Dedusting unit

A unit and dust cage technology, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of dust removal system not working properly, easy hardening of filter material, air permeability rate, and increased resistance of dust removal equipment, etc., to achieve small space , Simple processing, low cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

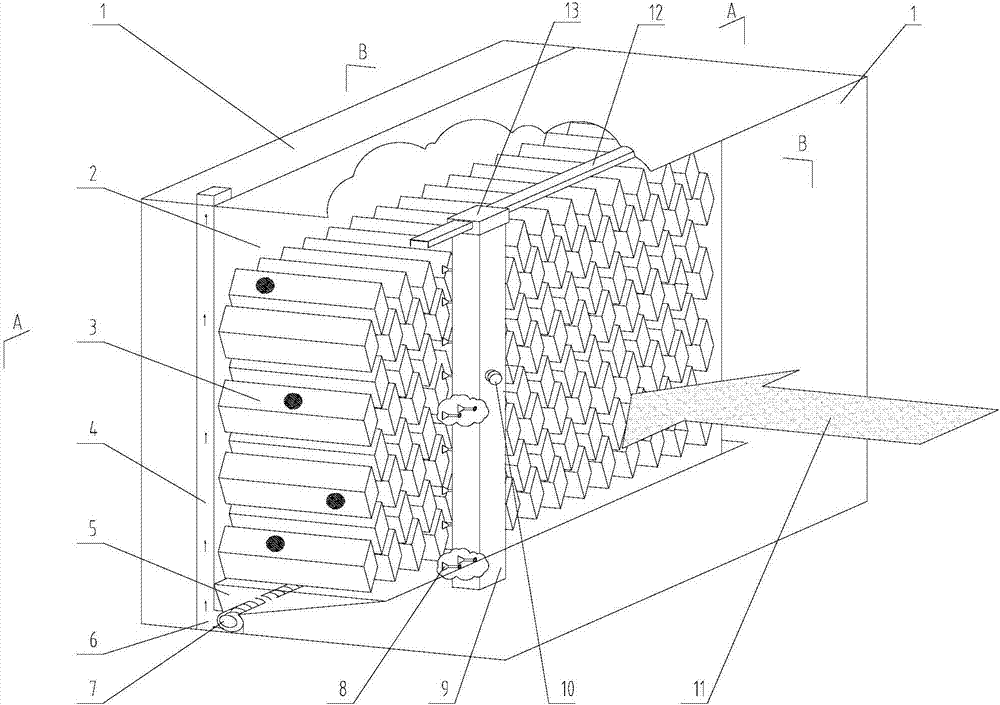

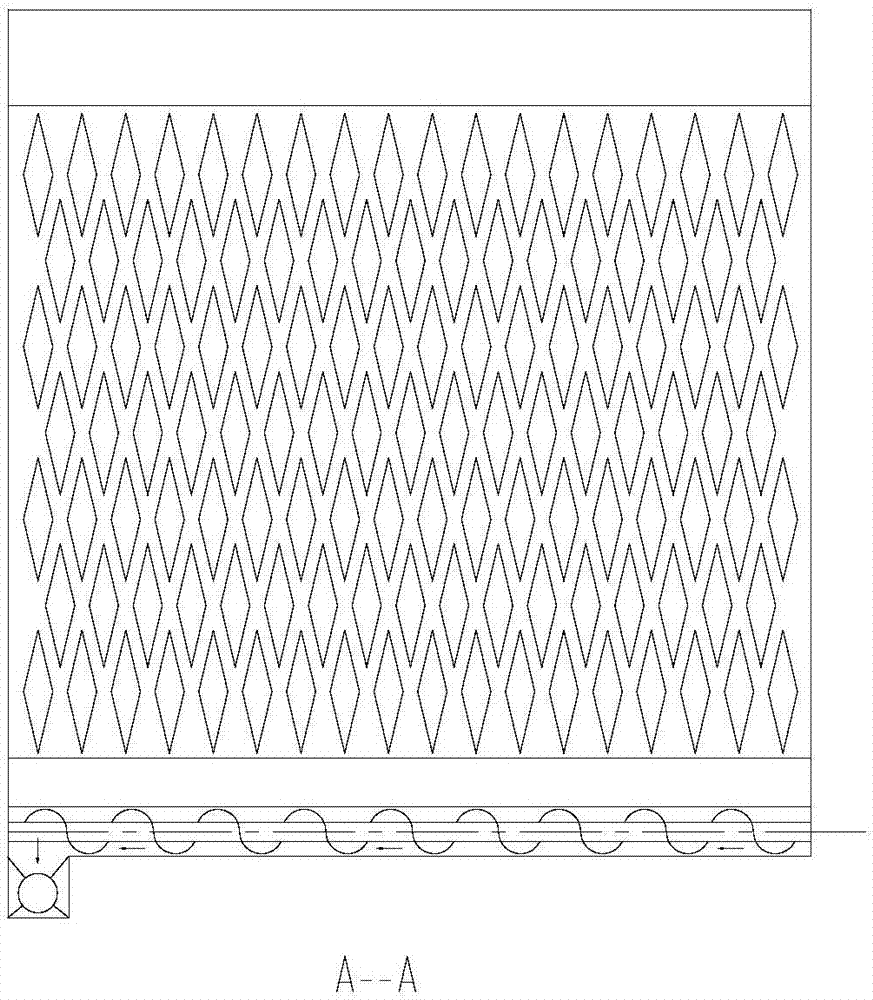

[0020] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. Such as Figure 1-Figure 4 As shown, the dust removal unit is composed of a sealed box 1 with an inspection door, a diamond-shaped small dust cage filter unit 3 arranged in an array on one side of the sealed box 1, a walking blowing box 9, a blowing nozzle 8, and a walking mechanism 13, the dust collecting bucket 5 forms. The diamond-shaped small dust cage filter unit can be set to 8 layers, 17-18 rows, a total of 70 diamond-shaped small dust cages are fixed on the partition 2, and communicate with the diamond-shaped holes on the partition 2, and the partition 2 is fixed on the sealed box 1 , the other end of the diamond-shaped small dust cage filter unit is directly fixed on the partition. The filter material on the outer surface of the diamond-shaped small dust cage filter unit is a new type of nano-no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com