Sand filtering device for building

A filter device and construction technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of reduced performance, large impact force, and impact on service life, so as to reduce impact force, avoid impact, and prolong service life The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

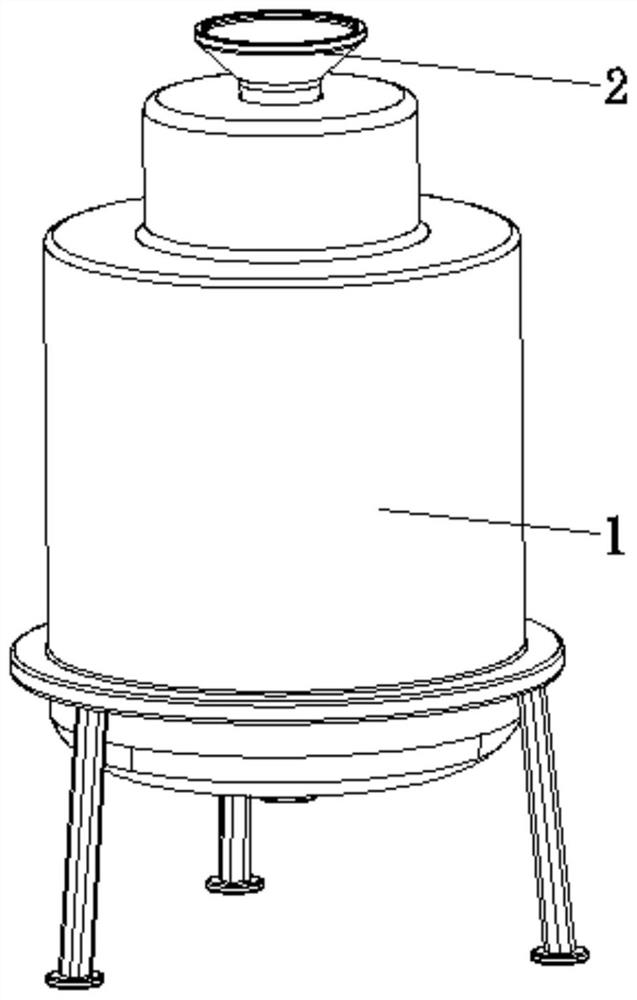

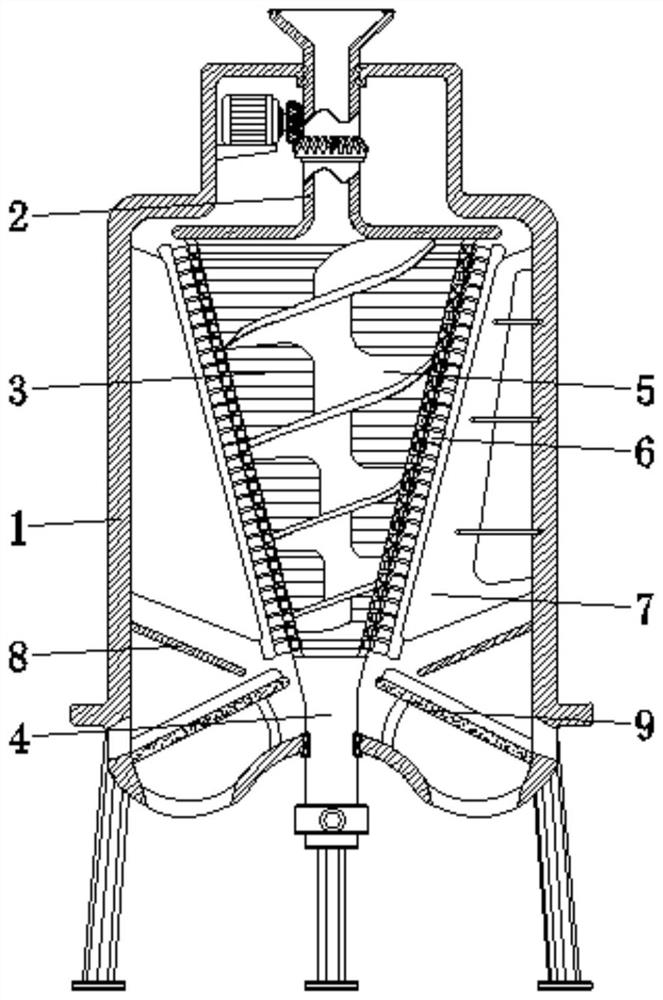

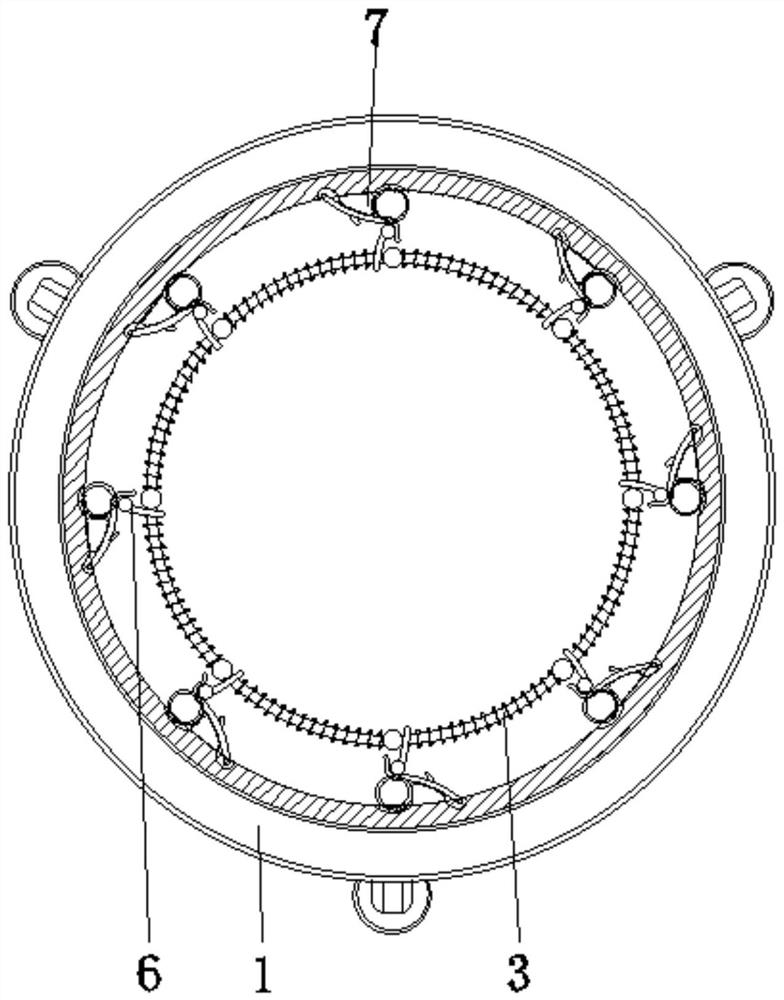

[0032] see Figure 1-7, the present invention provides a technical solution: a sand filtering device for construction, including a body 1, the inside of the body 1 is provided with a feed hopper 2, a conical screen 3, a miscellaneous storage chamber 4, a spiral blade 5, and a cleaning device 6 , pressing device 7, deflector 8, filter screen 9, feed hopper 2 is connected to the top of body 1 in rotation, conical screen 3 is fixed on the bottom of feed hopper 2, miscellaneous storage chamber 4 is fixed on conical screen 3, the surface of the miscellaneous storage chamber 4 is rotationally connected with the bottom of the body 1, the spiral blade 5 is located inside the conical screen 3 and fixed on the bottom of the feed hopper 2, and the cleaning device 6 is arranged on the surface of the conical screen 3 , the pressing device 7 is arranged on the inner wall of the body 1, the deflector 8 is fixed on the inner wall of the body 1 and close to the bottom position, and the filter ...

Embodiment example 2

[0036] The pressing device 7 is provided with a pressing plate device 71, an arc-shaped elastic member 72, and an elastic air bag 73. The end of the pressing plate device 71 is rotatably connected with the inner wall of the body 1. Between the corresponding two sides, the elastic airbag 73 is arranged between the surface of the pressing plate device 71 and the inner wall of the machine body 1 and close to the arc-shaped elastic member 72. When the scraper device 61 compresses the return spring 63 to the limit , at this time, the thrust of the spherical push bar 62 is greater than the elastic force of the arc-shaped elastic member 72, and the pressing plate device 71 is quickly pressed in the opposite direction, and the arc-shaped elastic member 72 is deformed by the pressure, so that the pressing plate device 71 and the arc-shaped elastic member 72 simultaneously The elastic airbag 73 is pressed, so that the internal gas is ejected to the position of the scraper device 61 insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com