Grinding machine and method for grinding a workpiece

A grinding machine and grinding technology, which is applied to machine tools, grinders, abrasive belt grinders and other directions suitable for grinding workpiece planes, and can solve the problems of long response time and disadvantage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

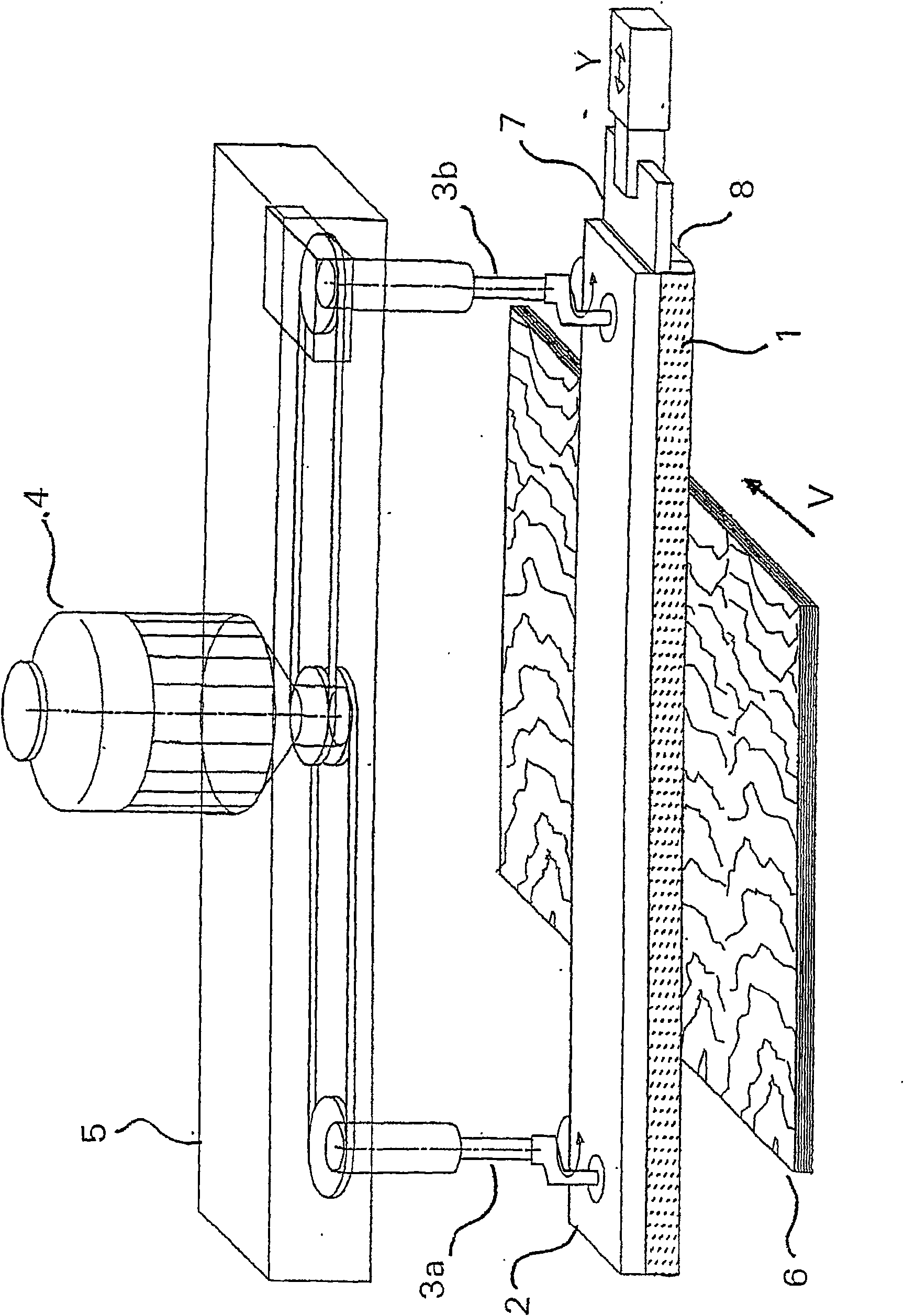

[0029] figure 1 A grinding machine according to the invention can be seen in a view in a cross-section perpendicular to the feed direction V. An abrasive element 1 in the form of an abrasive cloth or abrasive belt is mounted exchangeably on a holding device 2 . The holding device 2 itself is carried by at least one eccentric shaft 3 perpendicular to the grinding plane, ie perpendicular to the grinding surface of the abrasive element 1 , which can be driven in rotation by an electric motor 4 at a variable rotational speed. The abrasive material 1 is forced to perform a circular grinding movement in the grinding plane by the eccentric shaft 3 . The electric motor 4 itself is fixedly connected to a grinder frame 5 . The supporting device of at least one of the provided eccentric shafts 3 can move in one direction of the grinding plane, preferably in the Y direction perpendicular to the feed direction V, so as to compensate for the longitudinal expansion of the grinding machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com