Powder sealing valve

A technology for sealing valves and powders, which is applied in the direction of lifting valves, valve devices, and cleaning methods using gas flow. The effect of solving the sticky problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

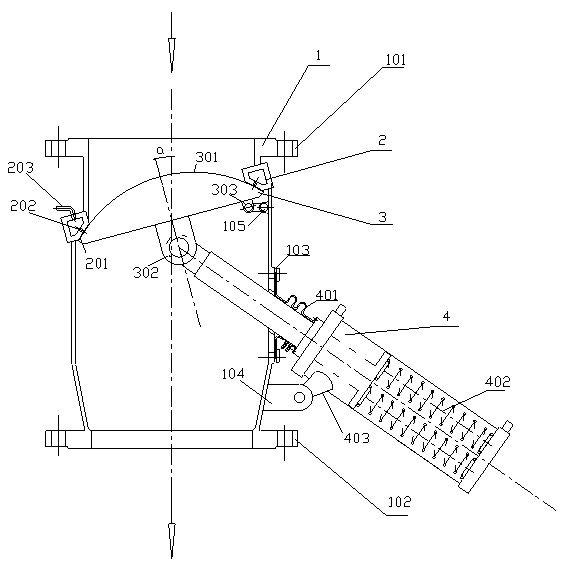

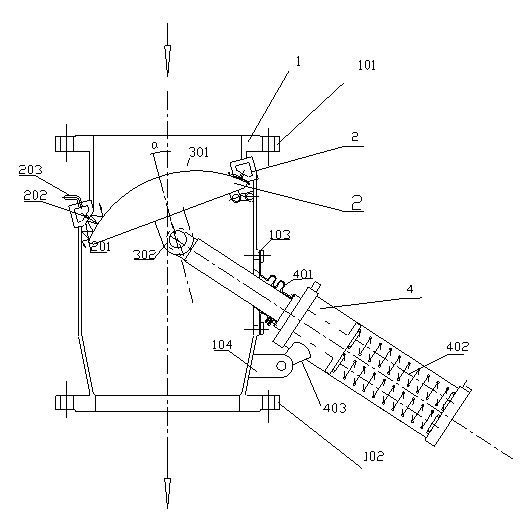

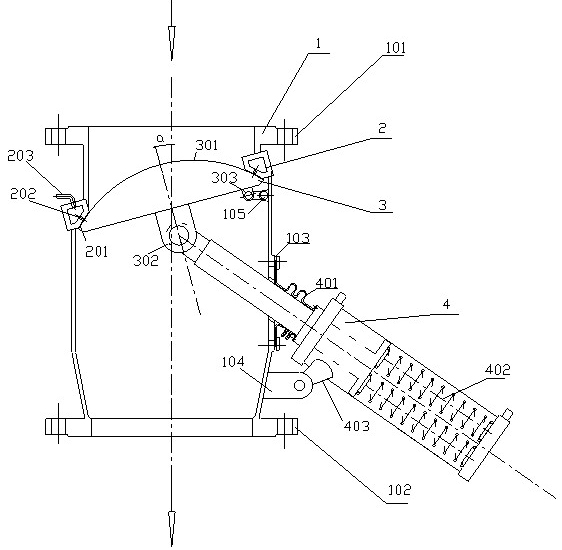

[0019] Below in conjunction with accompanying drawing, the present invention is described in detail:

[0020] Such as figure 1 As shown, the valve of the present invention includes: a valve body 1, a cleaning mechanism 2, a valve core 3, and an actuator 4; standard inlet and outlet flanges 101, 102 are set on the valve body 1; flanges 103 are set on one side of the valve body, The hole in the center of the flange is used as the movable port of the cylinder shaft, and the diameter of the inner hole shall not restrict the movement of the cylinder shaft; the lug 104 is set at the lower part of the valve body as the supporting point of the actuator, and the cylinder of the actuator is connected to the support through the fixing piece 403. On the ear 104; the shaft sleeve 105 is set in the valve body as the connection point of the valve core.

[0021] The main body of the cleaning mechanism 2 is an air chamber, which is a circular hollow cavity for storing and distributing gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com