Linear drive

A technology of linear drive and moving direction, which is applied in the direction of firework actuation device, transportation and packaging, seat belts in the car, etc., can solve the problems of expensive linear drive device, prolonged manufacturing time, and radial holes 26 costing work steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

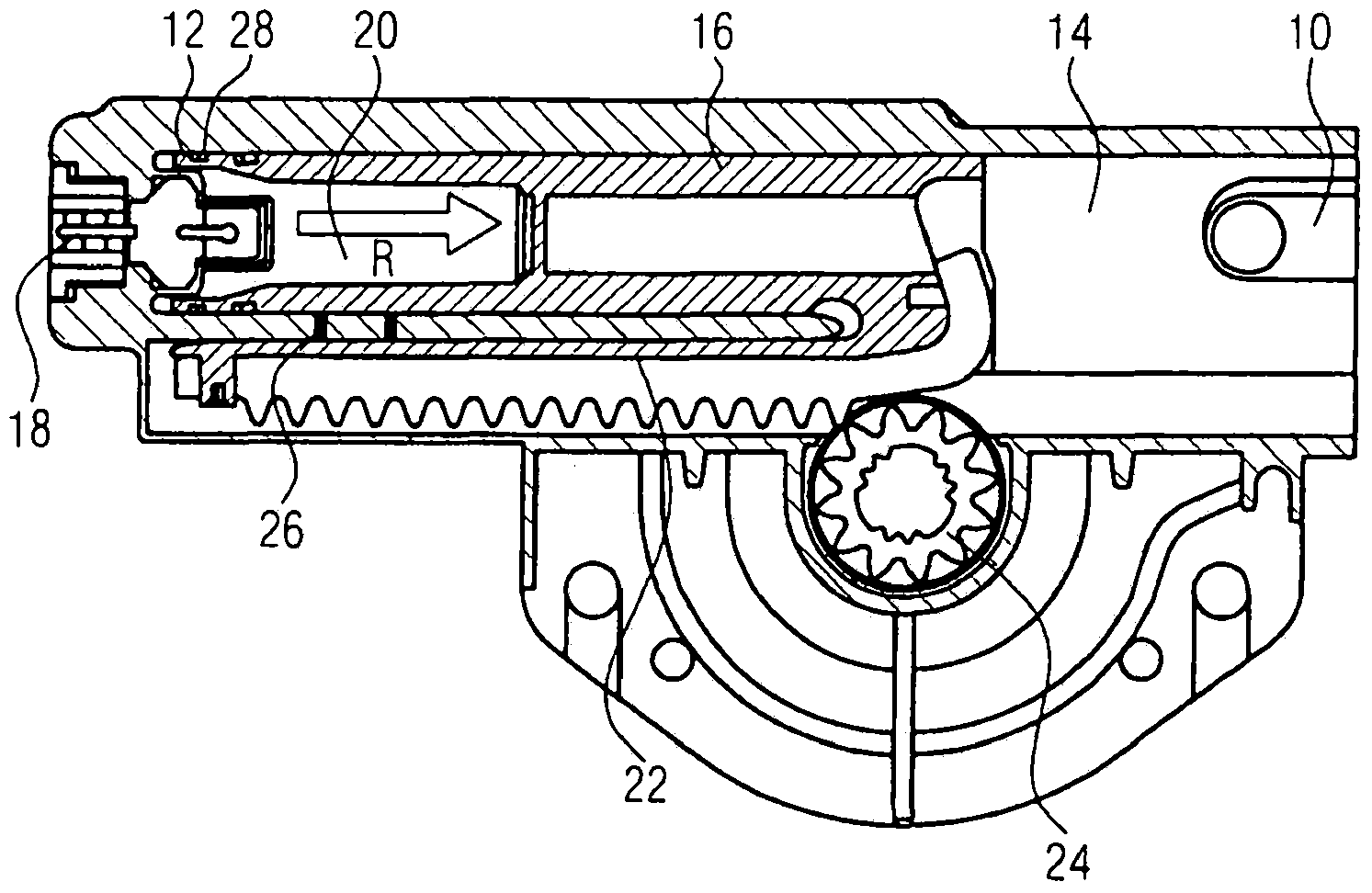

[0026] FIG. 1 , which has already been described in detail in the introduction, shows a known linear drive.

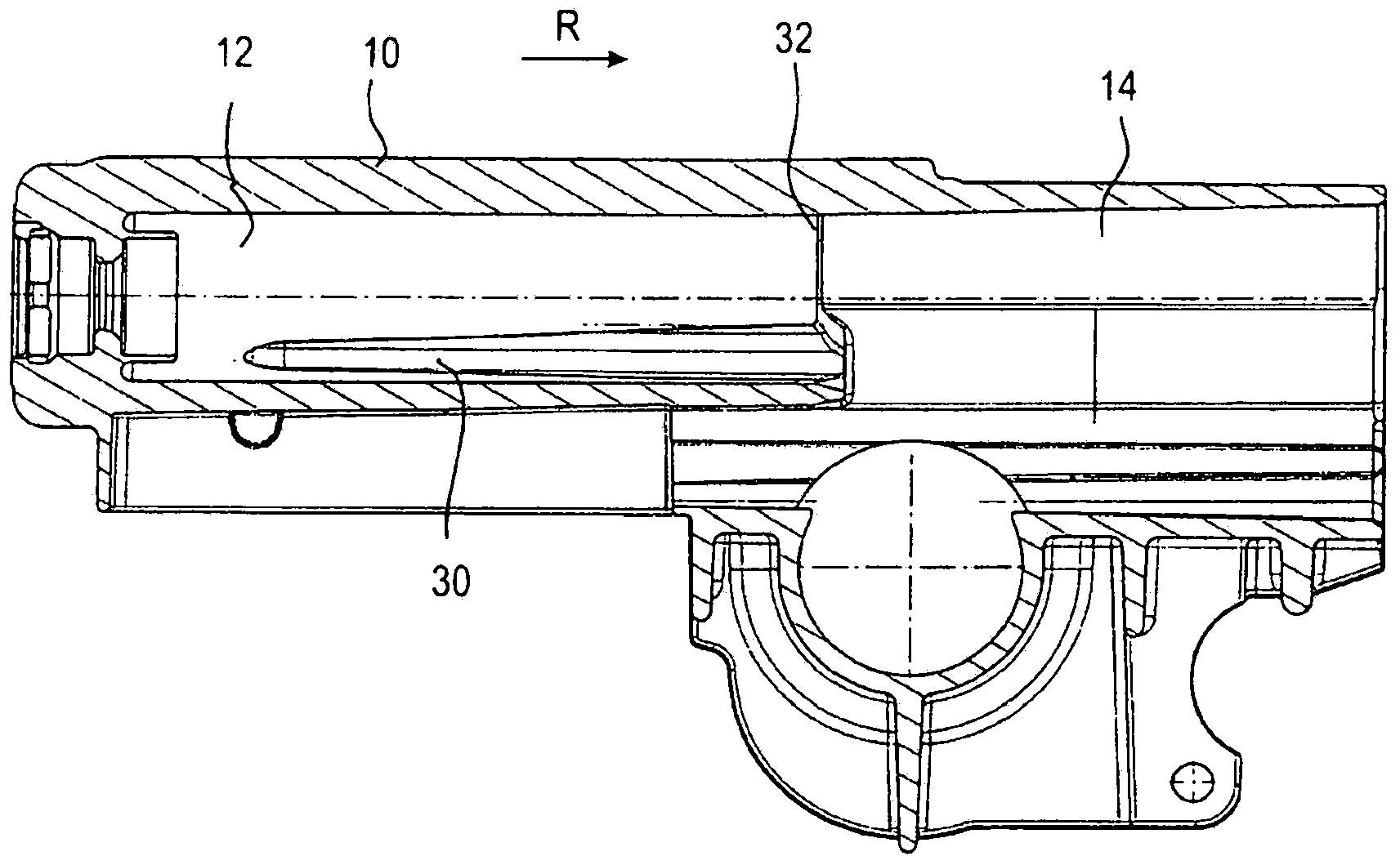

[0027] exist figure 2 The linear drive according to the invention shown in FIG. 1 differs from the linear drive shown in FIG. 1 essentially in how the gas escapes from the piston receptacle. exist figure 2 Components not shown in can be designed as shown in known linear drives. For this reason, the previously introduced reference numerals also continue to be used in figure 2 Components of the linear drive device according to the invention.

[0028] The housing 10 of the linear drive has a piston receptacle 12 and a cavity 14 adjoining directly thereto in the axial direction, into which cavity a piston element 16 , not shown here, moves as it moves in the direction of movement R . The cavity 14 is fluidically connected to the surroundings of the linear drive.

[0029] A rack 22 , likewise not shown, drives a pinion 24 , likewise not shown, which is connected to a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com