Novel film expanding platform

A film and platform technology, applied in the field of casting, can solve the problems of low automation, low efficiency, time-consuming and labor-intensive, etc., and achieve the effect of improving automation and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

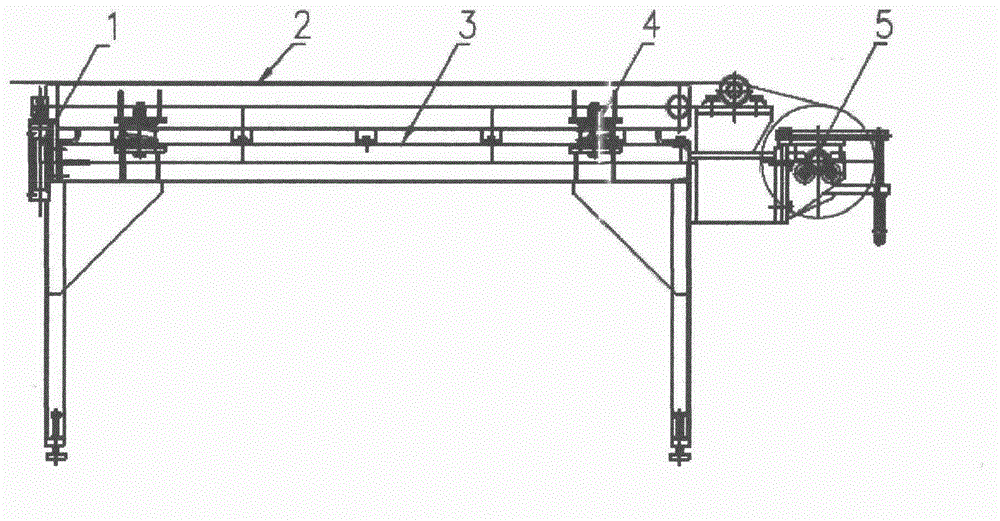

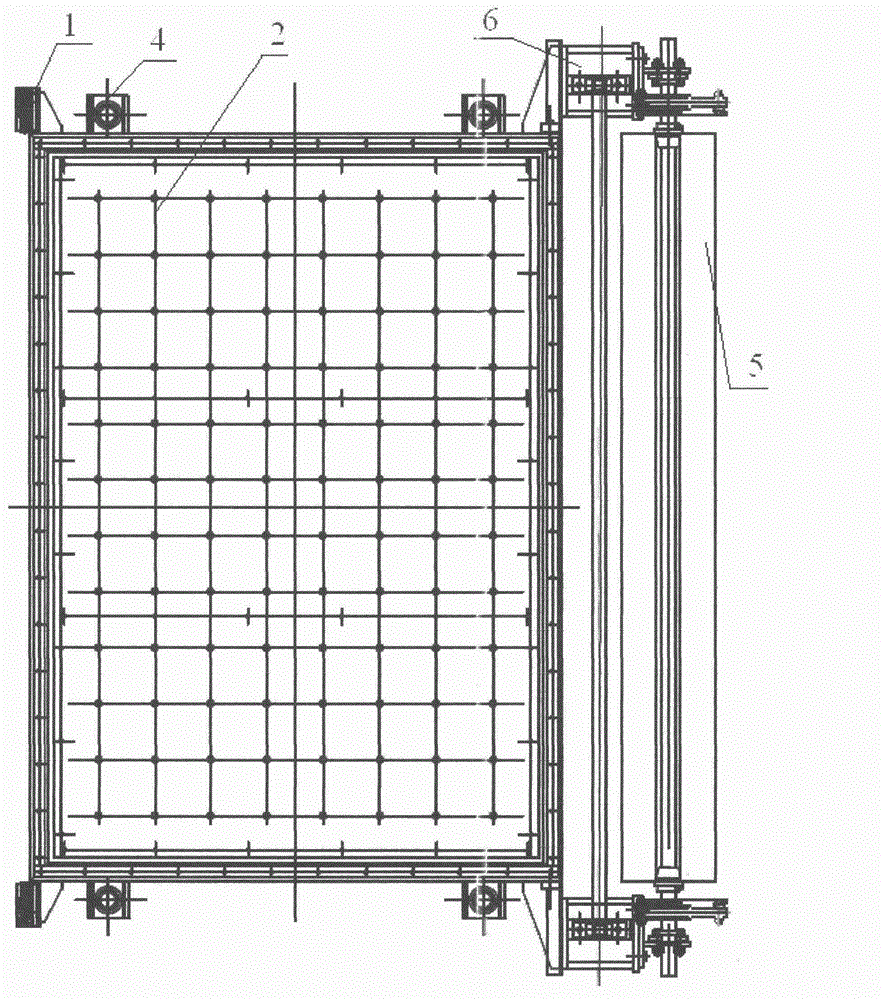

[0012] see Figure 1 to Figure 2 As shown, the present invention includes a film cutting mechanism 1, a film suction frame 2, a support 3, a spring 4 and a film support roller 5, the film suction frame 2 is arranged on the support 3, and the frame of the film suction frame 2 is rectangular The film suction frame 2 is provided with a film suction network line interwoven vertically and horizontally, and the film suction network lines are bonded together at each interweaving point in the film suction frame 2, and the film support roller 5 is arranged on one side of the film suction frame 2. The film cutting mechanism 1 is arranged on the other side of the film suction frame 2, and the two sides of the film support roller 5 are respectively provided with a driving device and a control system. There are four springs 4, and each two springs 4 are respectively arranged on the film suction frame. 2 at both ends, every two springs 4 are arranged between the film suction frame 2 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com