Patents

Literature

433results about How to "Integrity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

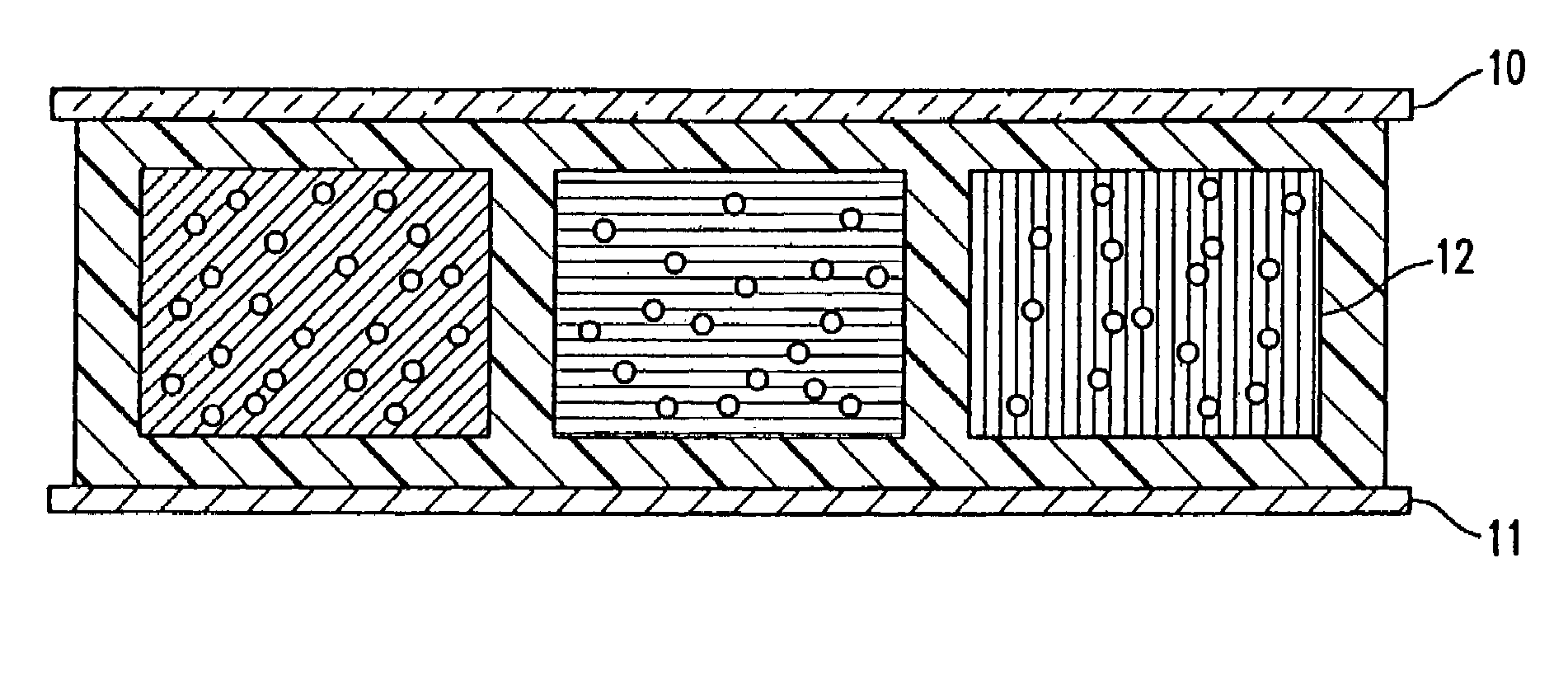

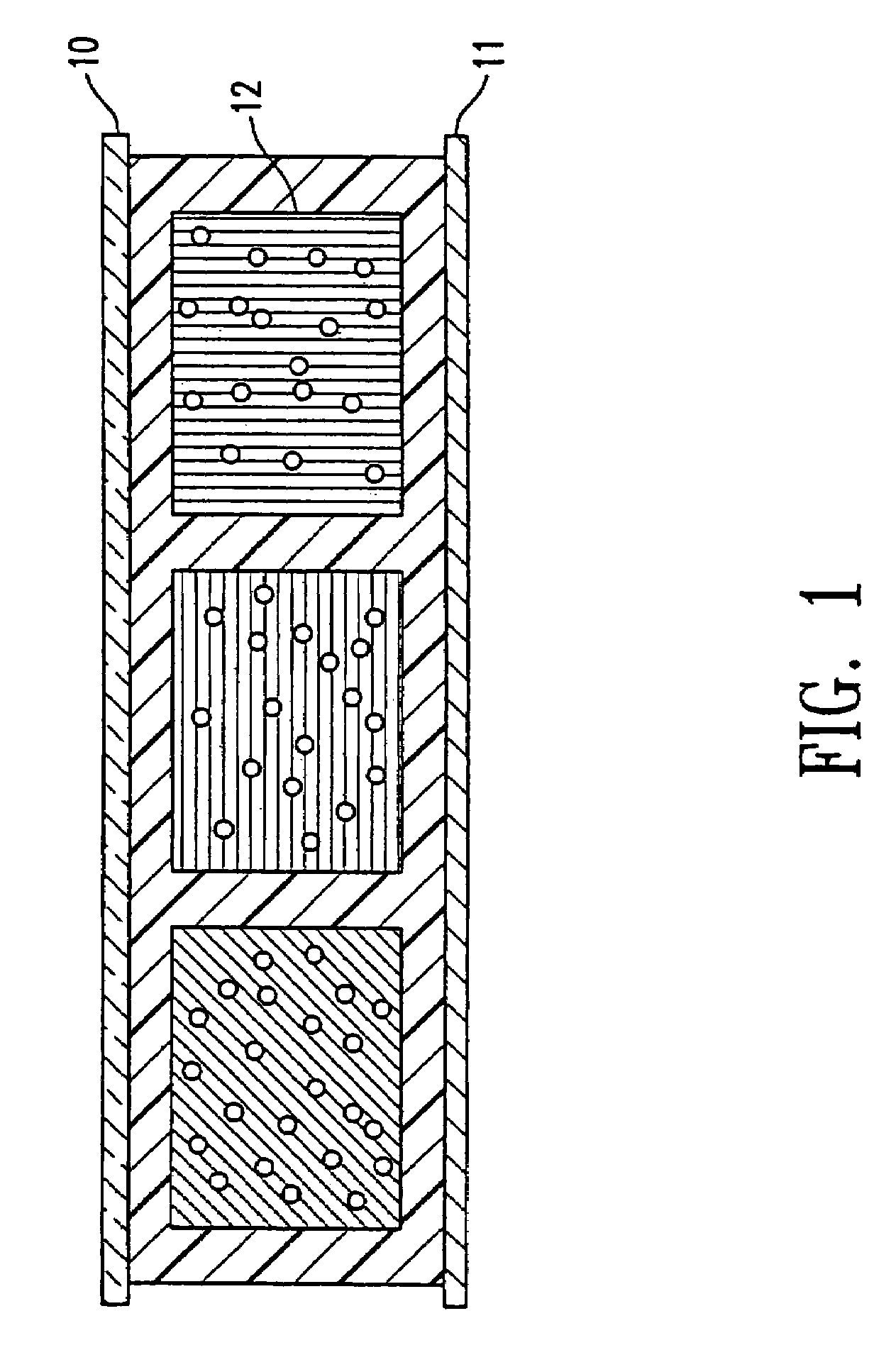

Electrophoretic display

InactiveUS7715088B2Improve adhesionImprove the display effectStatic indicating devicesNon-linear opticsElectrophoresisDisplay device

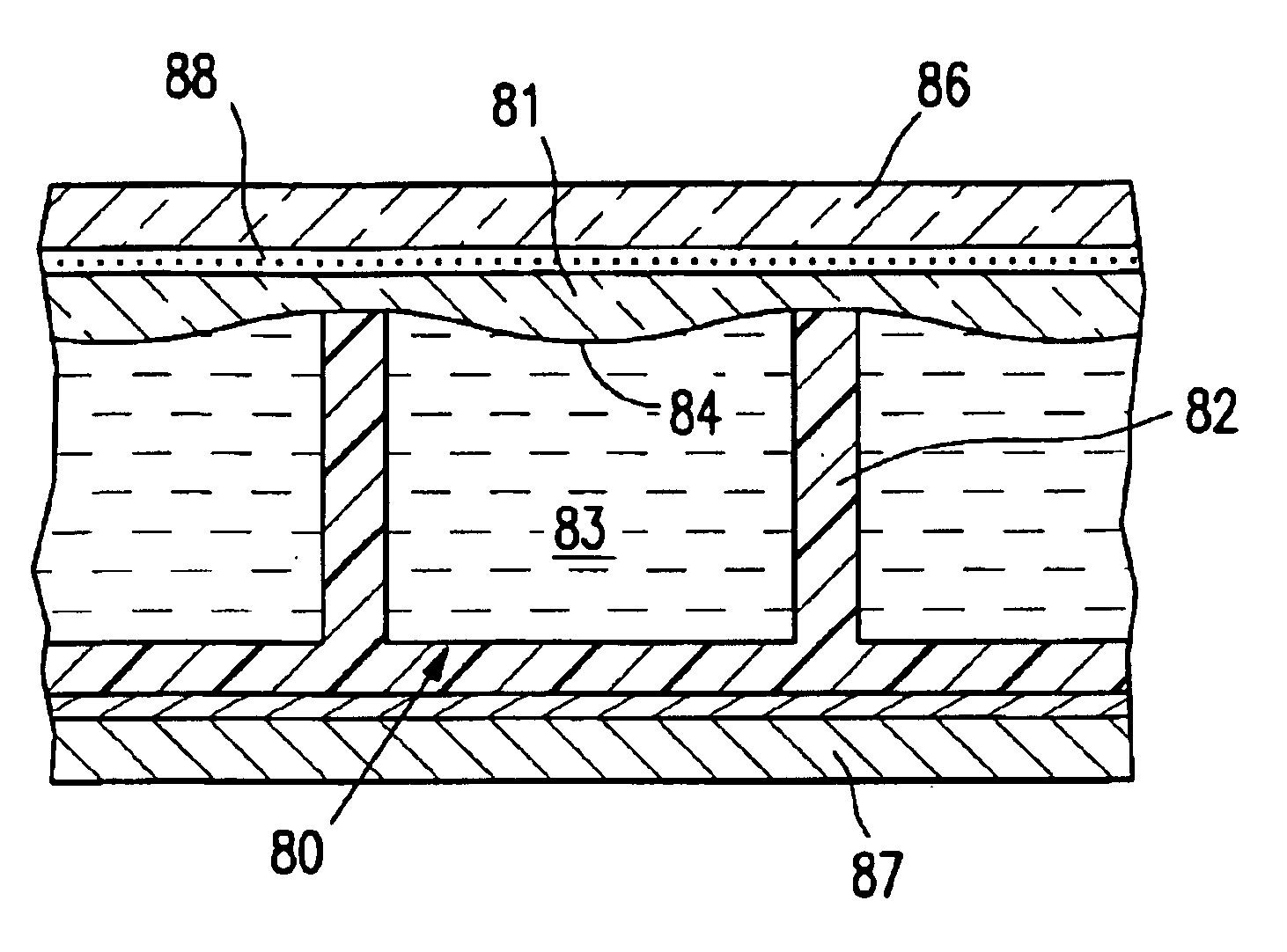

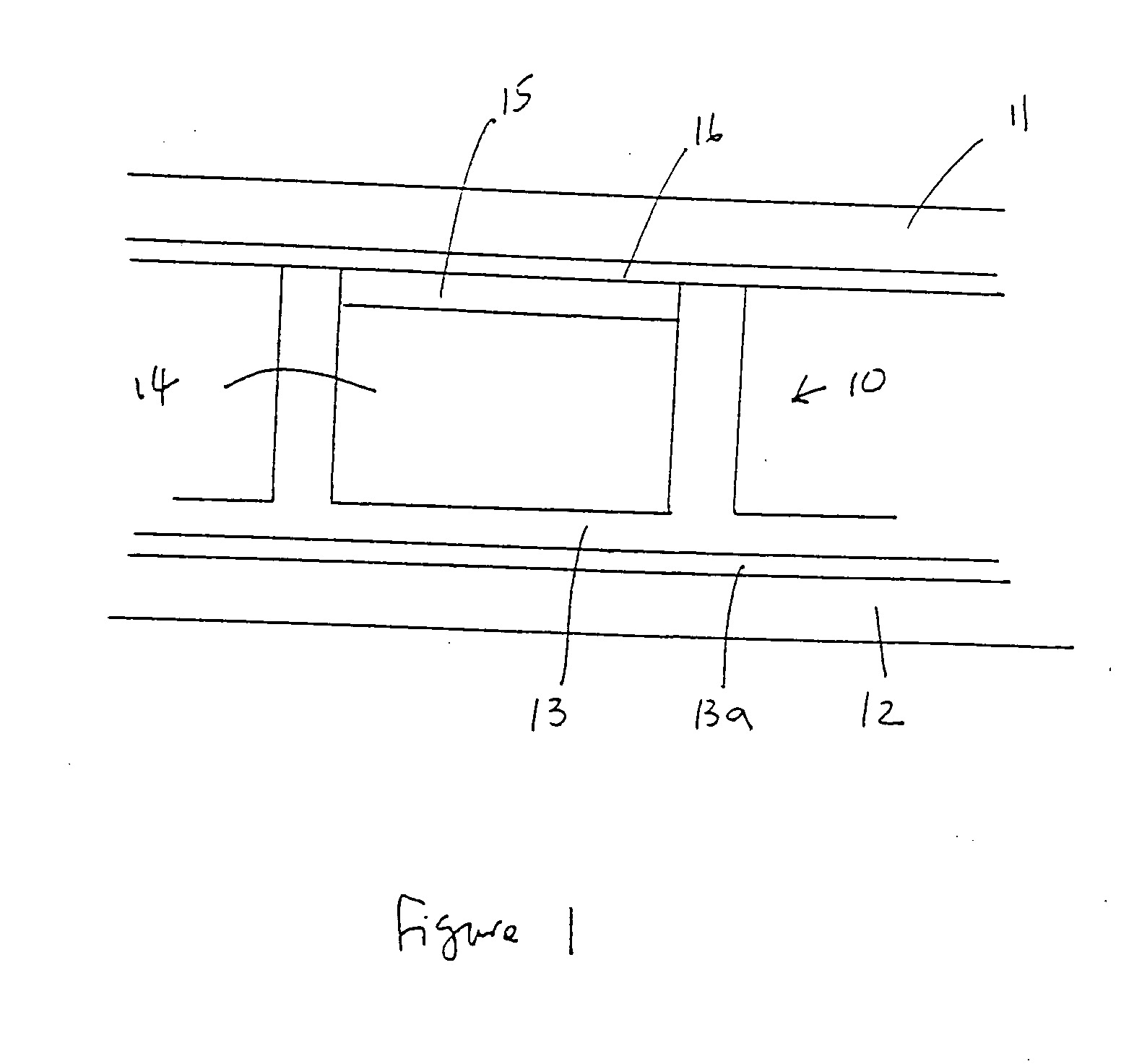

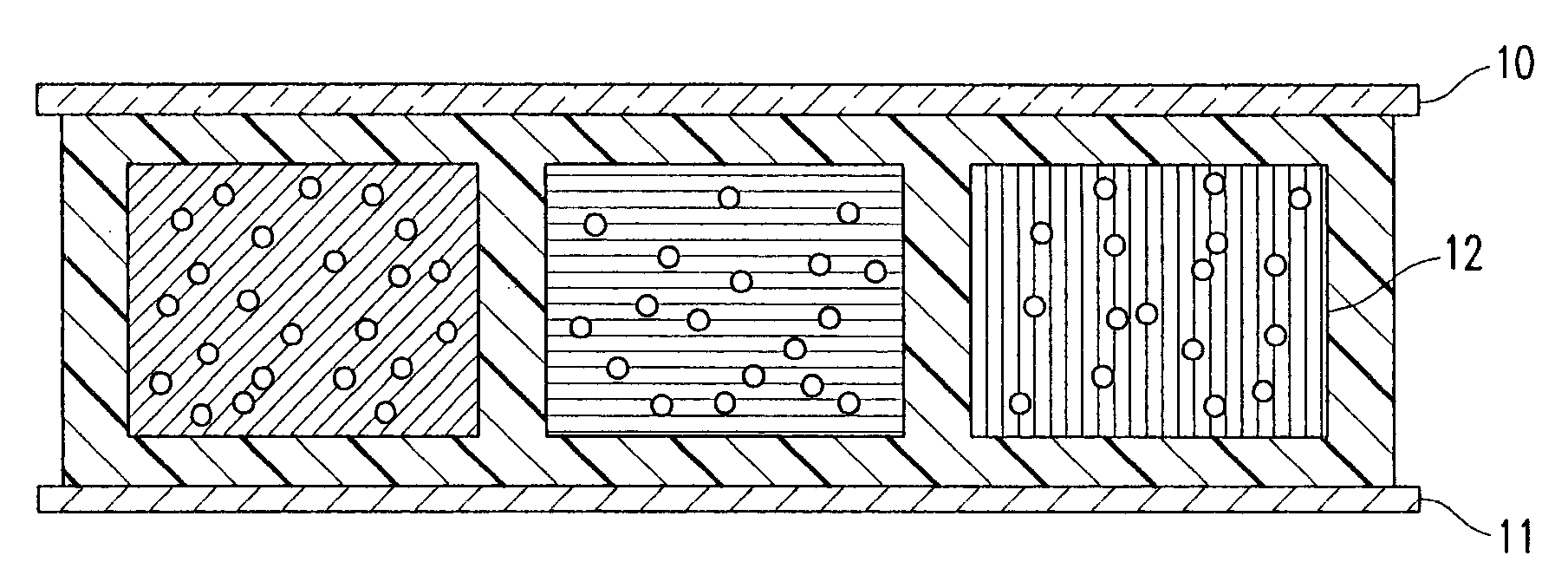

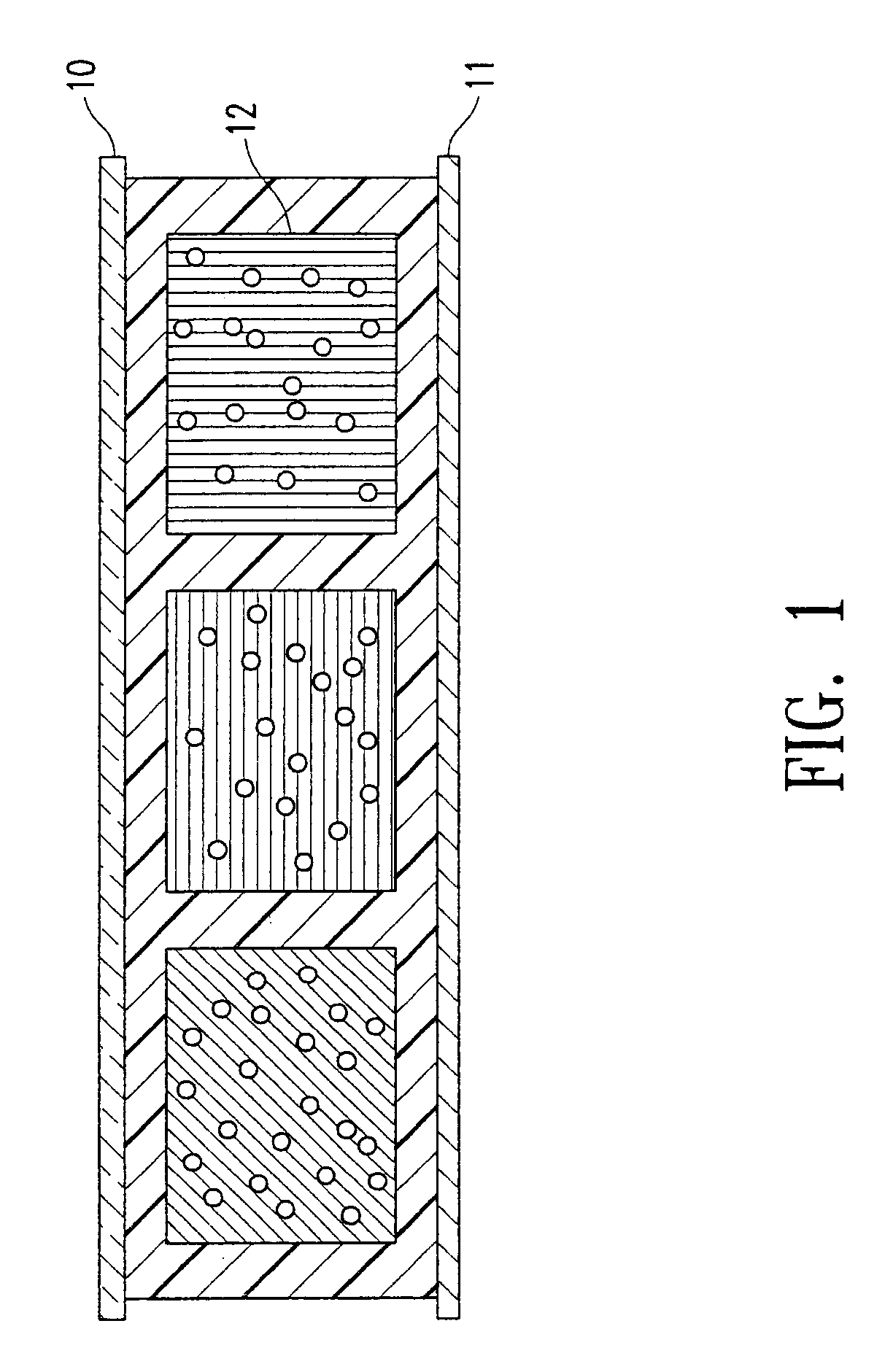

This invention relates to an electrophoretic display comprising a plurality of cells, each of said cells comprises: a) partition walls; b) an electrophoretic fluid filled therein; c) a polymeric sealing layer to enclose the electrophoretic fluid within the cell; and d) an interface between the electrophoretic fluid and the sealing layer.

Owner:E INK CALIFORNIA

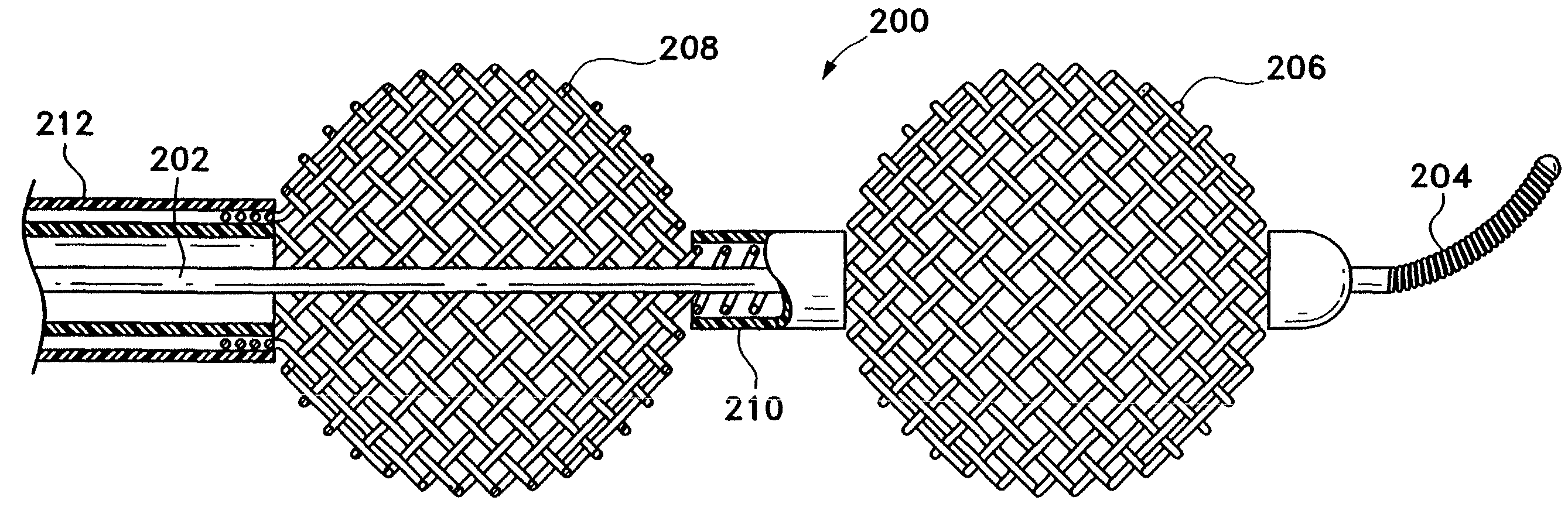

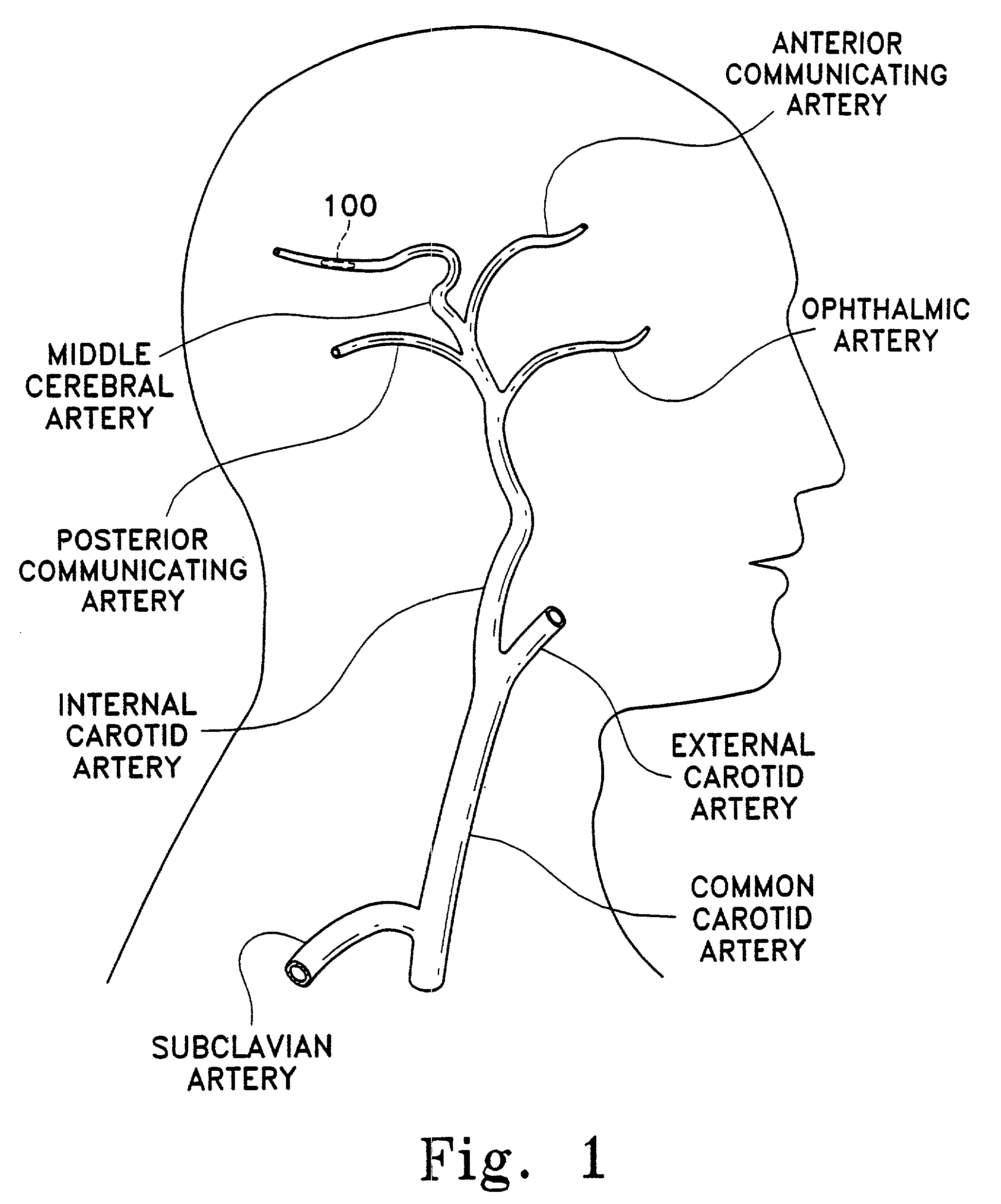

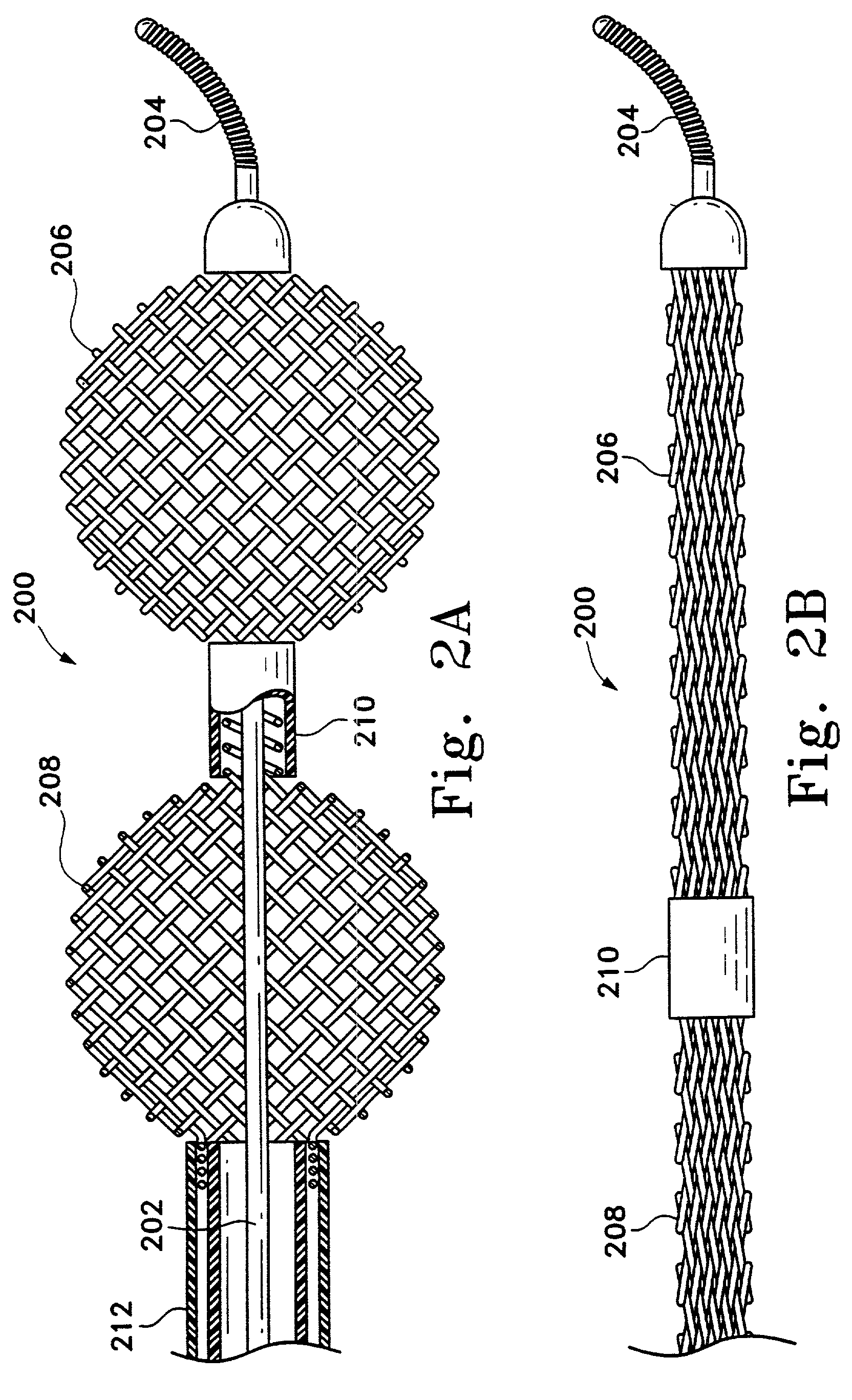

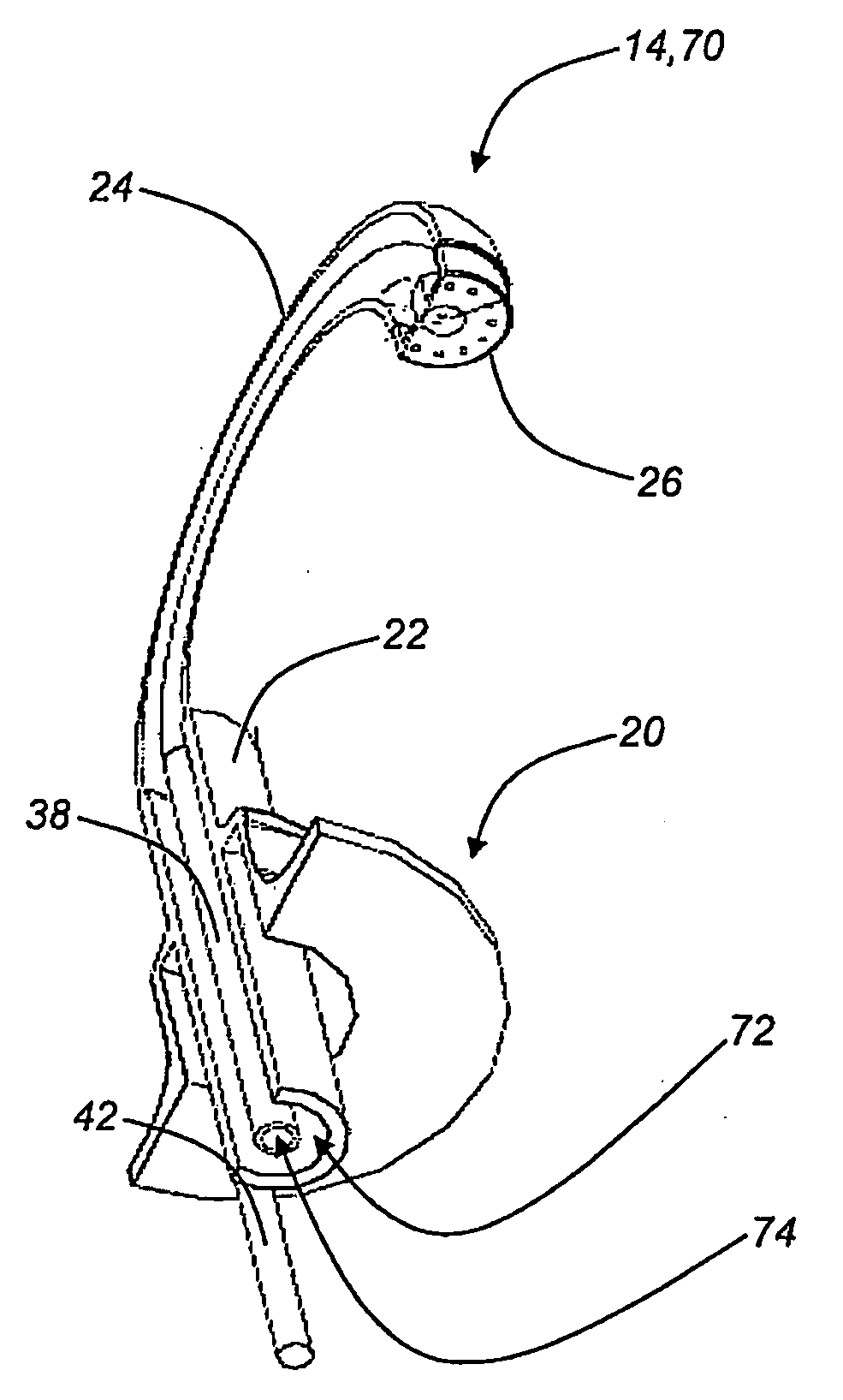

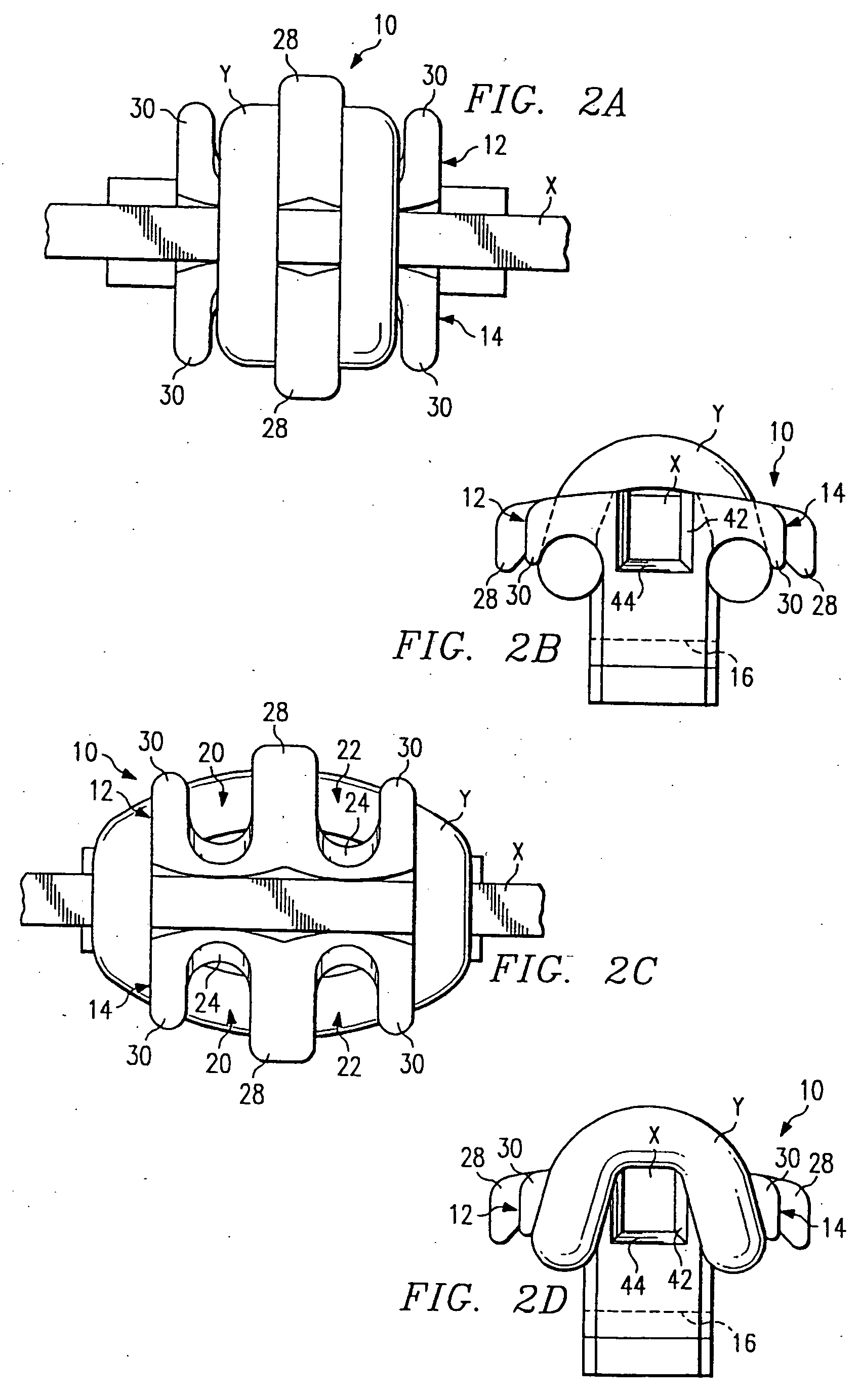

Mechanical clot treatment device

InactiveUS7875050B2Preserving abilityPreserving cage assembly shapeInfusion syringesSurgeryEngineeringActuator

An embolism treatment device includes an elongated core wire having a coil tip coupled to the distal end of the core wire and a cage assembly substantially coaxial to the core wire, having a first deployment shape and a second expanded shape. The core wire is freely moveable axially through the cage assembly. The device additionally includes an inner coil surrounding the core wire within the cage assembly and an actuator element, having a first position and a second position, located proximally to the cage assembly, wherein when the actuator element is in the first position, the cage assembly is in the first deployment shape and when the actuator element is in the second position, the cage assembly is in the second expanded shape.

Owner:STRYKER CORP +1

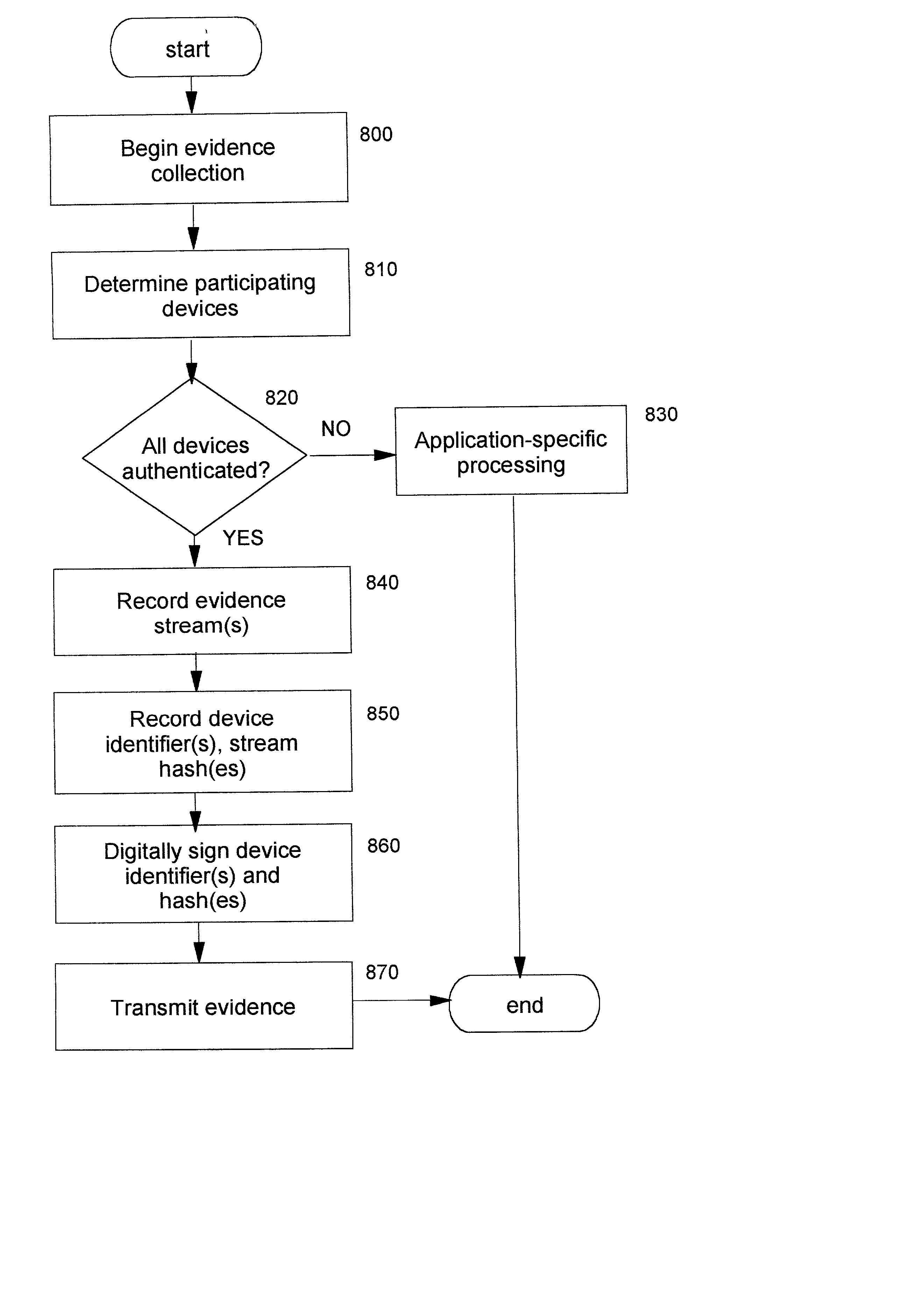

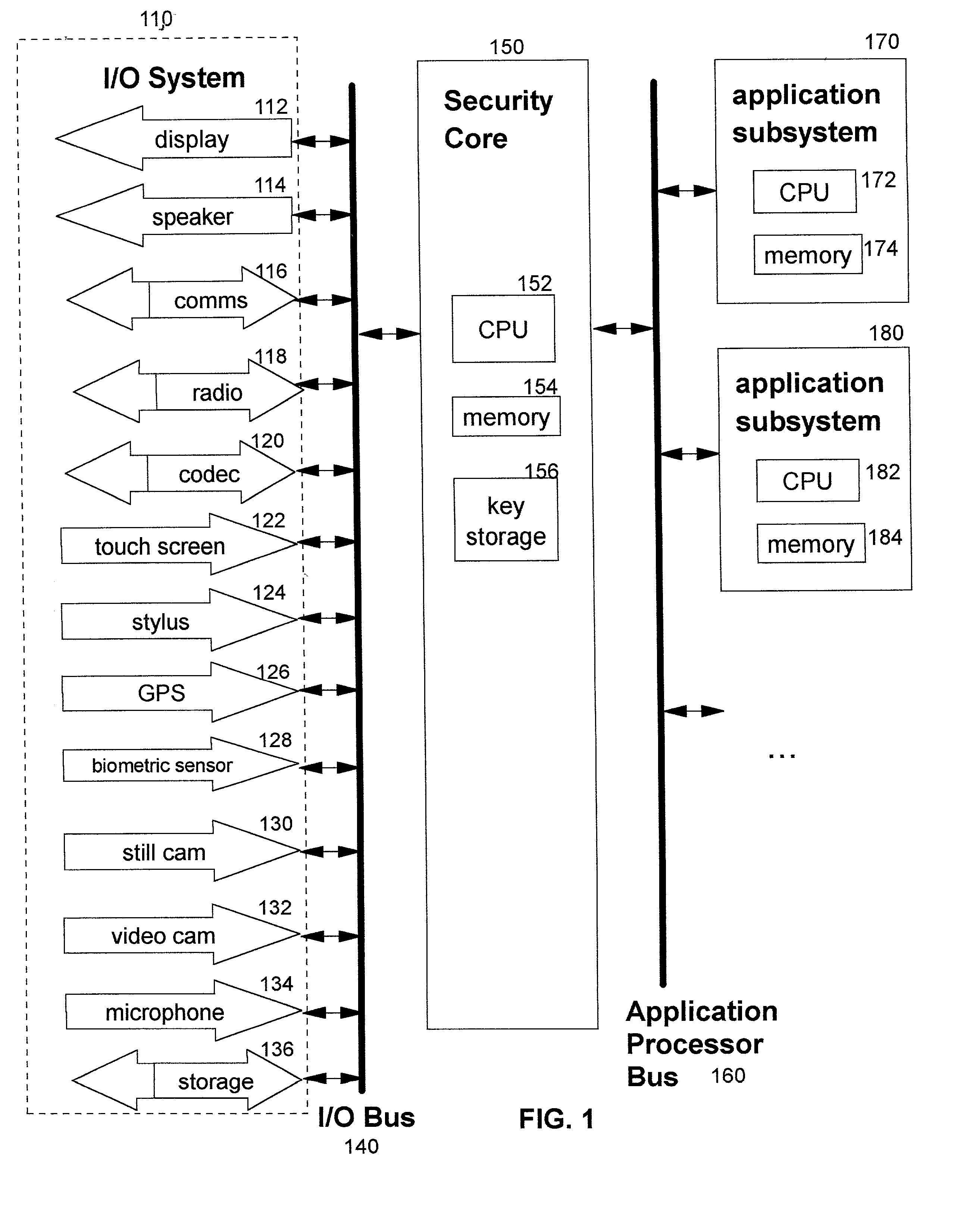

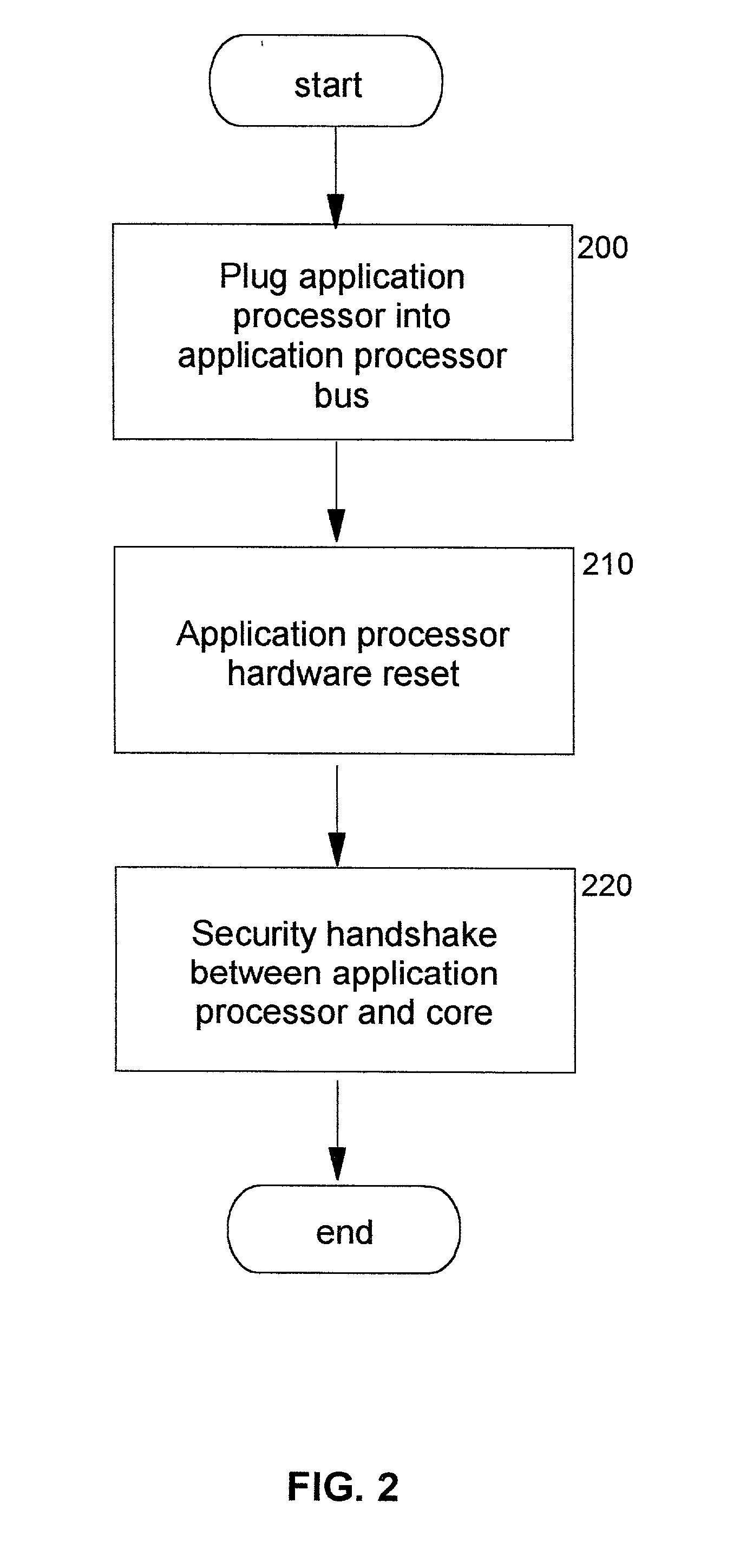

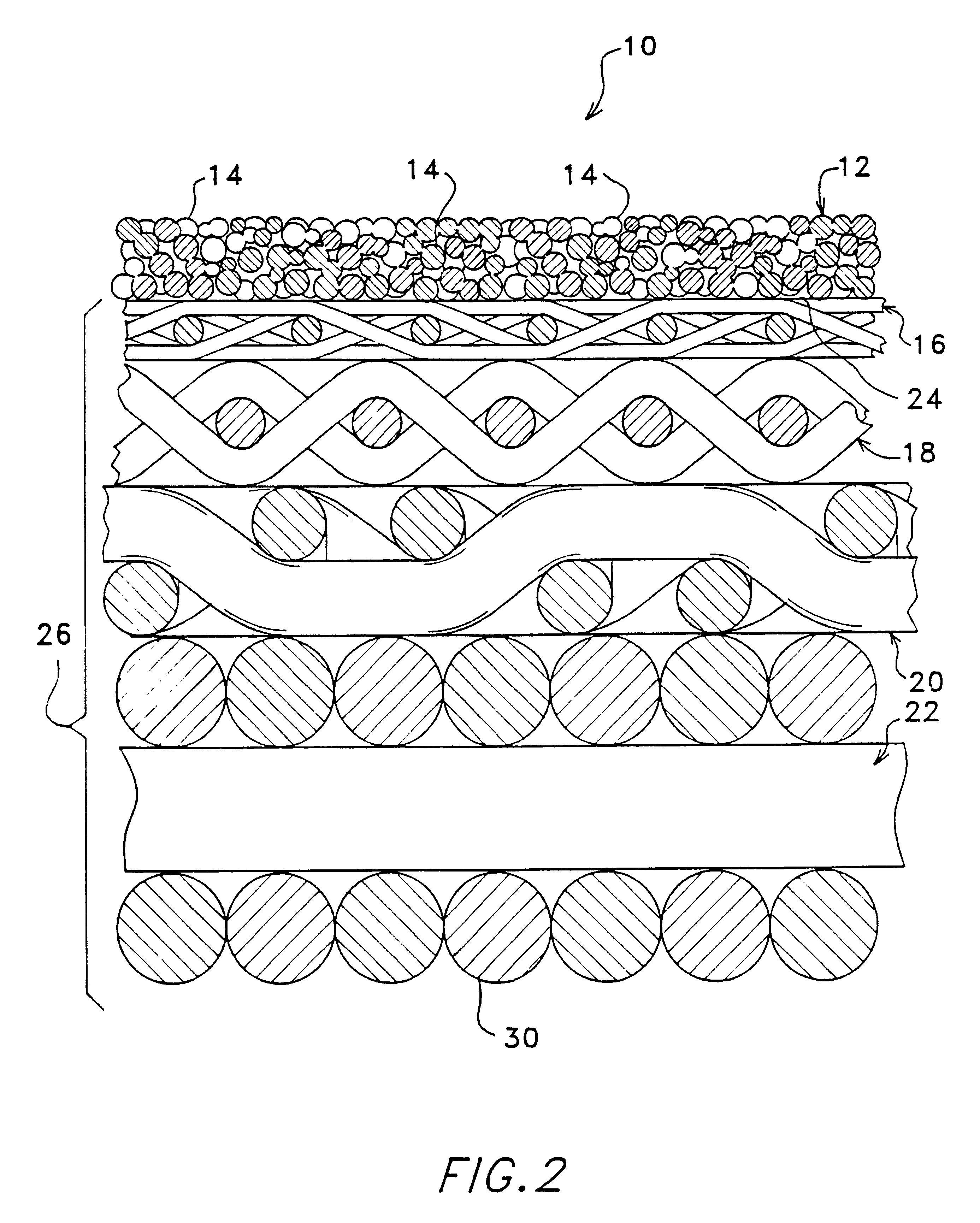

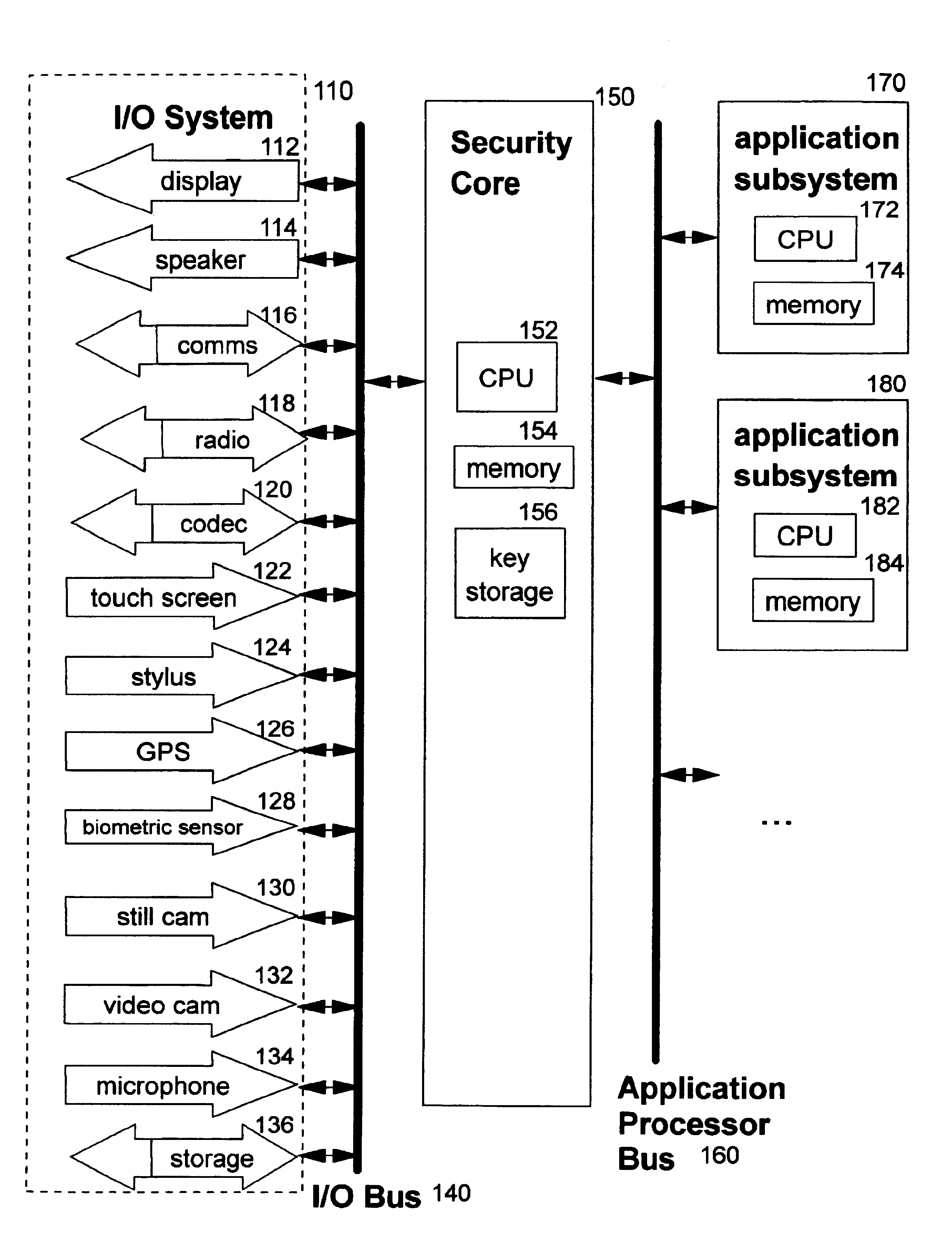

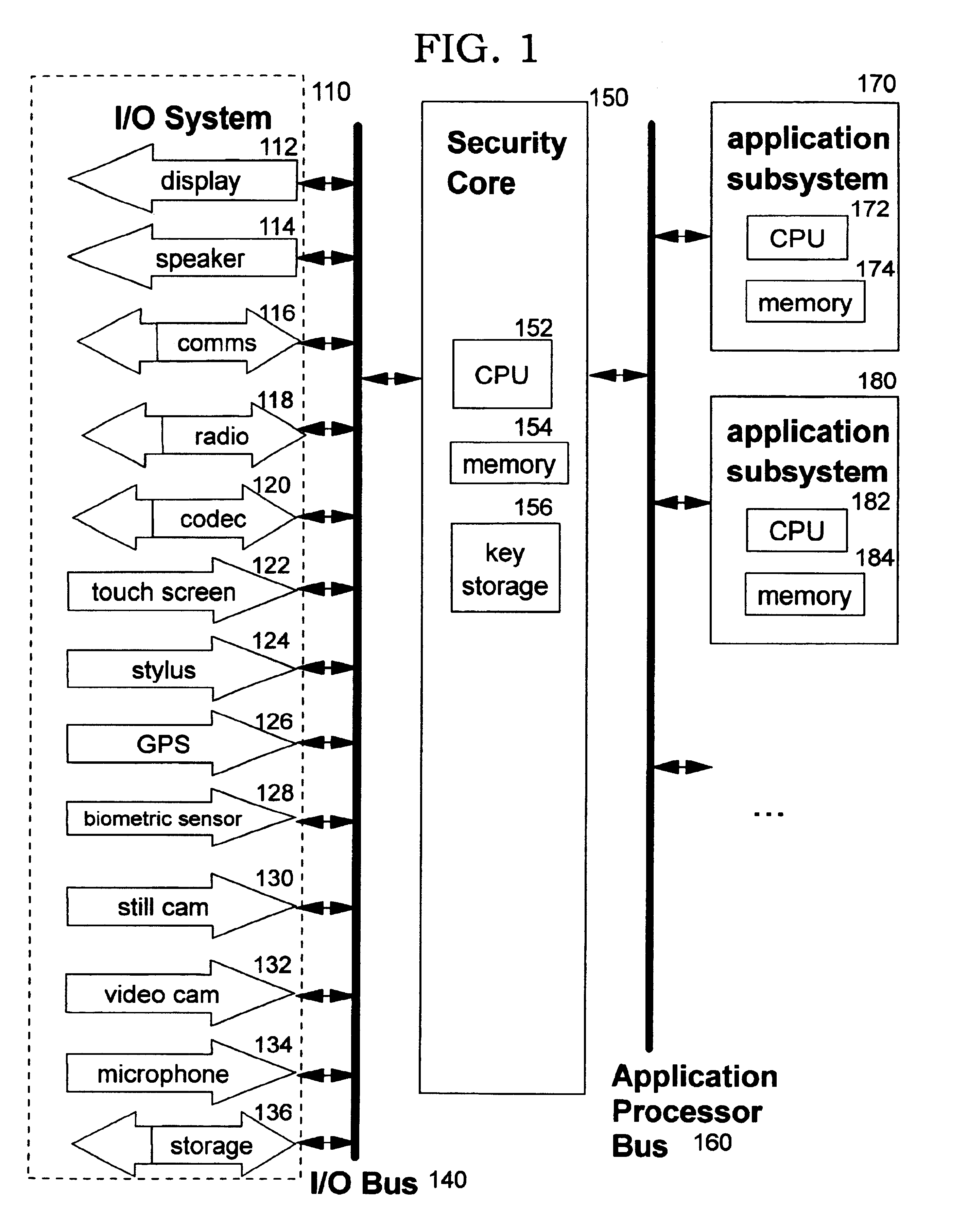

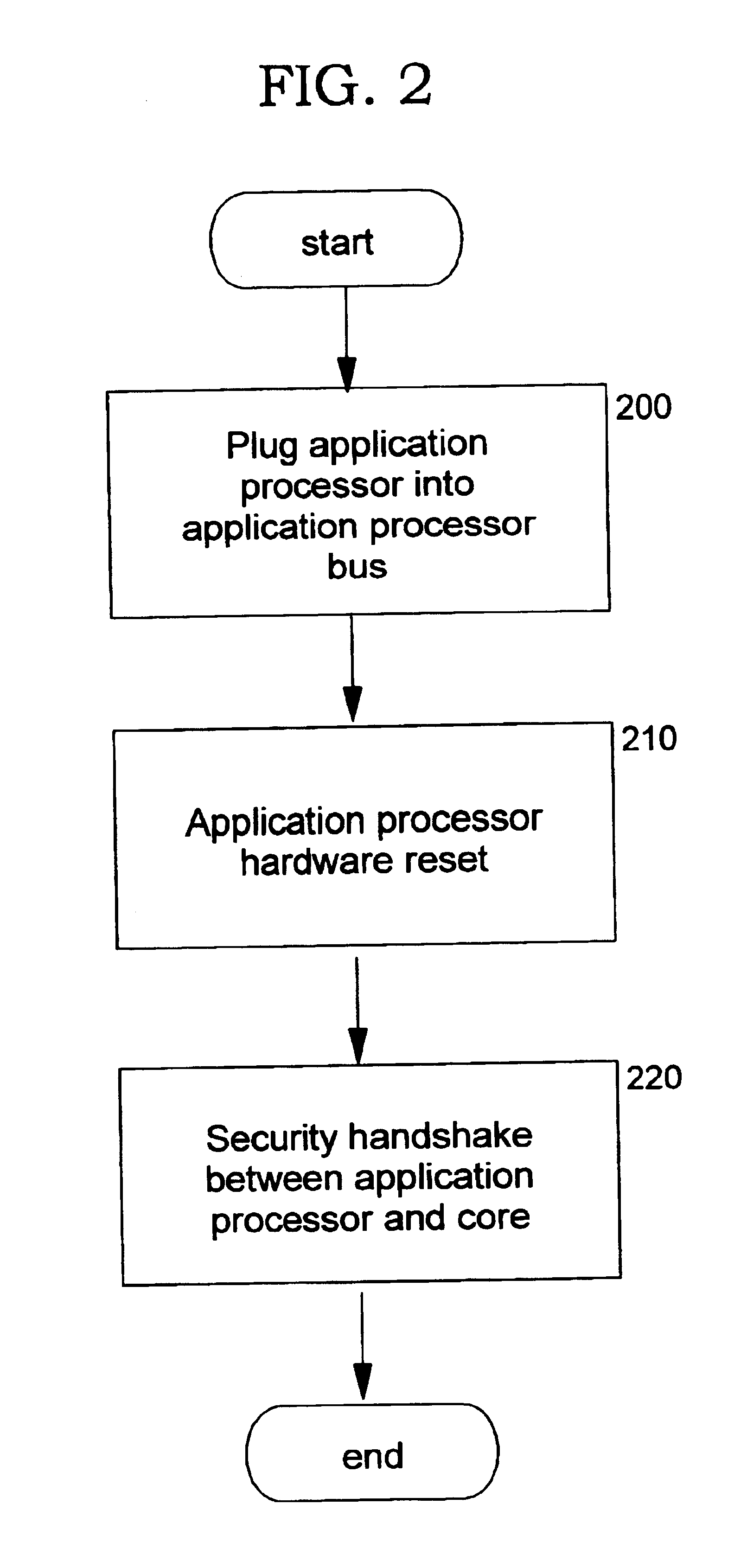

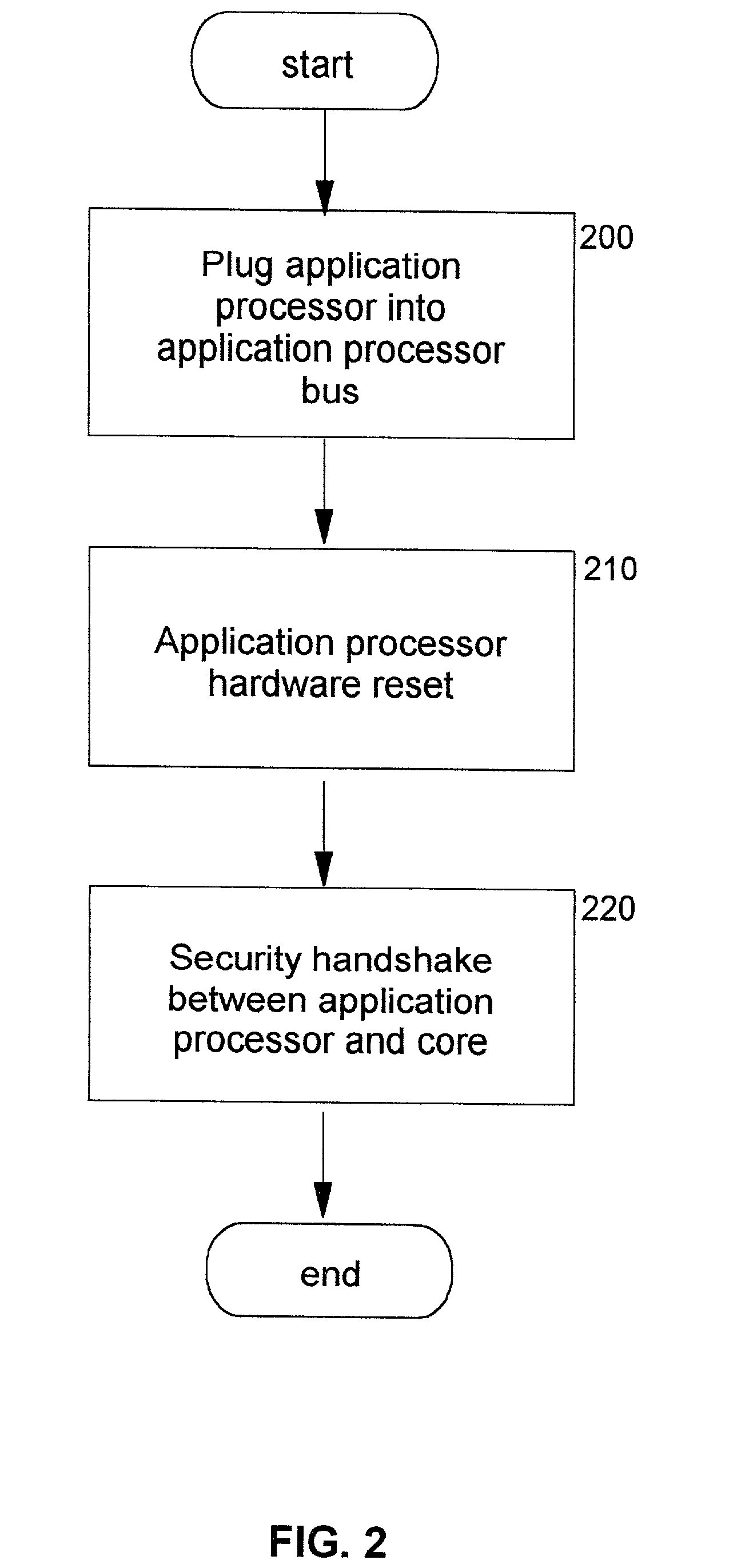

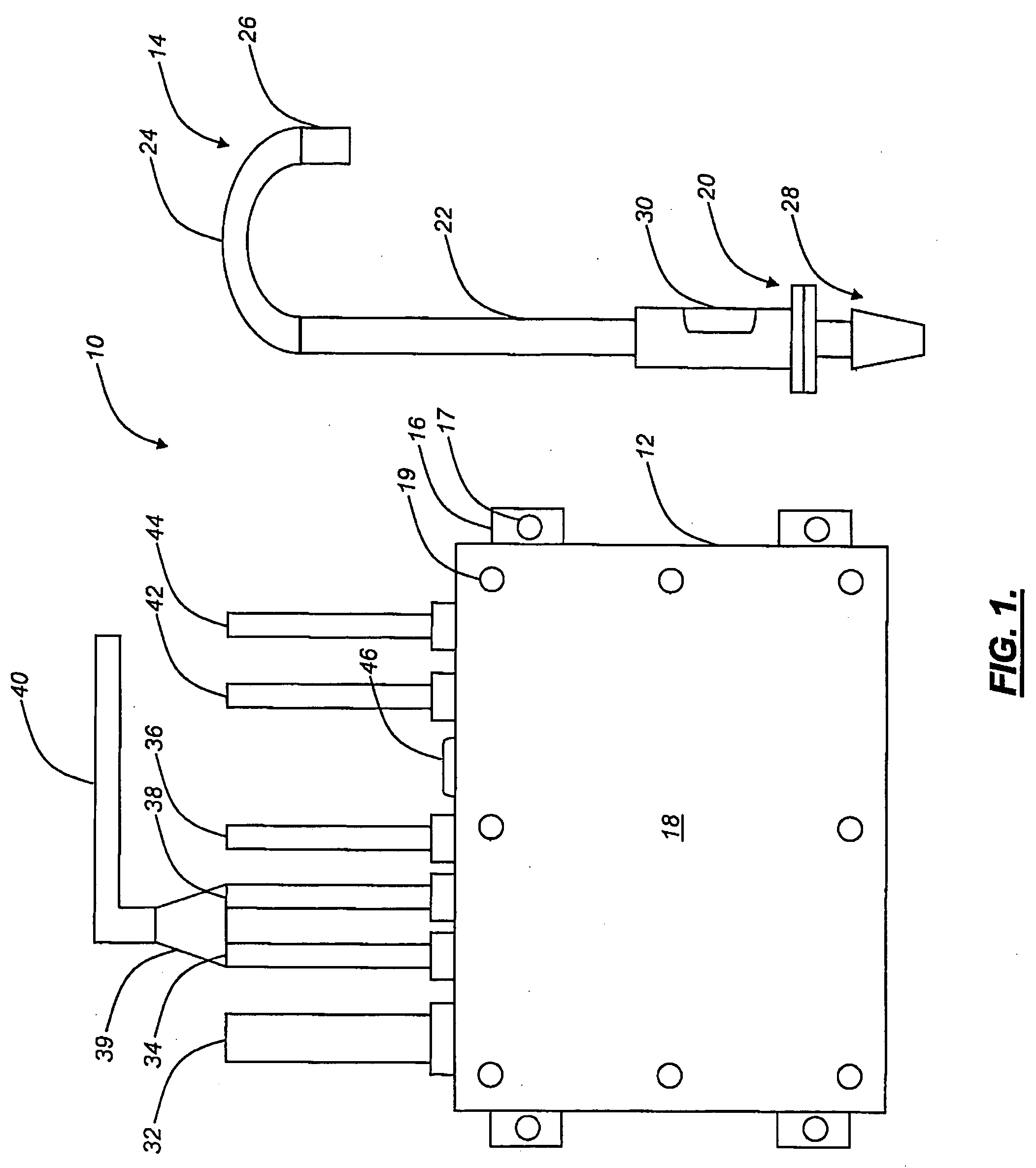

Technique for establishing provable chain of evidence

InactiveUS20020095601A1IntegrityMemory loss protectionError detection/correctionData streamDigital signature

A method, system, computer program product, and method of doing business by providing a provable chain of evidence for data stream(s) created by one or more components (such as input / output devices and application processing components). Components that create the evidence collection are authenticated. A unique identifier of each such component is included within cryptographically-protected information that is added to the evidence collection. A digital signature is preferably used for the cryptographic protection, thereby digitally notarizing the evidence collection. The authenticity and integrity of the evidence collection can be verified. In preferred embodiments, the authenticated identities of components providing the evidence can also be determined from the cryptographically-protected information. One or more data streams may be included within the evidence collection to establish information such as the date and time the evidence collection was captured, the geographic location where the capture was performed, an identification of a person performing the evidence capture, and so forth. When present in a provable chain of evidence, these types of additional evidence are provided by authenticated components which are identified within the cryptographically-protected information.

Owner:IBM CORP

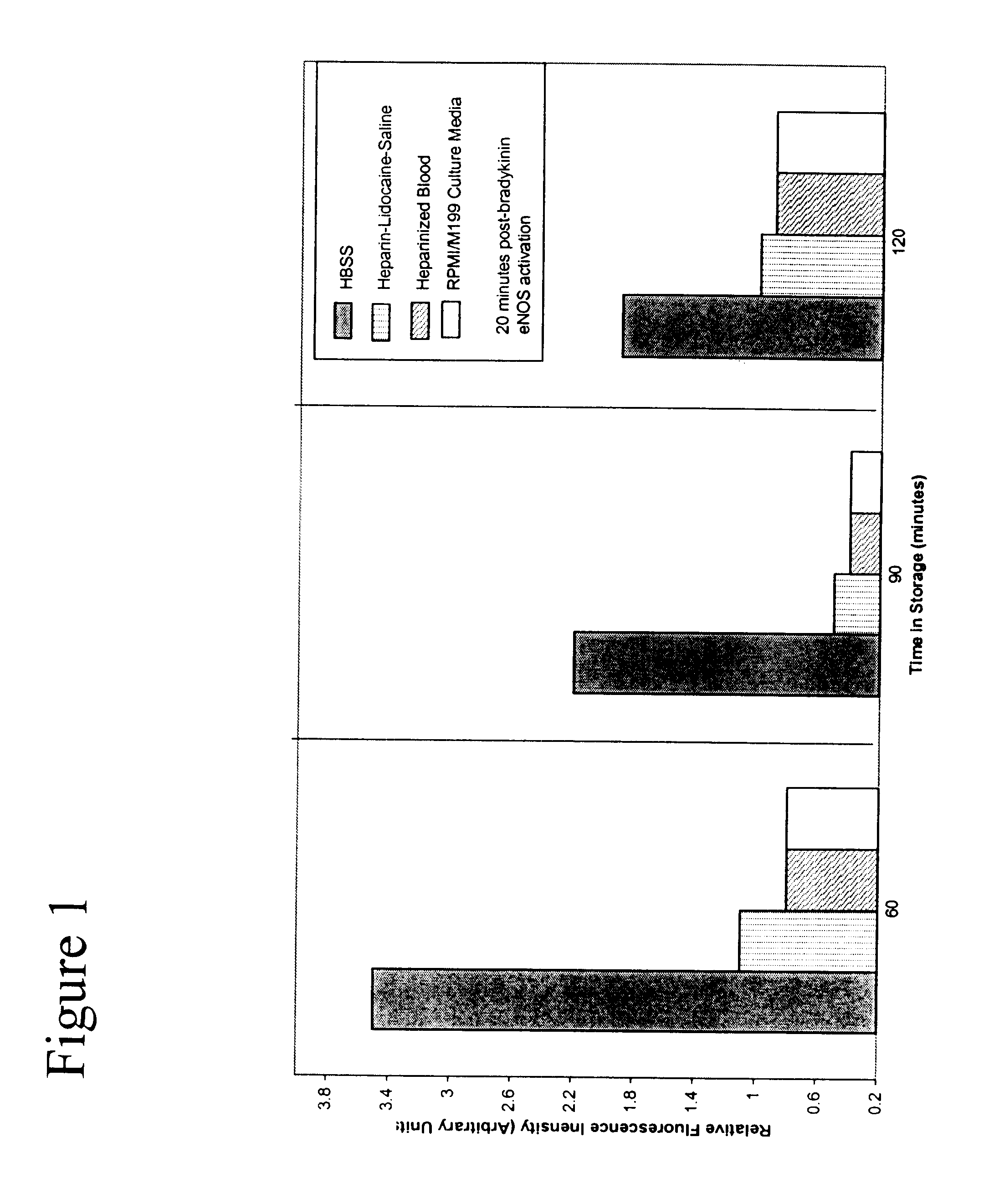

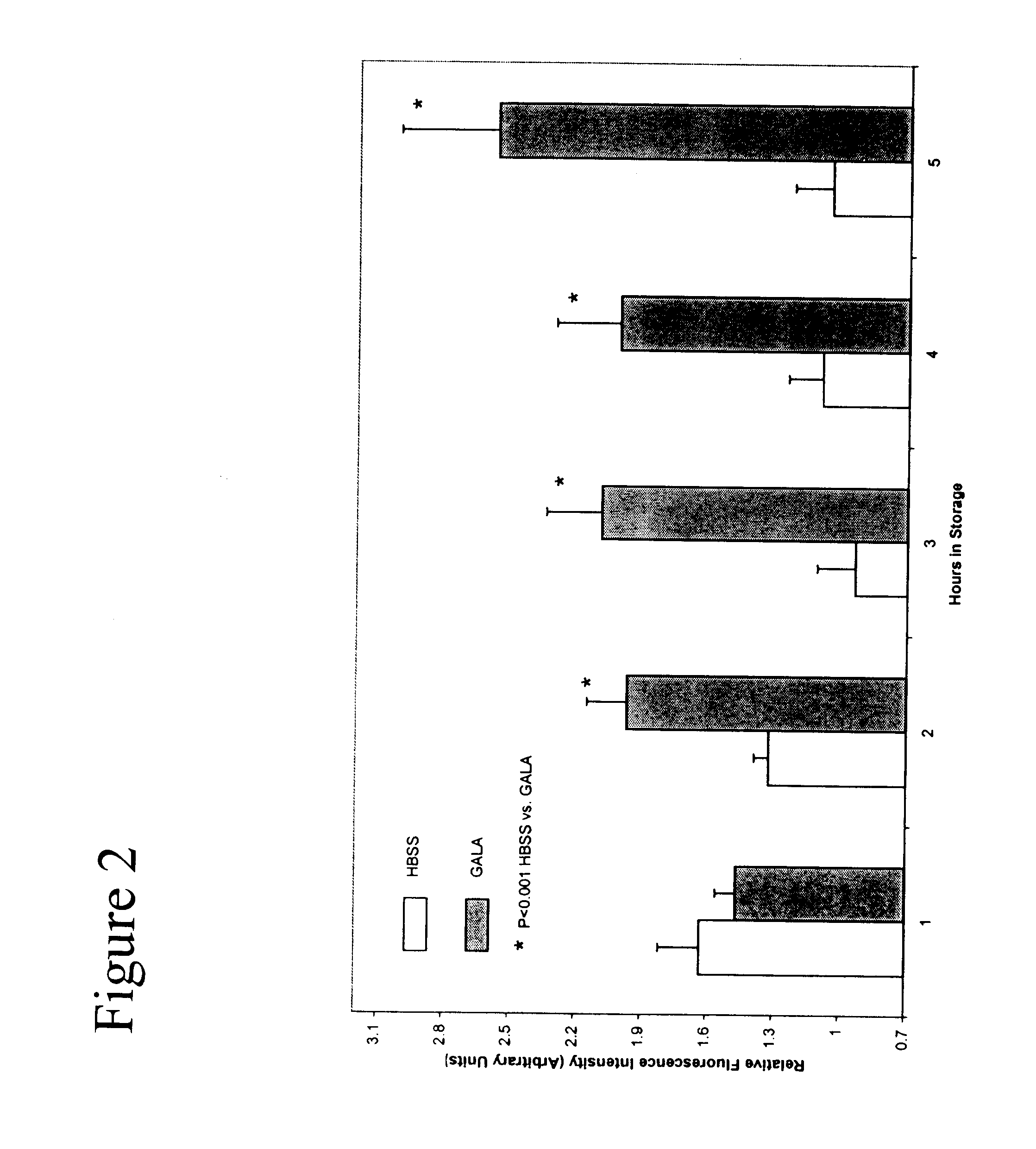

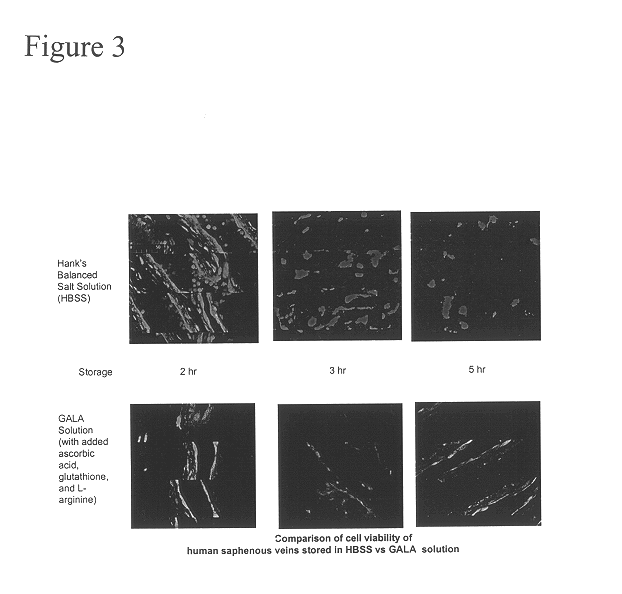

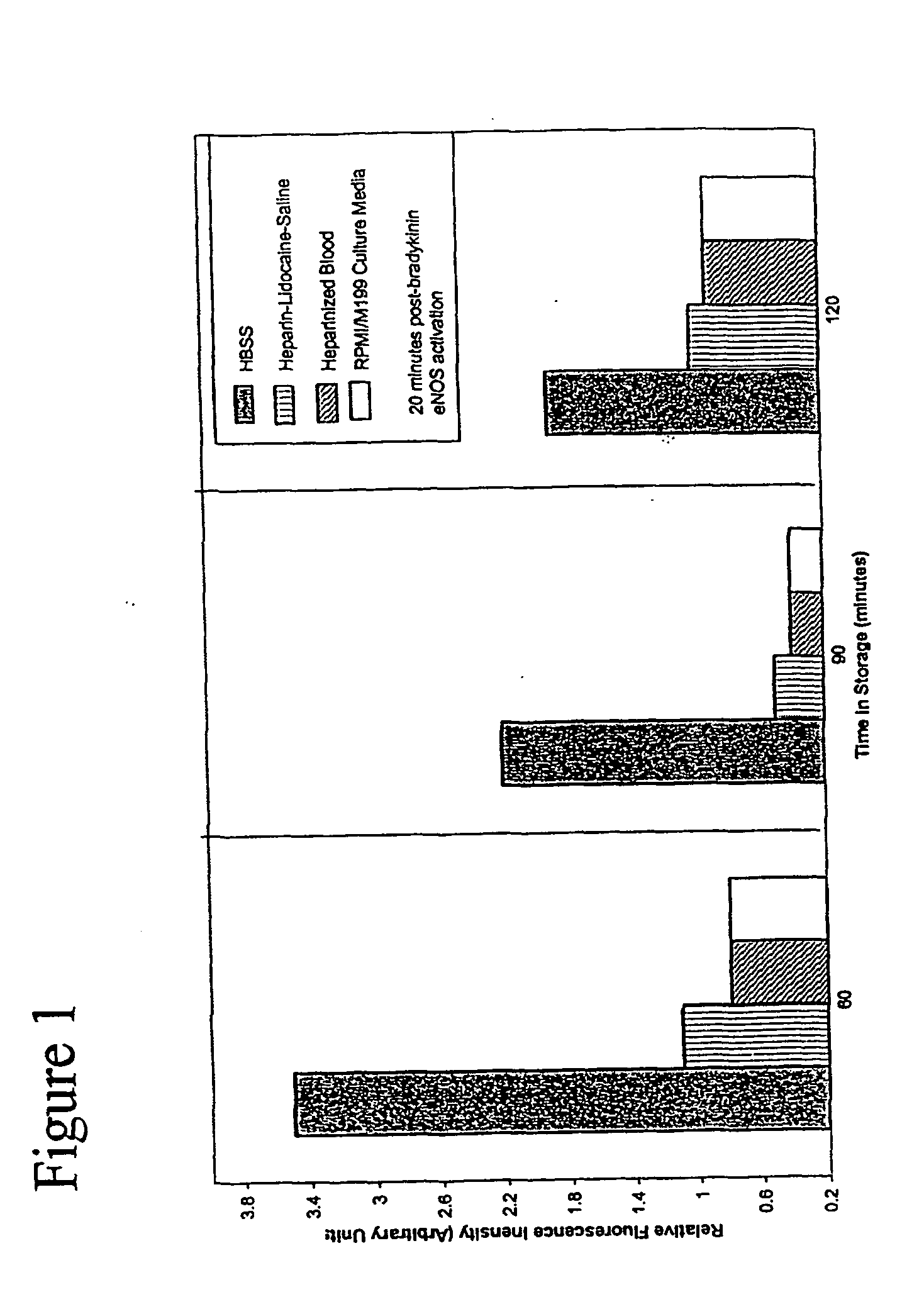

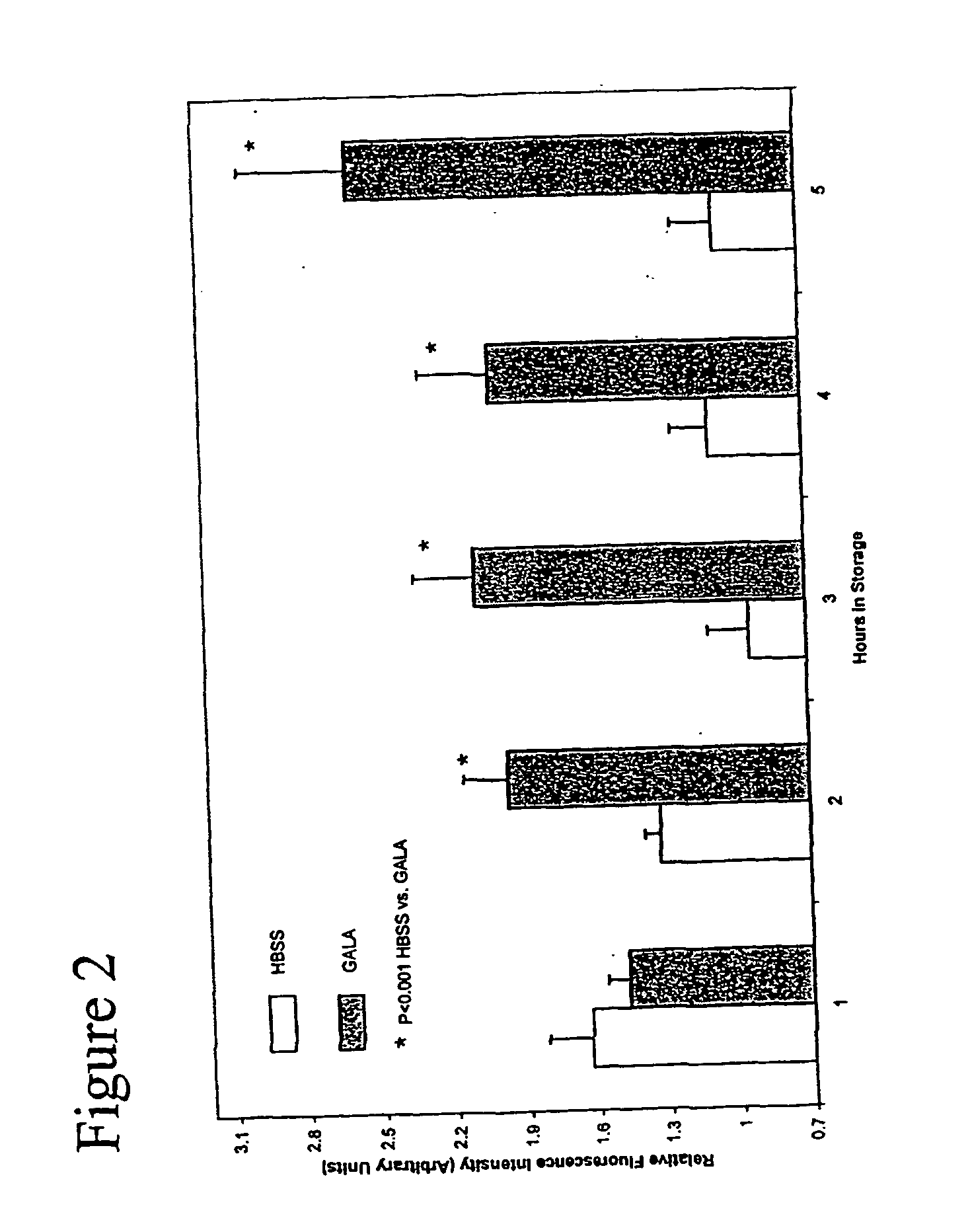

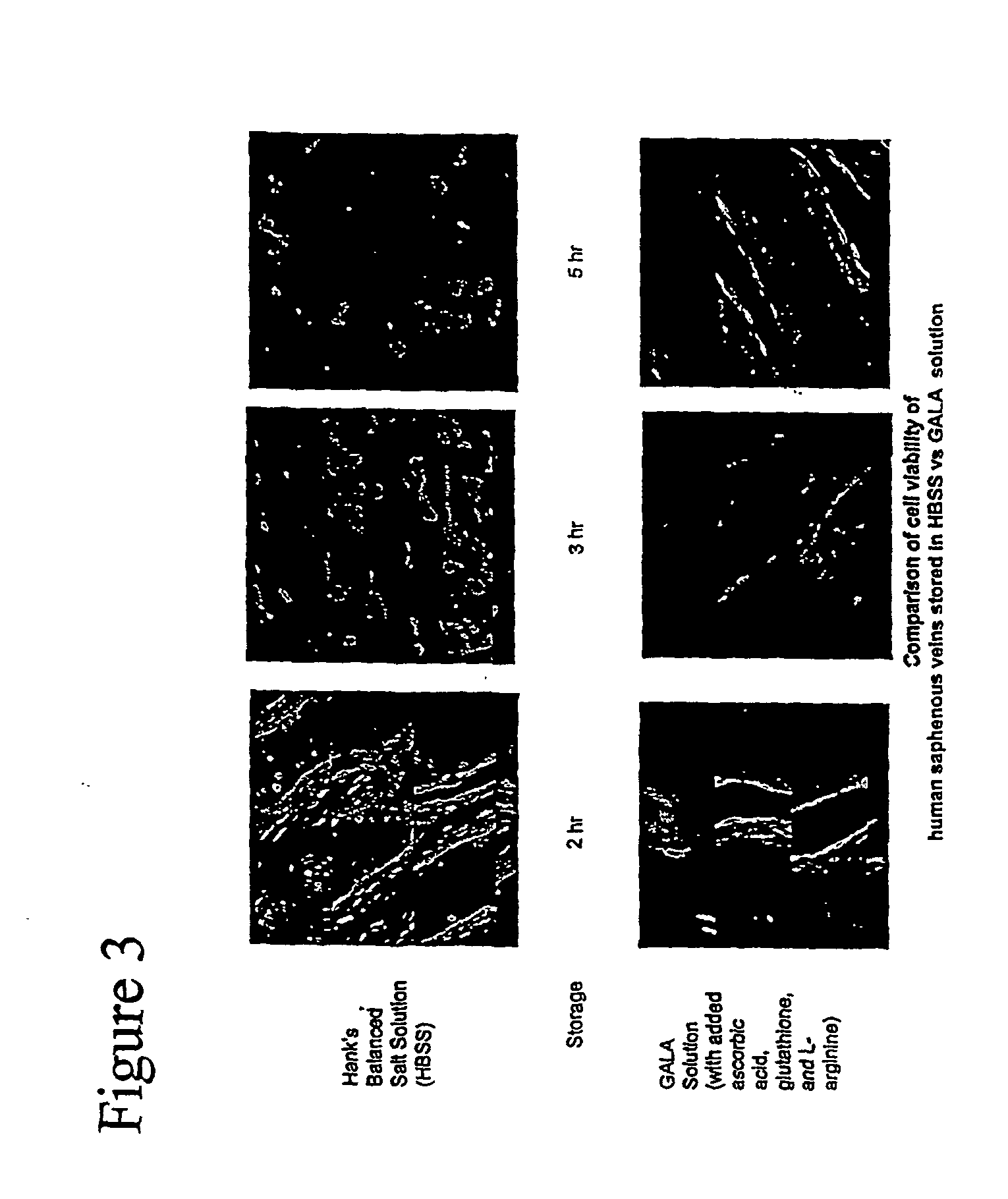

Composition and methods for tissue preservation

The present invention provides for compositions and methods for the preservation of tissues and organs ex vivo and in situ. In addition, the present invention provides for kits that may be used in the preparation of the solutions of the present invention.

Owner:VETERANS AFFAIRS UNITED STATES OF AMERICA AS REPRESENTED BY THE DEPT OF

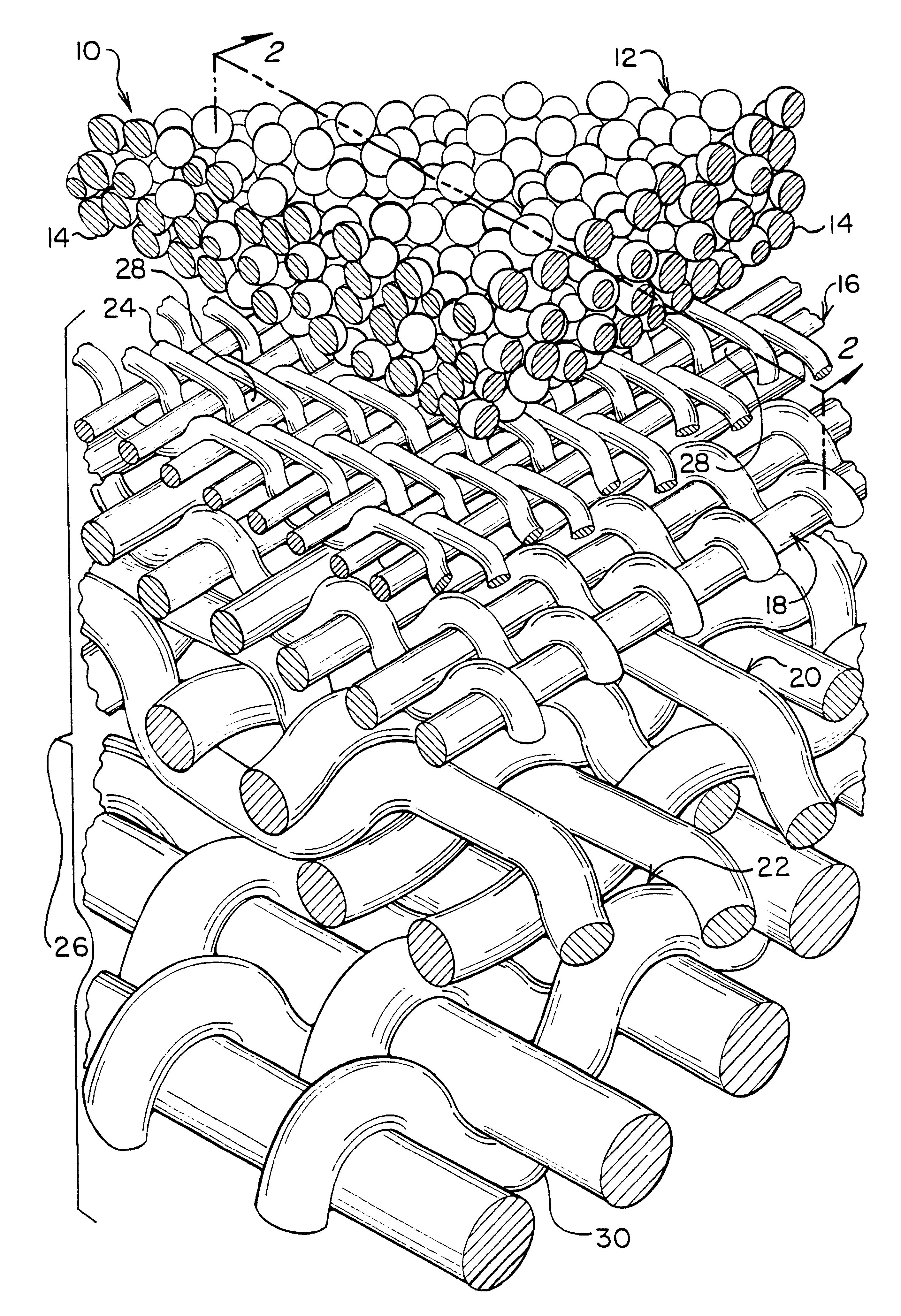

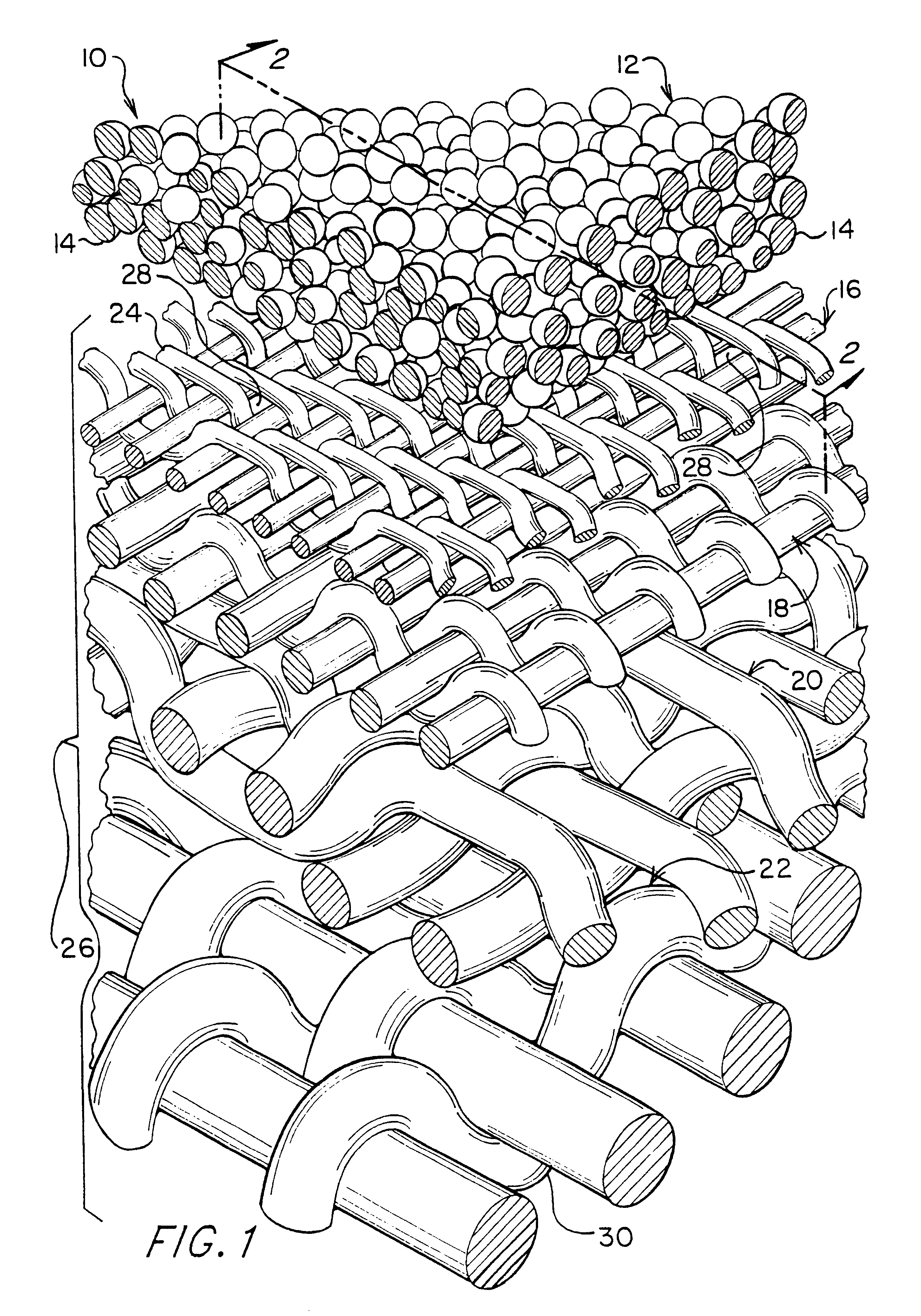

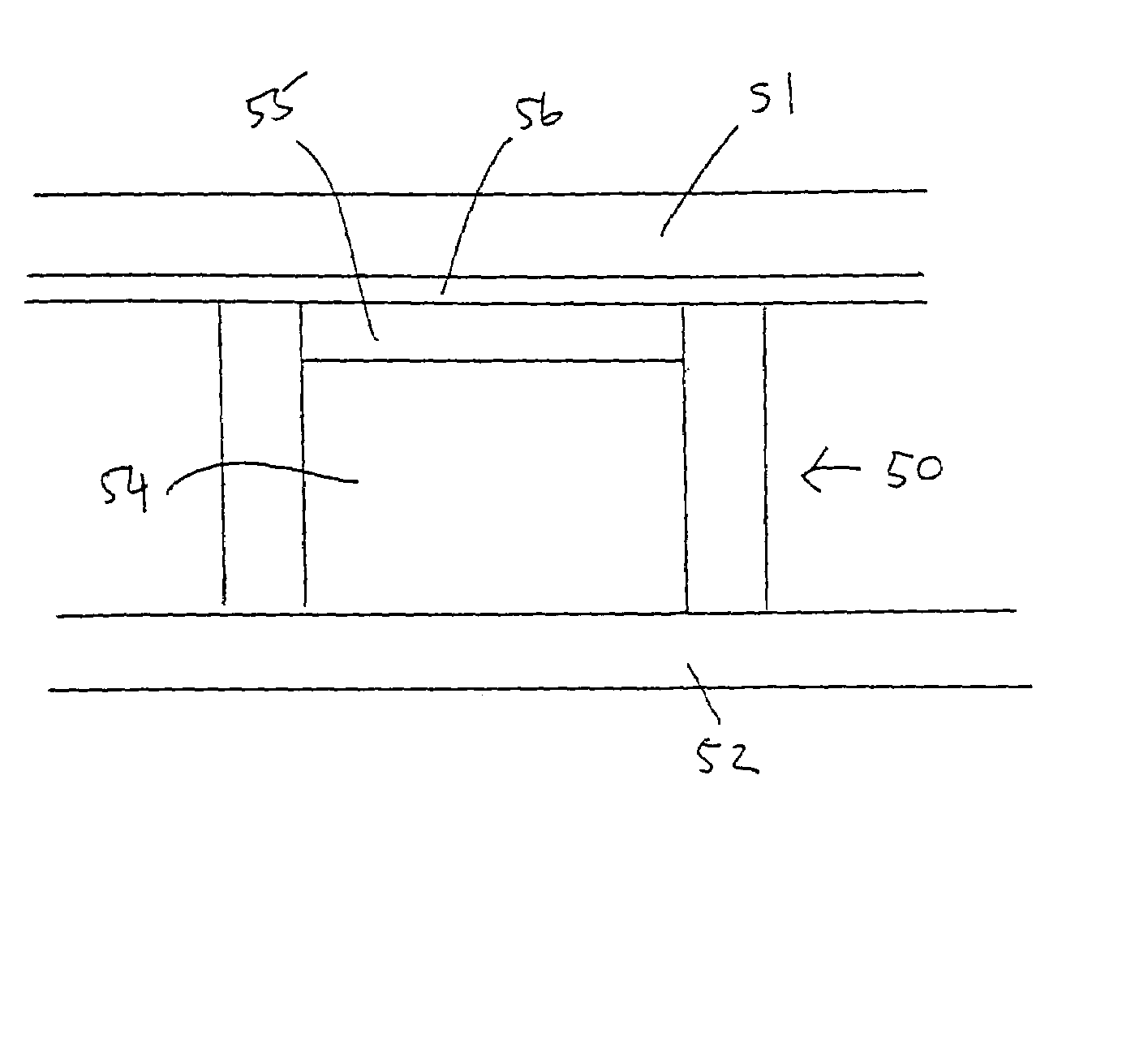

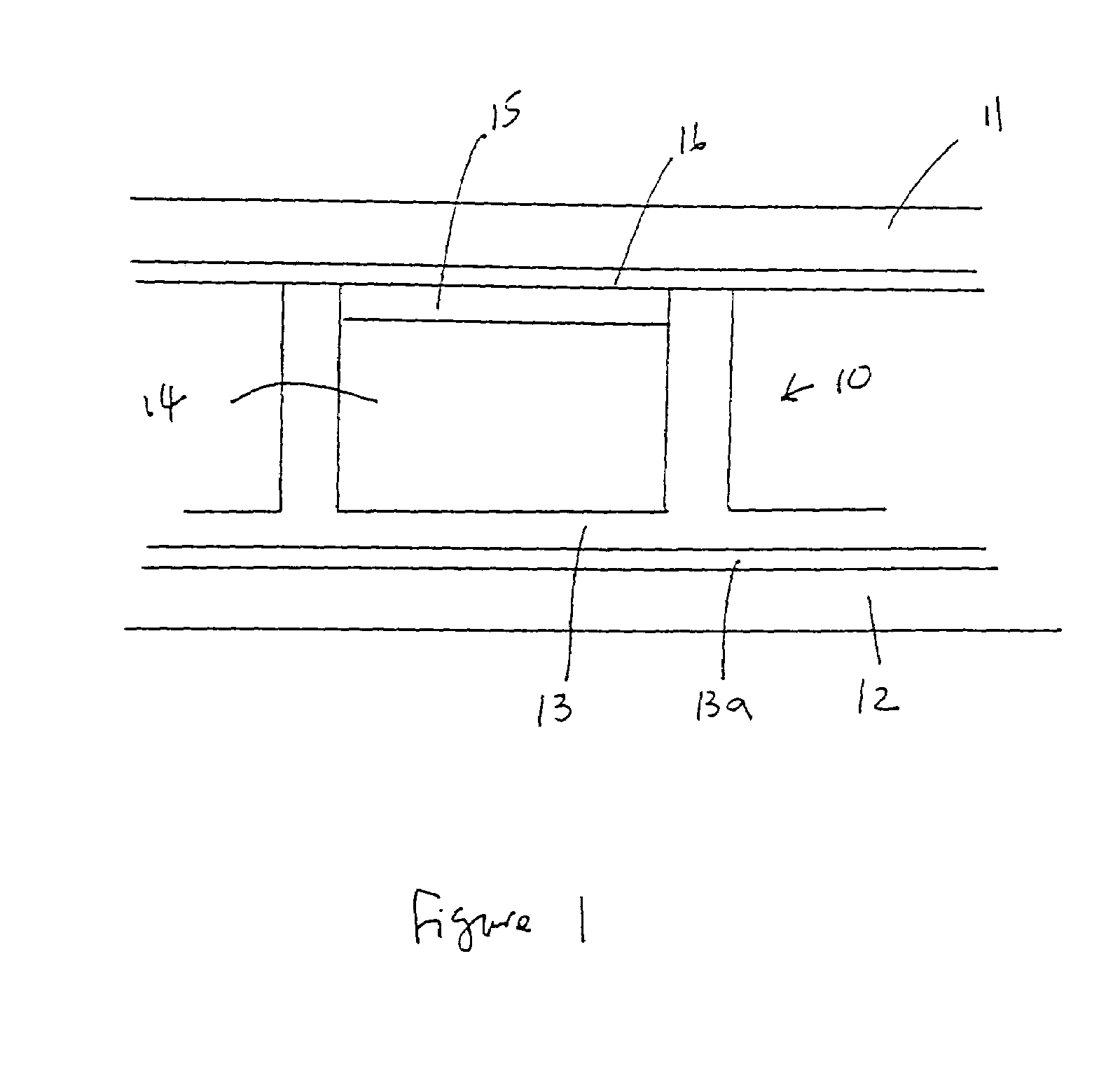

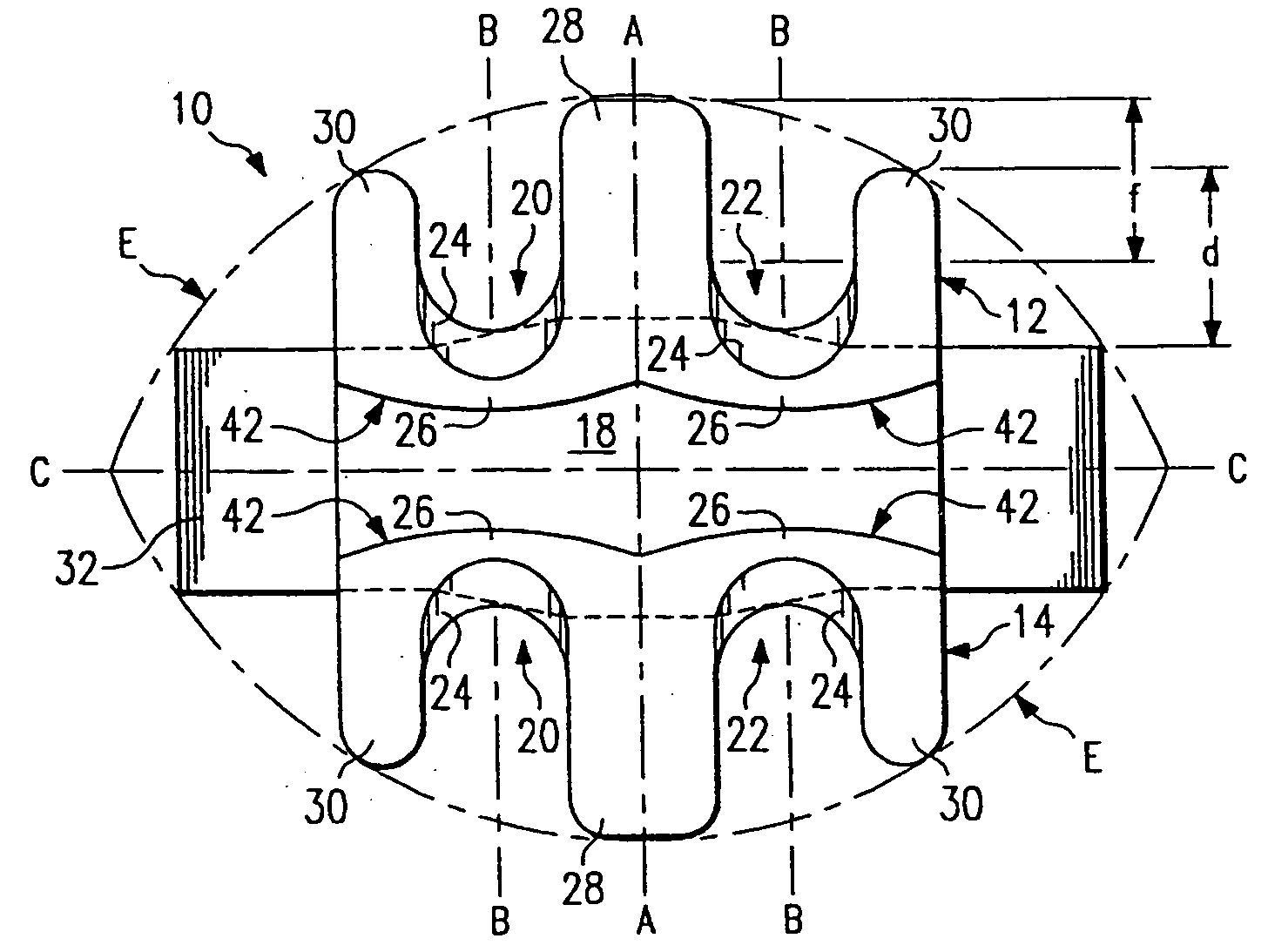

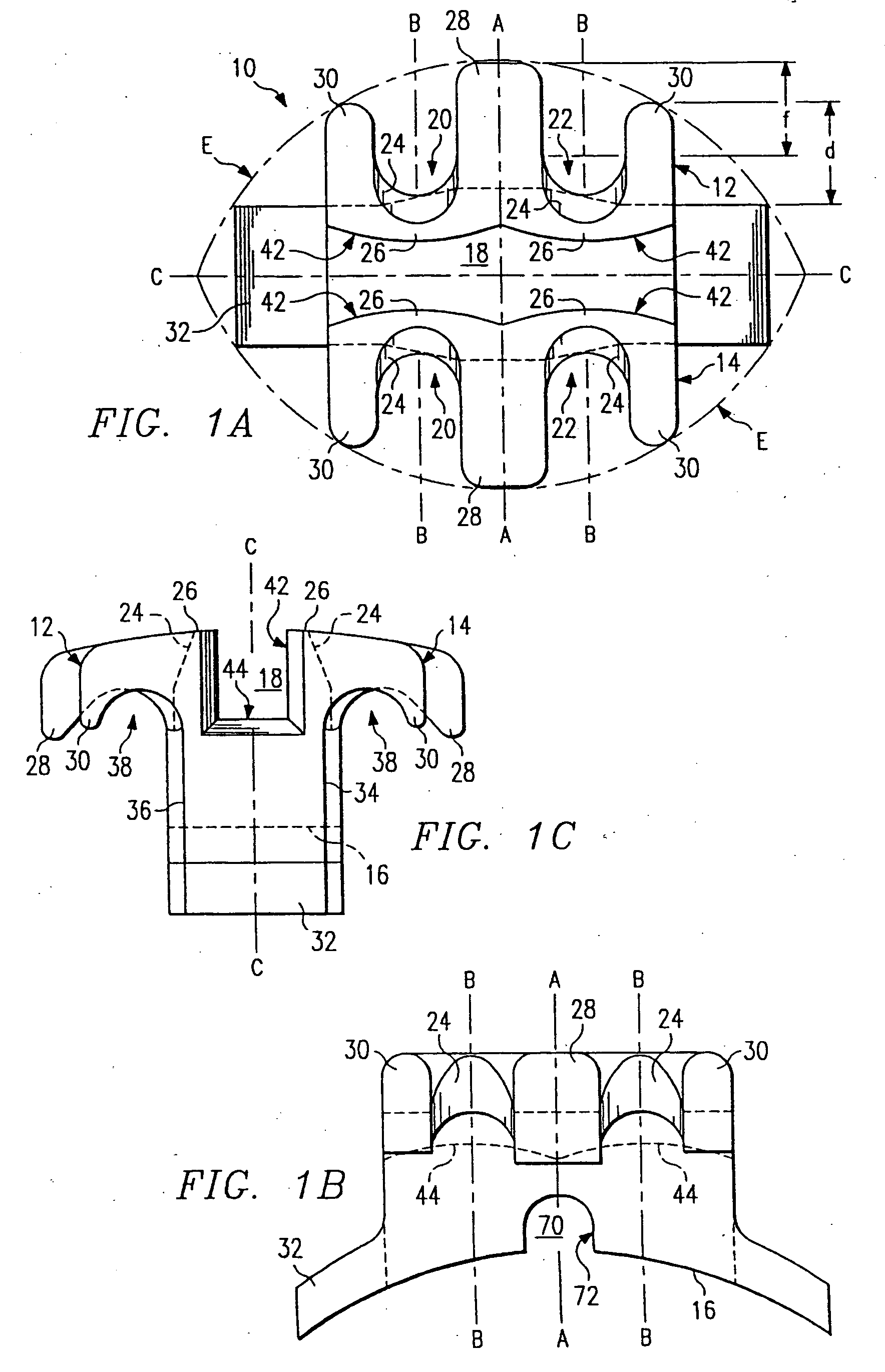

Micro and ultrafilters with controlled pore sizes and pore size distribution and methods for making

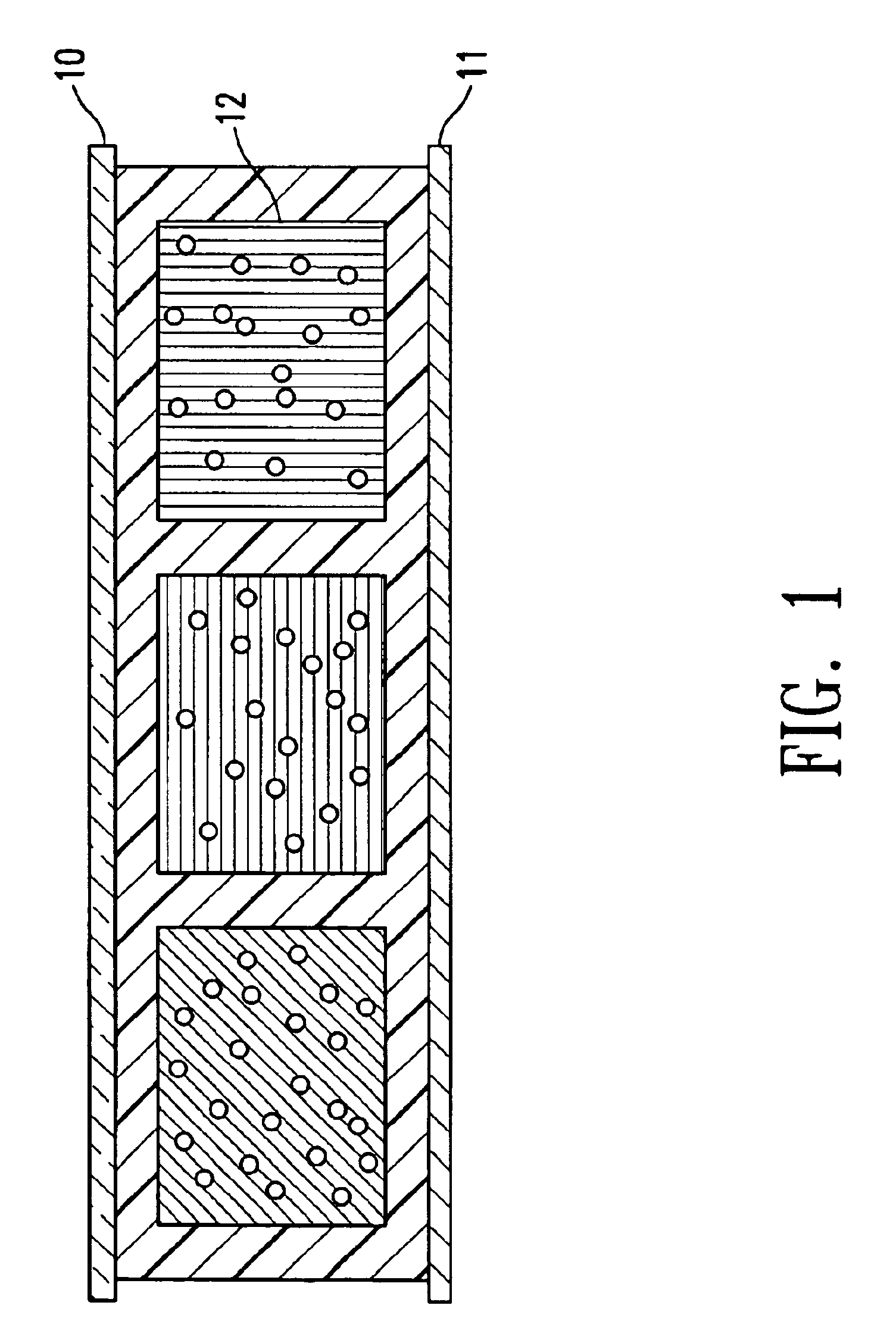

InactiveUS6309546B1High permeabilityMinimal pressure dropSemi-permeable membranesMembranesMicrometerPore diameter

A micro / ultrafiltering element (10) and method for making a filter element are provided. The filtering element comprises a multi-level support (26) having a filtering membrane layer (12) formed thereon comprising sintered particles (14) of uniform diameter. The filtering membrane preferably has an average pore size of from about 0.005-10 micrometers. The filter element is capable of being formed in a variety of geometrical shapes based on the shape of the porous support,

Owner:ELLIPSIS CORP

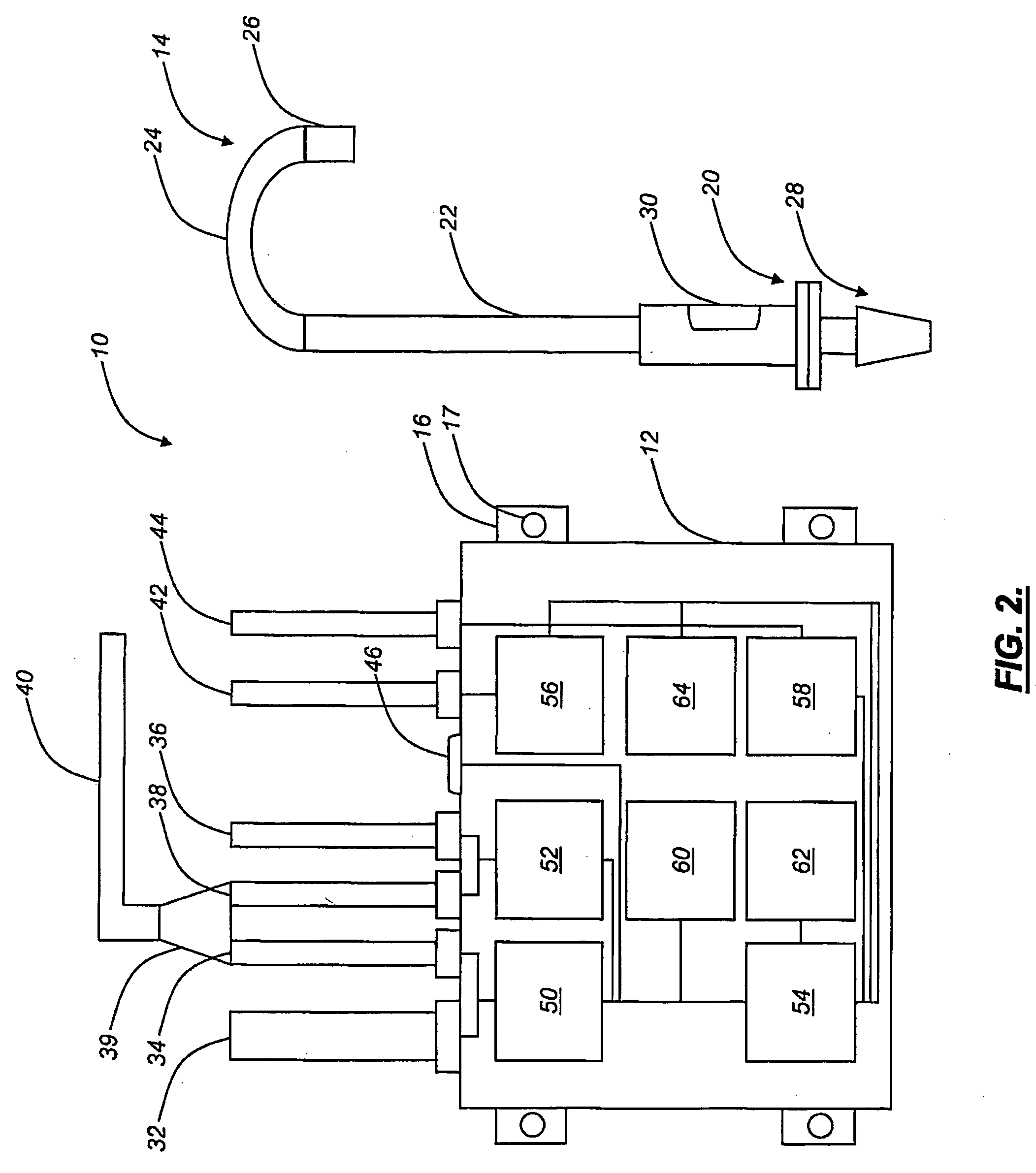

Technique for establishing provable chain of evidence

InactiveUS6948066B2IntegrityMemory loss protectionError detection/correctionData streamDigital signature

A method, system, computer program product, and method of doing business by providing a provable chain of evidence for data stream(s) created by one or more components (such as input / output devices and application processing components). Components that create the evidence collection are authenticated. A unique identifier of each such component is included within cryptographically-protected information that is added to the evidence collection. A digital signature is preferably used for the cryptographic protection, thereby digitally notarizing the evidence collection. The authenticity and integrity of the evidence collection can be verified. In preferred embodiments, the authenticated identities of components providing the evidence can also be determined from the cryptographically-protected information. One or more data streams may be included within the evidence collection to establish information such as the date and time the evidence collection was captured, the geographic location where the capture was performed, an identification of a person performing the evidence capture, and so forth. When present in a provable chain of evidence, these types of additional evidence are provided by authenticated components which are identified within the cryptographically-protected information.

Owner:IBM CORP

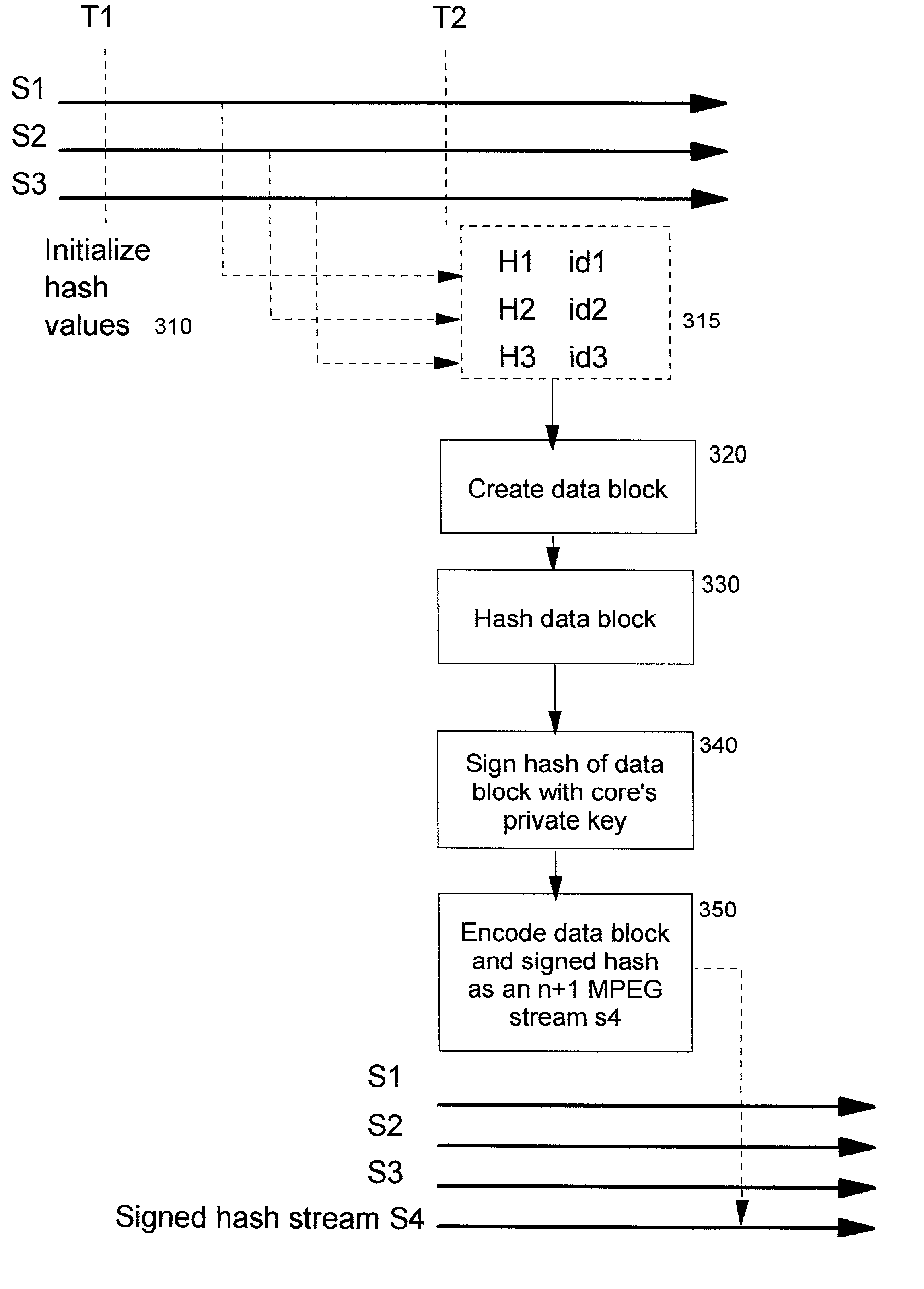

Technique for digitally notarizing a collection of data streams

InactiveUS20030212893A1IntegrityUser identity/authority verificationTelevision systemsData streamDigital signature

A method, system, computer program product, and method of doing business by digitally notarizing a collection of data streams, thereby improving security of the contents of the data streams. Preferably, public key cryptography is used, wherein the collection of data streams is digitally signed (i.e. notarized) using a private cryptographic key of a digital notary, such that an associated public cryptographic key can be used to verify the authenticity and integrity of the collection of data streams. One or more components which are involved in creating the data streams are preferably authenticated, and a unique identifier of each such component is included within cryptographically-protected information that is provided for the digital notarization. The authenticated identities of the components can therefore be determined from the digital notarization.

Owner:IBM CORP

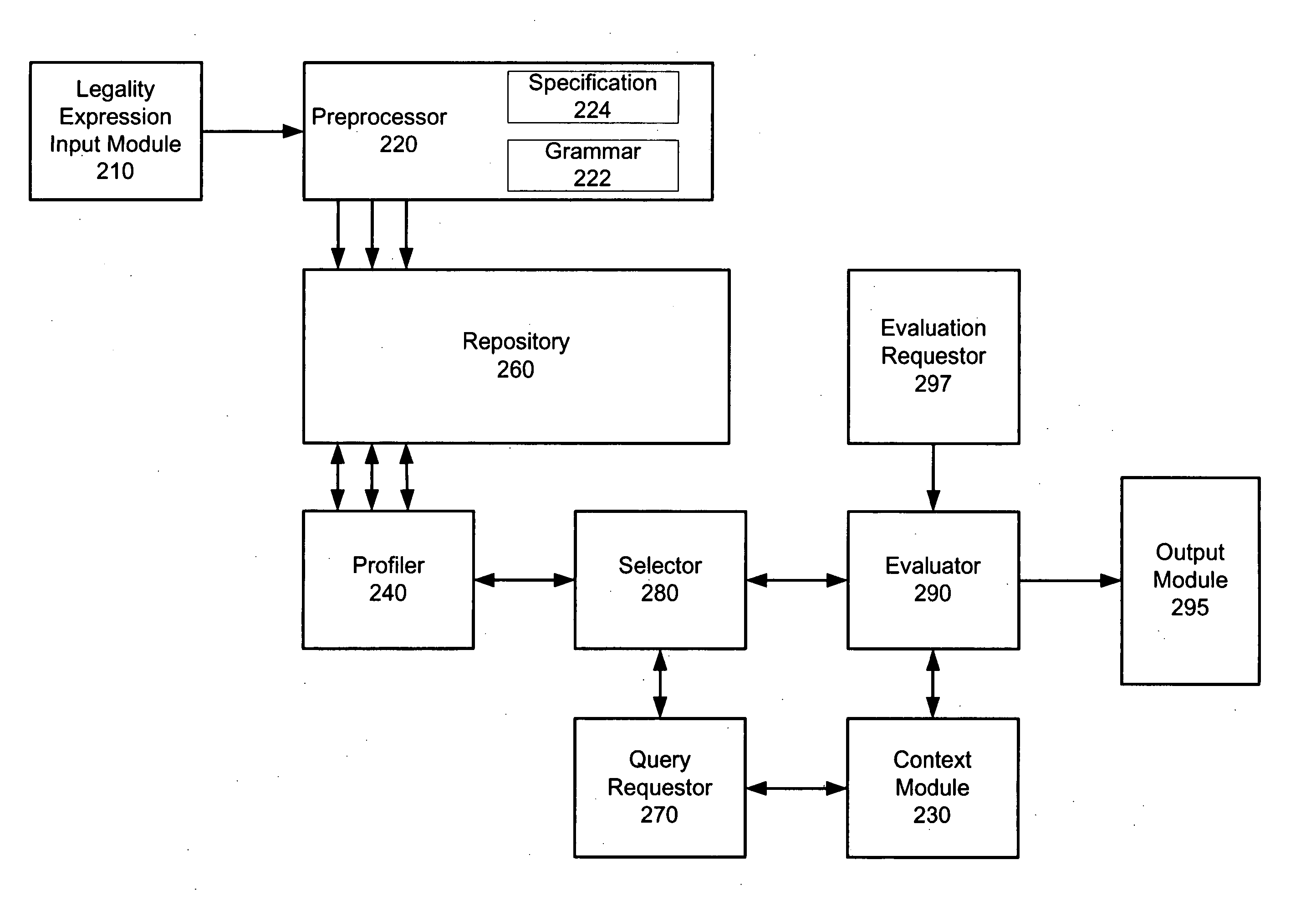

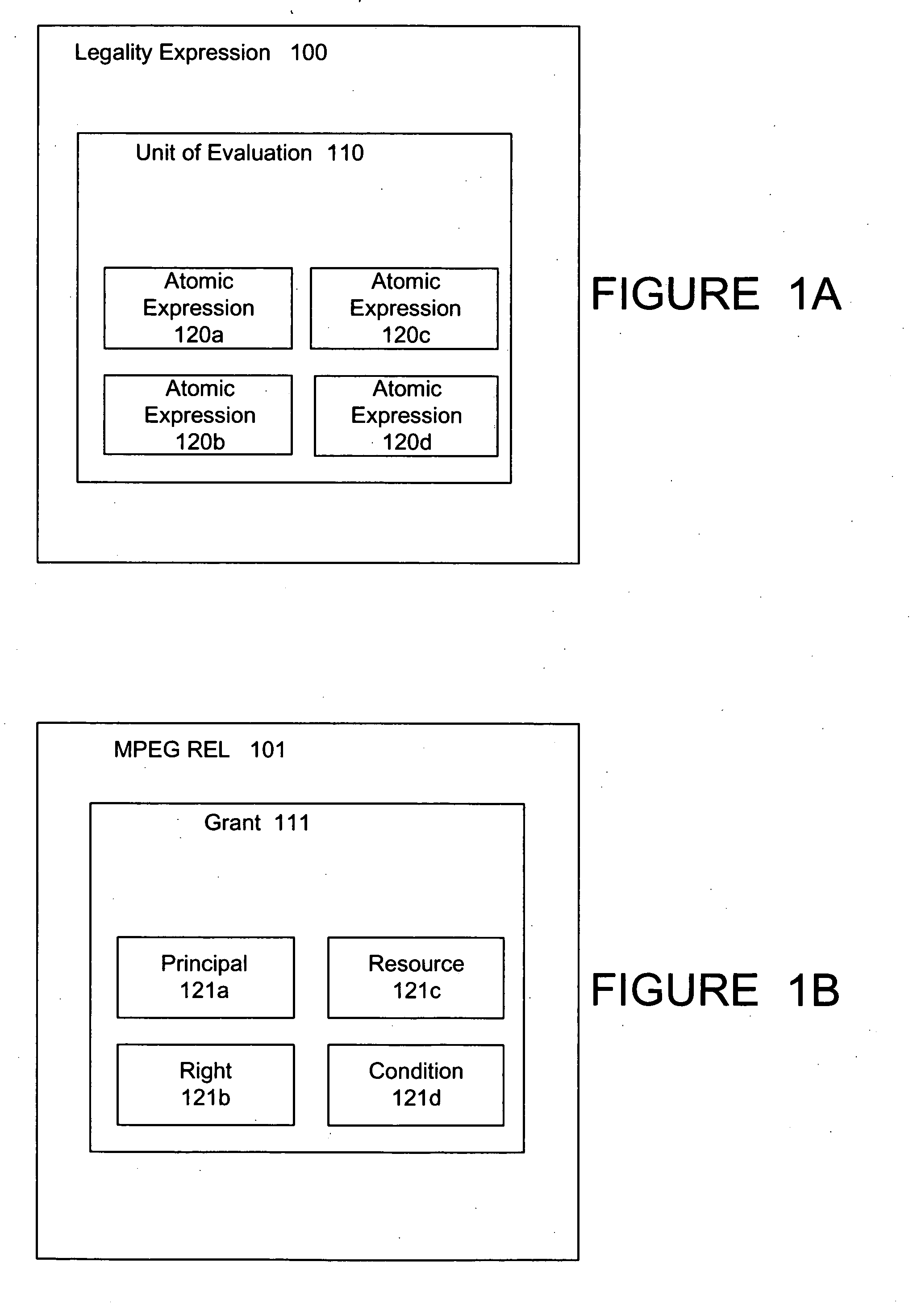

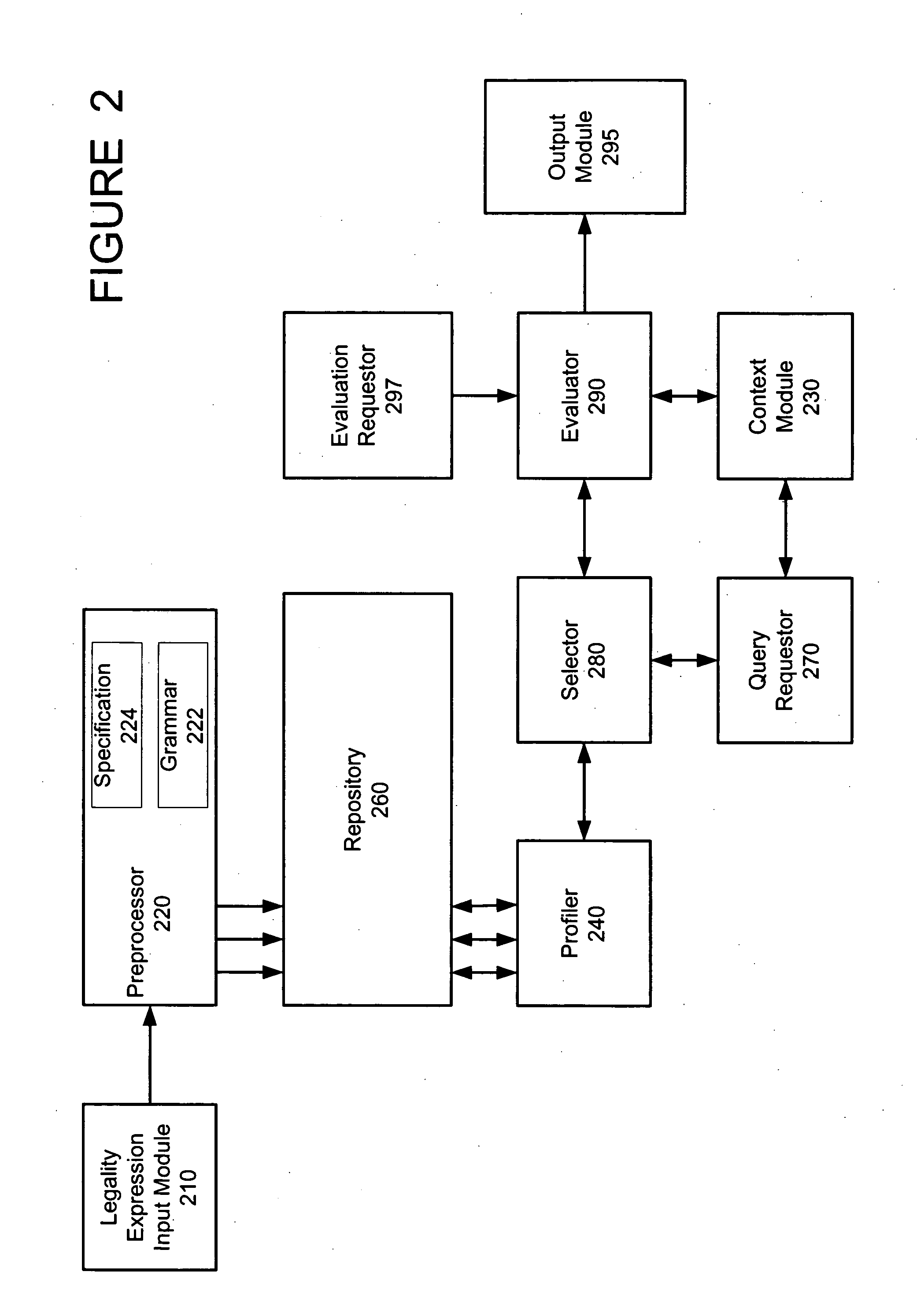

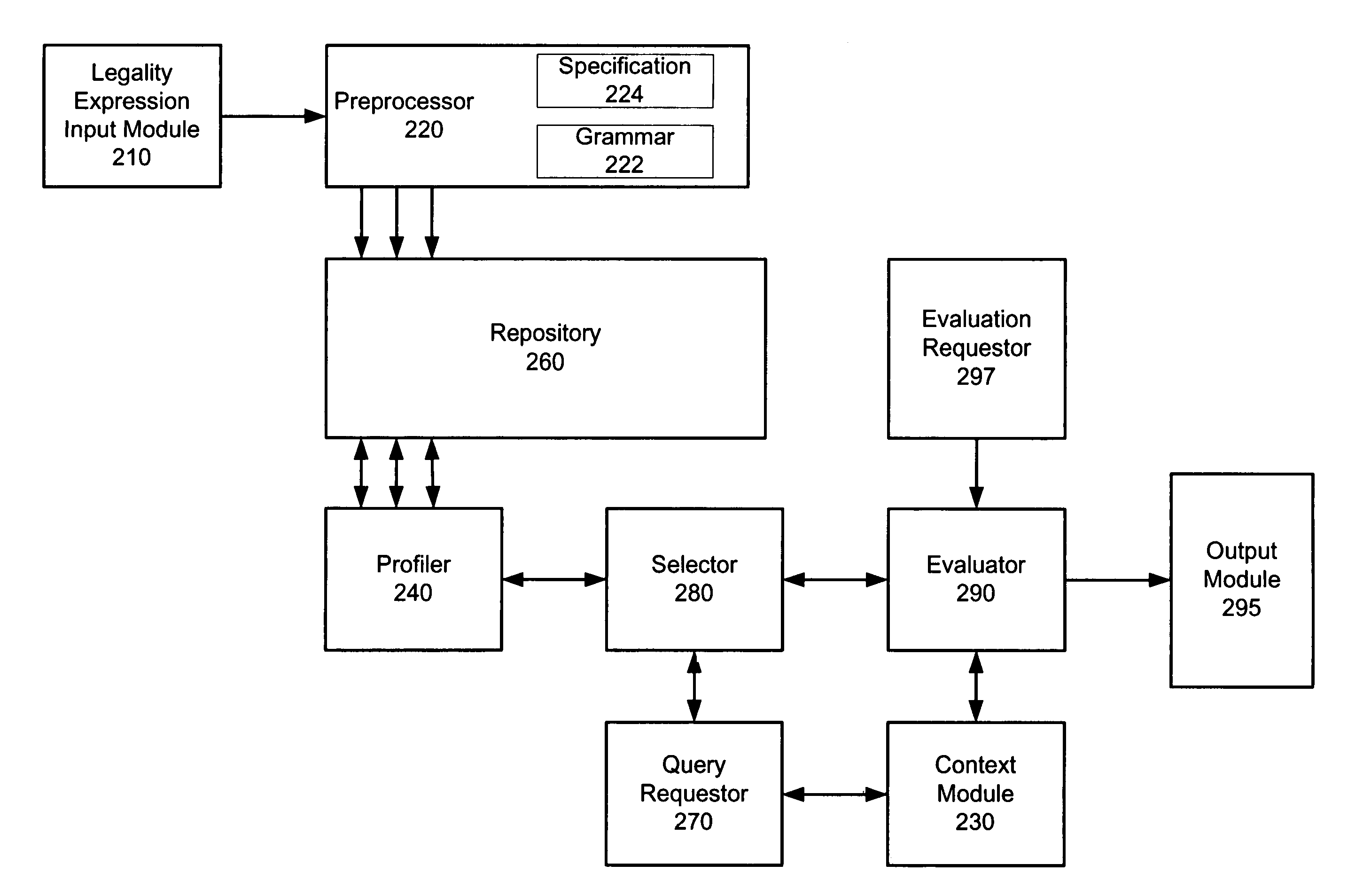

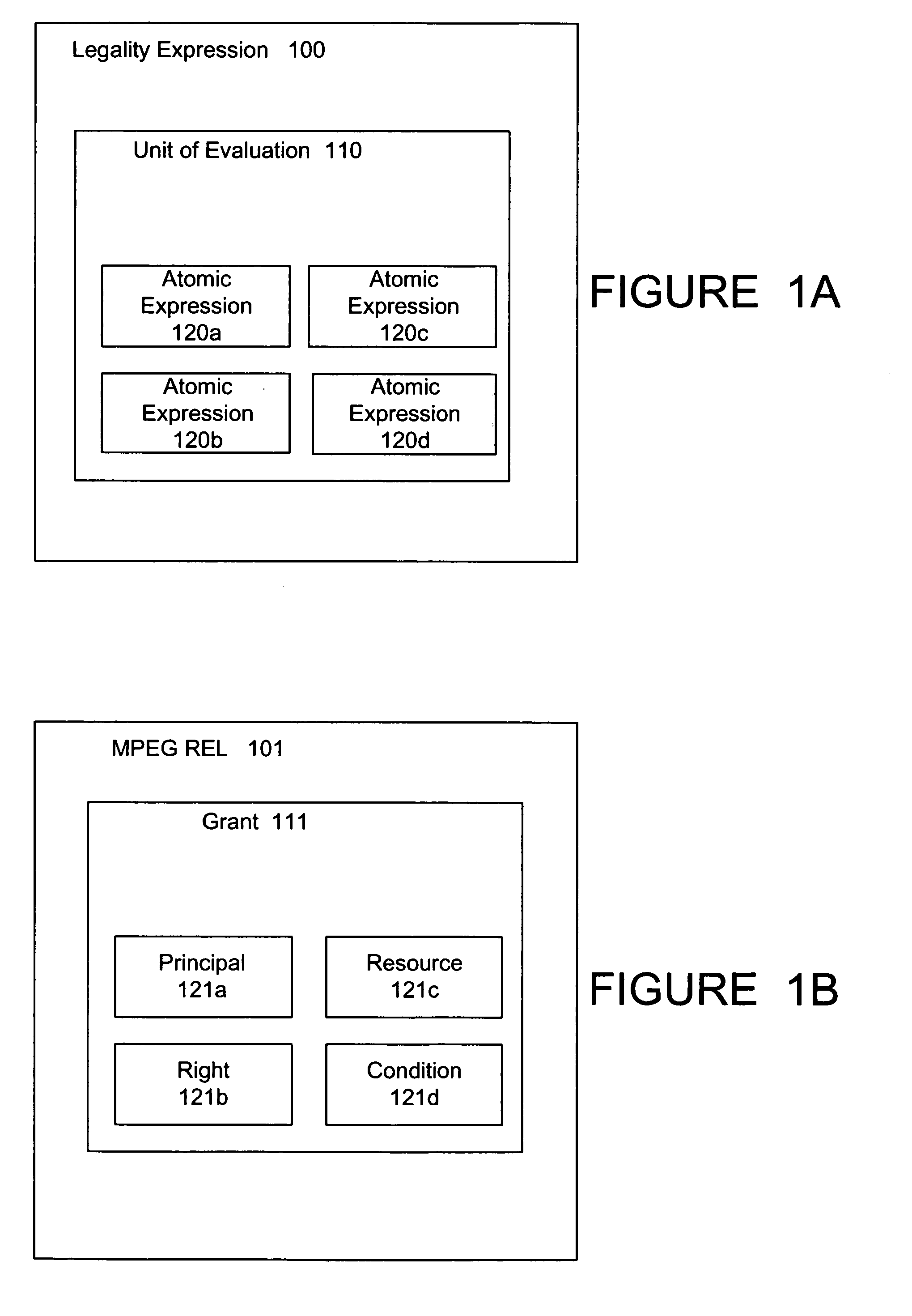

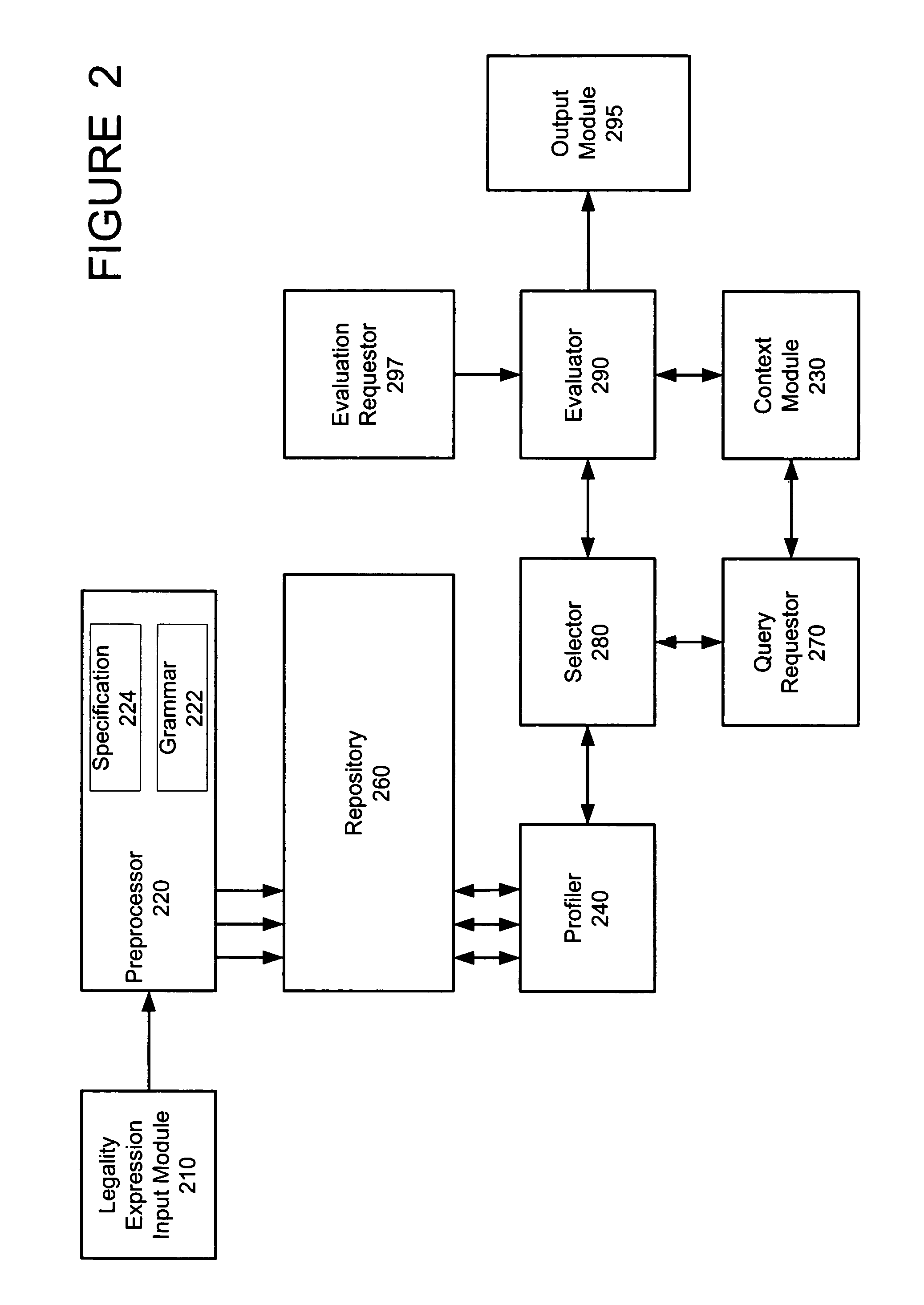

Method and system for processing grammar-based legality expressions

ActiveUS20060041421A1Efficient storageExceptional integrityProgram/content distribution protectionSpecial data processing applicationsTime responsePredictability

Legality expressions are systematically pre-processed, organized, and stored to achieve faster real-time response, improved predictability, and increased reliability for queries against a large volume of legality expressions. Exponential improvements in both the time to locate the set of legality expressions matching specified search criteria and the processing costs of evaluating the request against the matching legality expressions are achieved using the disclosed systems, devices, and methods. The systems, devices, and methods are unique to the optimization of legality expression processing, but they can also enable the use of other optimization techniques for processing large amounts of data.

Owner:CONTENTGUARD HLDG

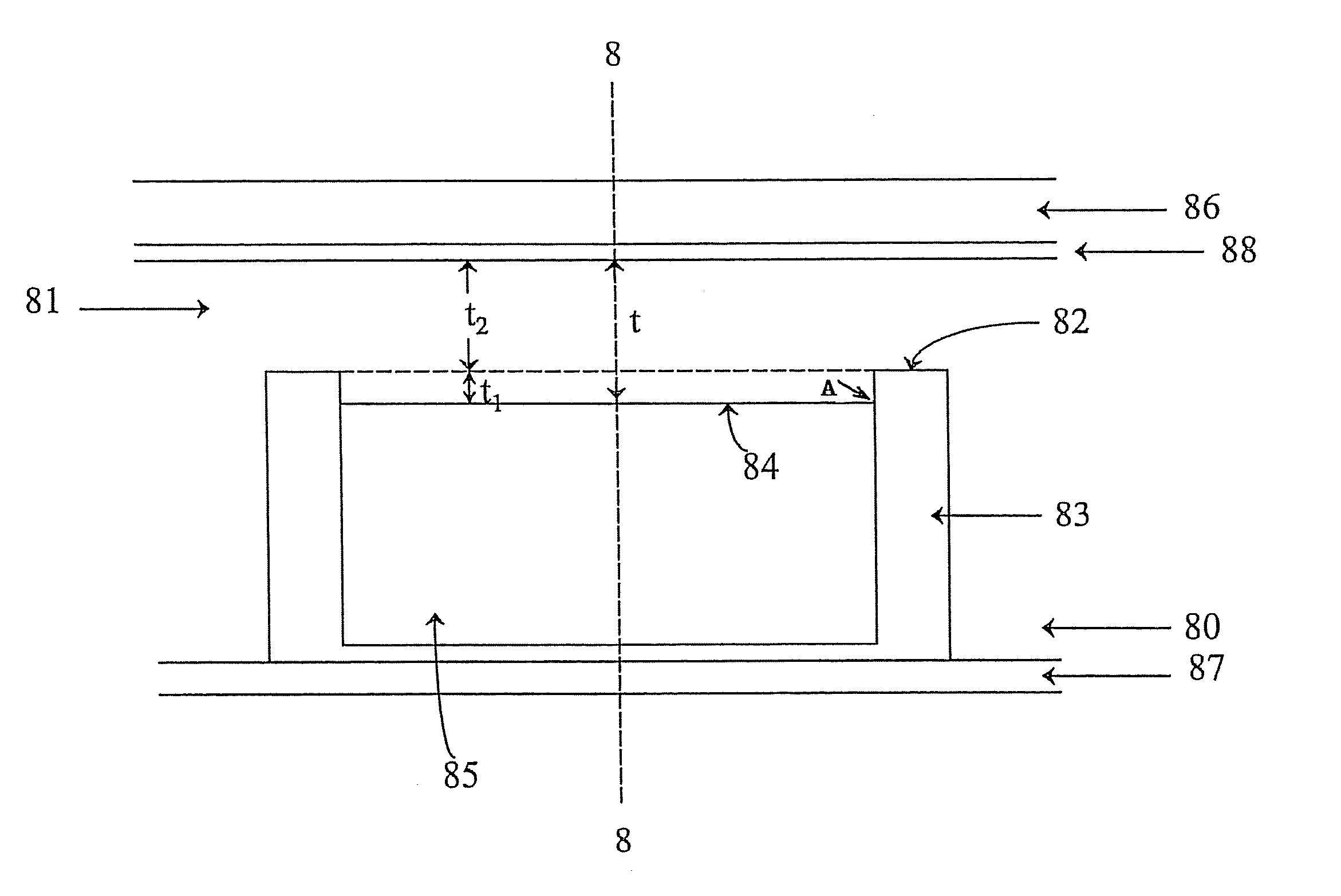

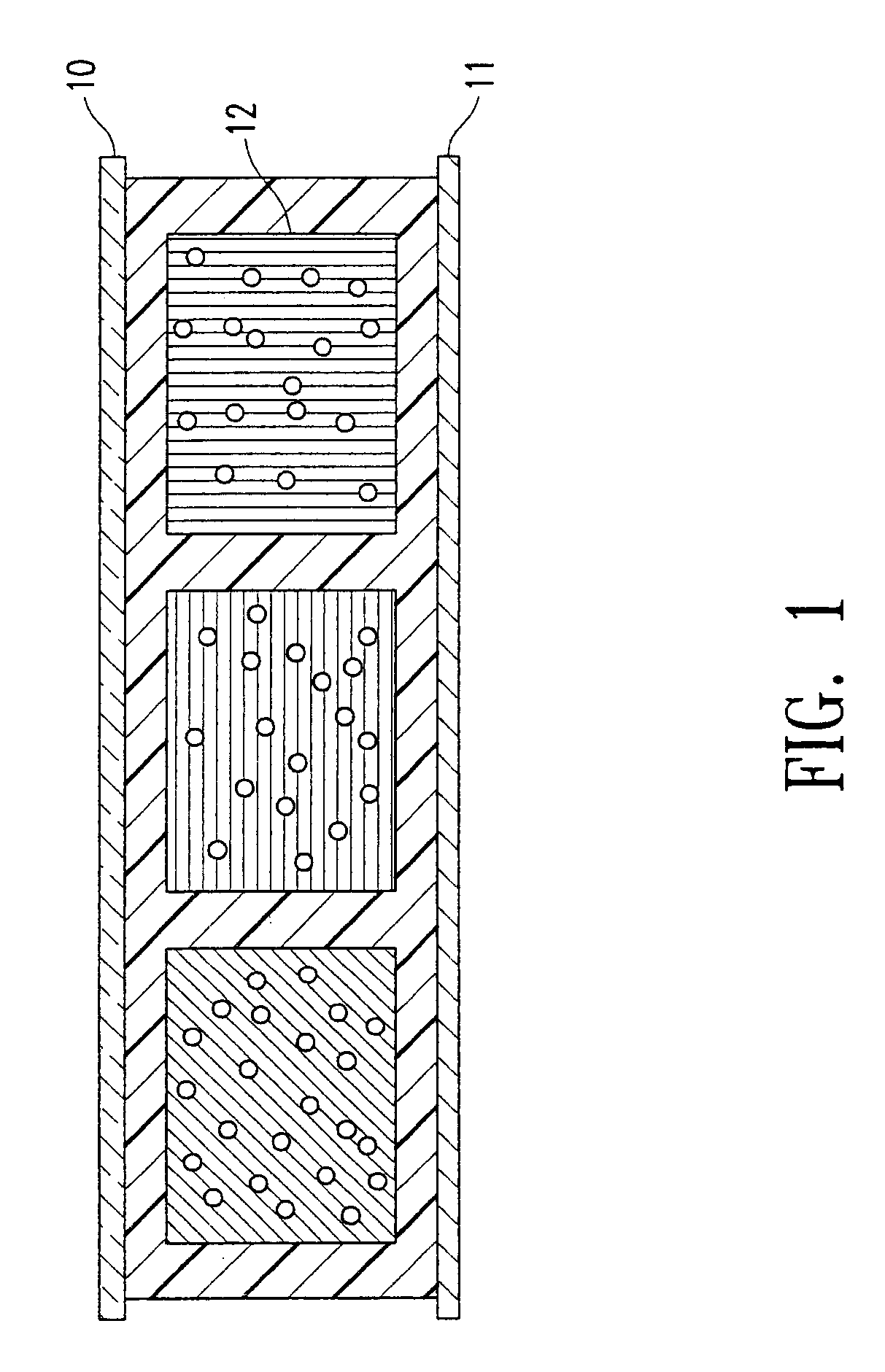

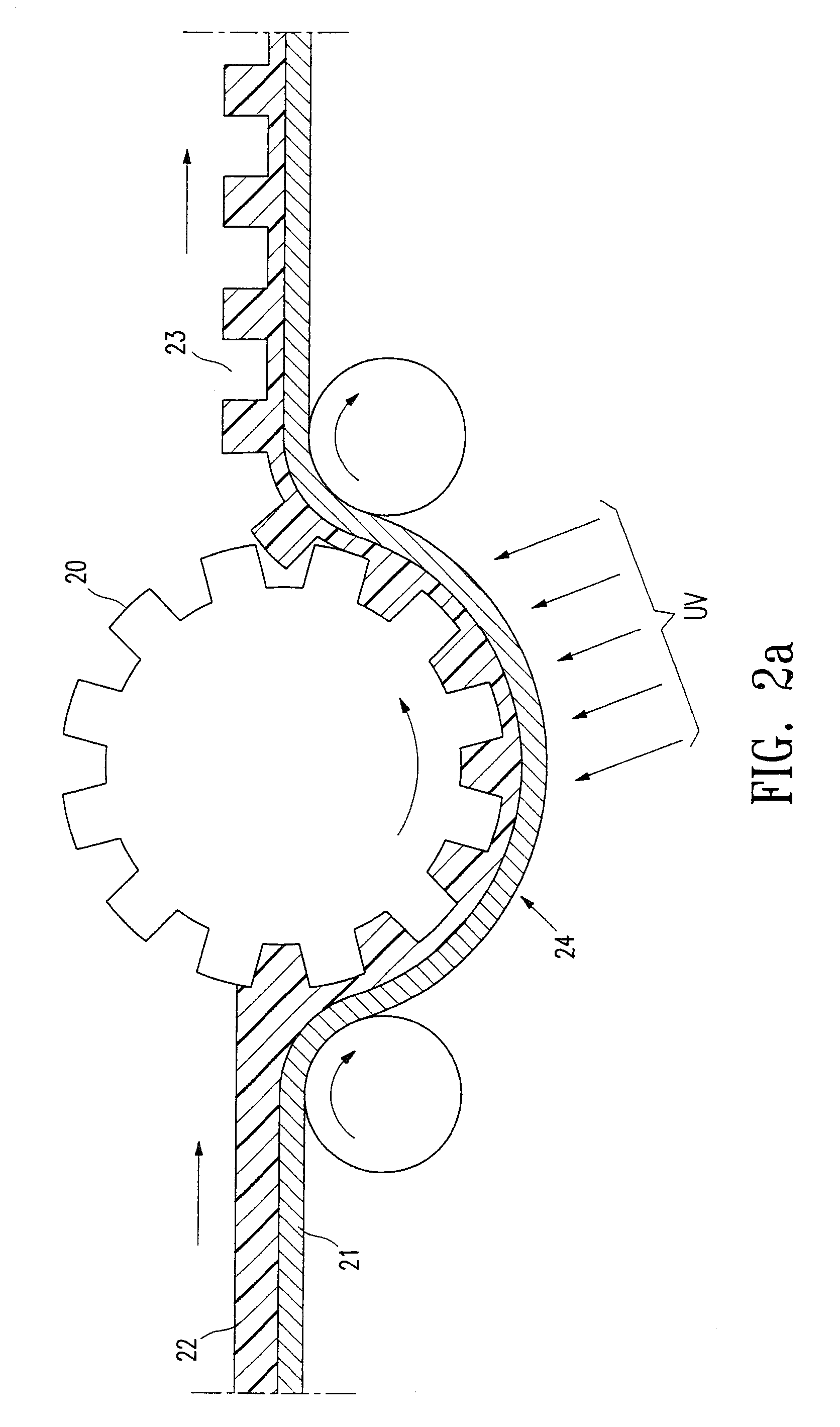

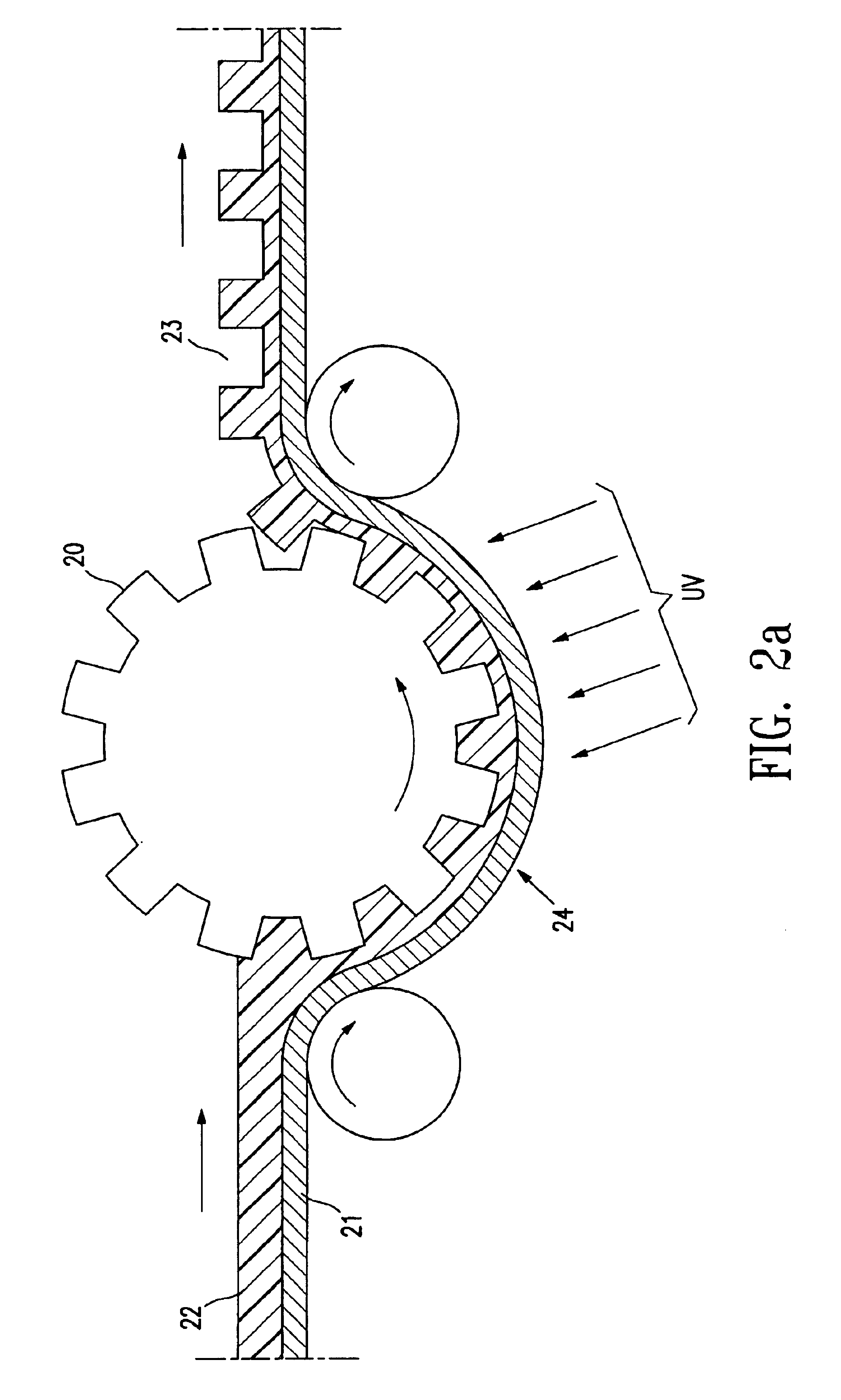

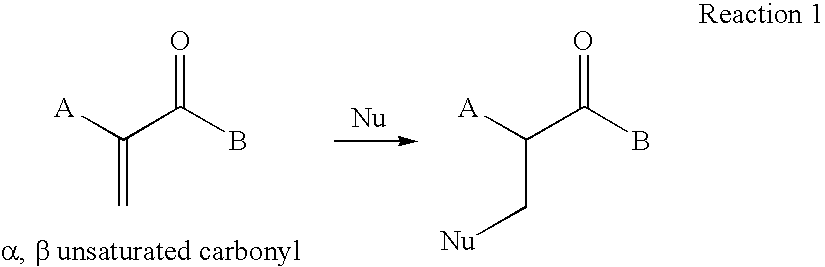

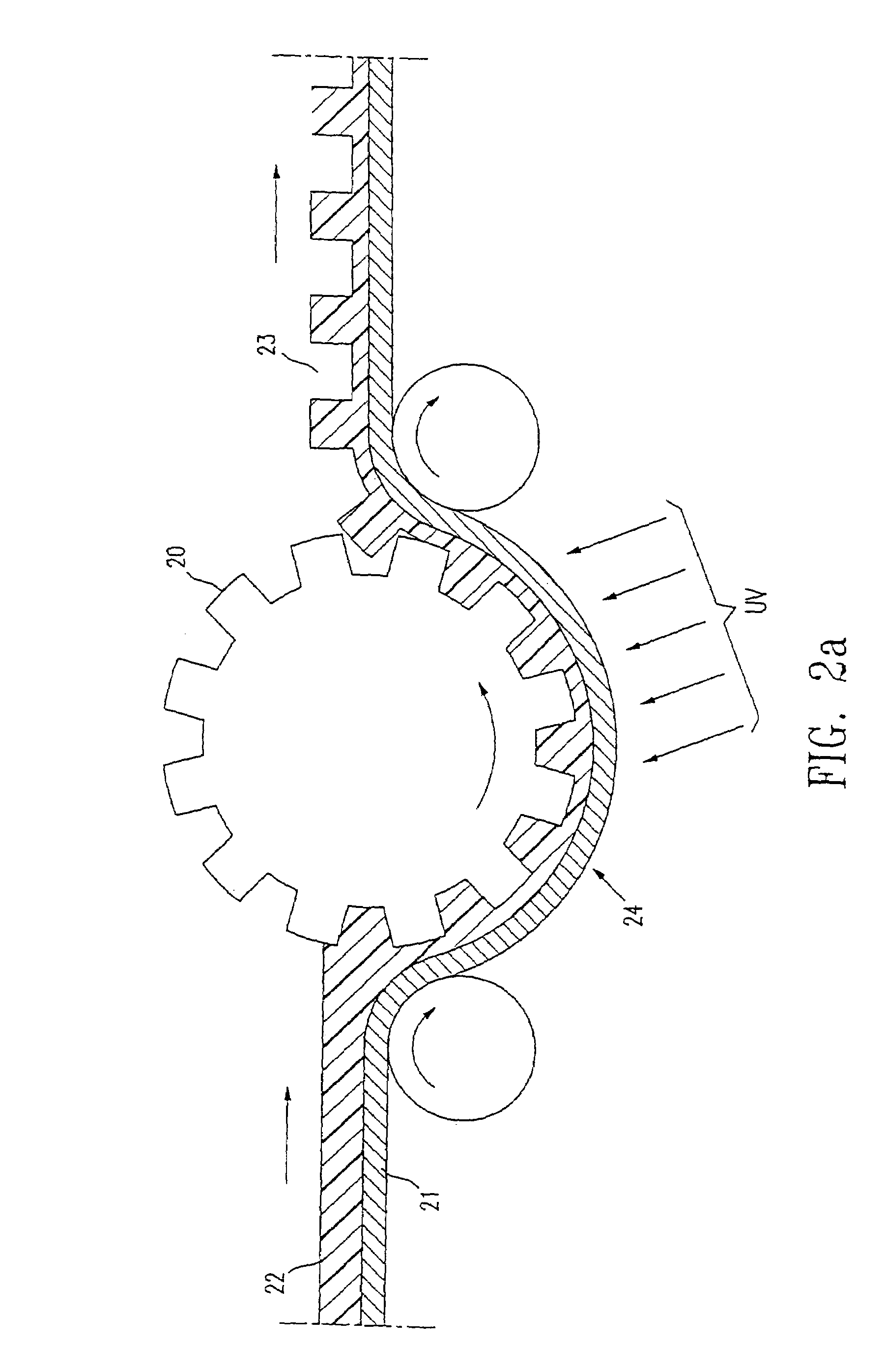

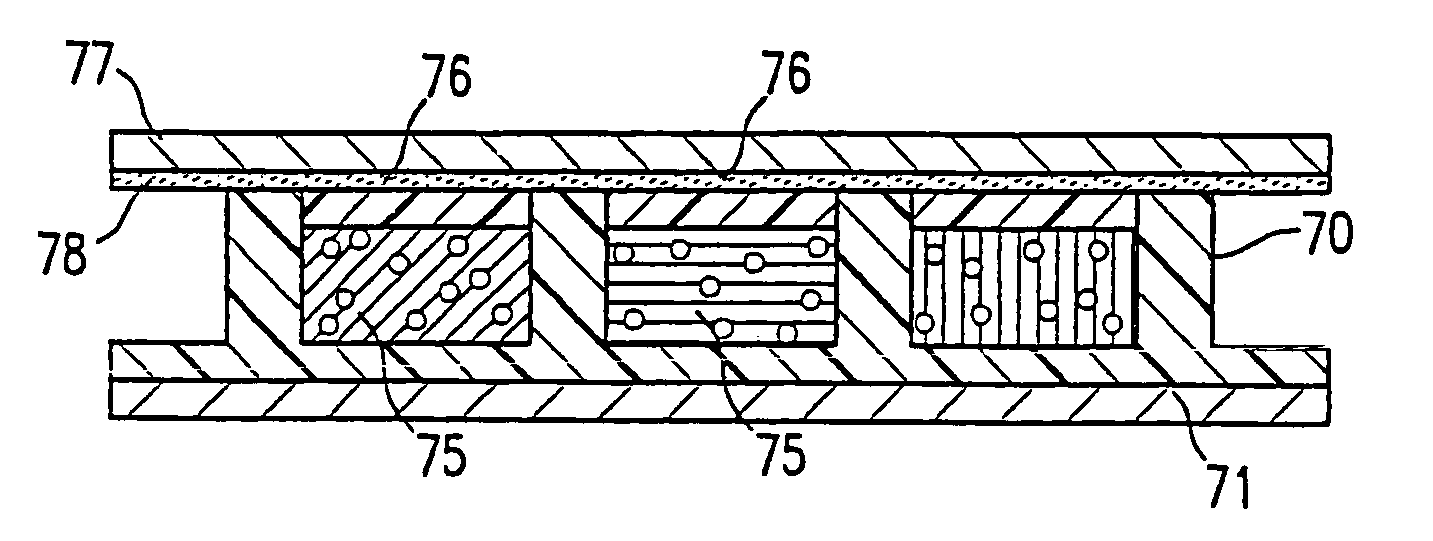

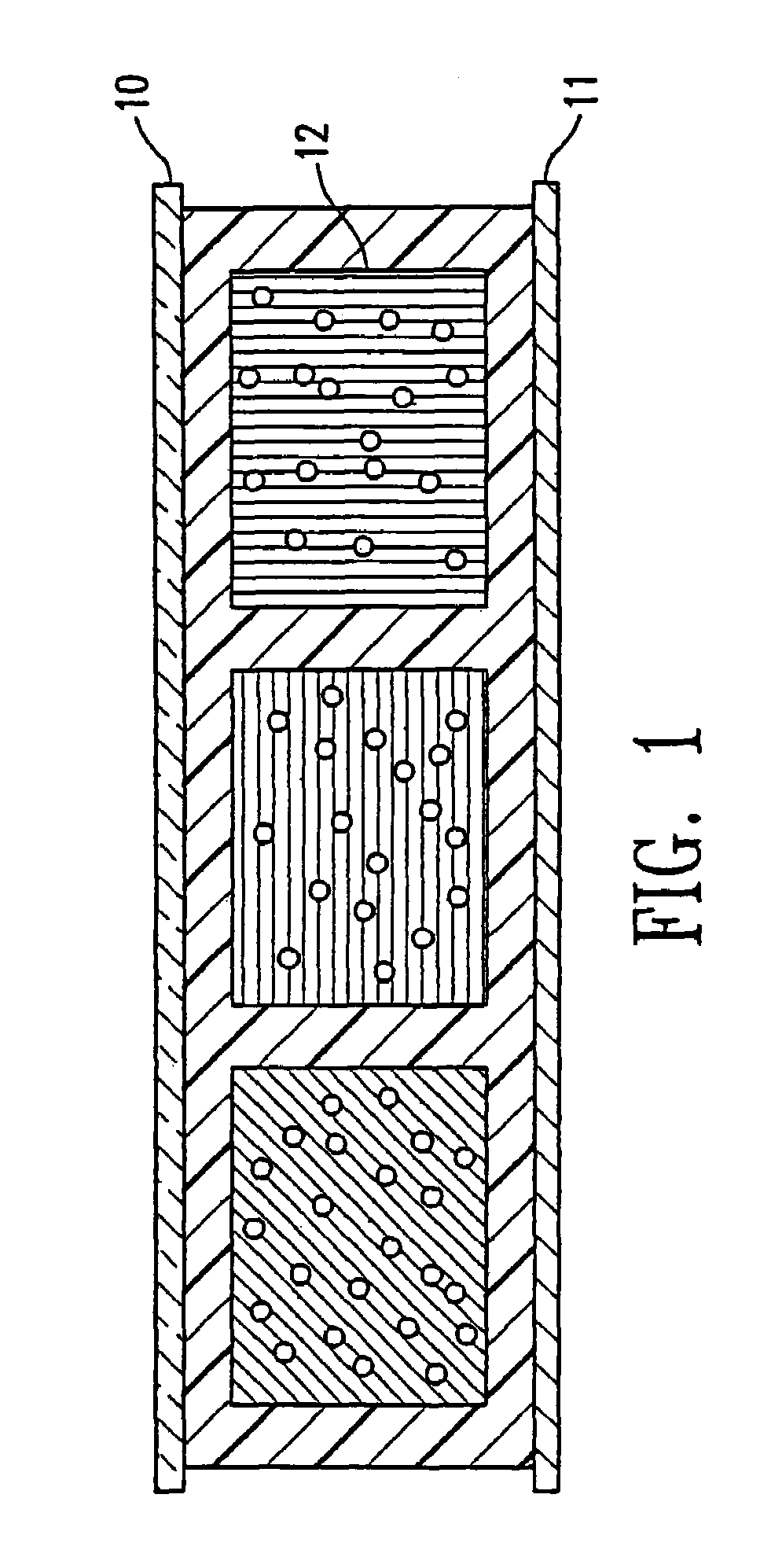

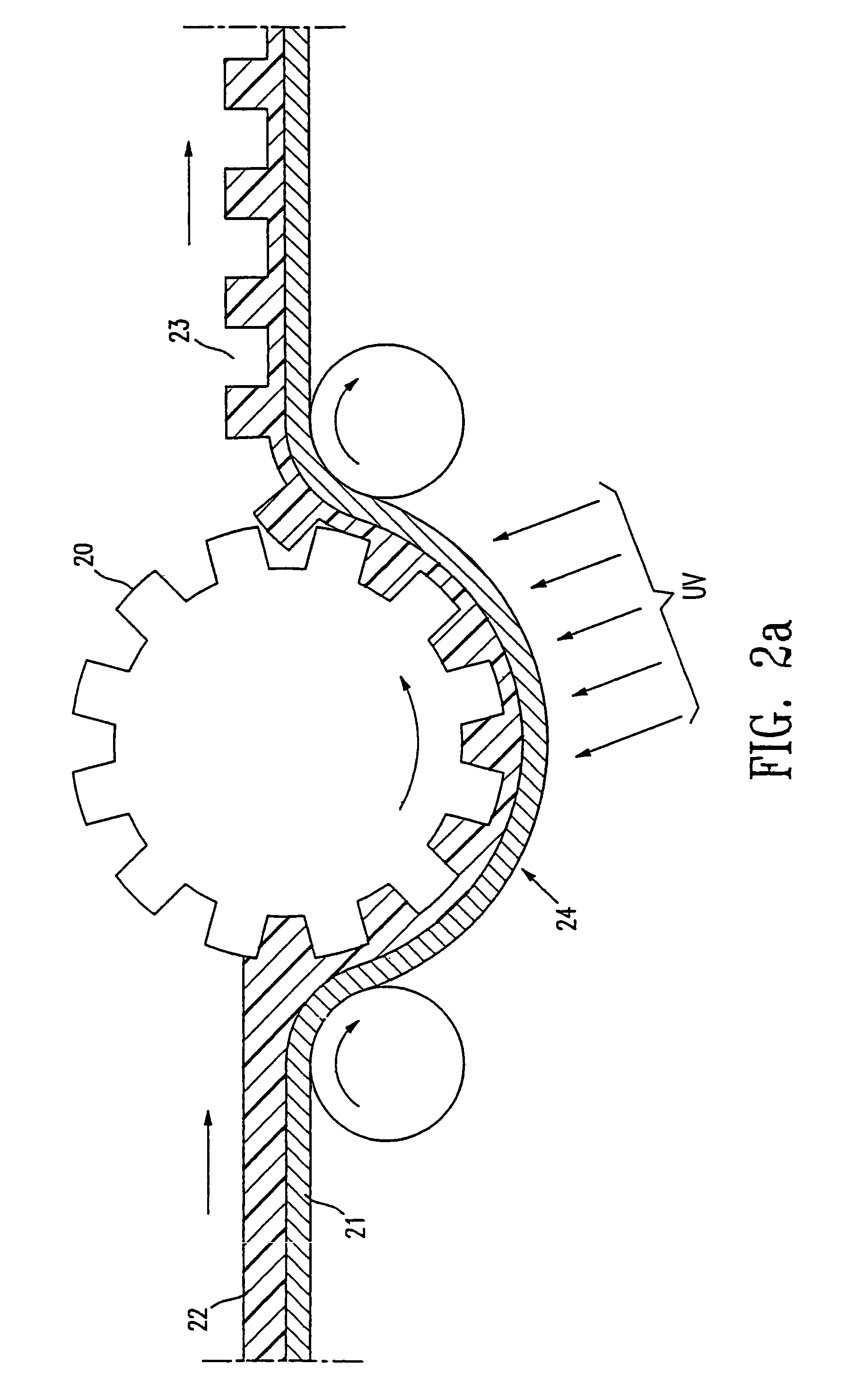

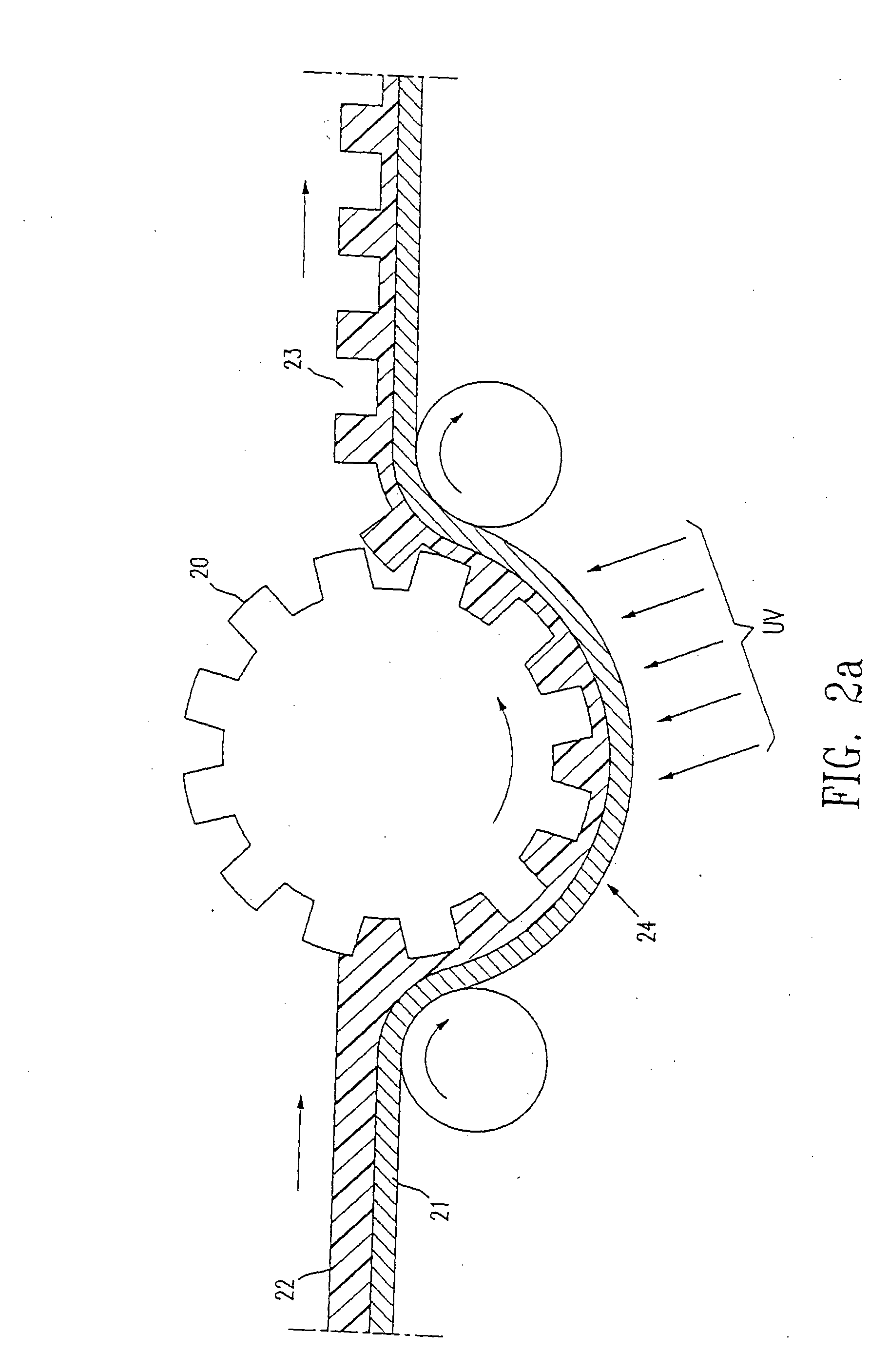

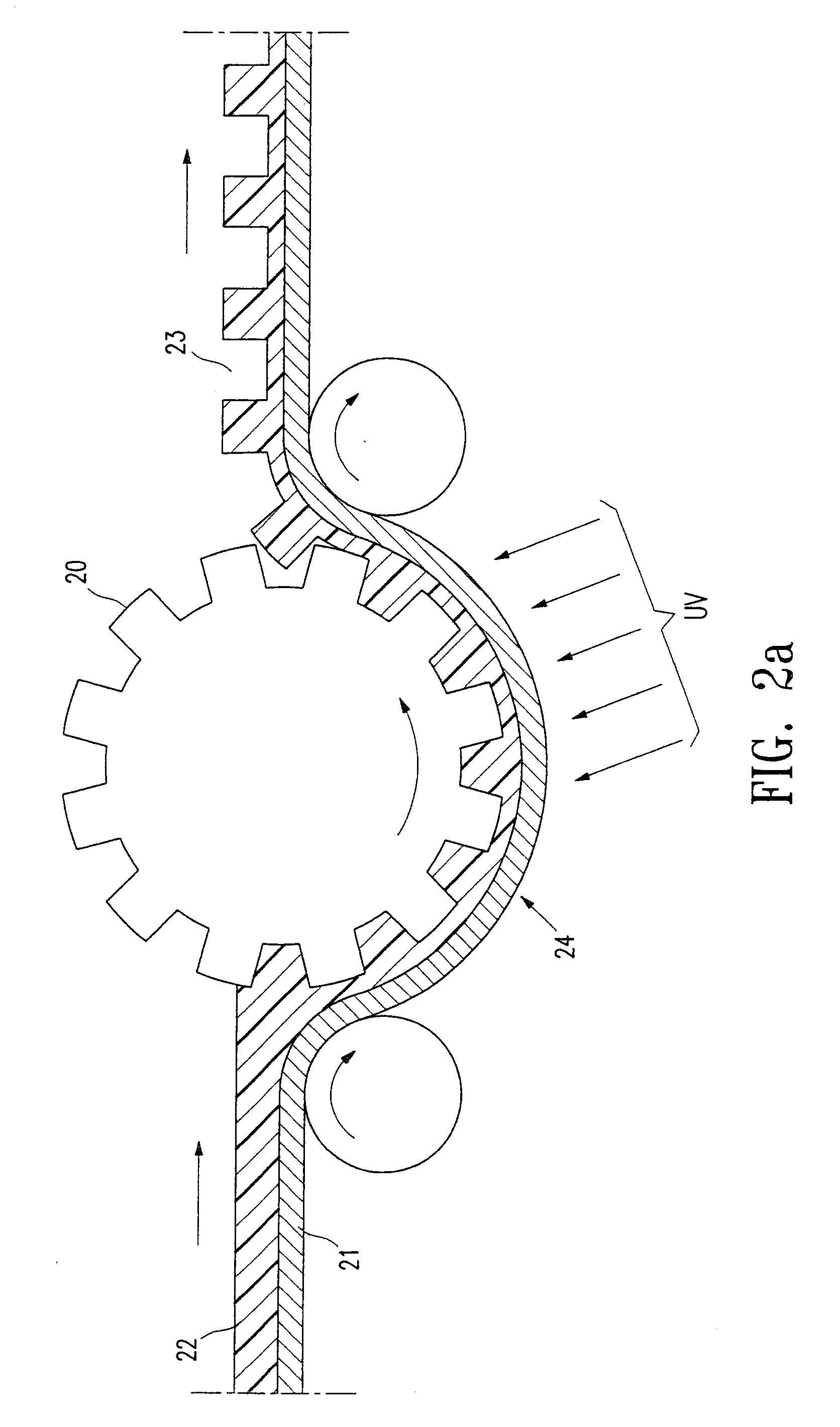

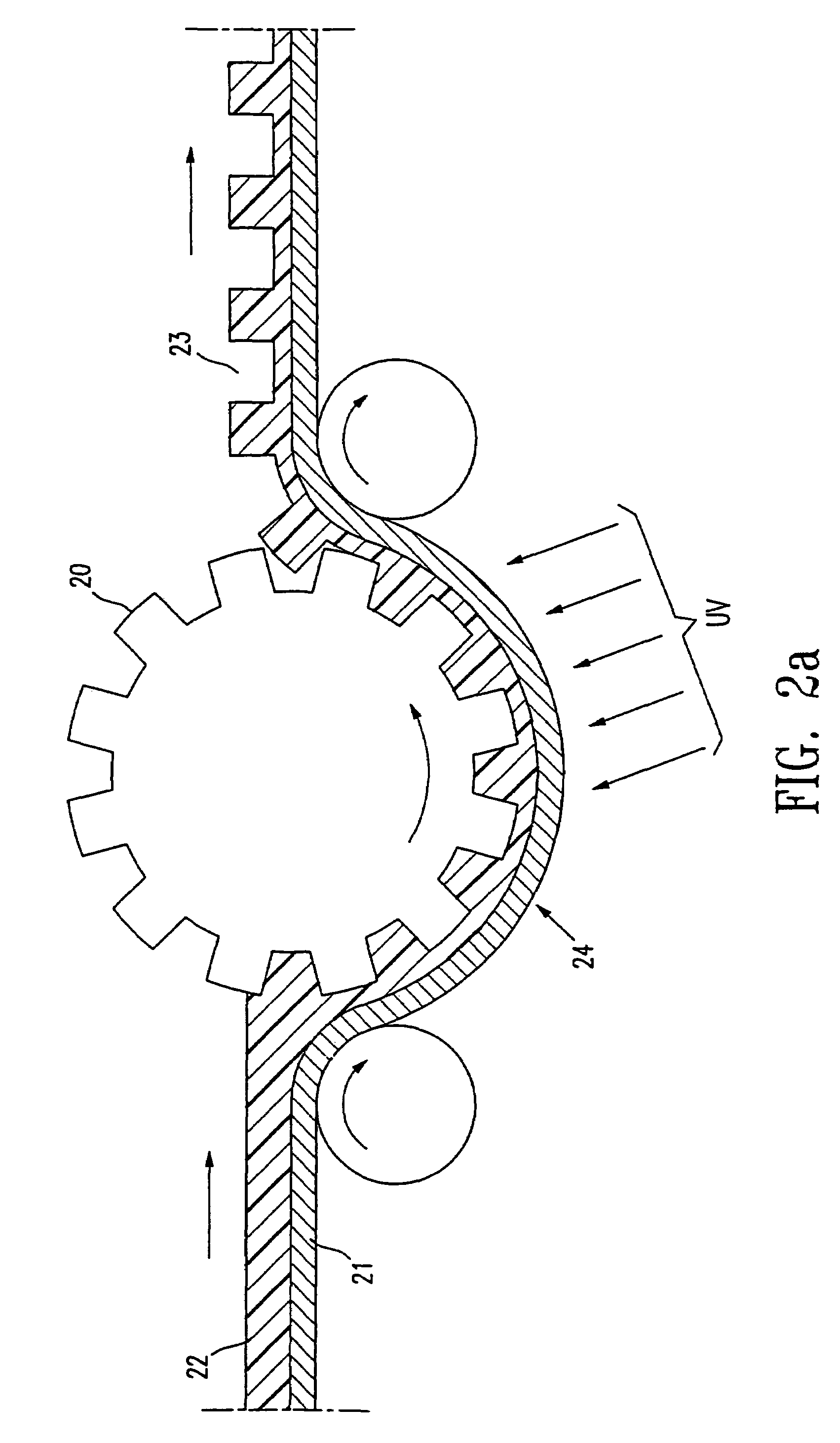

Electrophoretic display and novel process for its manufacture

InactiveUS6833943B2Improve the display effectCost effectiveStatic indicating devicesMaterial analysis by electric/magnetic meansElectrophoresisElectrical battery

This invention relates to an electrophoretic display comprising cells which are filled with charged particles dispersed in a solvent and are individually sealed with a polymeric sealing layer which is an integral part of the display and is curved.

Owner:E INK CALIFORNIA

Biodegradable Modified Caprolactone Polymers for Fabricating and Coating Medical Devices

InactiveUS20070264307A1Structural integrity and mechanical durabilityIncreased durabilitySurgeryCatheterBiomedical engineeringTreating Site

Disclosed herein are biodegradable modified caprolactone polymers for coating and forming medical devices. The properties of the polymers are fine tuned for optimal performance depending on the medical purpose. Moreover, the polymers are suitable for the controlled in situ release of drugs at the treatment site.

Owner:MEDTRONIC VASCULAR INC

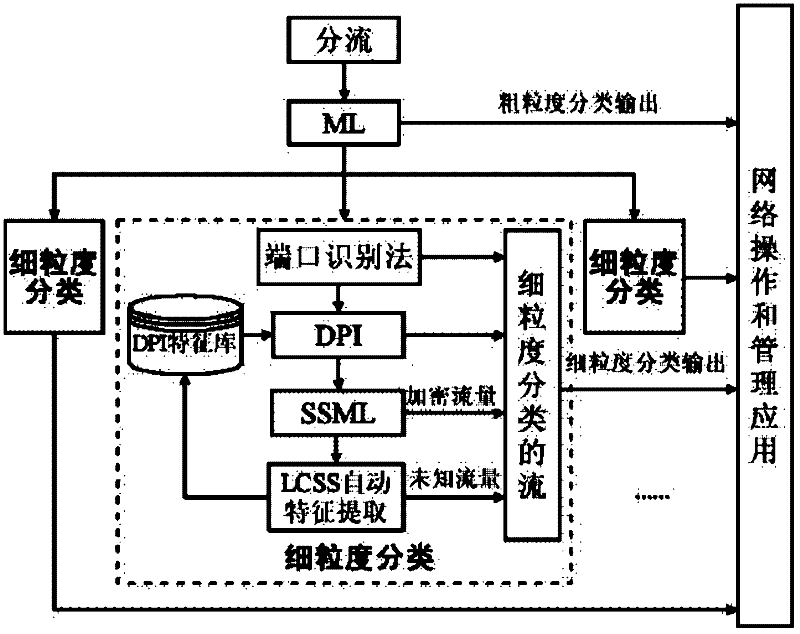

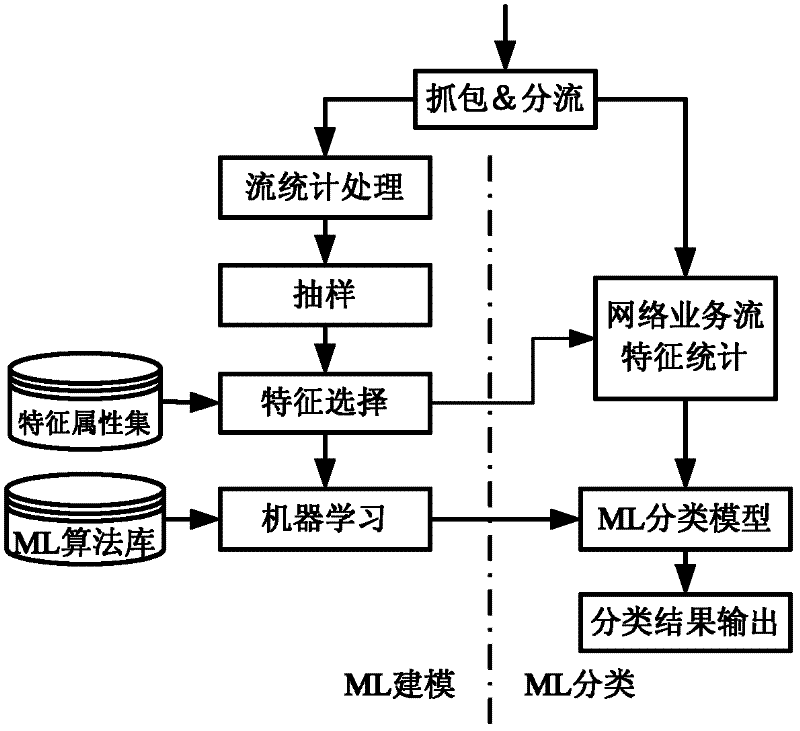

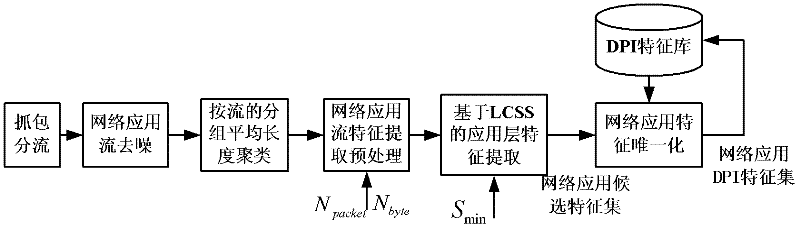

Hierarchical classification method for internet flow

InactiveCN102394827AImprove classification performanceAccurate identification and processingData switching networksTraffic volumeInternet traffic classification

The invention relates to a hierarchical classification method for internet flow, comprising the following steps: firstly, coarse grained classification is conducted as follows: a flow statistical property method based on machine learning is adopted for quickly classifying network flow, the network flow is divided into applied categories with different characteristics, if the flow distinguished by the coarse grained classification needs to be used, the flow can be output directly, and if the flow needs further classification, next step is conducted; and secondly, fine grained classification is conducted as follows: classification is further conducted on the applied categories distinguished by the coarse grained classification, the network flow can be intelligently, accurately and effectively identified in real time, good integrity and expandability are realized, and the requirements on the internet flow classification with different application targets and classification grain size can be met.

Owner:ZHEJIANG WANLI UNIV

Composition and methods for tissue preservation

ActiveUS20040102415A1Preserve functionPreserve Structural IntegrityBiocideDipeptide ingredientsBiologyEx vivo

The present invention provides for compositions and methods for the preservation of tissues and organs ex vivo and in situ. In addition, the present invention provides for kits that may be used in the preparation of the solutions of the present invention. The present invention also provides a device for perfusing tissues and organs with the solutions of the present invention.

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE DEPT OF VETERANS AFFAIRS

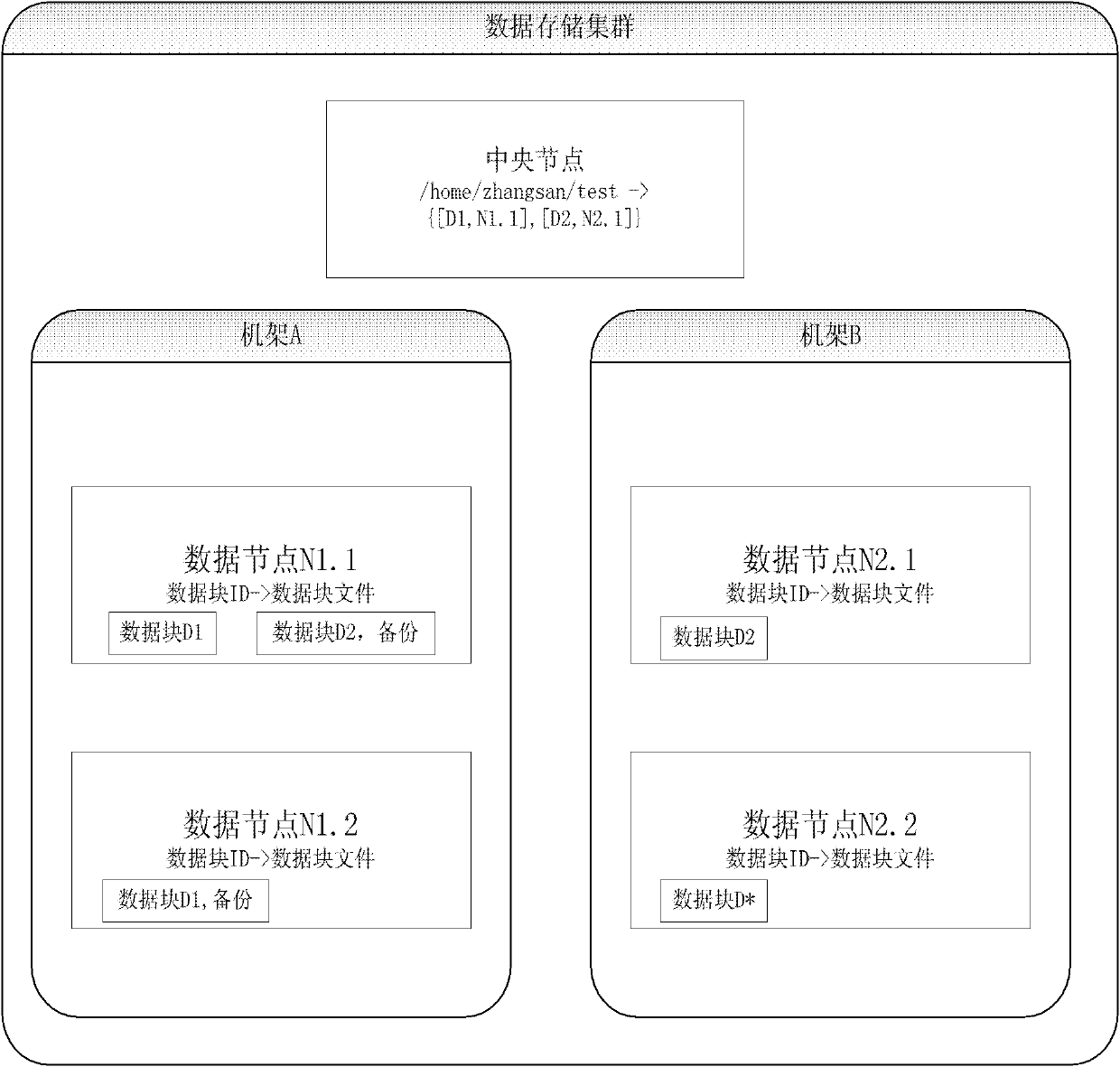

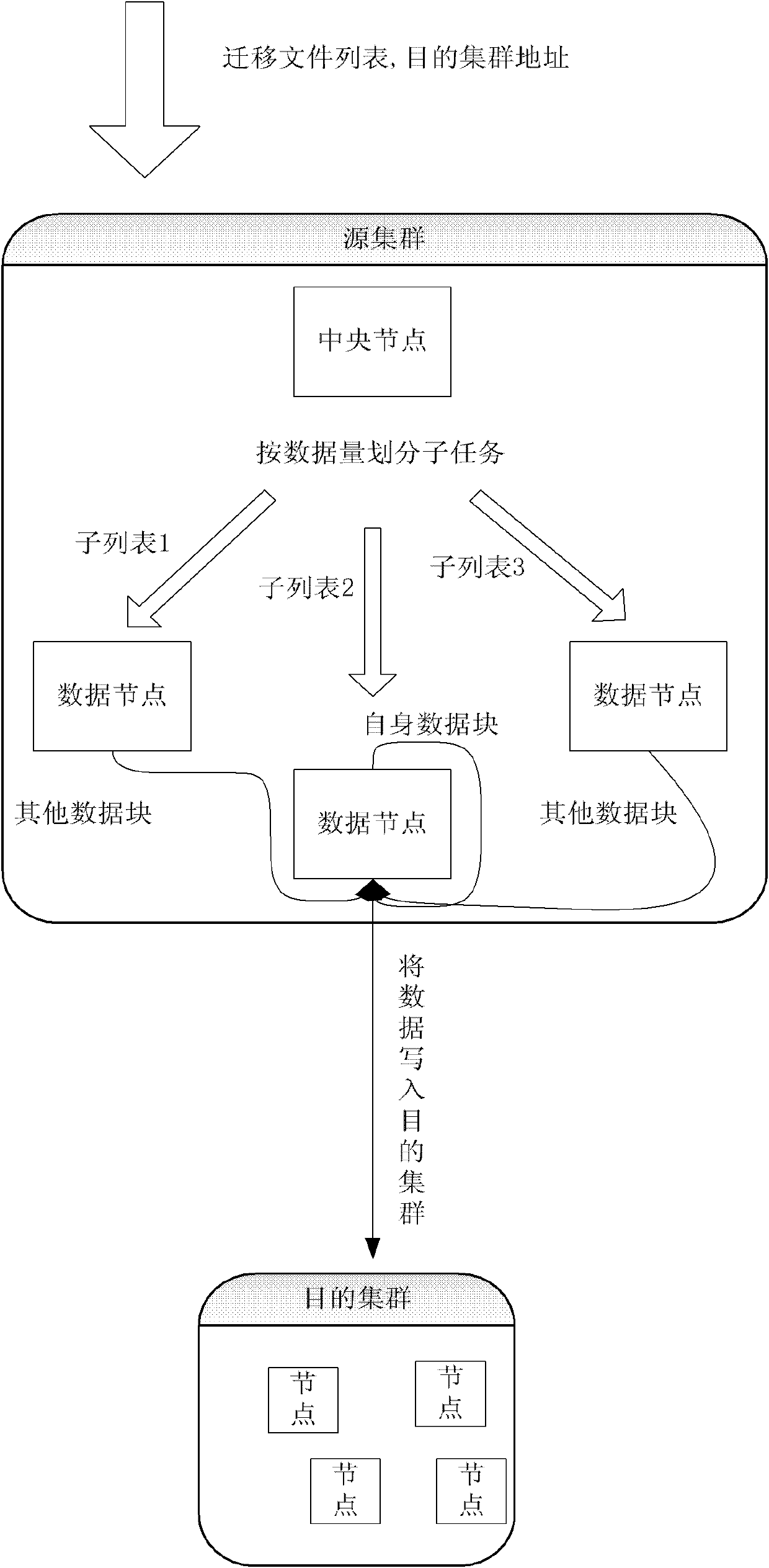

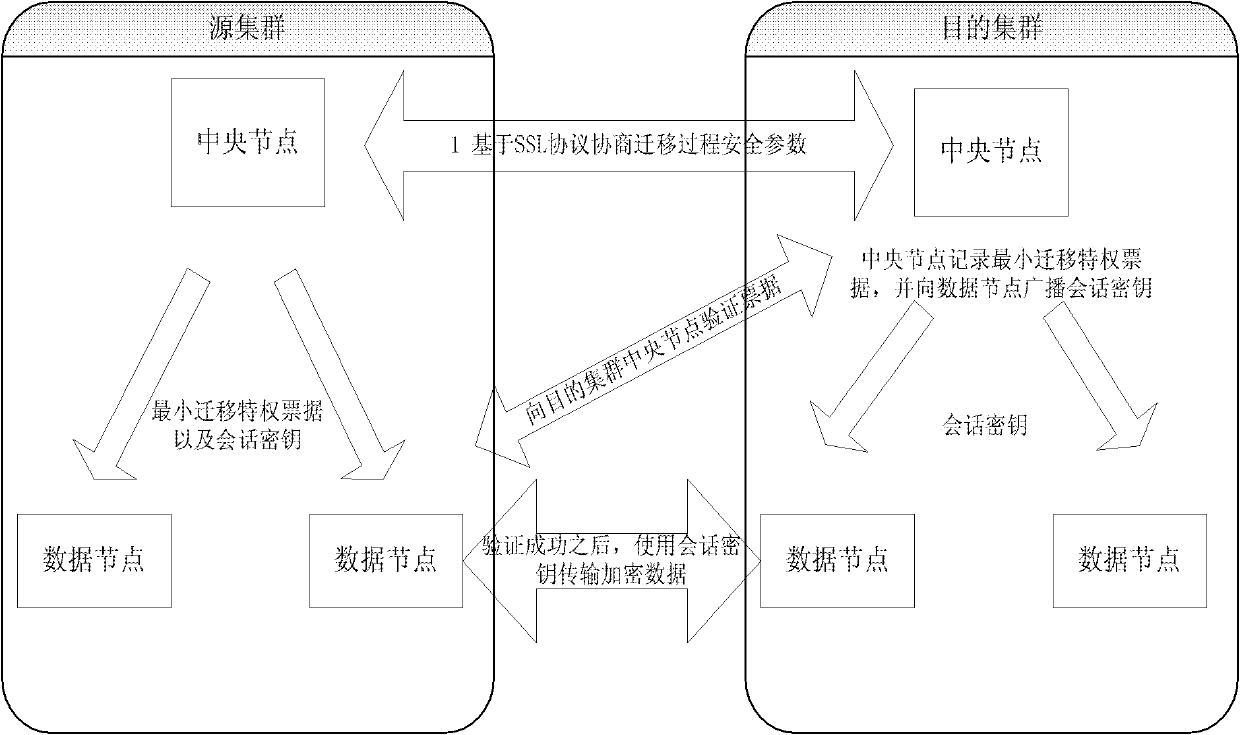

Method suitable for safely migrating data between storage clouds

The invention discloses a method suitable for safely migrating data between storage clouds, belonging to the field of a distributed file system. The method comprises the following steps: SSL (Security Socket Layer) connection is set up between a source cluster and a destination cluster; central nodes of the source cluster and the destination cluster generate a secret key through the SSL connection, and the secret key is transmitted to a data node executing the data migration; an approved migration privilege bill is encrypted by the central node of the destination cluster, is then transmitted into the data node executing the data migration in the source cluster, and is recorded; the encrypted migration privilege bill is transmitted to the central node of the destination cluster through the data node executing the data migration to be verified, then the central node of the destination cluster transmits a destination data node address to the data node executing the data migration; and the data node executing the data migration encrypts data to be migrated by the secret key and then transmits the data to the destination data node. The method greatly improves the safety of the data migration between the storage clouds.

Owner:PEKING UNIV

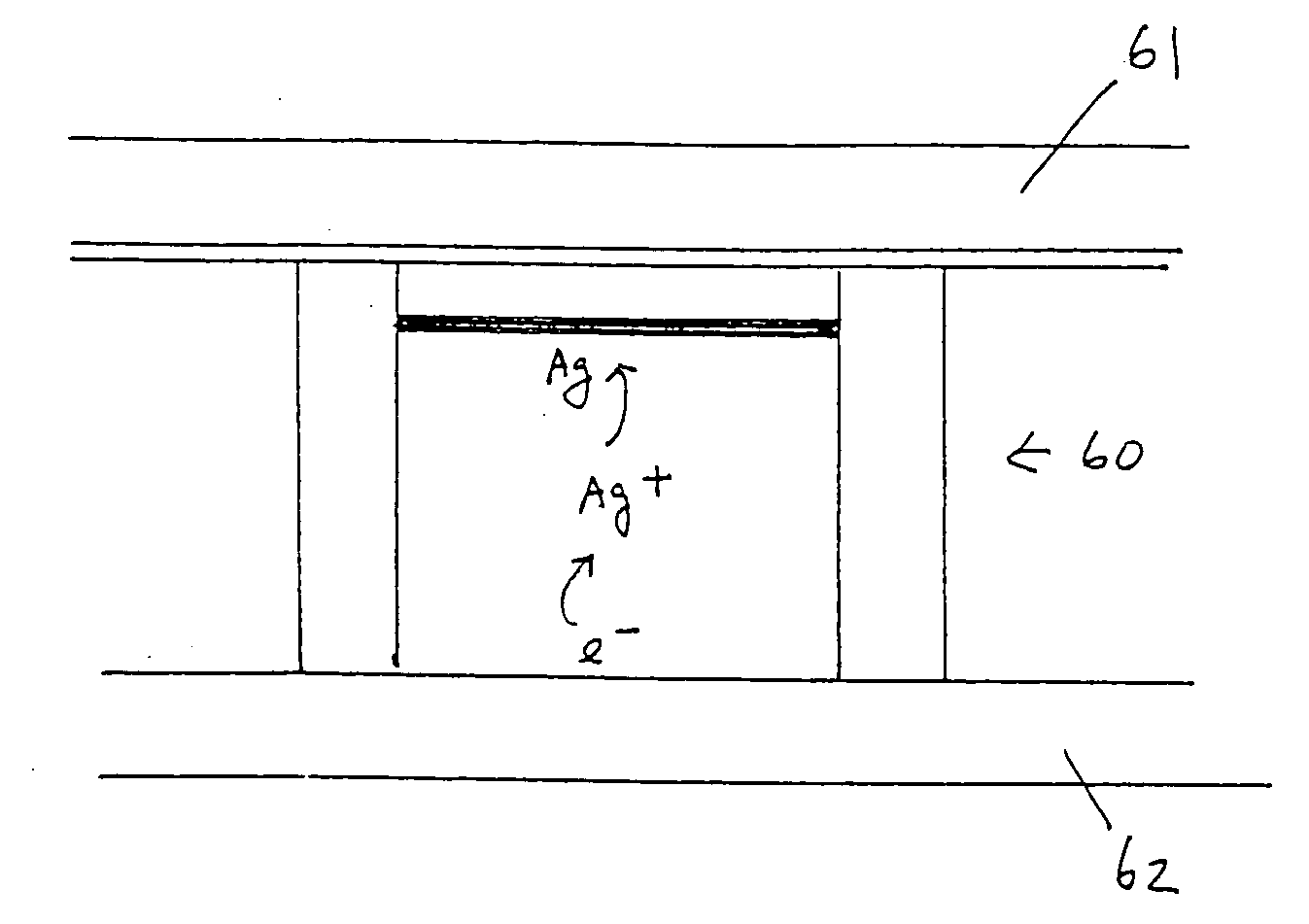

Electrochromic or electrodeposition display and novel process for their manufacture

ActiveUS7245414B2Extend your lifeImprove throughputNon-linear opticsOptical elementsEngineeringElectrochromism

The present invention is directed to an improved electrodeposition and an electrochromic display. The display cells formed from microcups are filled with an electrolyte fluid and are individually sealed with a polymeric sealing layer.

Owner:E INK CORPORATION

Electrophoretic display and process for its manufacture

InactiveUS7557981B2Improve the display effectIntegrityNon-linear opticsOptical elementsElectrophoresisDisplay device

This invention relates to an electrophoretic display comprising cells which are filled with charged particles dispersed in a solvent and are individually sealed with a polymeric sealing layer.

Owner:E INK CALIFORNIA

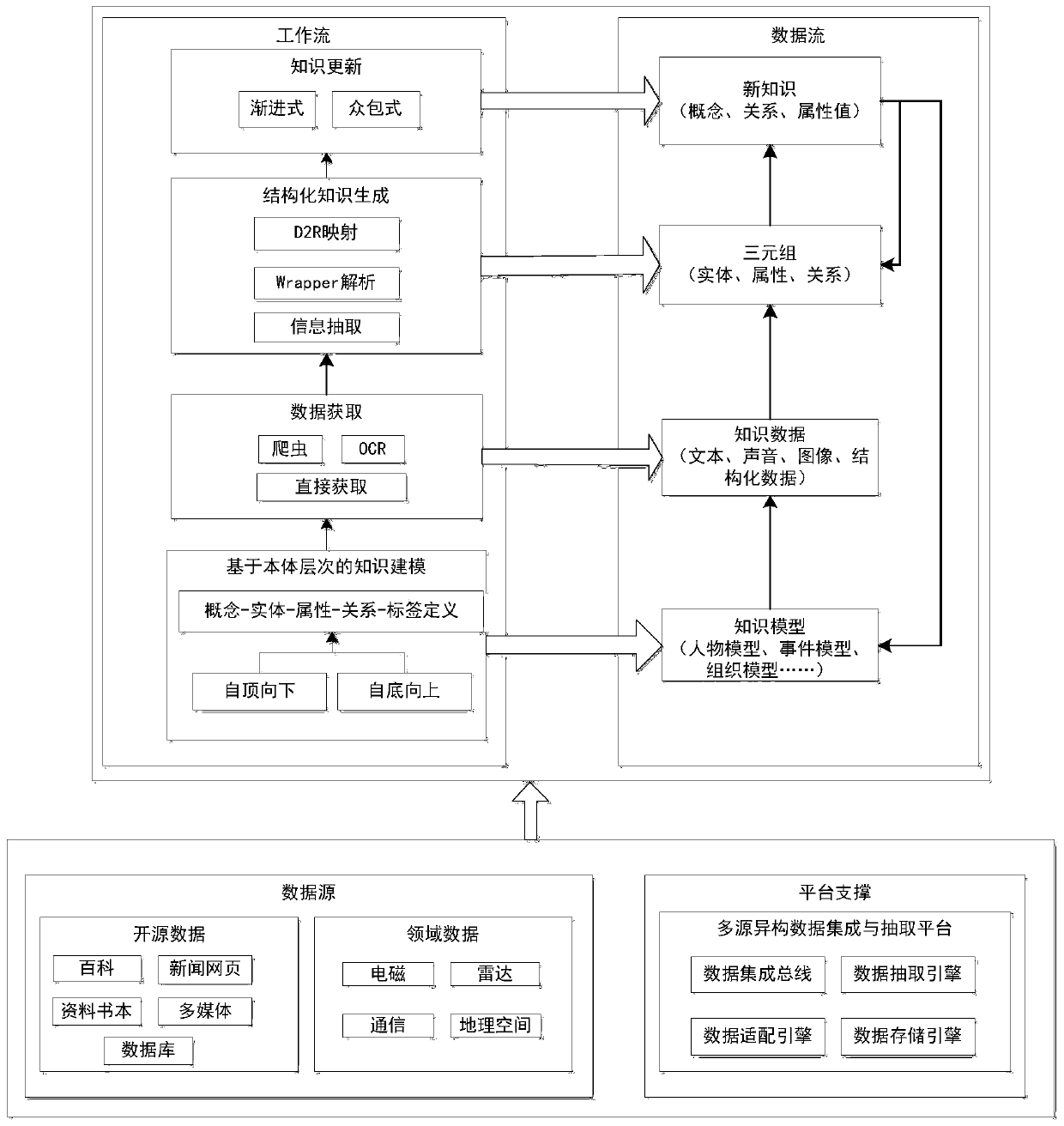

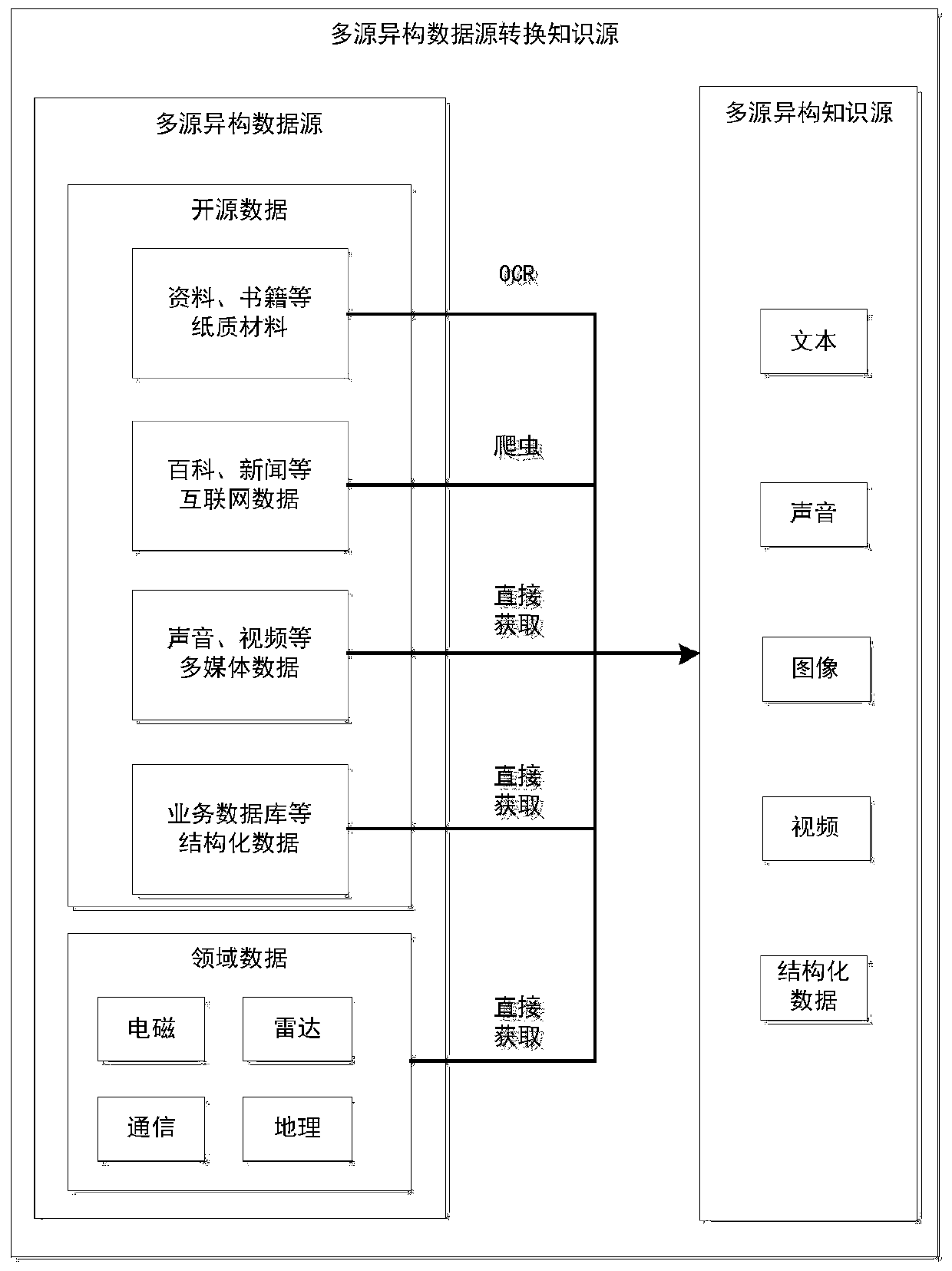

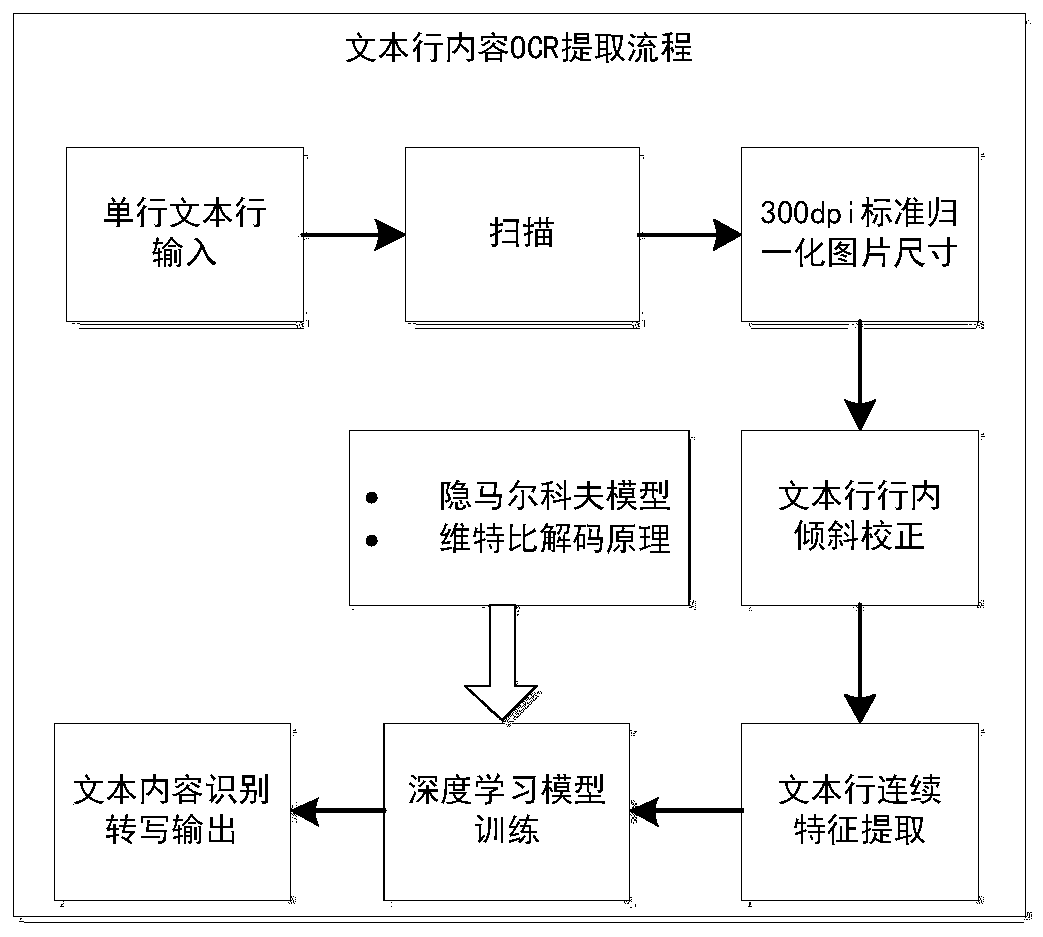

Method for automatically acquiring multi-source heterogeneous data knowledge

ActiveCN110489395AIntegrityImplement associative storageDatabase management systemsRelational databasesKnowledge sourcesData source

The invention discloses a method for automatically acquiring multi-source heterogeneous data knowledge, and aims to provide a method which has better integrity, universality and convenience and is beneficial to knowledge transmission. The method of the invention is realized through the following technical scheme: the method comprises the following steps: 1, processing; a concept-entity-attribute-relation-label is defined from top to bottom or from bottom to top, a knowledge model of an entity object is obtained, then data is obtained through direct data storage and crawler software, OCR and other recognition software, knowledge data is obtained, and conversion from a heterogeneous data source to a heterogeneous knowledge source is completed; obtaining entity-attribute-relationship triad instantiation under a known knowledge mode through a structured knowledge generation method; and updating knowledge and knowledge models by using a long-short-term memory network model (LSTM model) anda publisher-accomplisher cooperation mode to obtain a workflow for expanding and supplementing new knowledge, and obtaining a data flow accommodating concept, entity, relationship and attribute valueinstantiation triples by using the knowledge model formed by knowledge modeling.

Owner:10TH RES INST OF CETC

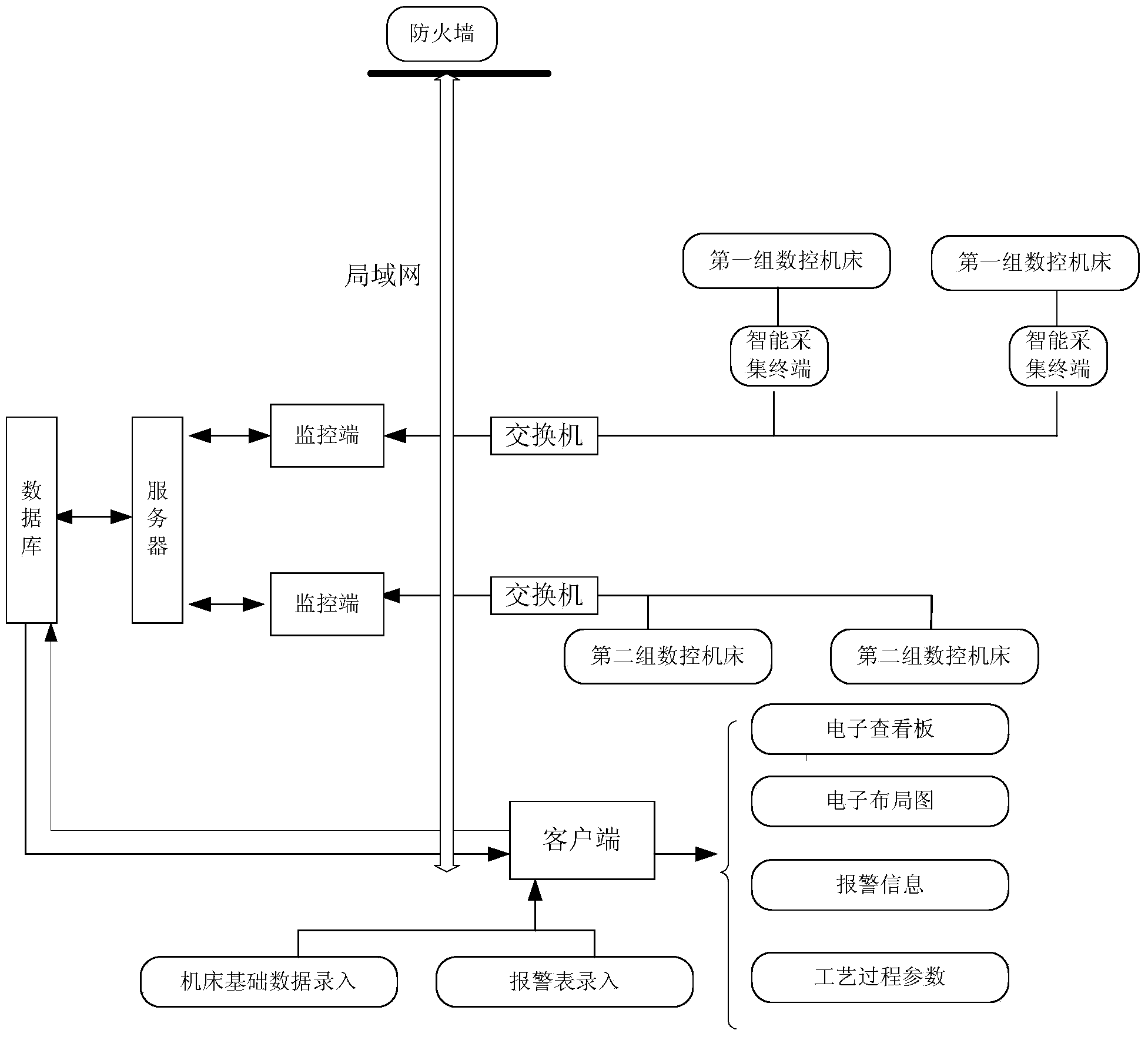

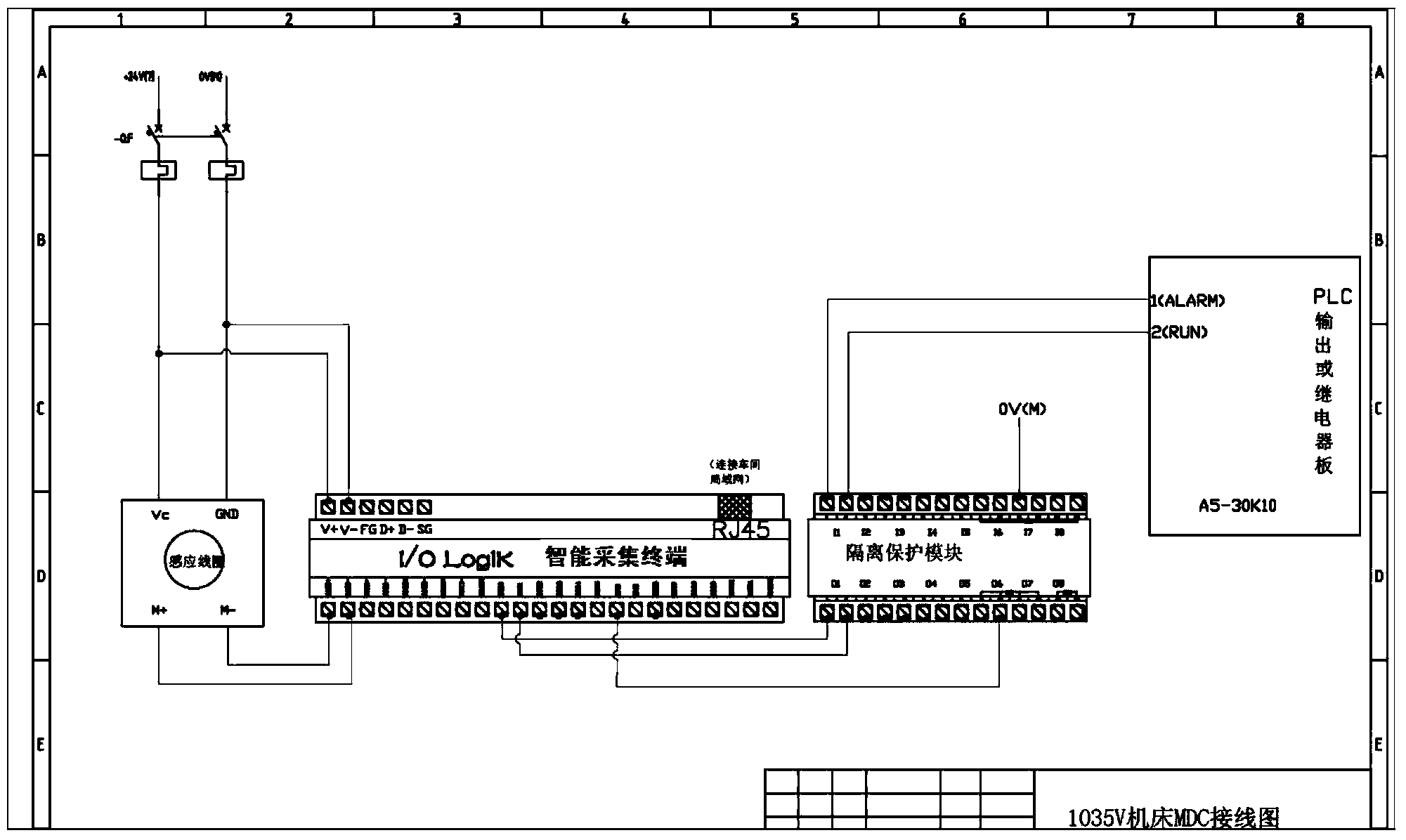

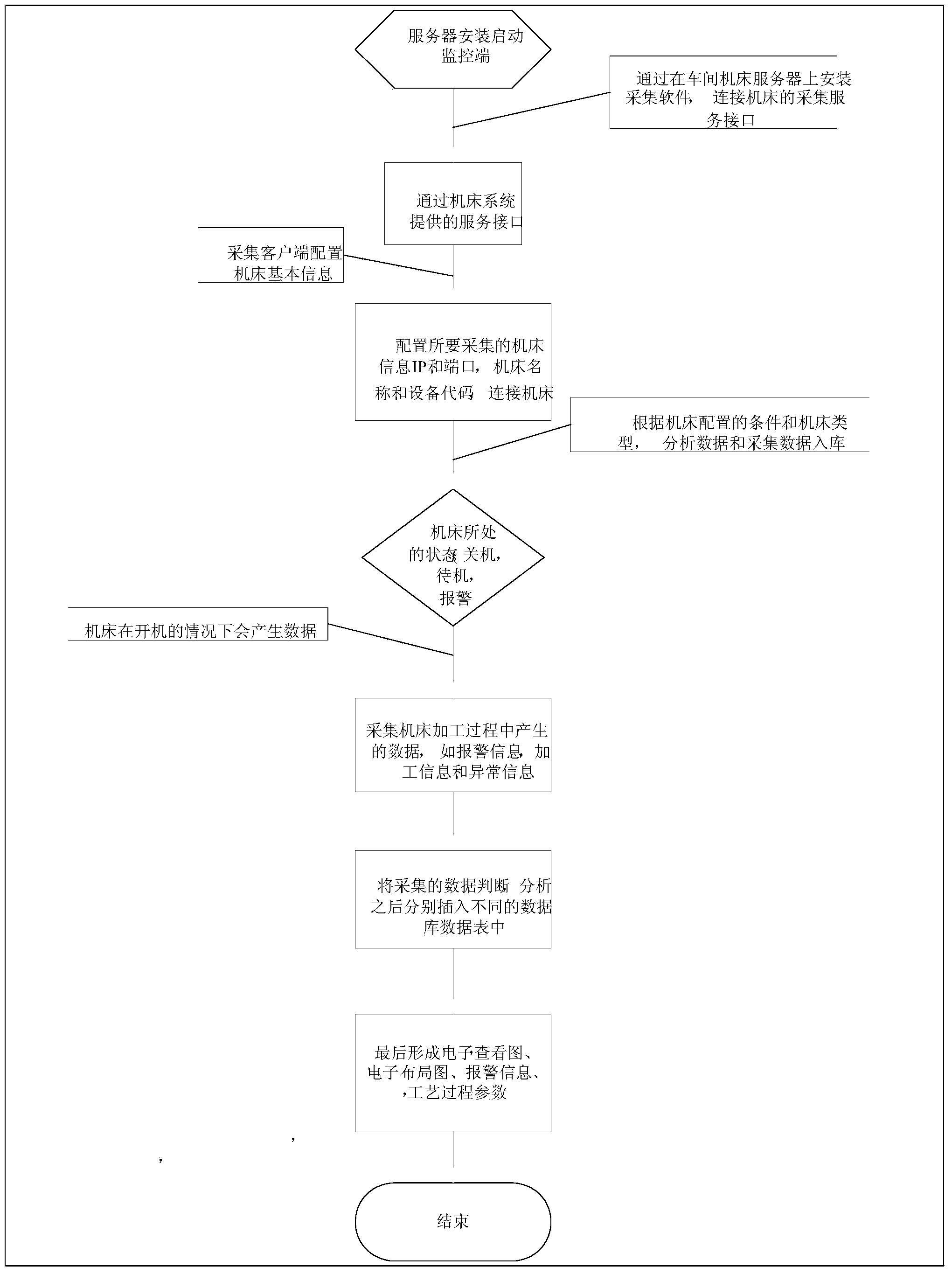

Networked real-time monitoring-oriented numerically-controlled machine tool machining process parameter acquiring method

ActiveCN104298173AAutomate the processImplement automatic deliveryProgramme controlComputer controlNumerical controlCommunication interface

The invention relates to a networked real-time monitoring-oriented numerically-controlled machine tool machining process parameter acquiring method. According to the method, networked real-time monitoring of the machining states of multiple numerically-controlled machine tools with different control system types and different communication interface modes is achieved based on one server, real-time acquisition and recording of technological process parameters of FANUC, SIEMENS, HEIDENHAIN system machine tools can be achieved based on program names of NC programs and rules with a specific postprocessing format, and automatic transmission, storage and reusing of technological process parameters are achieved. The method is characterized in real-time performance, visibility, integrity, accuracy and the like. Real-time monitoring of the states of the numerically-controlled machine tools, full display of alarm number-based automatch alarm information and automatic transmission, storage and reusing of technological process parameters are achieved based on the spacecraft product numerically-controlled processing flow and the normalized numerically-controlled program format, and integrated application of a digital workshop information system is achieved on the basis.

Owner:BEIJING SATELLITE MFG FACTORY

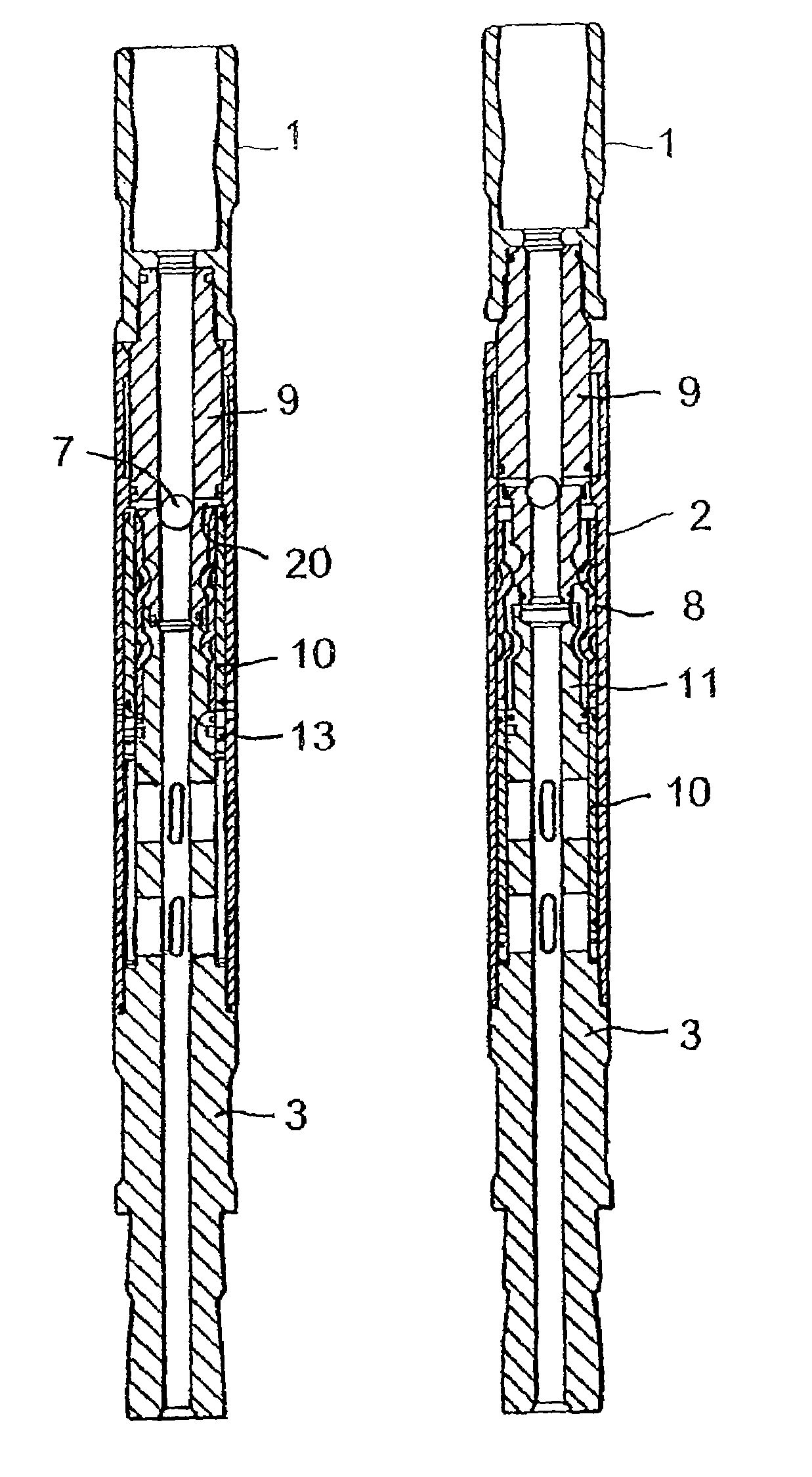

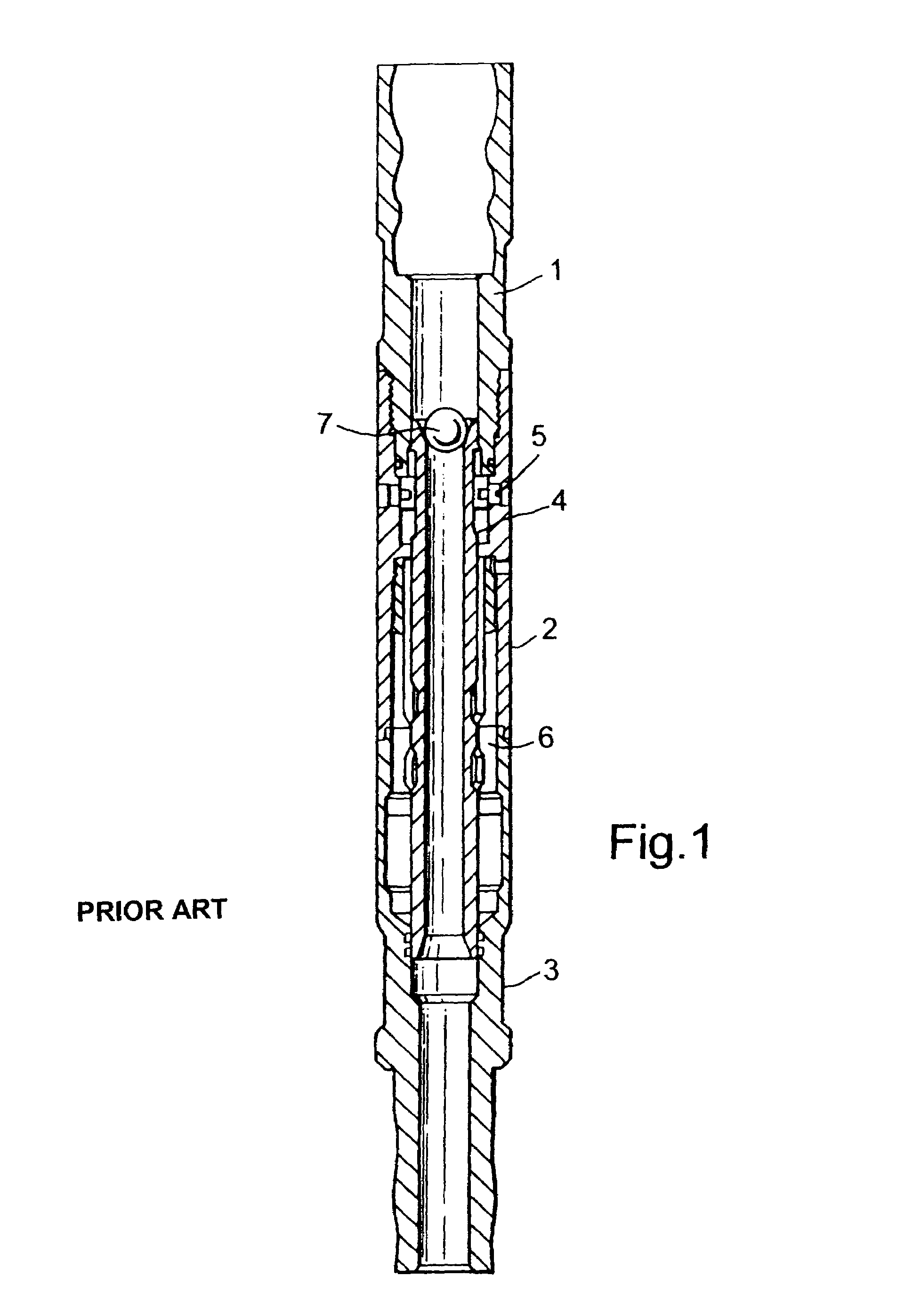

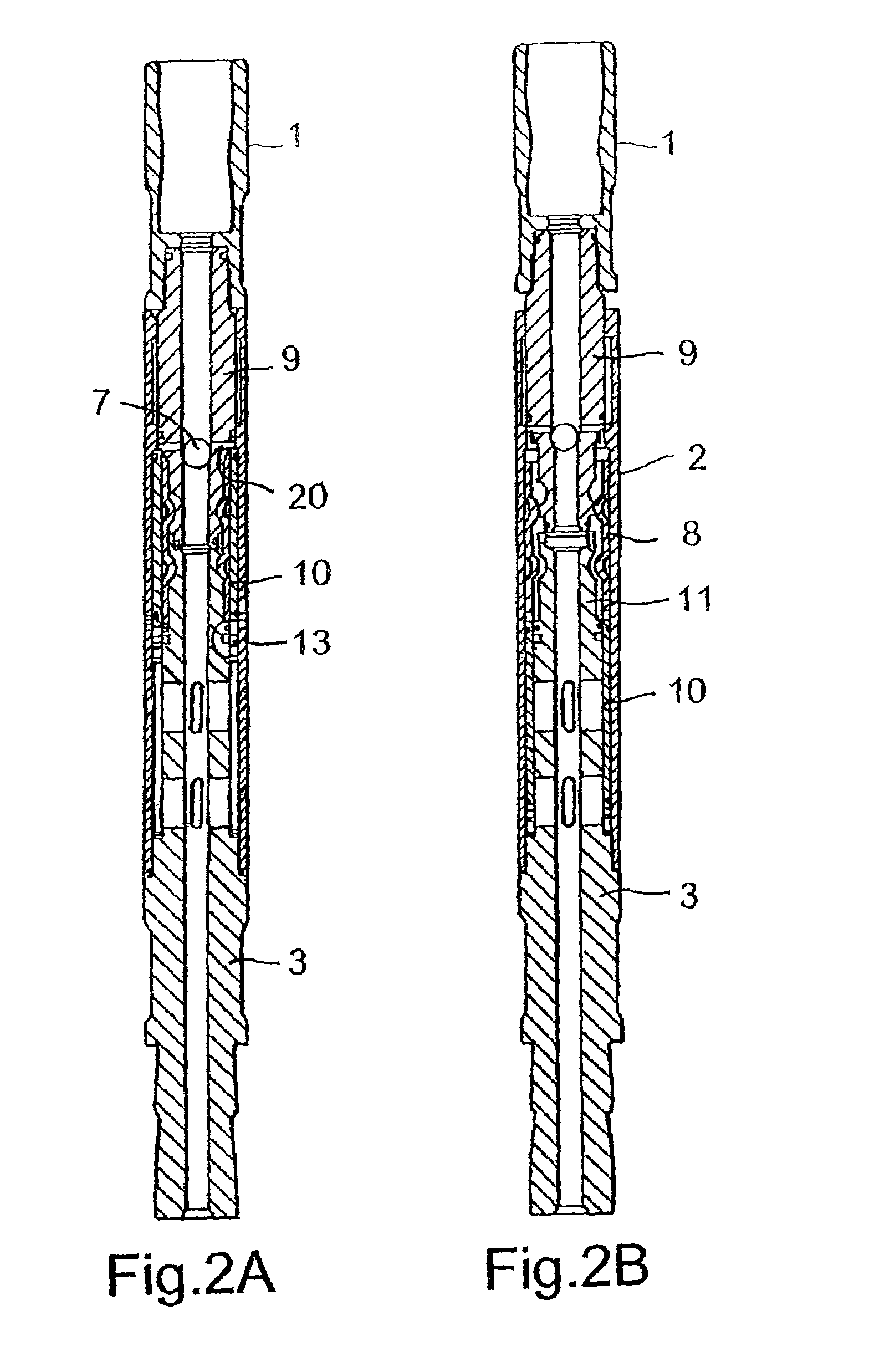

Disconnect devices

A disconnect device for use as part of a tubing string downhole in an oil or gas well and which comprises a tubular body, at least one slip held within the tubular body, and a sleeve housed within the tubular body to hold the at least one slip in coupling engagement with at least one of a coupling component of an upper sub and a coupling component of a lower sub, in use, the sleeve being selectively moveable relative to the at least one slip to release the slip and thereby release the coupling, wherein the slip cooperatively engages with at least one of the coupling component of the upper sub and the coupling component of the lower sub by means of at least one localized protrusion on the slip or on the coupling component extending into a corresponding shaped local depression or hole in the other of the at least one slip and the coupling component whereby tensile load and torque may be transmitted by the coupling, that part of the device which is to be released and left downhole by releasing the coupling engagement having a fishneck configuration to enable subsequent retrieval by a fishing tool.

Owner:WEATHERFORD TECH HLDG LLC

Automatic hand washing system

InactiveUS20090100593A1Easy to cleanSave resourcesGeneral water supply conservationDomestic plumbingNatural resourceControl system

The present invention provides an automatic hand washing system for original and retrofit residential and commercial installation and use. The automatic hand washing system dispenses a predetermined amount of soap and water to effectively clean the hands of a user in a short, predetermined amount of time, ensuring that sanitary protocols are followed while conserving natural resources. In this respect, the automatic hand washing system represents an automatic hand washing protocol compliance control system. Advantageously, the automatic hand washing system isolates the soap delivery path from the water delivery path until each is delivered to the hands of the user, preventing self-contamination, allowing the proper viscosity and flow of each to be maintained, eliminating the need for inefficient internal mixing mechanisms, etc. Advantageously, the automatic hand washing system also identifies and certifies the soap source being utilized, such that the integrity of the hand washing process is ensured and a revenue stream for the manufacturer of the automatic hand washing system and / or the provider of the soap source is maintained.

Owner:BLACK PEARL IND

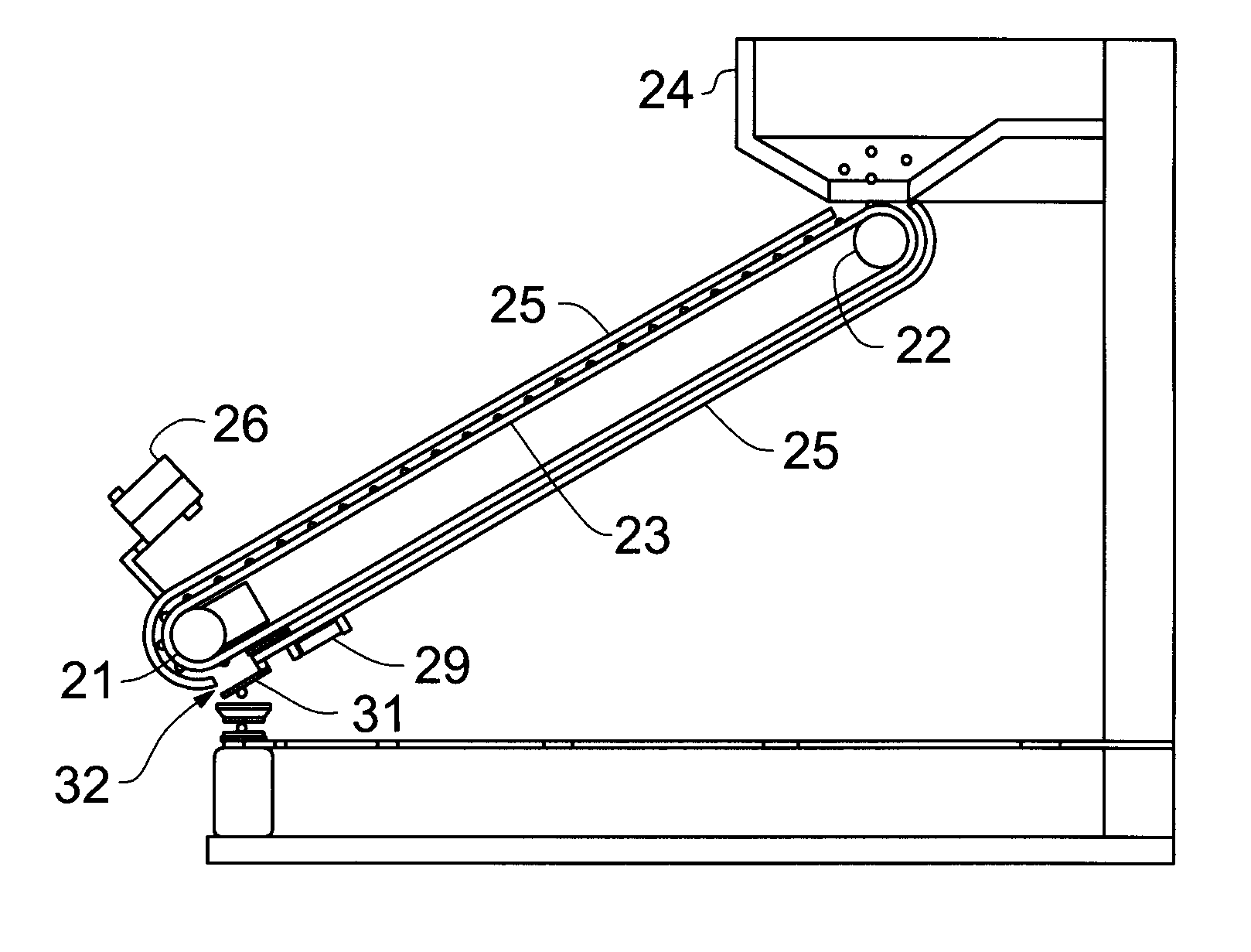

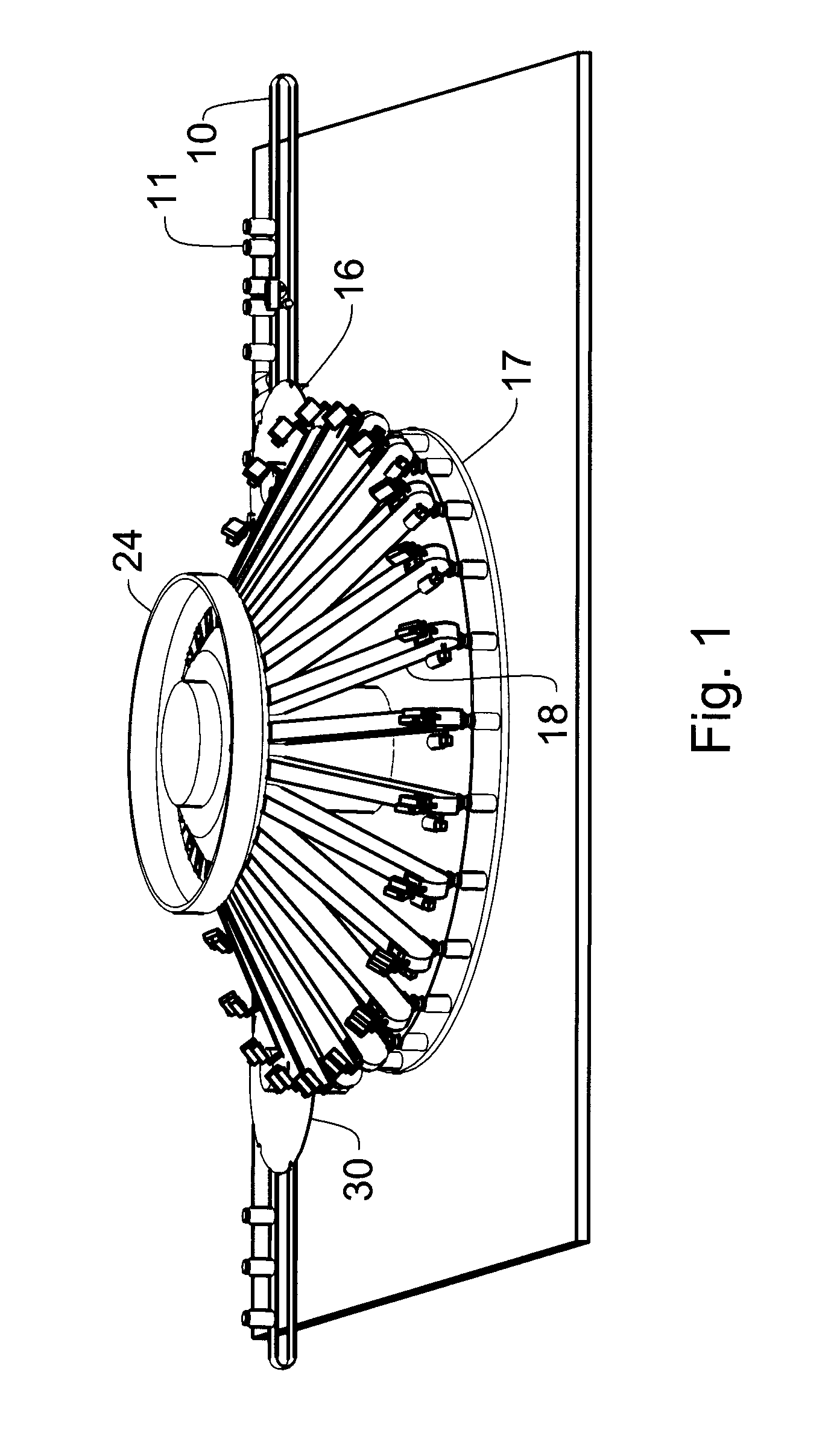

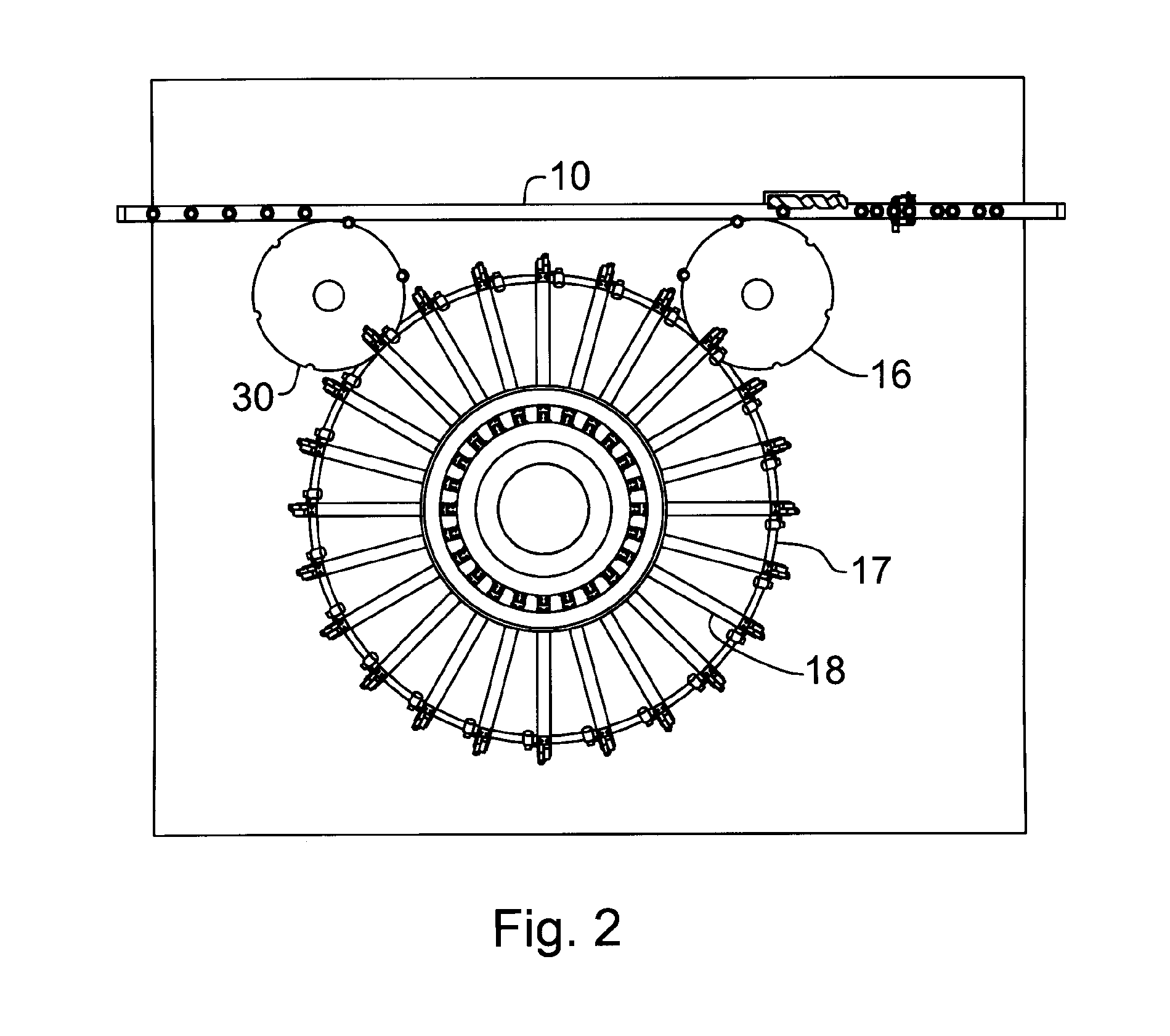

Packaging apparatus

InactiveUS7795556B1Advantage in throughputAdvantage in count accuracyConveyorsCoin-freed apparatus detailsComputer scienceContinuous rotation

An automated, continuous rotary-motion, positive-count, container-filling machine used for counting, color inspecting, geometric inspecting, and batching a predetermined quantity of multiple or discrete objects such as tablets, capsules, caplets, or packets of collated items (multiple objects to a pack). Apparatus comprises a plurality of rotary slats, each of which is independently driven, and able to pick up multiple objects at one location and deliver multiple objects simultaneously to a container through multiple counting and inspection devices.

Owner:DEAN EDWARD T

Electrochromic or electrodeposition display and novel process for their manufacture

ActiveUS20060139724A1Eliminates undesirable particle sedimentationResponse rateNon-linear opticsEngineeringElectrochromism

The present invention is directed to an improved electrodeposition and an electrochromic display. The display cells formed from microcups are filled with an electrolyte fluid and are individually sealed with a polymeric sealing layer.

Owner:E INK CALIFORNIA

Electrophoretic display and process for its manufacture

InactiveUS20080007815A1Desirable mechanical propertyImprove the display effectNon-linear opticsOptical elementsElectrophoresisDisplay device

This invention relates to an electrophoretic display comprising a plurality of cells, each of said cells comprises: a) partition walls; b) an electrophoretic fluid filled therein; c) a polymeric sealing layer to enclose the electrophoretic fluid within the cell; and d) an interface between the electrophoretic fluid and the sealing layer.

Owner:E INK CALIFORNIA

Electrophoretic display and process for its manufacture

InactiveUS7522332B2Improve the display effectCost effectiveElectrographic processes using photoelectrophoresisElectrographic process apparatusElectrophoresisDisplay device

This invention relates to an electrophoretic display comprising cells which are filled with charged particles dispersed in a solvent and are individually sealed with a polymeric sealing layer.

Owner:E INK CALIFORNIA

Edgewise orthodontic bracket with character base

InactiveUS20050003320A1Reduce frictional contactEnhanced treatment controlBracketsDental toolsEngineeringSingle pair

An improved edgewise orthodontic bracket is disclosed. In one embodiment, a bracket comprises a single pair of opposing T-shaped tie wings which define an archwire slot therebetween. Notches are provided on each of the mesial and distal sides of the center leg of each T-shaped tie wing for selectively receiving a ligating device. The notches are defined in the gingival / occlusal edges of the tie wings and comprise sloped portions that extend labially towards the archwire slot. Convex sidewall portions and convex floor portions are provided in the archwire slot adjacent to the notches. The body of the bracket is interconnected to a base that includes a continuous series of characters that serve as texturing to facilitate bonding of the bracket with a tooth. A discontinuous perimeter rail may be used at the edge of the base. A method for forming a bracket is also provided.

Owner:ORTHOAMERICA HLDG LLC

Environment-friendly type insulated dope for cold rolling non-oriented silicon steel and preparation method for coat thereof

The invention relates to an environment-friendly insulating coating for cold-rolled non-oriented silicon steel and a preparation method thereof. The components of the insulating coating include: phosphate, molybdate, water, organic resin, silane coupling agent, and glycerol; the above-mentioned The weight ratio of each component is: phosphate 100, molybdate 3-20, water 800-1500, organic resin 20-50, silane coupling agent 0.5-5, glycerol 8-15. The steps of the coating preparation method are: (1) coating insulating paint on the surface of cold-rolled non-oriented silicon steel; (2) baking and drying, the baking temperature is 150-300 ° C; 600°C, the sintering time is 30-90 seconds; (4) Finished product. The insulating paint of the invention does not contain harmful elements, and the coating has good insulating performance, good adhesion and corrosion resistance, good punching and shearing processability and weldability, and can withstand heat resistance of stress-relieving annealing. The method of the invention is simple to operate, and the coating prepared by the method has good punching and shearing processability and weldability, and can withstand heat resistance of stress-relieving annealing.

Owner:武钢集团有限公司

Method and system for processing grammar-based legality expressions

ActiveUS7299171B2Efficient storageIntegrityProgram/content distribution protectionSpecial data processing applicationsTime responsePredictability

Legality expressions are systematically pre-processed, organized, and stored to achieve faster real-time response, improved predictability, and increased reliability for queries against a large volume of legality expressions. Exponential improvements in both the time to locate the set of legality expressions matching specified search criteria and the processing costs of evaluating the request against the matching legality expressions are achieved using the disclosed systems, devices, and methods. The systems, devices, and methods are unique to the optimization of legality expression processing, but they can also enable the use of other optimization techniques for processing large amounts of data.

Owner:CONTENTGUARD HLDG

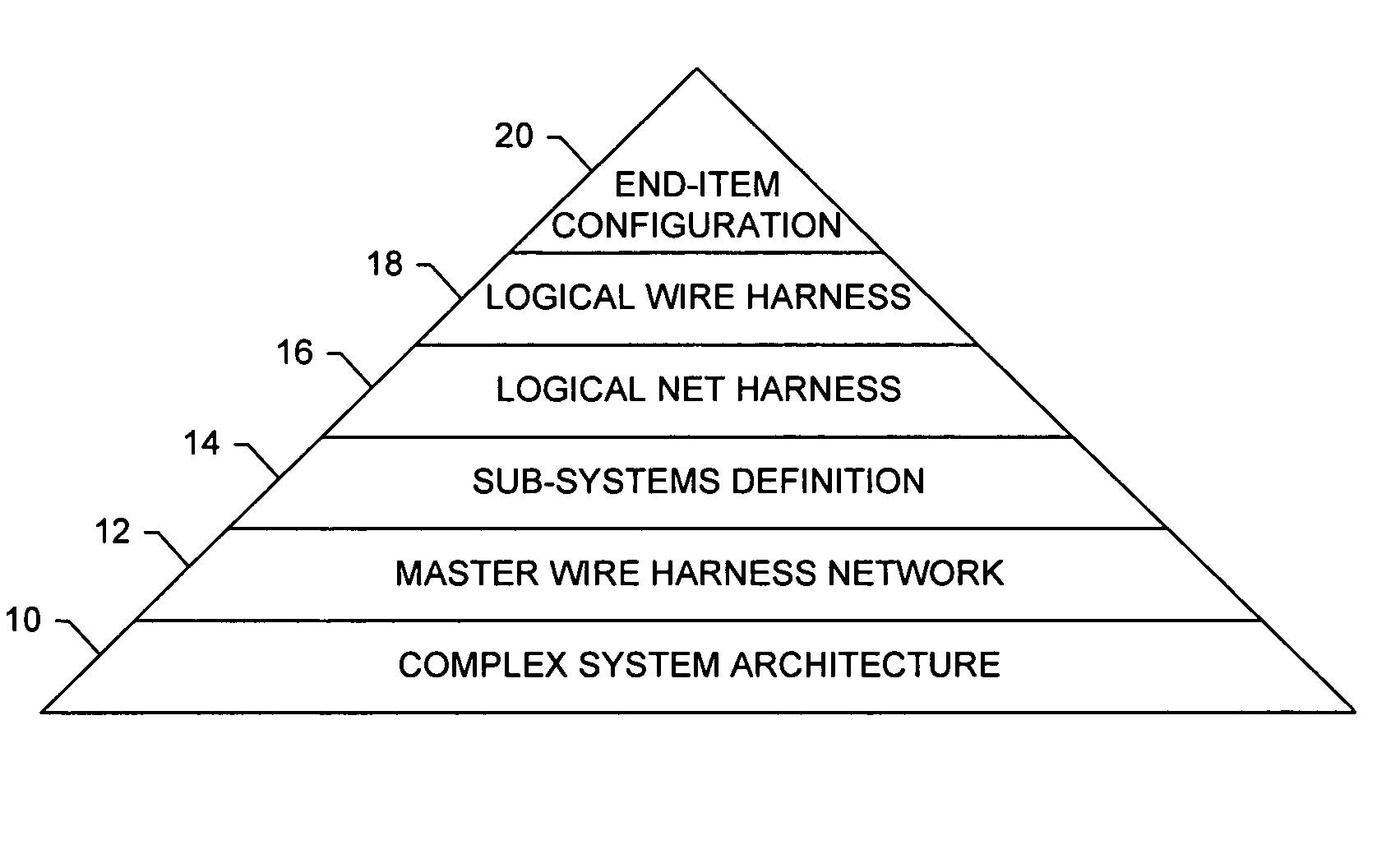

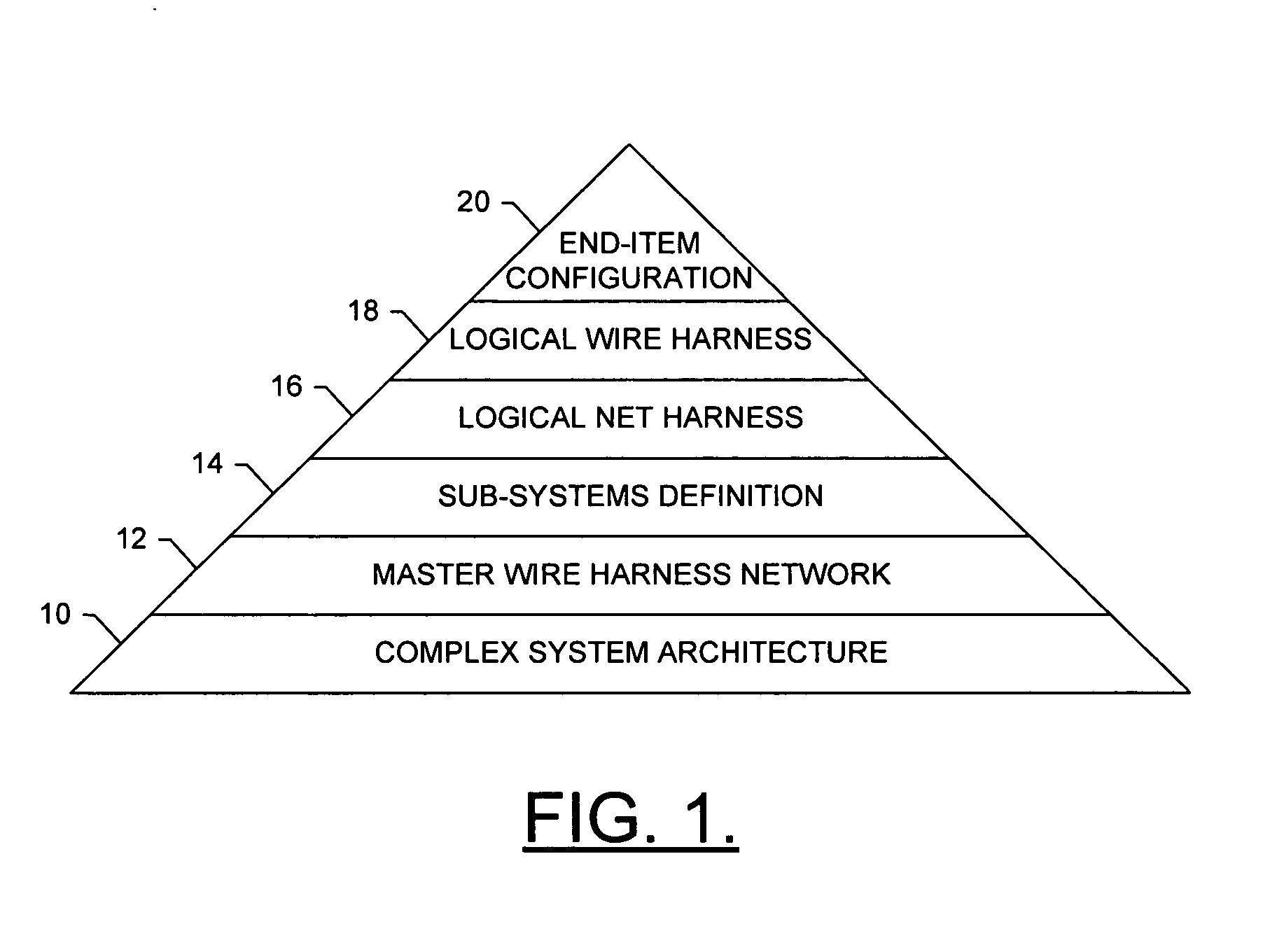

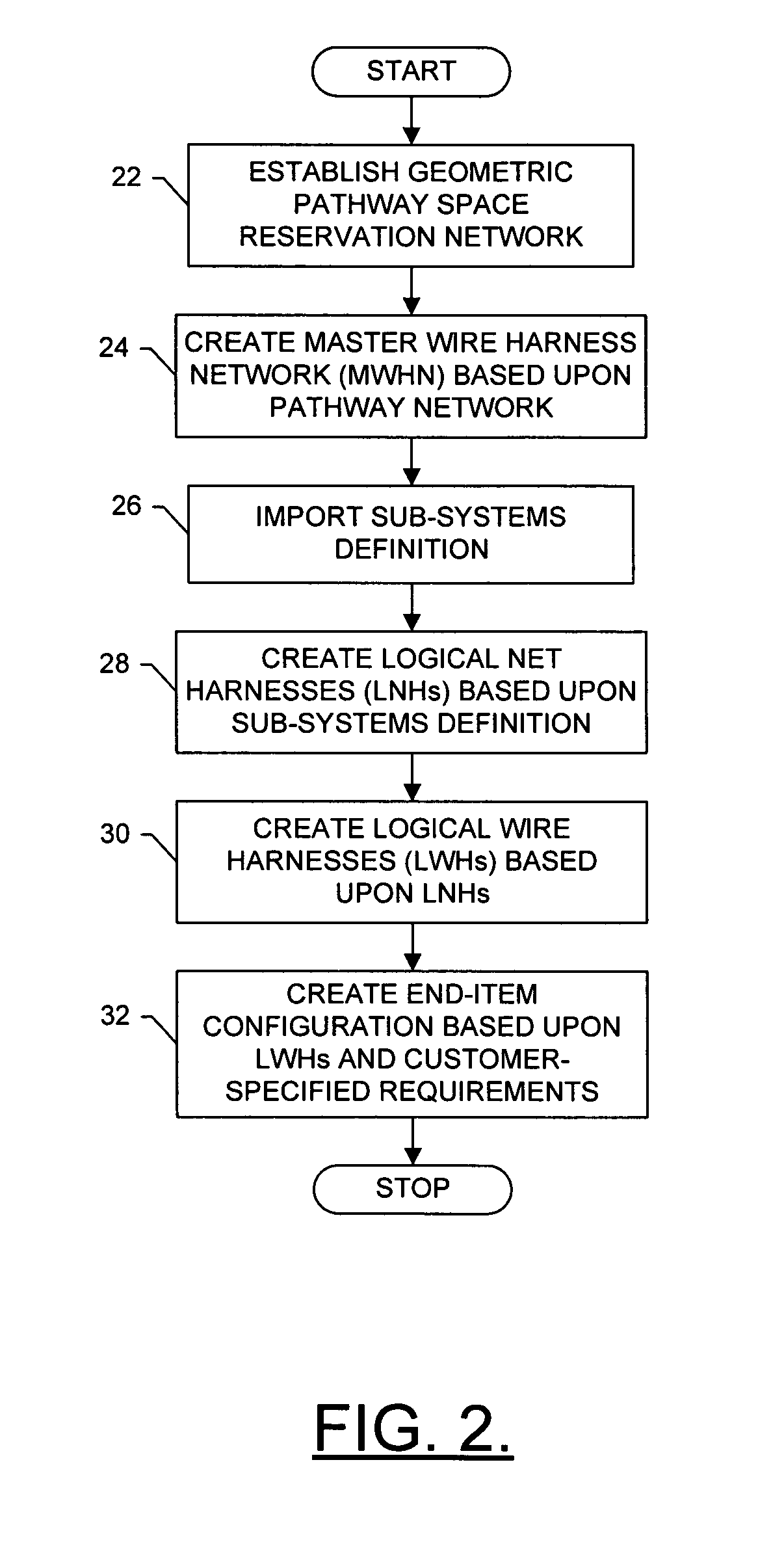

Topology-driven apparatus, method and computer program product for developing a wiring design

ActiveUS20070141899A1Effective implementation of designEnhance/maintain data integrityGeometric CADContact member assembly/disassemblyEngineeringInterconnection

A method for developing a wiring design for a complex system includes creating a master wire harness network (MWHN) within pathway space reservations of a pathway space-reservation network of the complex system. In this regard, the MWHN can comprise a model of possible wiring pathways between equipment of the complex system, and can include wire harness elements interconnecting termination device elements. The method can also include importing a subsystems definition capable of being represented by interconnections between the equipment. Thus, one or more logical net harnesses (LNHs) can be created based upon the MWHN and the subsystems definition. The LNH, then, can comprise a collection of interconnections routed within the MWHN. One or more logical wire harnesses (LWHs) can be created based upon the LNHs, after which one or more end-item configurations (EICs) can be created based upon the LWHs.

Owner:THE BOEING CO

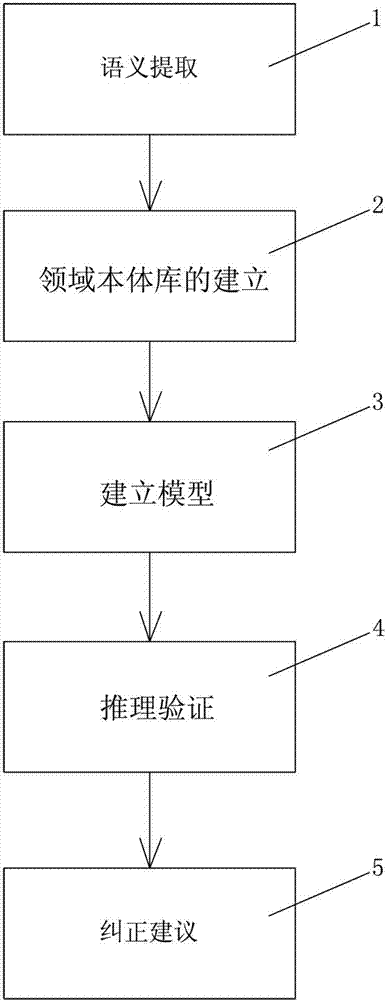

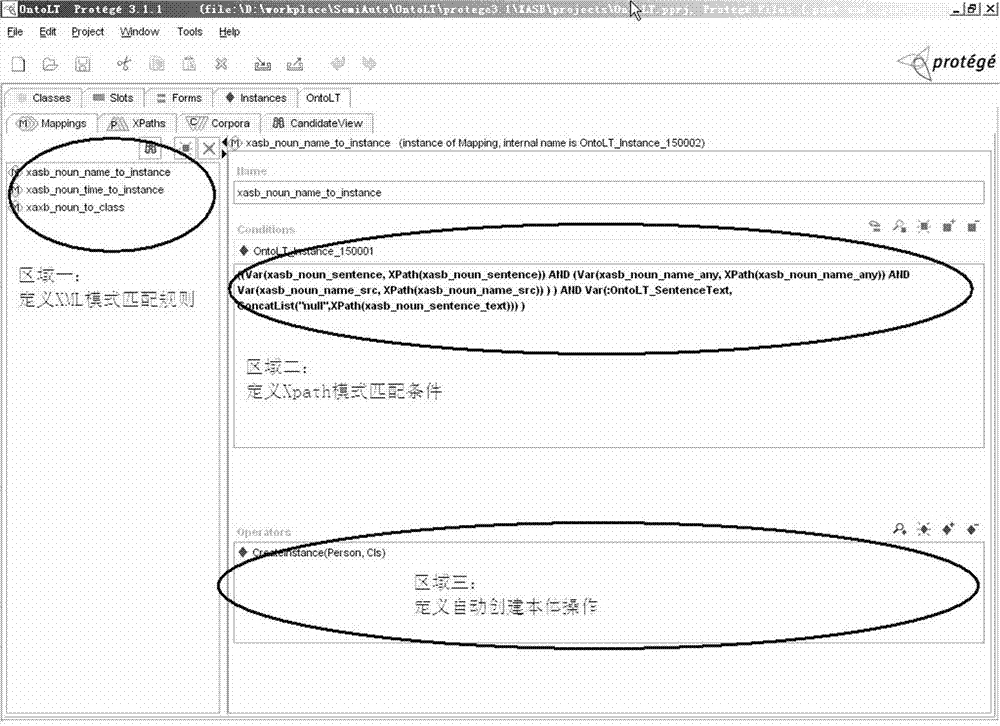

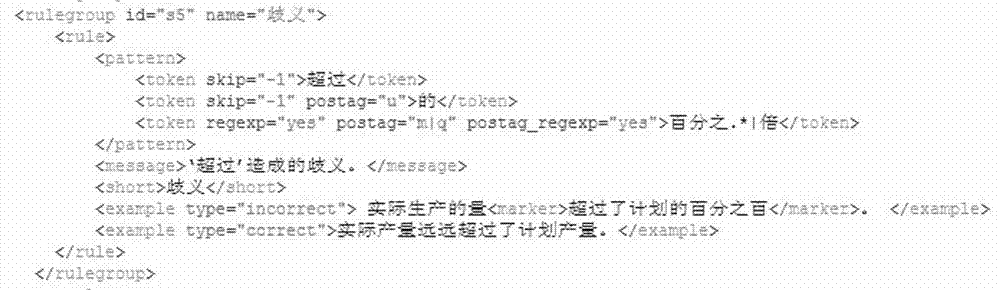

Chinese semantic proofreading method based on ontology consistency verification and reasoning

InactiveCN103593335AAccurately determine the cause of the errorNo ambiguitySpecial data processing applicationsLogical consistencyNatural language

A Chinese semantic proofreading method based on ontology consistency verification and reasoning includes: using the ontology learning technology to extract semantic contents from non-structural natural Chinese languages, and converting the extracted semantic contents into structural ontology forms; establishing field ontology databases, and using corresponding ontology databases according to different fields; building models integrating the formed Chinese semantic proofreading key technology, in a form of plug-in, into a grammar verifying tool or using other implementation forms such as independent Chinese semantic verification software; in the grammar verifying tool, using the consistency reasoning and verification mechanism based on description logic and contained in the ontology reasoning language to sequentially perform consistency verification and reasoning on the extracted semantic contents and correct field ontology database input into a reasoning machine according to preset orders, and labeling error labels on the Chinese semantic contents, with inconsistent logic, in the reasoning result. By the method, word-level and grammar-level Chinese proofreading can be achieved, and Chinese semantic proofreading in special fields can also be achieved.

Owner:姜赢

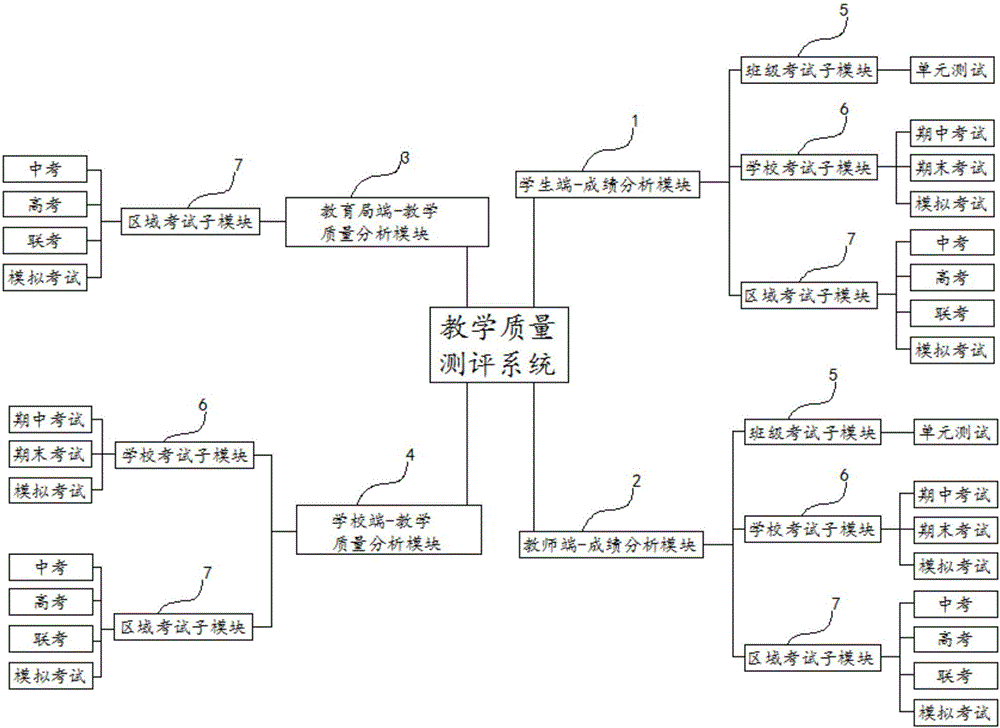

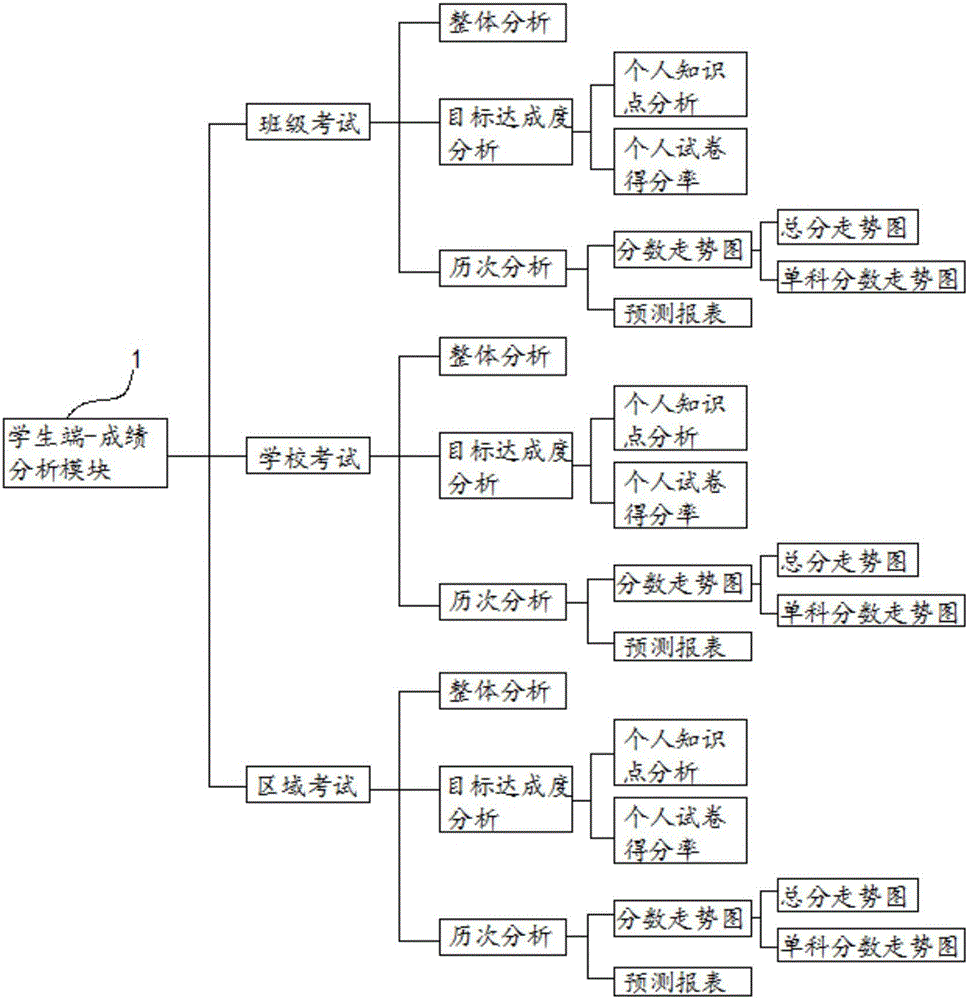

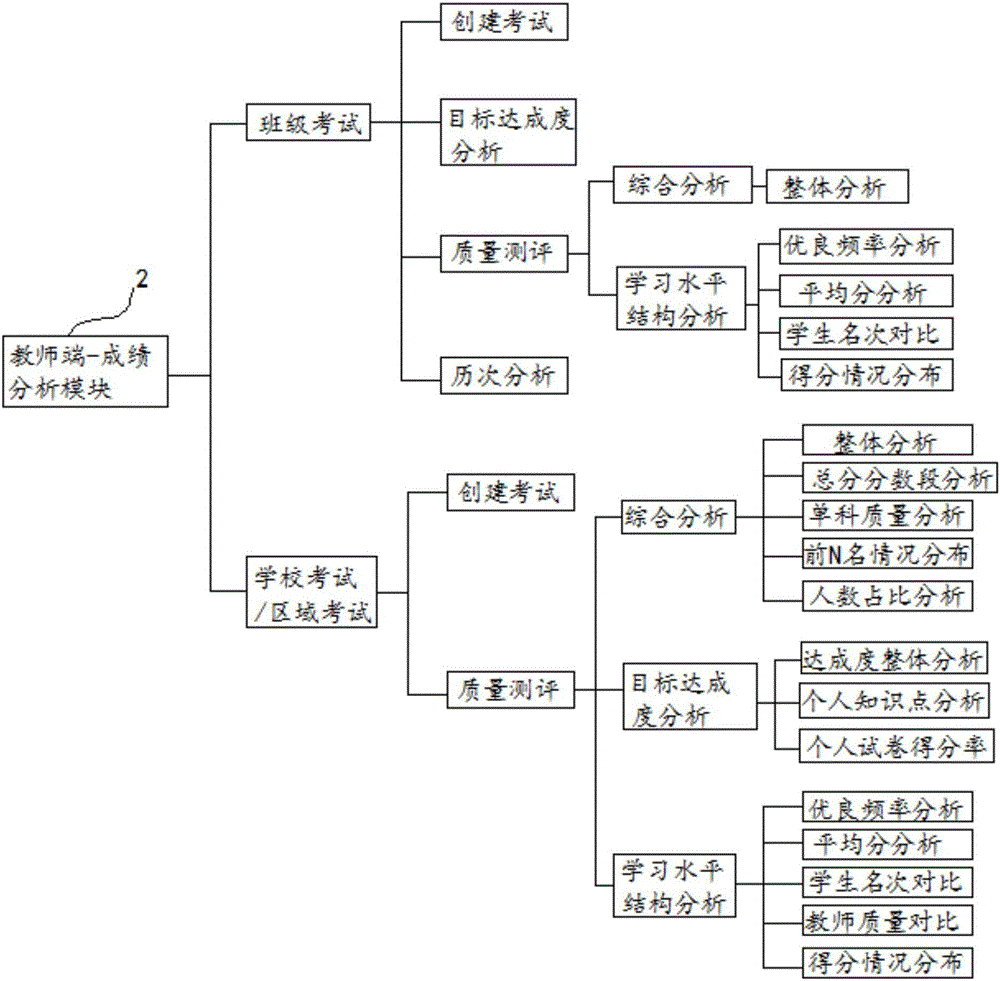

Teaching quality assessment system based on big data

InactiveCN106373055AUnderstand in timeSpread widelyData processing applicationsElectrical appliancesQuality assessmentData science

The present invention discloses a teaching quality assessment system based on big data. The system comprises a student terminal-score analysis module, a teacher terminal-score analysis module, a school terminal-teaching quality analysis module and an education bureau terminal-teaching quality analysis module; the teacher terminal-score analysis module is configured for teachers to perform browsing and analysis of the administered class test scores; the school terminal-teaching quality analysis module is configured for school administrators to perform browsing and analysis of the administered class test scores; and the education bureau terminal-teaching quality analysis module is configured to the education bureau managers to perform browsing and analysis of the administered region school test scores. Through the analysis of test scores each time, the teaching quality assessment system based on big data can obtain each layer of score dimension reports which are displayed for each role, and carries out each comparison mode to provide reliable scientific basis for improvement of the teaching level assessment through lateral comparison and vertical comparison.

Owner:武汉颂大教育科技股份有限公司

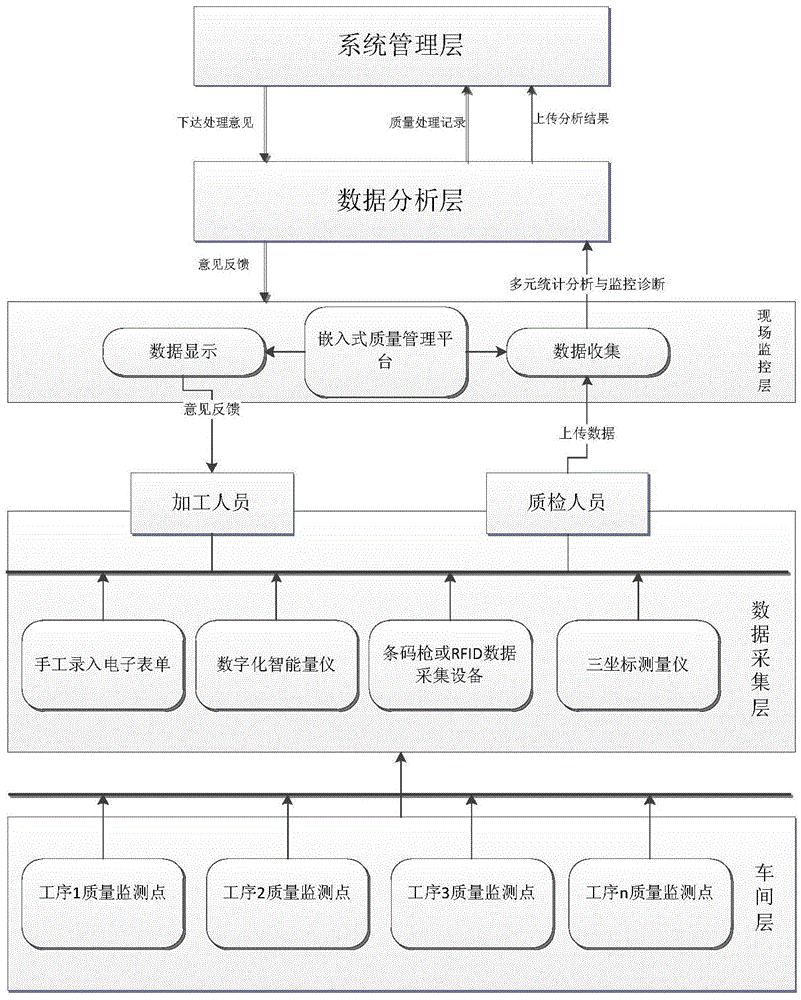

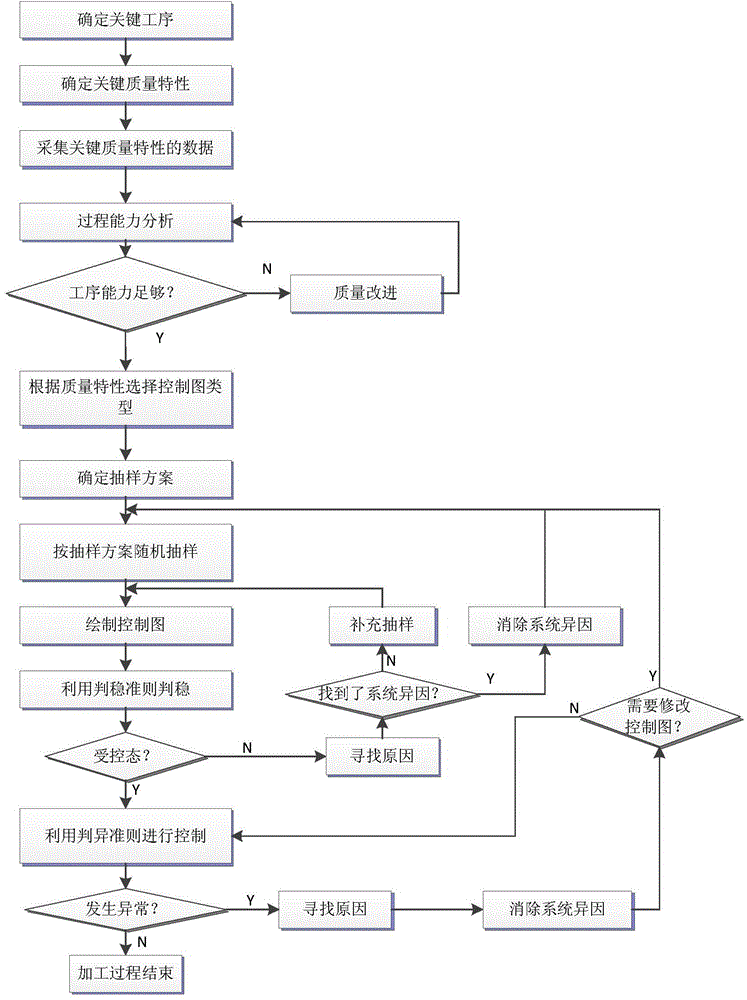

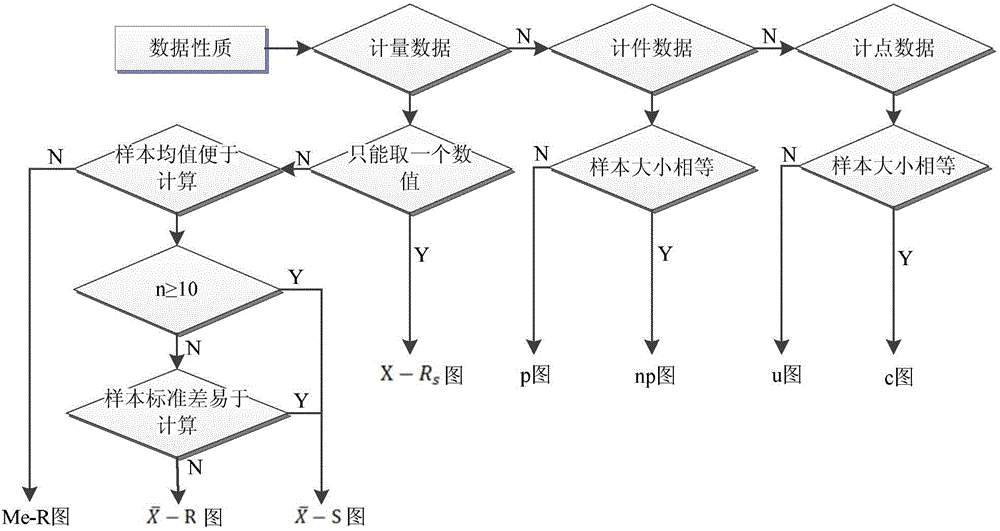

Multivariate product quality monitoring method oriented to digital workshop

ActiveCN104700200AReliableGuaranteed reliabilityResourcesQuality assurancePrincipal component analysis

A multivariate product quality monitoring method oriented to a digital workshop includes the steps: building a quality information acquisition scheme suitable for the digital workshop; building a quality control and improvement model oriented to the digital workshop, and particularly performing multivariate process capacity analysis based on an improved principal component analysis method according to multiple quality characteristics of key processes of key products of a machining workshop; controlling and diagnosing multivariate product by the aid of principal component analysis technology to solve the problem that a multivariate statistical control chart difficultly diagnoses and positions process exception. The quality assurance capability of the key processes of the key products can be quantitatively evaluated by the workshop, and a source of a quality problem is timely positioned when the quality problem arises, so that further cost loss is avoided.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com