Cutting mechanism of spring coiling machine

A technology of cutting mechanism and coiling machine, applied in the field of coiling machine, can solve the problems of low safety, unstable steel wire, easy rebound, etc., and achieve the effects of simple transformation, free and convenient adjustment, and reduced vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

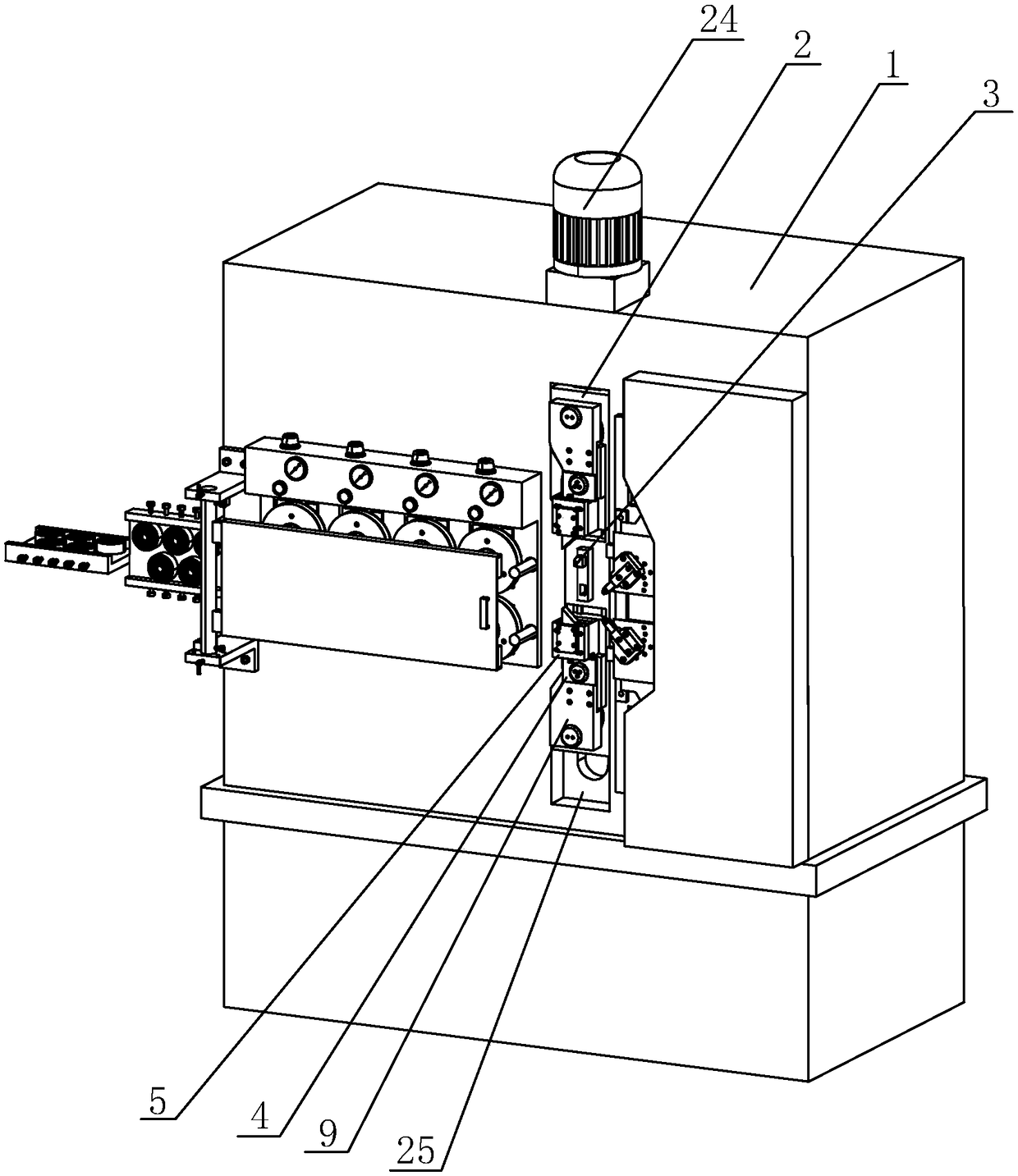

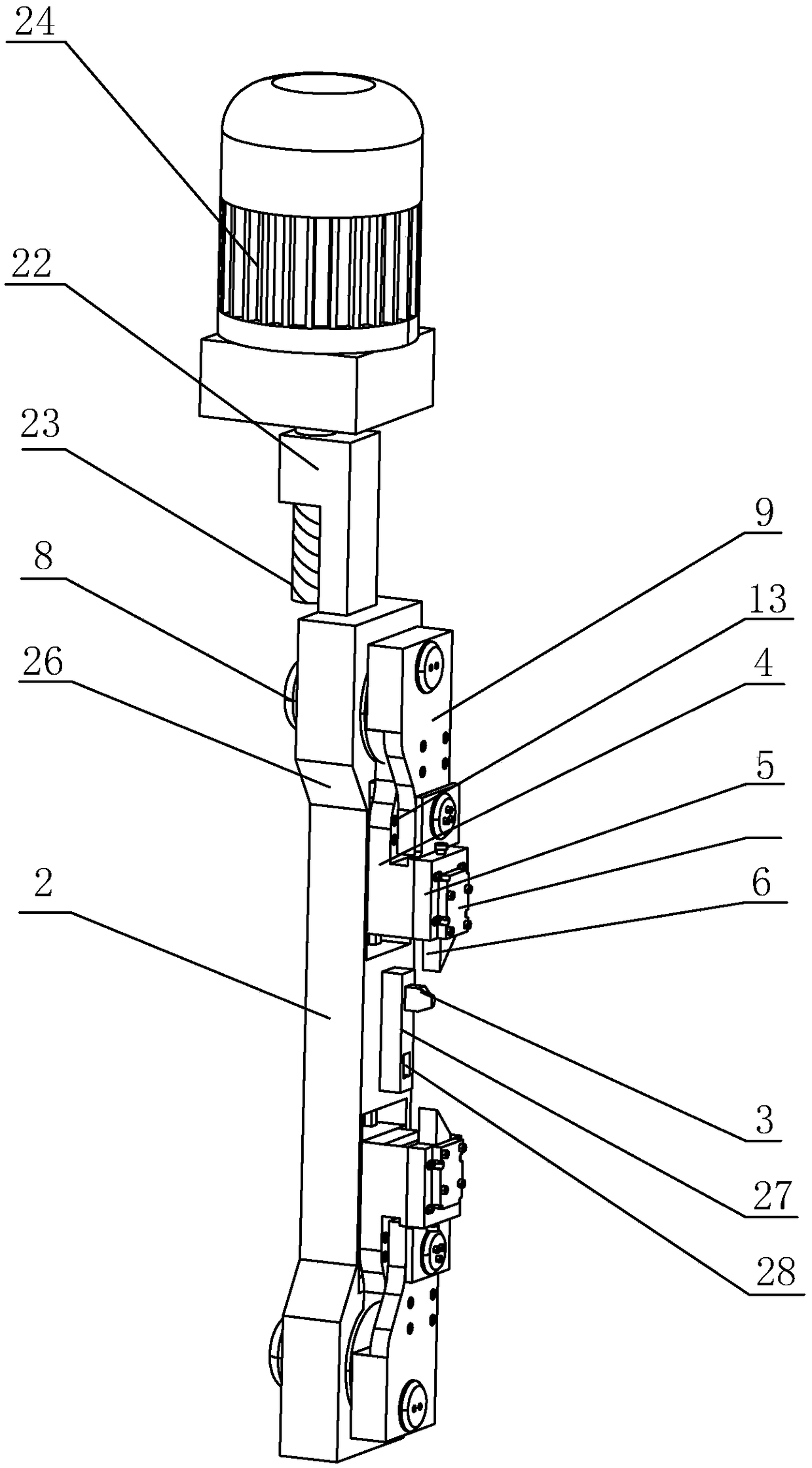

[0041] A cutting mechanism of a coil spring machine, such as figure 1 As shown, including the cabinet 1, the cabinet 1 is in the shape of a cuboid, and a long main board 2 is arranged on one side of the cabinet 1. The surface of the cabinet 1 is provided with an activity space 25 for the lifting of the long main board 2. Both ends of the long main board 2 are provided with cutting surfaces 26. , the side wall of the activity space 25 can be attached to the cut surface 26 . The length of the active space 25 is greater than the length of the long main board 2 . The long main board 2 can be raised and lowered in the movable space 25, and when the cut surface 26 touches the side wall of the movable space 25, the position of the long main board 2 is restricted.

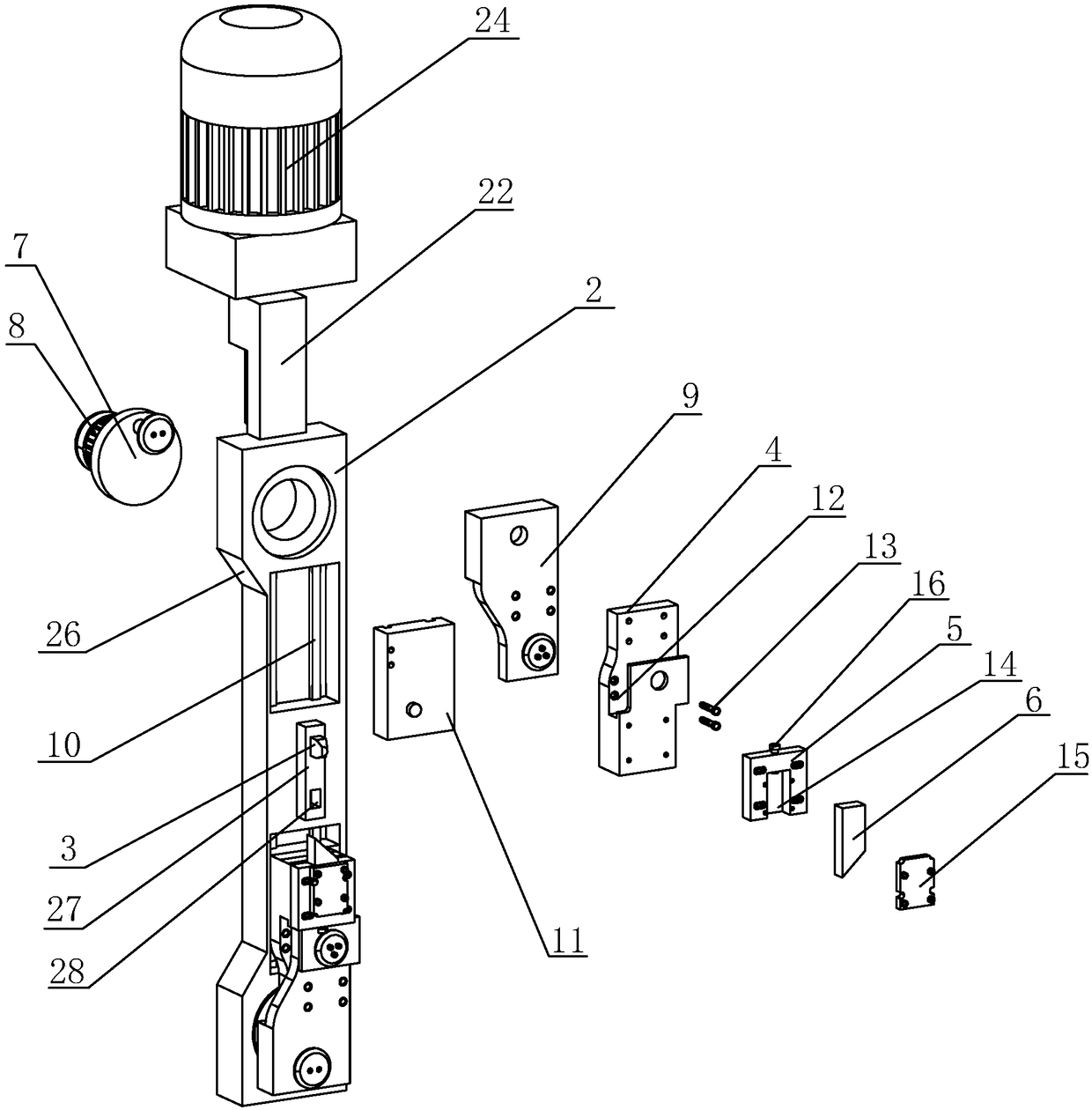

[0042] like figure 1 and figure 2As shown, between the cabinet 1 and the long main board 2, there is a control assembly for driving the long main board 2 to rise and fall. The control assembly includes a lifting seat 2...

Embodiment 2

[0048] A kind of cut-off mechanism of spring coiling machine, differs from Embodiment 1 in that:

[0049] Such as Figure 4 and Figure 5 As shown, the side of the connecting main seat 4 away from the cabinet 1 is rotatably connected with a tool seat 5, the tool seat 5 is arranged parallel to the connecting main seat 4, the tool seat 5 is in the shape of a cube, and the outer walls of the tool seat 5 are provided with holes for placement and cutting. There are four knife grooves 17 of the knife 6, and the adjacent knife grooves 17 are arranged orthogonally. Cutting knives 6 with different cutting angles and sizes can be placed in different knife grooves 17, and the knife seat 5 is far away from the long main board. One side of 2 is fixed with pressing plate 18 by bolt. A plurality of cutting knives 6 can be simultaneously fixed in the knife groove 17 and pressed by the pressing plate 18. According to the type of spring to be processed, the required cutting knives 6 can be re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com