Novel carbon brush structure

A carbon brush, a new type of technology, applied in current collectors, electrical components, rotating current collectors, etc., can solve problems such as easy sparks, poor heat dissipation, offset of commutator and carbon rods, etc., and achieve the effect of easy heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

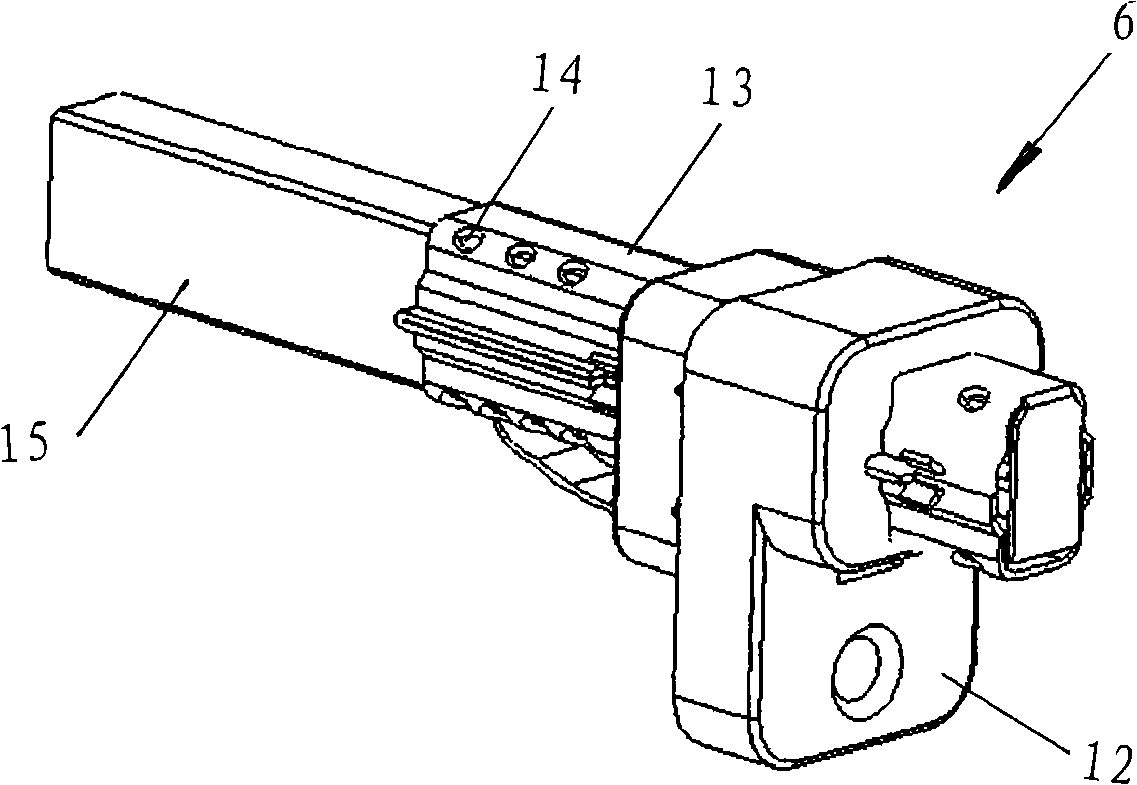

[0032] Below, a kind of novel carbon brush structure of the present invention is described in detail with reference to accompanying drawing and embodiment:

[0033] The components of the present invention and the existing carbon brushes with the same structure adopt the same symbols.

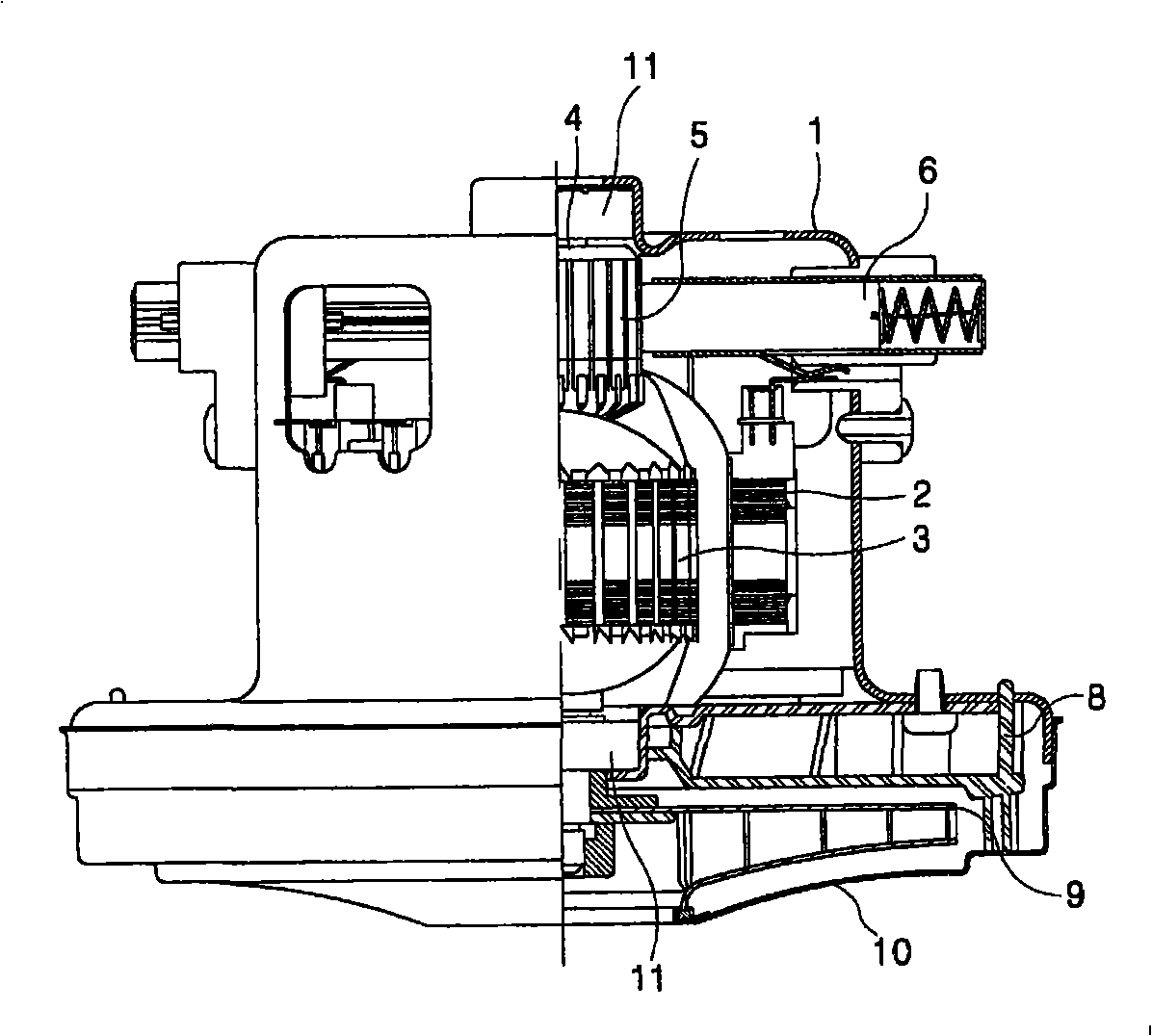

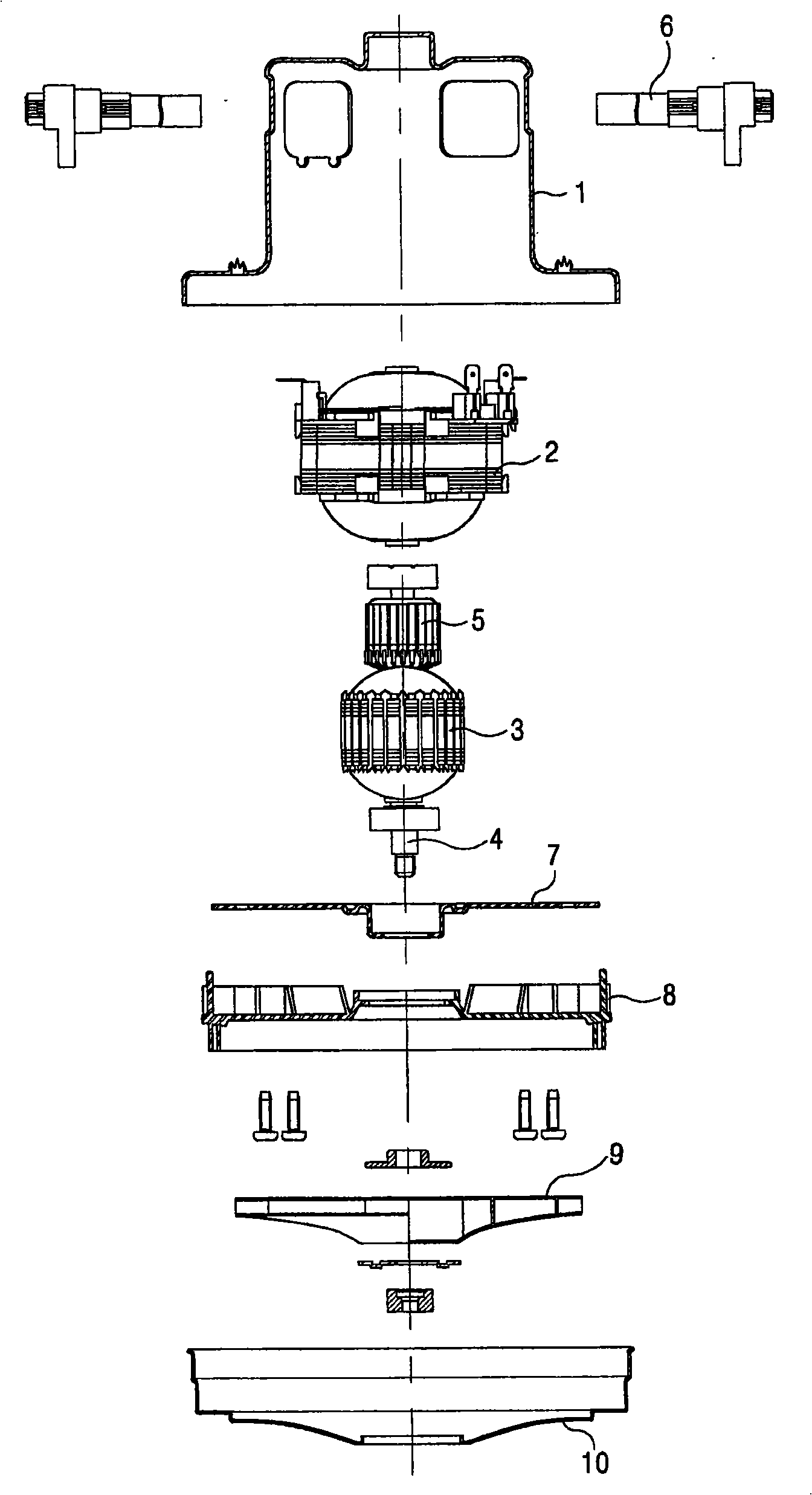

[0034] Such as figure 1 As shown in ~8, the single-phase motor includes a casing 1 with openings, a stator 2 is fixed inside the casing 1, and a rotor that can rotate at a certain distance from the inner peripheral surface of the stator 2 is provided on the inside of the stator 2. 3. A rotating shaft 4 is installed at the center of the rotor 3 . Bearings 11 are arranged on both ends of the rotating shaft 4, and the bearings 11 are fixed by the casing 1 and the wind cover 8 to make the rotating shaft 4 rotate.

[0035] On the upper side of the rotor 3, there is a commutation rectifier 5 that converts the supplied AC current into a DC current. On both sides of the commutation rectifier 5, there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com