Automatic hand washing system

a hand washing and automatic technology, applied in the field of automatic hand washing system, can solve the problems of ineffective hand washing, time-consuming, wasteful, and ineffective hand washing, and achieve the effect of reducing the number of hands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

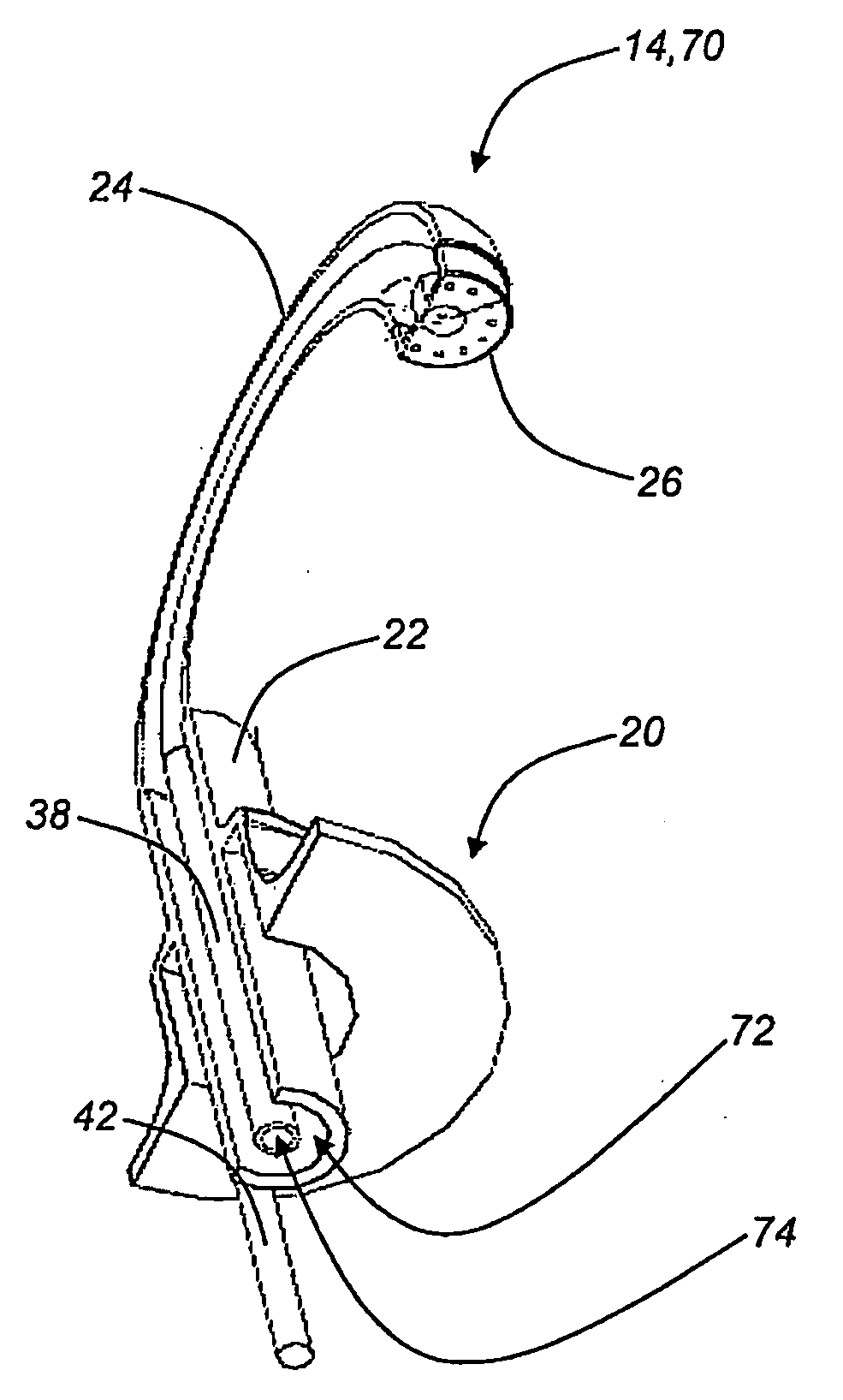

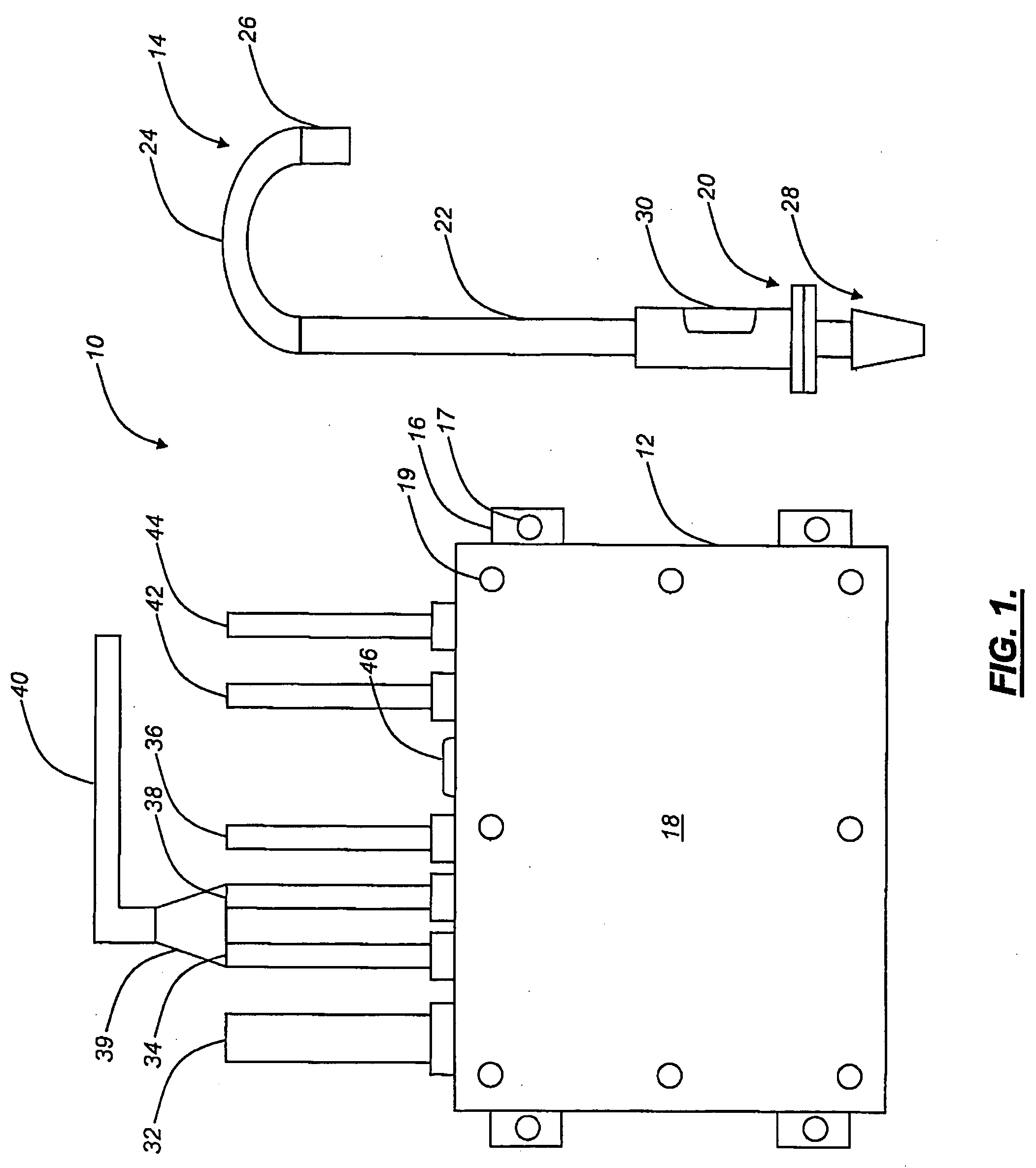

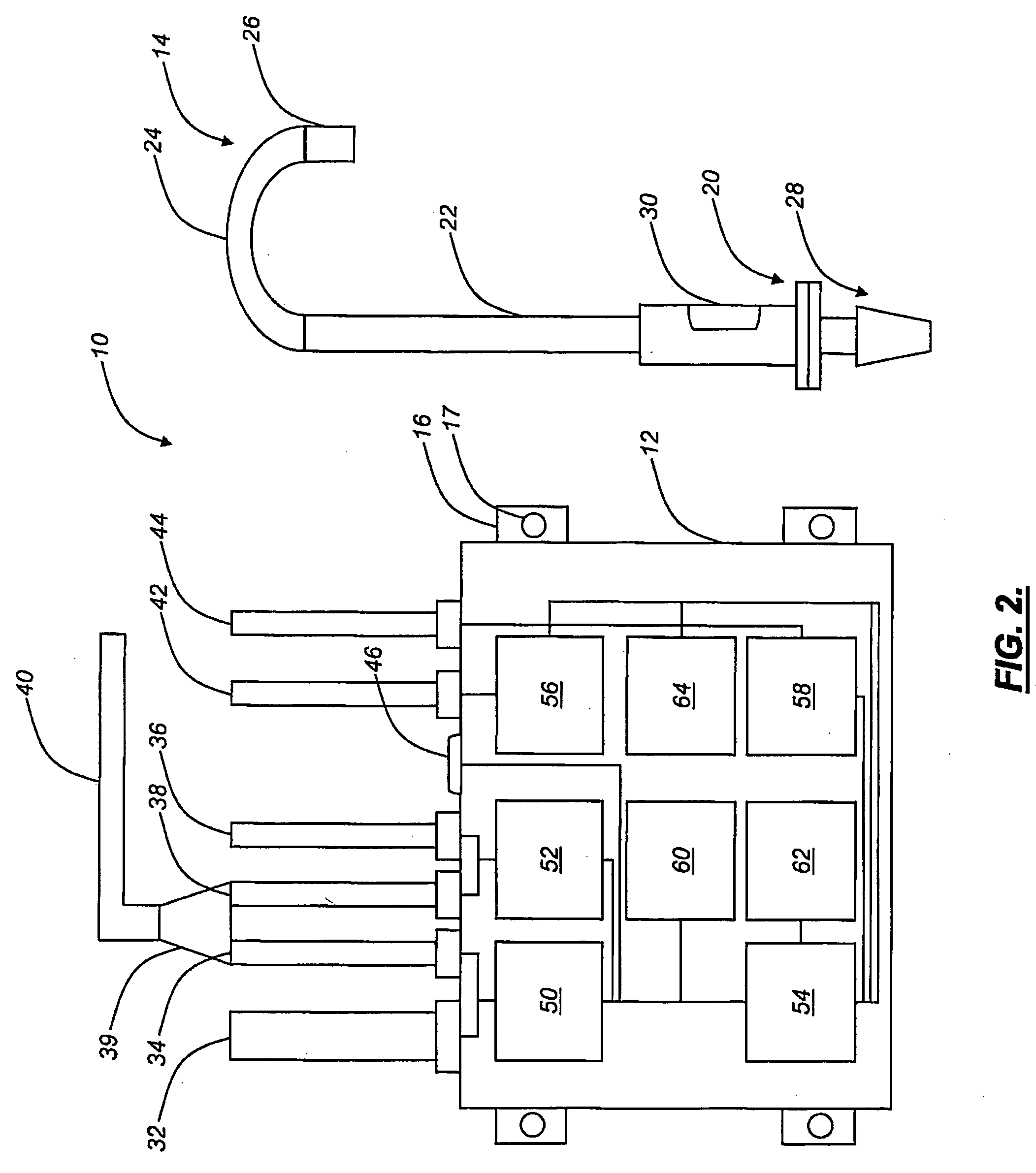

[0015]Again, in various exemplary embodiments, the present invention provides an automatic hand washing system for original and retrofit residential and commercial installation and use. The automatic hand washing system dispenses a predetermined amount of soap and water to effectively clean the hands of a user in a short, predetermined amount of time, ensuring that sanitary protocols are followed while conserving natural resources. In this respect, the automatic hand washing system represents an automatic hand washing protocol compliance control system. Advantageously, the automatic hand washing system isolates the soap delivery path from the water delivery path until each is delivered to the hands of the user, preventing self-contamination, allowing the proper viscosity and flow of each to be maintained, eliminating the need for inefficient internal mixing mechanisms, etc. Advantageously, the automatic hand washing system also identifies and certifies the soap source being utilized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com