Multivariate product quality monitoring method oriented to digital workshop

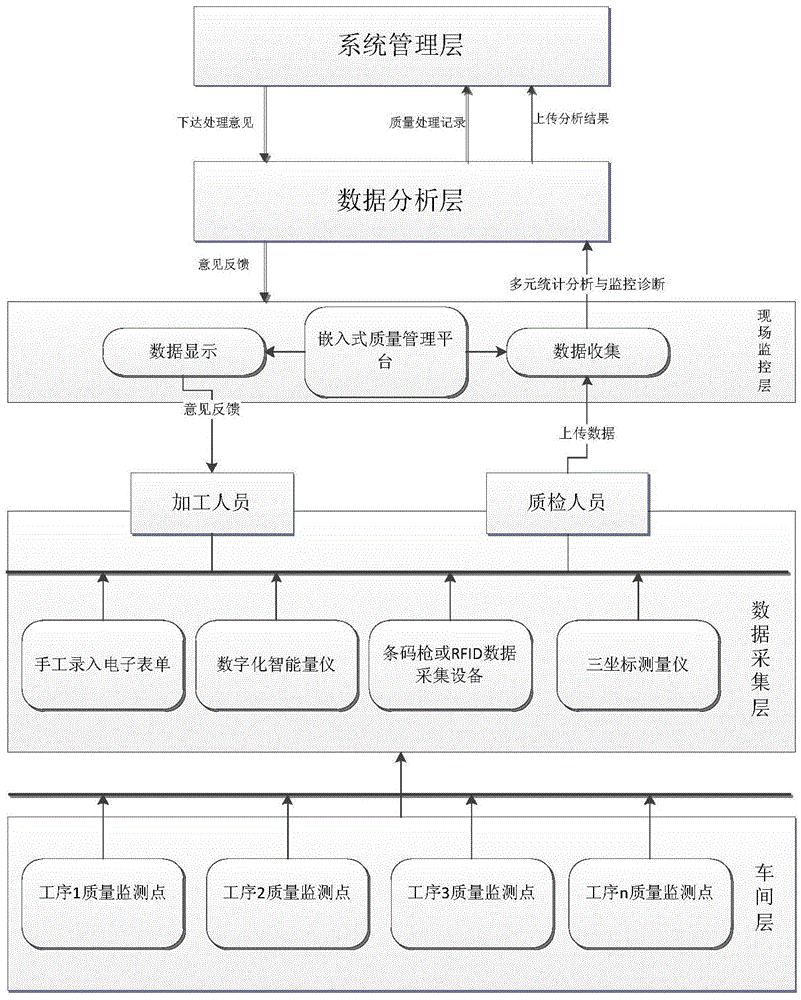

A quality monitoring and multivariate technology, which is applied in product multivariate quality monitoring, process capability analysis and quality problem diagnosis of machine-processed product manufacturing quality, can solve workshop quality control errors, low operability, and too much increase in the number of correlation diagrams Wait for the question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

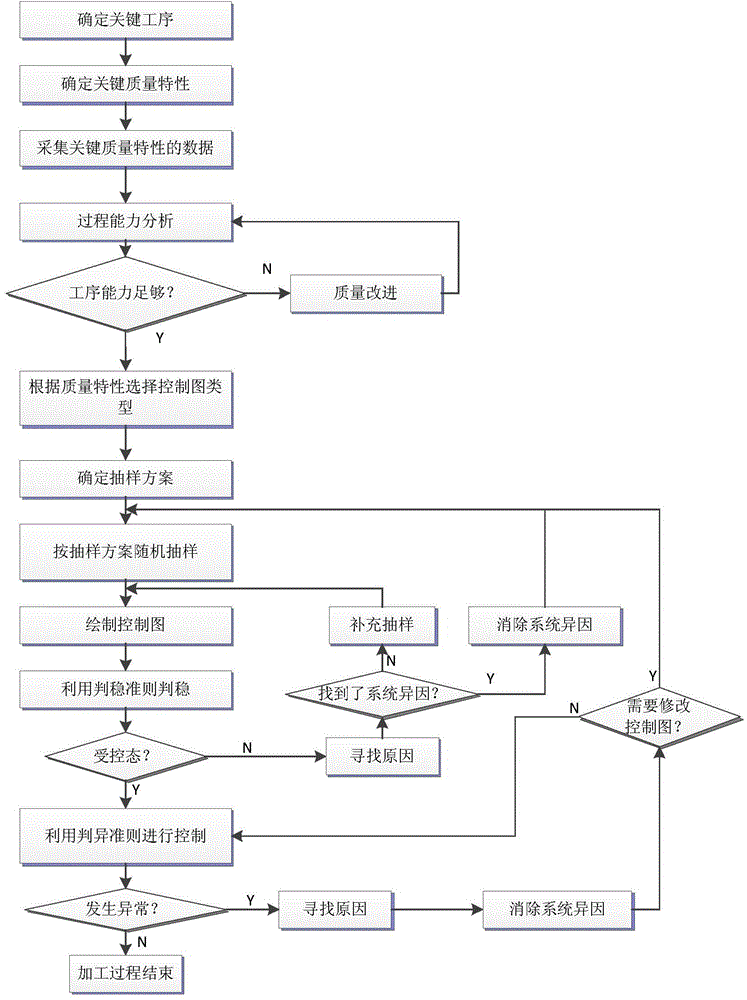

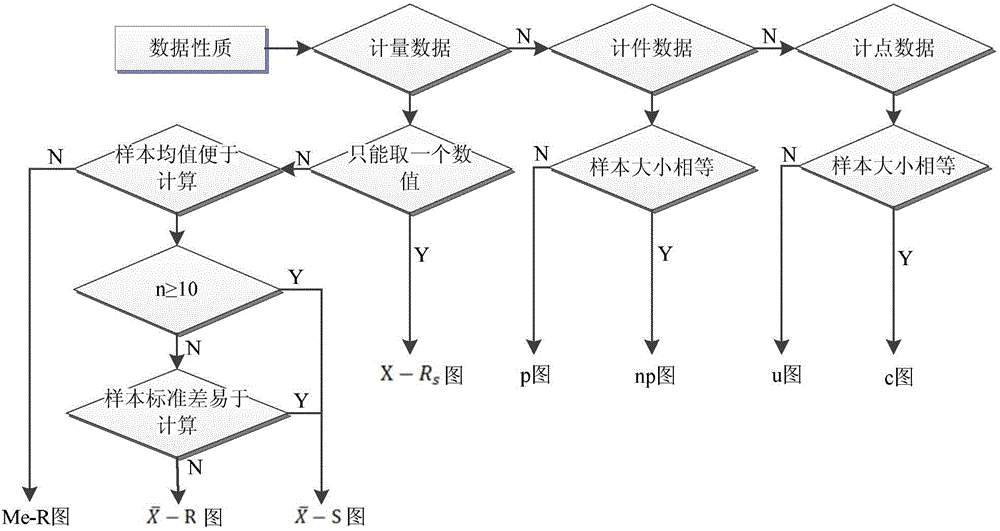

Method used

Image

Examples

Embodiment

[0069] Such as Figure 5 As shown, a switch manufacturer needs to mill a blind hole on the surface of a switch part in the process of processing a switch part. This process has four specific parameter requirements, as shown in Table 1. Multivariate quality control and diagnosis research was carried out for the four quality characteristics in Table 1, and the measurement data of the four quality characteristics are shown in Table 2. Based on 50 sets of sample data T collected on the workshop site for the four quality characteristics of diameter, depth, distance 1, and distance 2 2 Control charts and MEWMA control charts such as Figure 6 , Figure 7 shown.

[0070] Compare and observe the T of the milling process 2 control chart and MEWMA control chart, we can easily find that at T 2 Control chart, sample 37 is about to exceed T 2 The upper control limit, but not exceeded; in the MEWMA control chart, sample 37 obviously exceeded the upper control limit of the control char...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com