Film cutting machine

A film cutting machine and cutting knife technology, applied in metal processing and other directions, can solve the problems of high labor intensity, low production efficiency, and not suitable for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

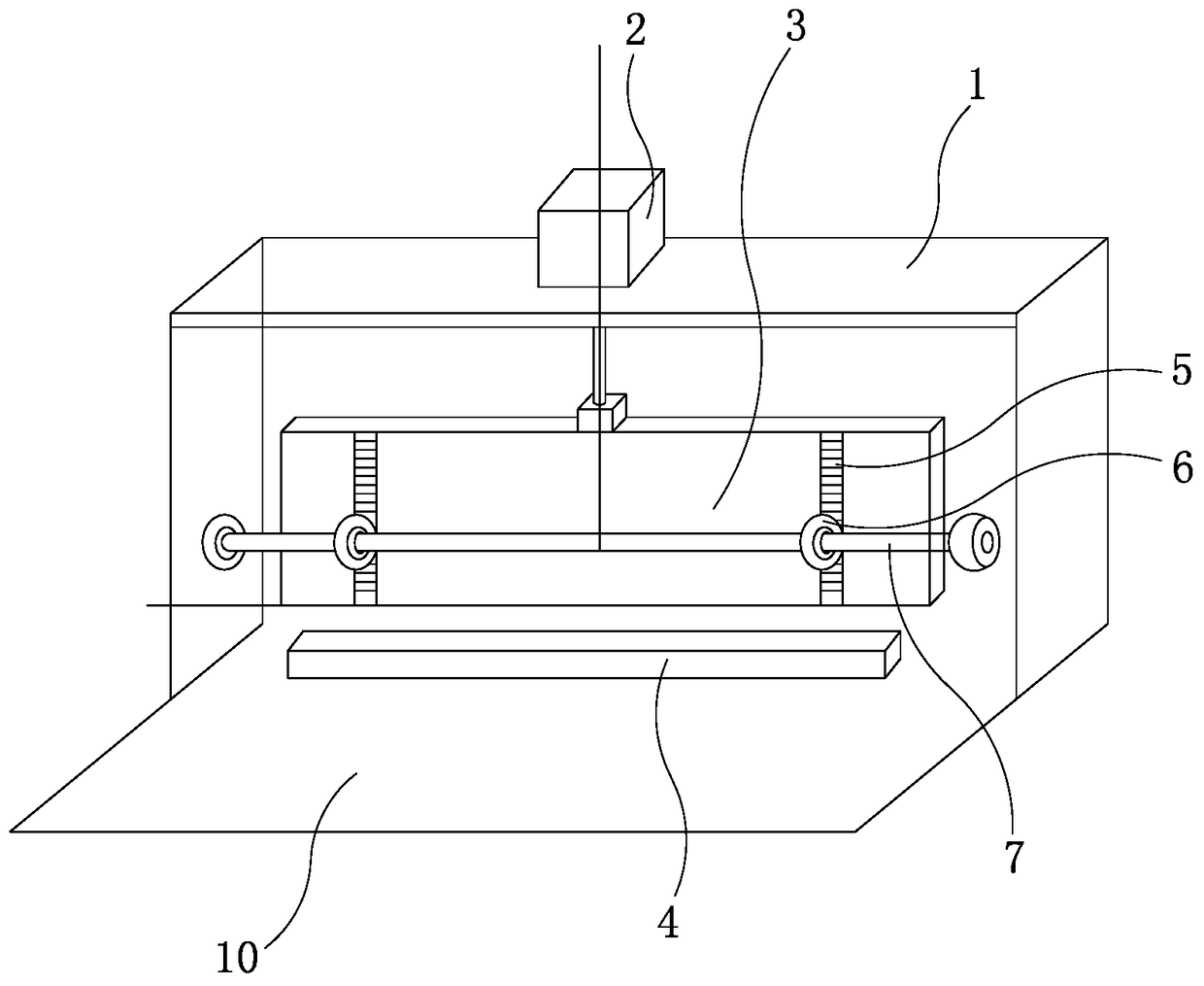

[0009] Such as figure 1 As shown, the present invention is a film cutting machine, including a cutter frame 1, a cutter cylinder 2, a cutter 3, a knife seat 4, two guide racks 5, two guide gears 6, and a guide shaft 7.

[0010] The cutter frame 1 is fixedly bridged on the frame 10, the cylinder block of the cutter cylinder 2 is fixedly mounted on the top of the cutter frame 1, and the piston rod end of the cutter cylinder 2 passes through the cutter frame 1 downwards. Connect with the upper end of cutter 3 afterward, the lower end of cutter 3 stretches to knife seat 4, and knife seat 4 is fixed on the frame 10; Described two guide racks 5 are installed on the side wall of cutter 3 respectively, The two guide gears 6 are fixedly sleeved on the guide shaft 7 and the two guide gears 6 are meshed with the two guide racks 5 respectively, so that the cutter 3 moves up and down more smoothly, and the guide shaft 7 is rotatably installed on the cutter frame 1 superior.

[0011] Work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com