Preliminary ore beneficiation equipment after rare earth mining in mine lot

A kind of mineral processing equipment and rare earth technology, which is applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of difficulty in reducing air dust content, slow rare earth screening rate, etc., and achieve the effect of reducing the probability of pneumoconiosis and reducing dust content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

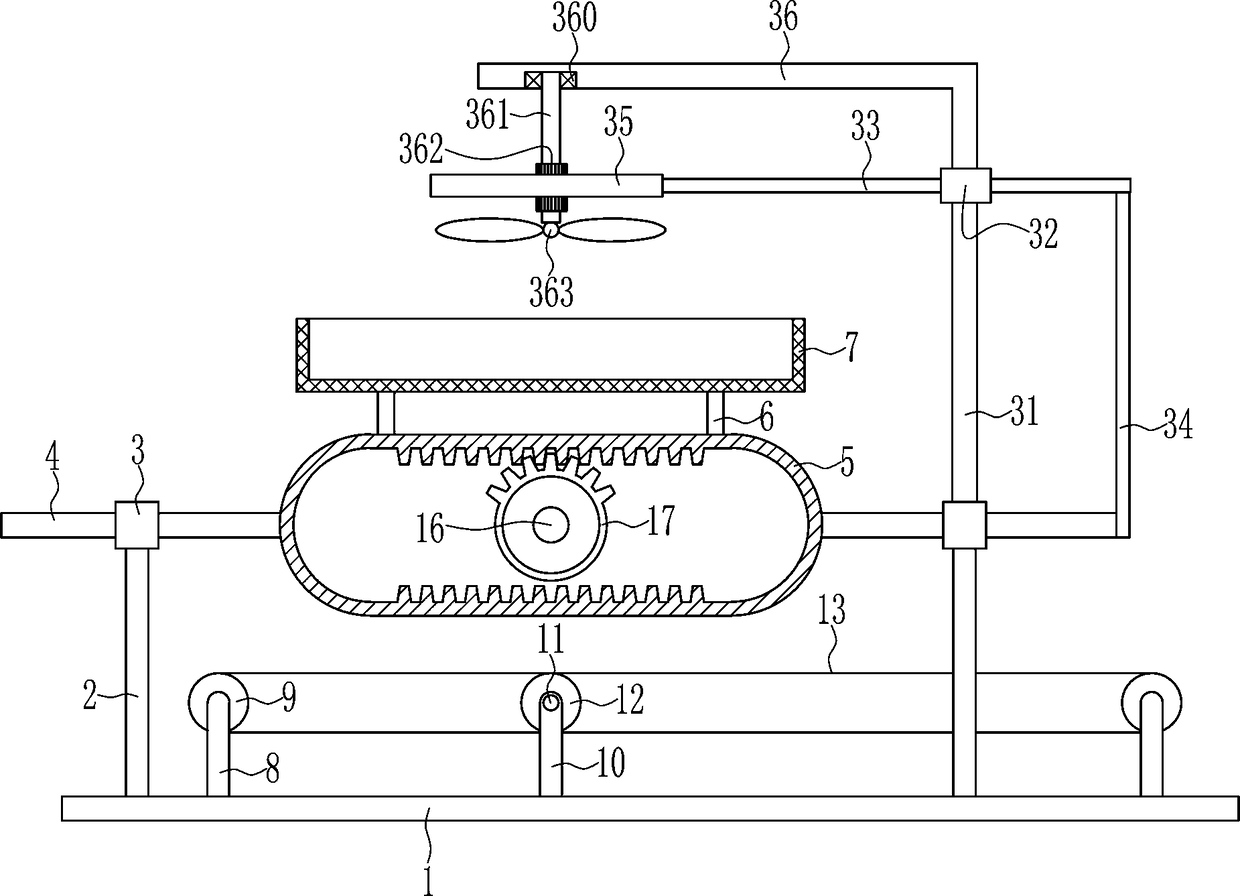

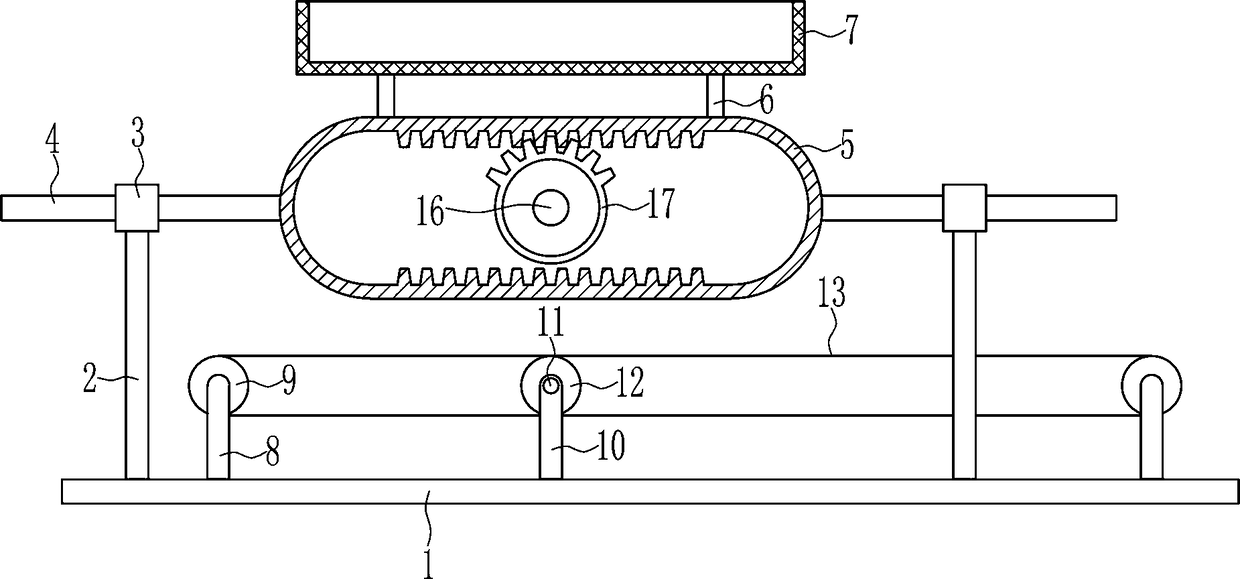

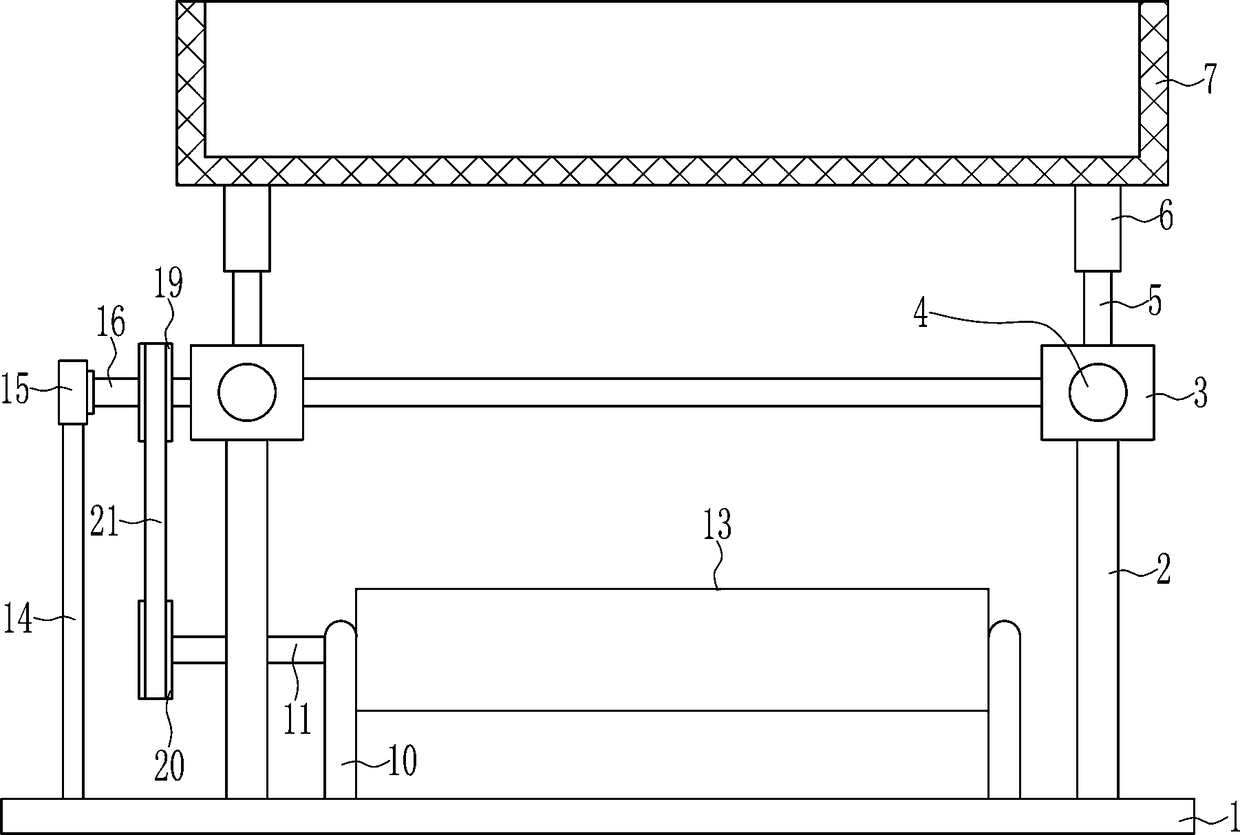

[0024] A primary beneficiation equipment after rare earth mining in a mining area, such as Figure 1-5 As shown, it includes a first mounting plate 1, a first pole 2, a first guide sleeve 3, a first guide pole 4, a rack frame 5, a second pole 6, a filter frame 7, a third pole 8, The first driven wheel 9, the first bearing housing 10, the first rotating shaft 11, the second driven wheel 12, the conveyor belt 13, the fourth pole 14, the motor 15, the second rotating shaft 16, the sector gear 17, the first pulley 19, the second Two belt pulleys 20 and flat belts 21, the first mounting plate 1 top, left and right sides, front and rear sides are all symmetrically provided with the first pole 2, and the top of the first pole 2 is provided with the first guide sleeve 3, and the first guide sleeve 3 is equipped with The first guide rod 4 is slidingly connected, and the inner ends of the first guide rods 4 on the left and right sides are provided with a rack frame 5, and the tops of th...

Embodiment 2

[0026] A primary beneficiation equipment after rare earth mining in a mining area, such as Figure 1-5 As shown, it includes a first mounting plate 1, a first pole 2, a first guide sleeve 3, a first guide pole 4, a rack frame 5, a second pole 6, a filter frame 7, a third pole 8, The first driven wheel 9, the first bearing housing 10, the first rotating shaft 11, the second driven wheel 12, the conveyor belt 13, the fourth pole 14, the motor 15, the second rotating shaft 16, the sector gear 17, the first pulley 19, the second Two belt pulleys 20 and flat belts 21, the first mounting plate 1 top, left and right sides, front and rear sides are all symmetrically provided with the first pole 2, and the top of the first pole 2 is provided with the first guide sleeve 3, and the first guide sleeve 3 is equipped with The first guide rod 4 is slidingly connected, and the inner ends of the first guide rods 4 on the left and right sides are provided with a rack frame 5, and the tops of th...

Embodiment 3

[0029] A primary beneficiation equipment after rare earth mining in a mining area, such as Figure 1-5 As shown, it includes a first mounting plate 1, a first pole 2, a first guide sleeve 3, a first guide pole 4, a rack frame 5, a second pole 6, a filter frame 7, a third pole 8, The first driven wheel 9, the first bearing housing 10, the first rotating shaft 11, the second driven wheel 12, the conveyor belt 13, the fourth pole 14, the motor 15, the second rotating shaft 16, the sector gear 17, the first pulley 19, the second Two belt pulleys 20 and flat belts 21, the first mounting plate 1 top, left and right sides, front and rear sides are all symmetrically provided with the first pole 2, and the top of the first pole 2 is provided with the first guide sleeve 3, and the first guide sleeve 3 is equipped with The first guide rod 4 is slidingly connected, and the inner ends of the first guide rods 4 on the left and right sides are provided with a rack frame 5, and the tops of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com