A 3D printing closed impeller abrasive flow finishing device

A closed impeller and processing device technology, which is applied in metal processing equipment, grinding workpiece support, grinding/polishing equipment, etc., can solve the problems of low production efficiency, harsh working environment, and poor consistency of processing quality, so as to prevent downturn Round, to avoid the effect of uneven processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

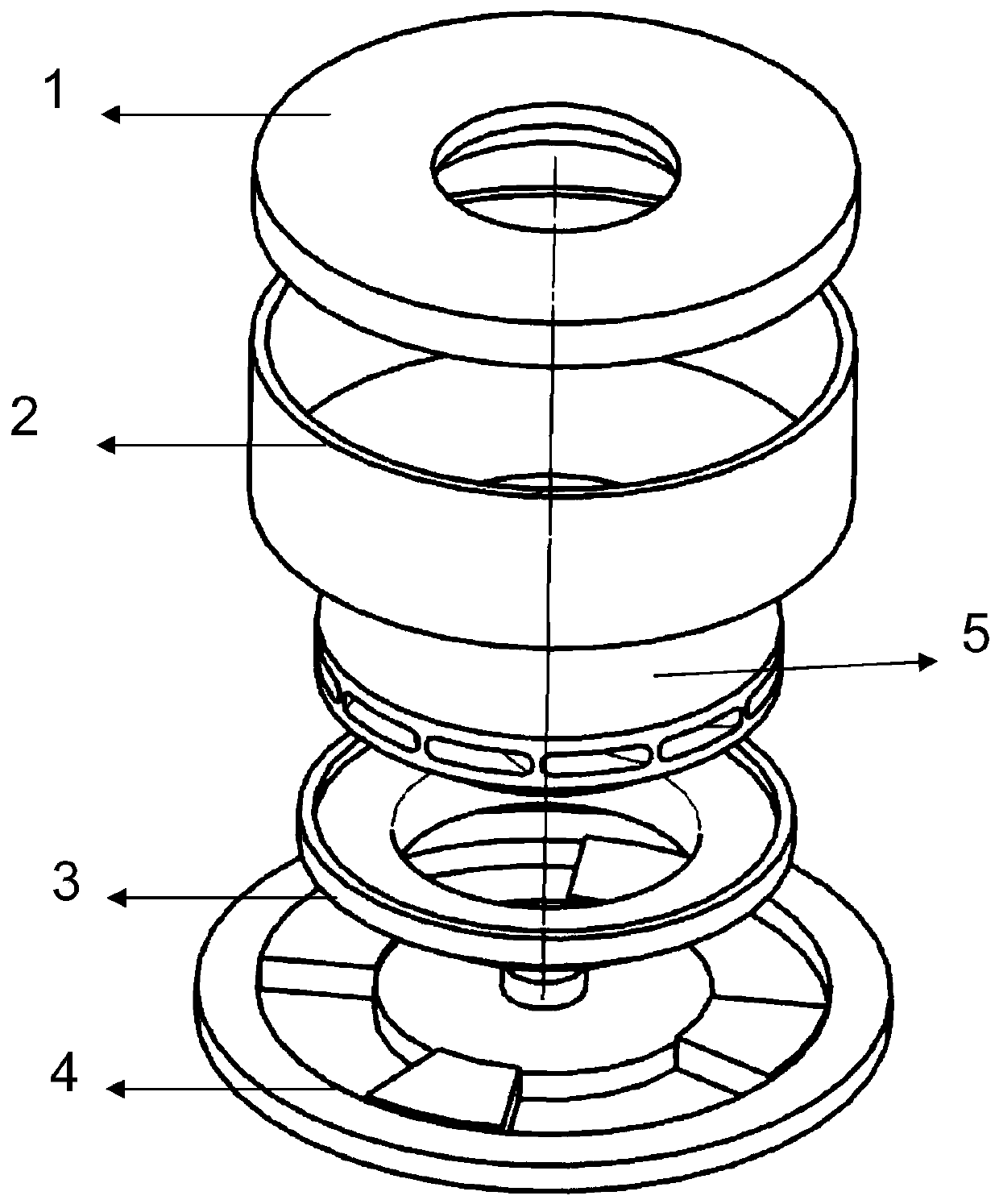

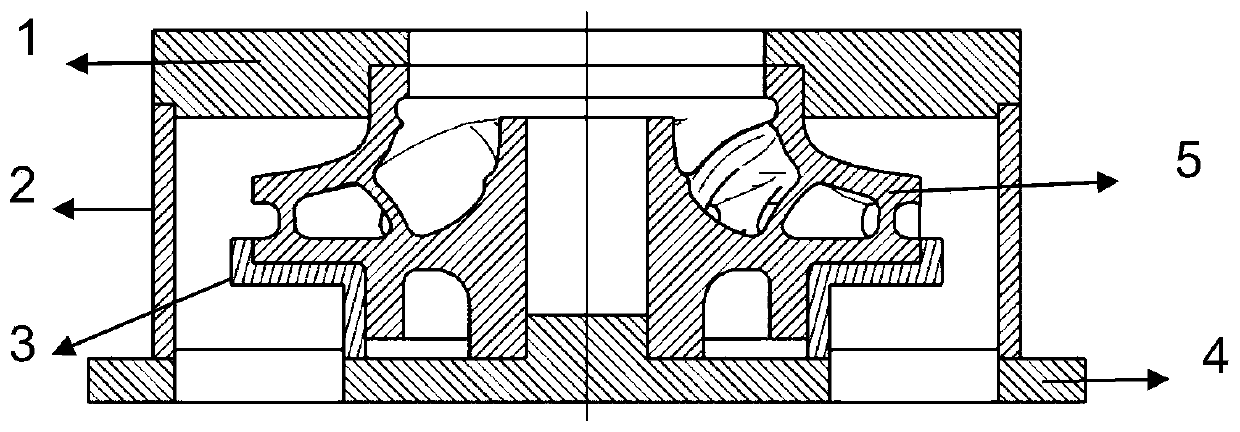

[0024] The center of the lower deflector 4 is provided with a Ф28 boss, and four 60° fan-shaped channels are arranged around it; the inner ring 3 is an L-shaped rotary body, which cooperates with the lower cover of the closed impeller part, and the entire lower cover of the closed impeller The plate is "wrapped", the upper edge is flush with the top of the impeller lower cover, and the width is 5mm, which is equivalent to extending the outline of the lower cover by 5mm in the radial direction, and transferring the rounding effect to the inner ring during abrasive flow processing upper edge.

[0025] The inner ring 3 and the closed impeller are placed at the center of the lower deflector 4. The outline size of the lower deflector 4 is Φ230mm. It is placed on the lower abrasive cylinder of the abrasive flow equipment. The boss of the lower deflector 4 and the center of the closed impeller The through hole is used to fix the parts and prevent the radial displacement of the parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com