Semiconductor device

A semiconductor and conductive layer technology, applied in semiconductor devices, measurement devices, semiconductor/solid device manufacturing, etc., can solve problems such as metal deterioration, open circuit, and reliability decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

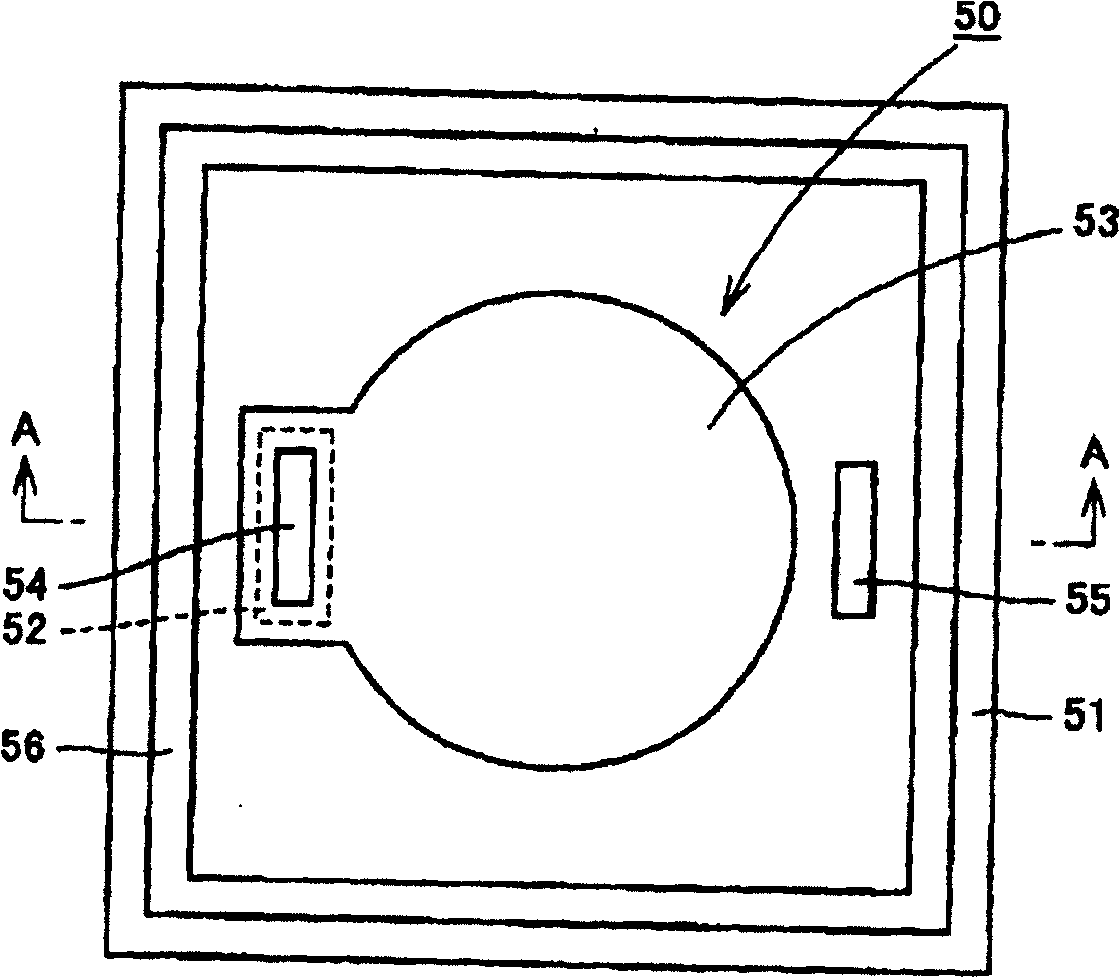

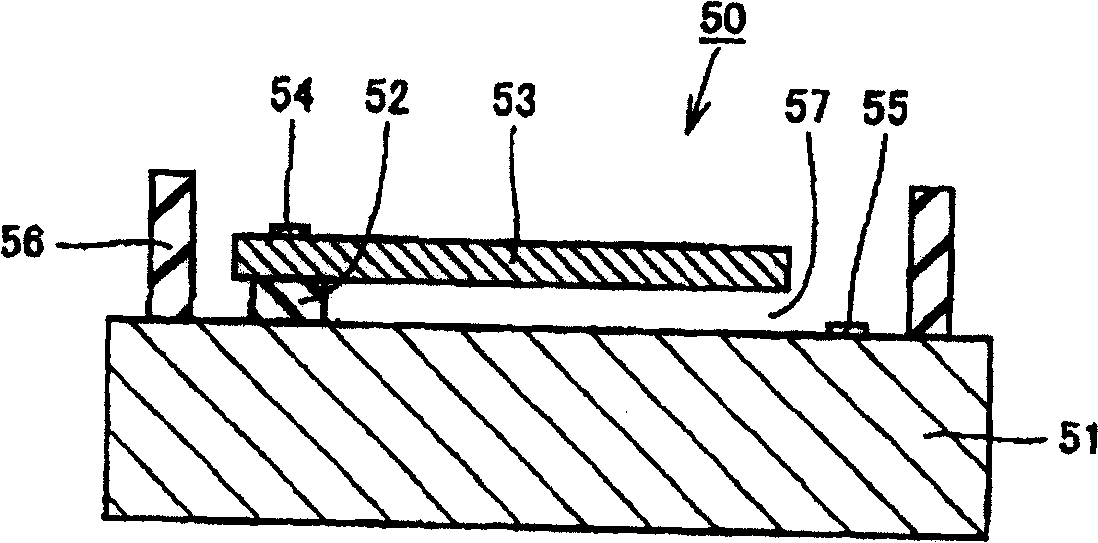

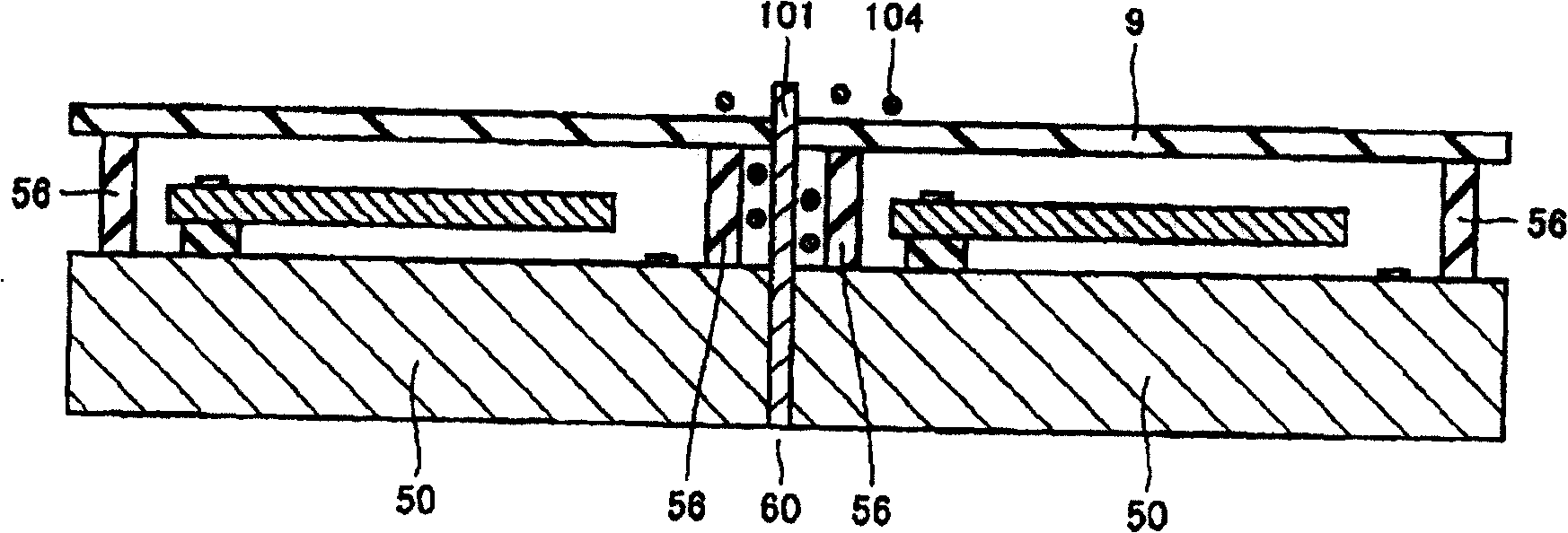

[0046] figure 1 is a plan view showing the semiconductor device in the first embodiment of the present invention, figure 2 is along figure 1 A cross-sectional view of line A-A.

[0047] exist figure 1 Among them, the actuator 50 constituting the semiconductor device has a laminated structure including a substrate 51 , a fixed portion 52 , a conductive layer 53 as a structure, electrode pads 54 and 55 for inputting and outputting signals, and a bank 56 . The conductive layer 53 is formed in a disk shape, and is supported by the fixing portion 52 in a cantilever beam manner, so as to form a gap region 57 with the substrate 51 . The conductive layer 53 moves up and down with the fixing portion 52 as a fulcrum in response to an electric signal supplied to the electrode pads 54 , 55 . In addition, as a structural body, an insulating layer or a semiconductor layer may be used instead of the conductive layer 53 .

[0048] The substrate 51 is formed in a rectangular shape wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com