Electroforming thin blade grinding wheel

A thin-blade and grinding wheel technology, used in abrasives, bonded grinding wheels, metal processing equipment, etc., can solve the problems of inability to cut, low concentration of abrasive particles, peeling, etc. sharpness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1 is the same.

[0044] Abrasive content (vol%)

[0045] Abrasive content (vol%)

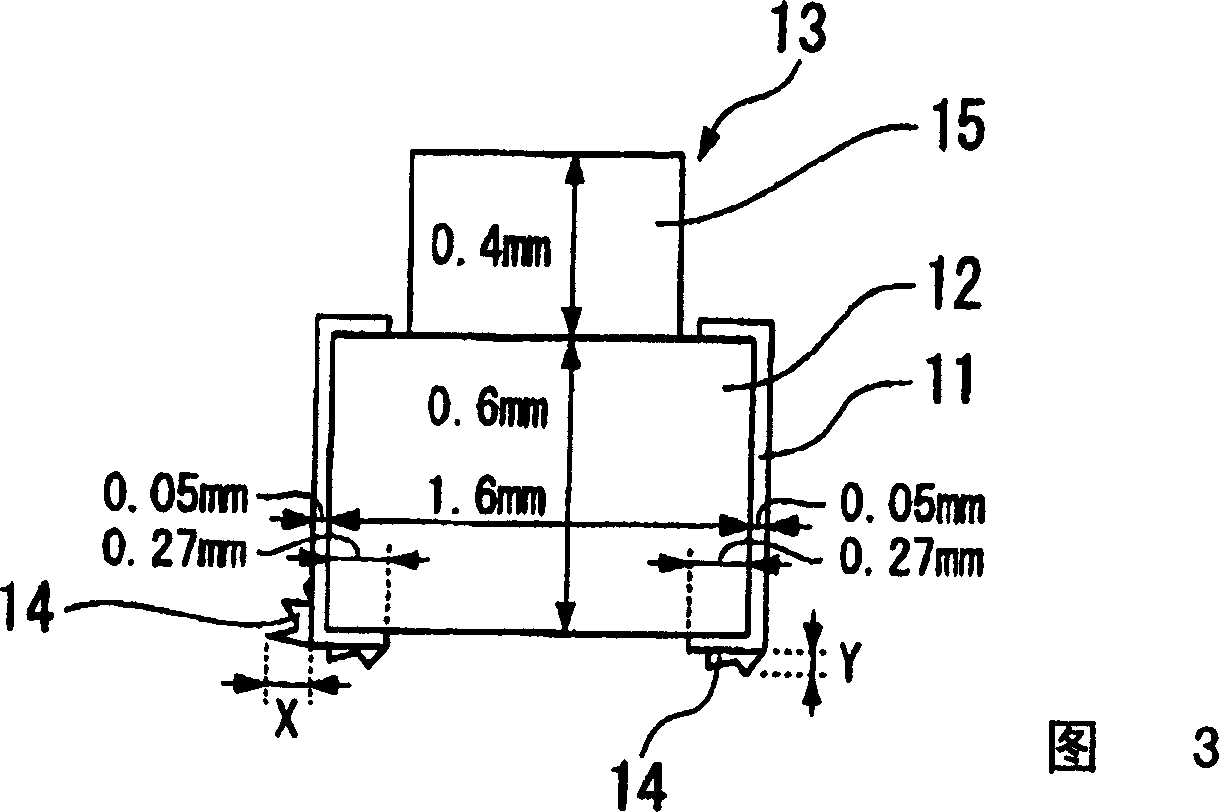

[0046] Wherein, at first, according to the results of Table 2, in Example 11 in which the abrasive grain content of the first, third, and fifth abrasive grain layers is relatively large, 45 vol%, from the moment of cutting distance 1 m in the initial stage of cutting, Both X and Y of the burr 14 are as large as close to 100 μm, and although they do not increase significantly as the cutting distance increases, the tendency is that Y becomes larger than 100 μm when the cutting continues to 50 m. In addition, in Example 17 in which the abrasive grain content of the first, third, and fifth abrasive grain layers was as small as 10 vol%, although the generation of burrs 14 was less in the initial stage of cutting, as the cutting distance increased, the burrs The amount of increase of 14 becomes large, and a burr 14 with a sharp increase in both X and Y is generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com