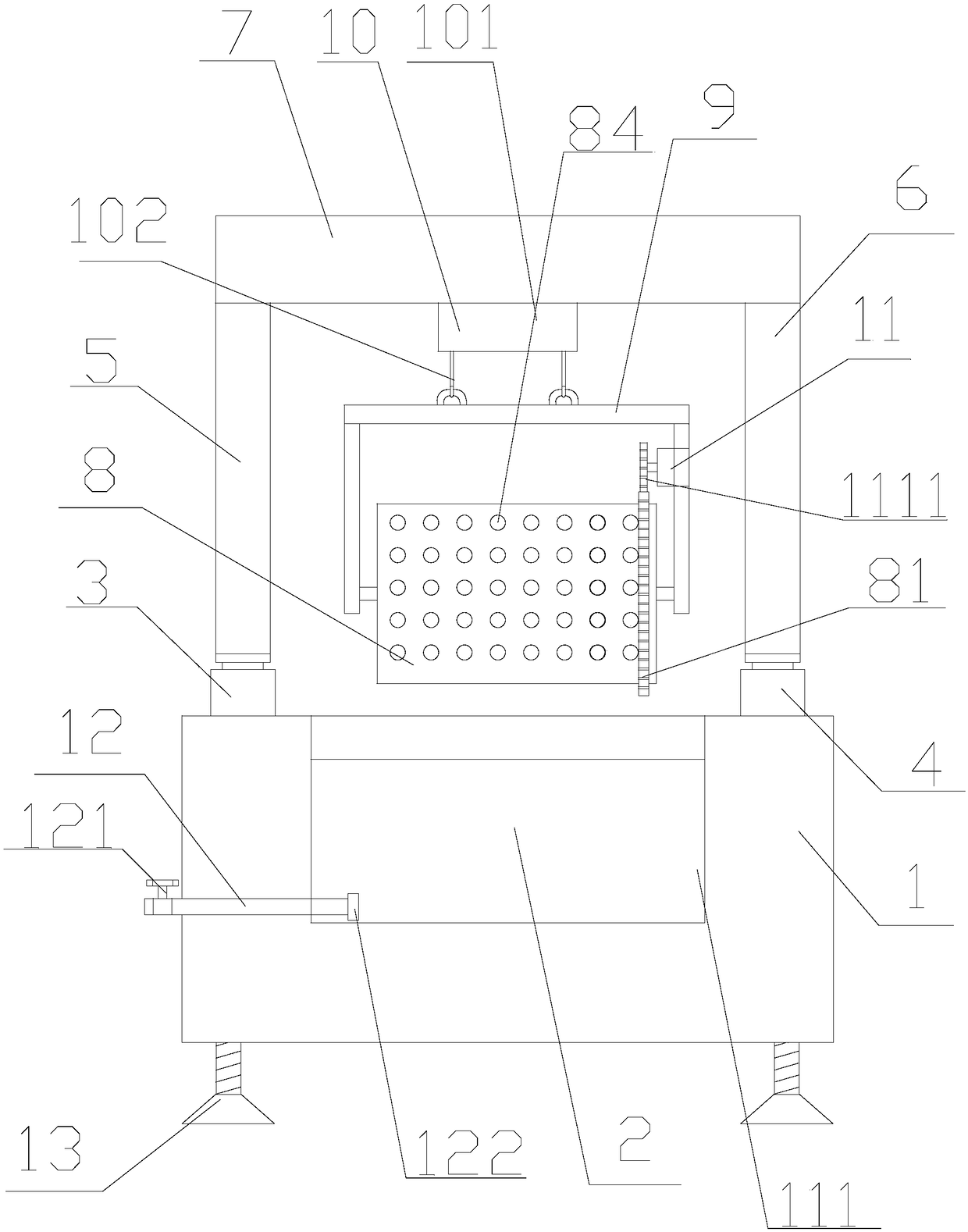

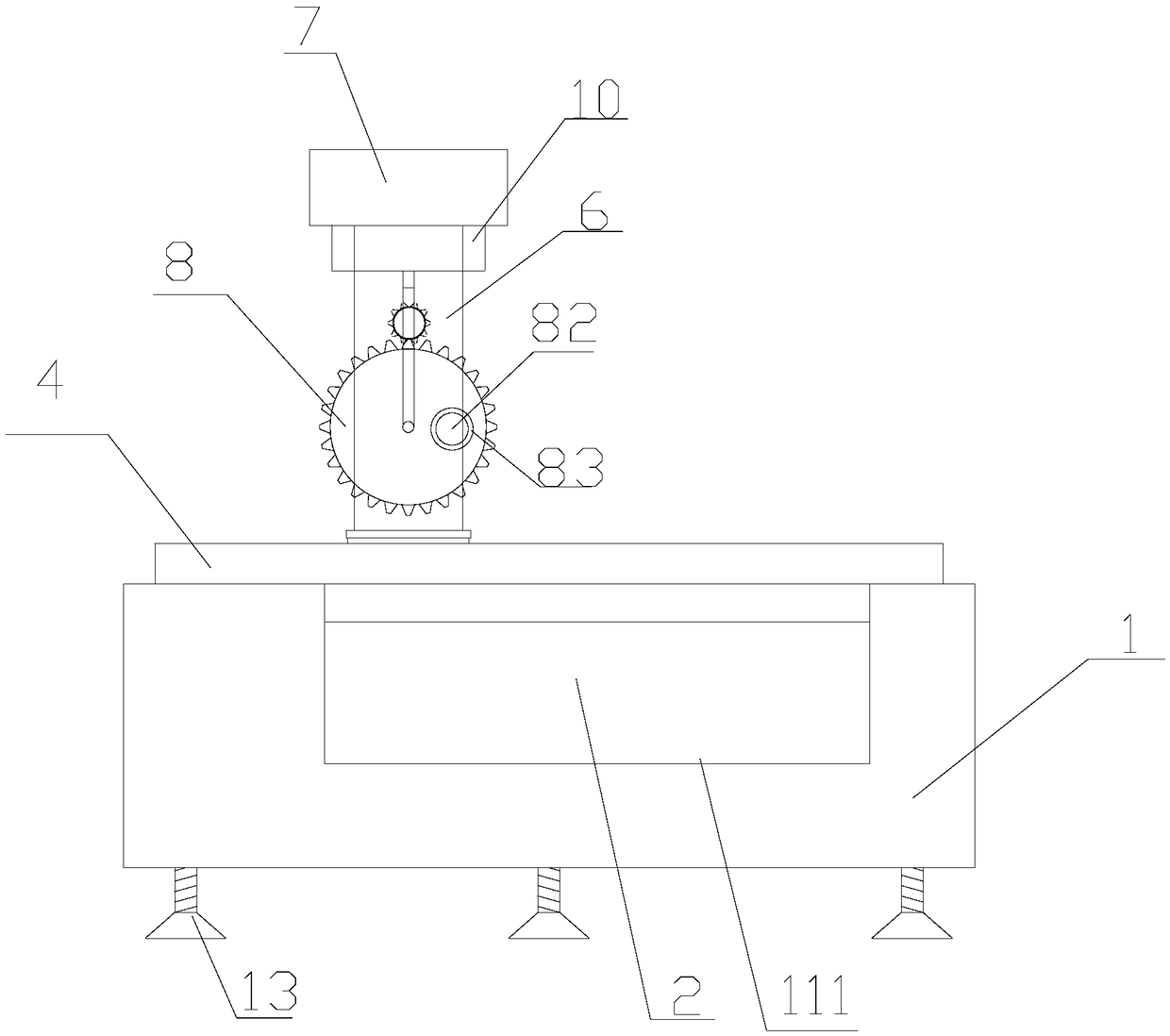

[0015] refer to figure 1 and figure 2 , a novel electroplating barrel plating device of the present invention, comprising a main frame base 1, an electroplating solution 2, a first electric cylinder 3, a second electric cylinder 4, a first pillar 5, a second pillar 6, a horizontal plate 7, a barrel plating Barrel 8, barrel plating barrel fixing bracket 9, lifting device 10, motor 11, the upper end of the main frame base 1 is provided with an electroplating pool cavity 111, and the electroplating pool cavity 111 is provided with an electroplating solution 2, and the described electroplating pool cavity 111 is provided with an electroplating solution 2. The two sides of the electroplating cell cavity 111 at the upper end of the main frame base 1 are respectively provided with a first electric cylinder 3 and a second electric cylinder 4, the first electric cylinder 3 and the second electric cylinder 4 are arranged relatively in parallel, and the first electric cylinder 4 The up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com