Patents

Literature

58results about How to "Smooth material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

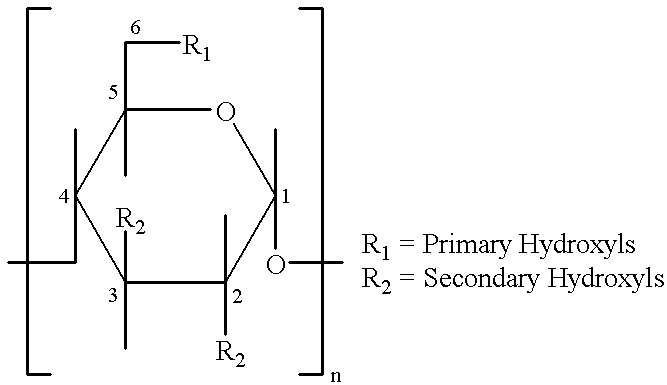

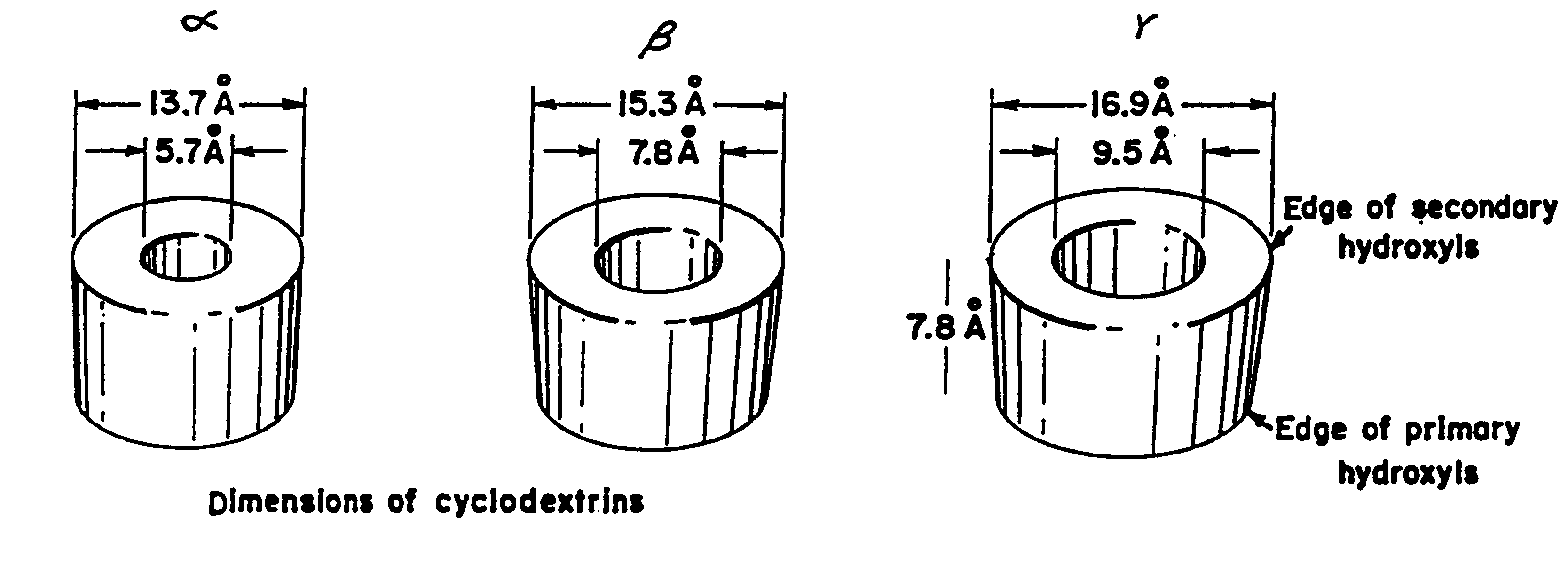

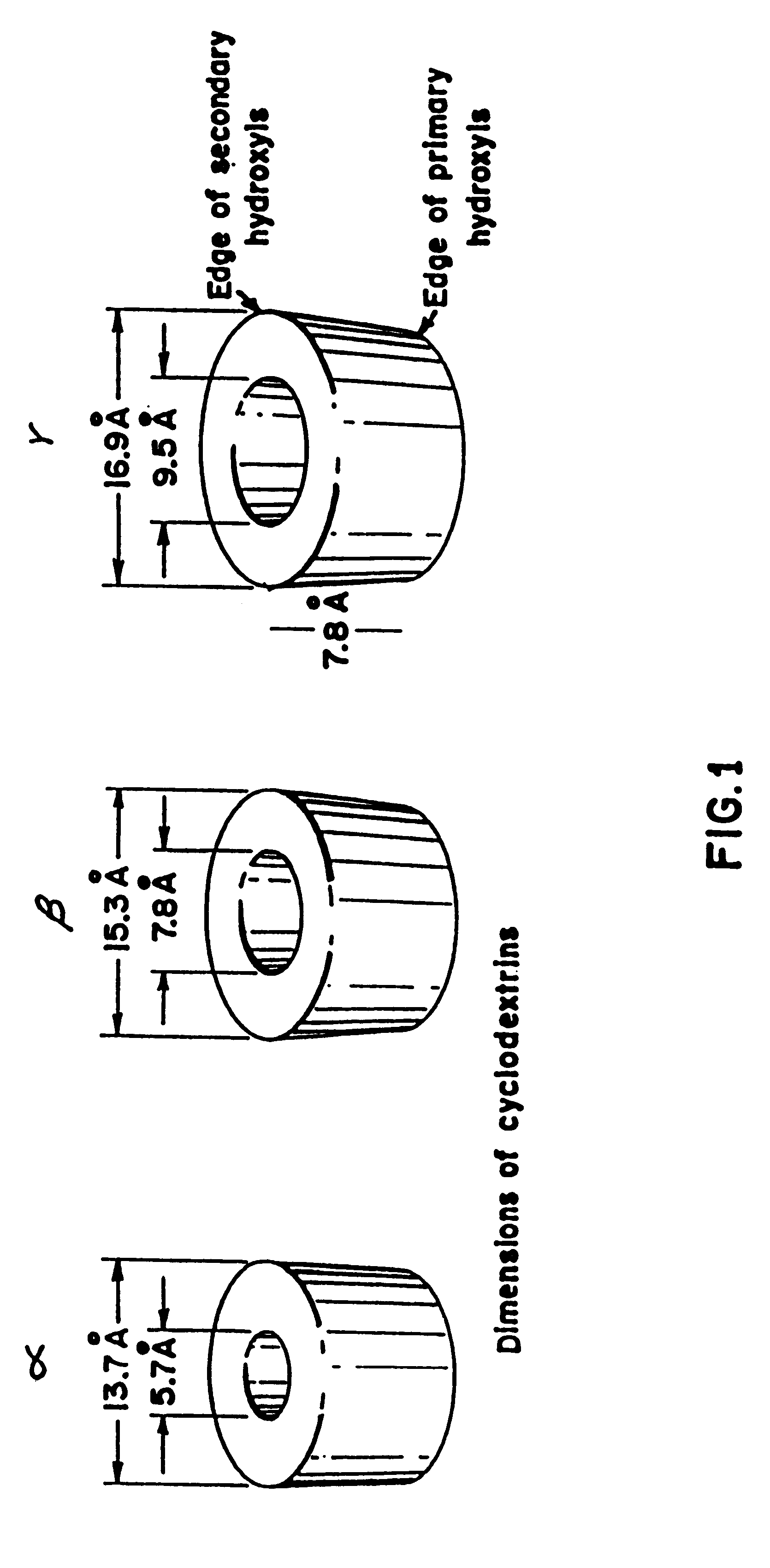

Barrier material comprising a thermoplastic and a compatible cyclodextrin derivative

InactiveUS6218013B1Easy to derivatizeImprove surface propertiesSemi-permeable membranesFlexible coversThermoplasticMoisture

A barrier film composition can comprise a thermoplastic web comprising a thermoplastic polymer and a dispersed cyclodextrin composition having substituents that compatibilize the cyclodextrin in the film. The thermoplastic / cyclodextrin film obtains substantial barrier properties from the interaction between the substituted cyclodextrin in the film material with a permeant. The substituents on the cyclodextrin molecule causes the cyclodextrin to be dispersible and stable in the film material resulting in an extrudable thermoplastic. Such materials can be used as a single layer film material, a multilayer film material which can be coated or uncoated and can be used in structural materials wherein the thermoplastic is of substantial thickness resulting in structural stiffness. The cooperation between the cyclodextrin and the thermoplastic polymer provides barrier properties to a web wherein a permeant can be complexed or entrapped by the cyclodextrin compound and held within the film preventing the permeant from passing through the film into the interior of a film, an enclosure or container. The permeant can comprise a variety of well known materials such as moisture, aliphatic or aromatic hydrocarbons, monomer materials, off flavors, toxic compounds etc.

Owner:CELLRESIN TECH

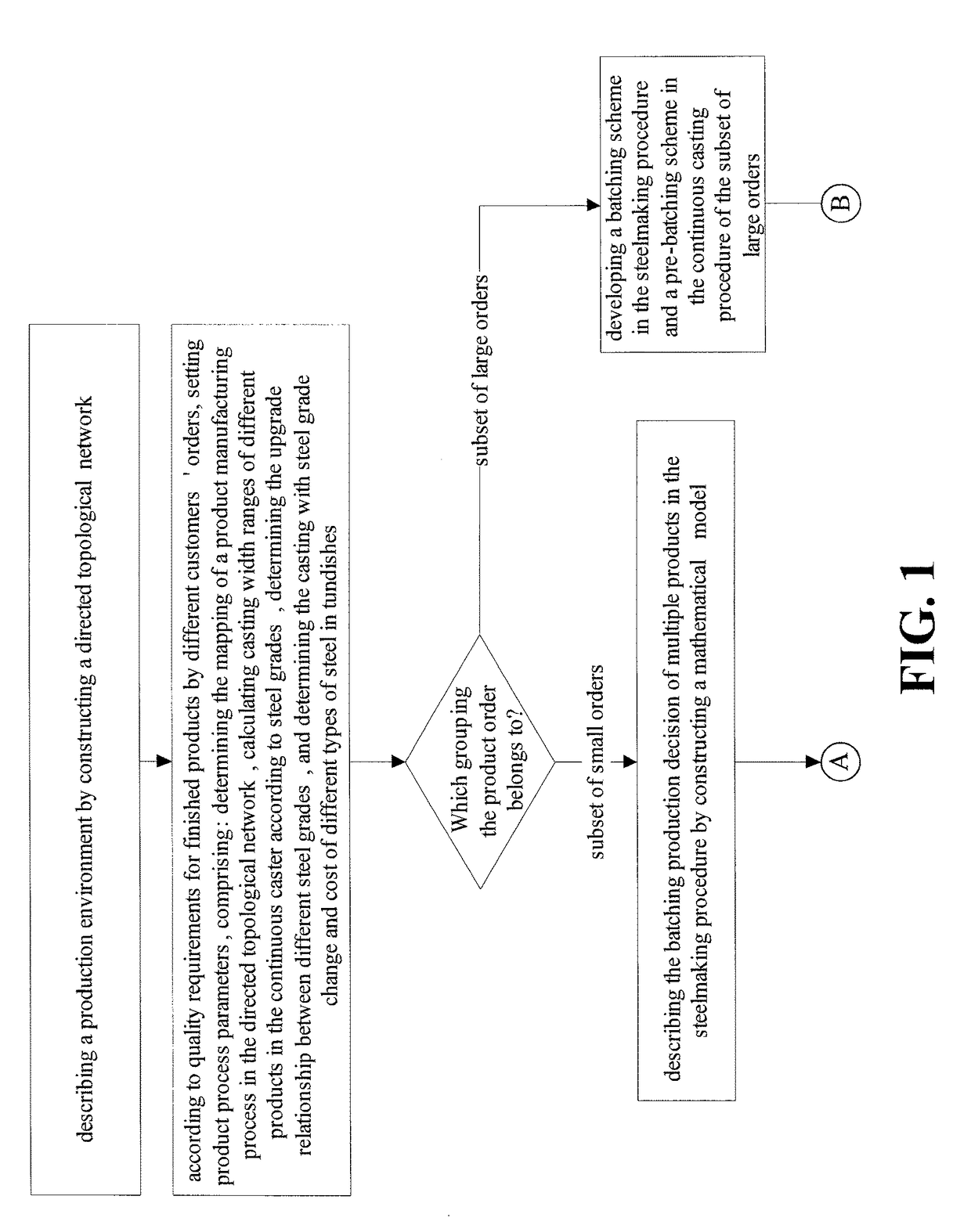

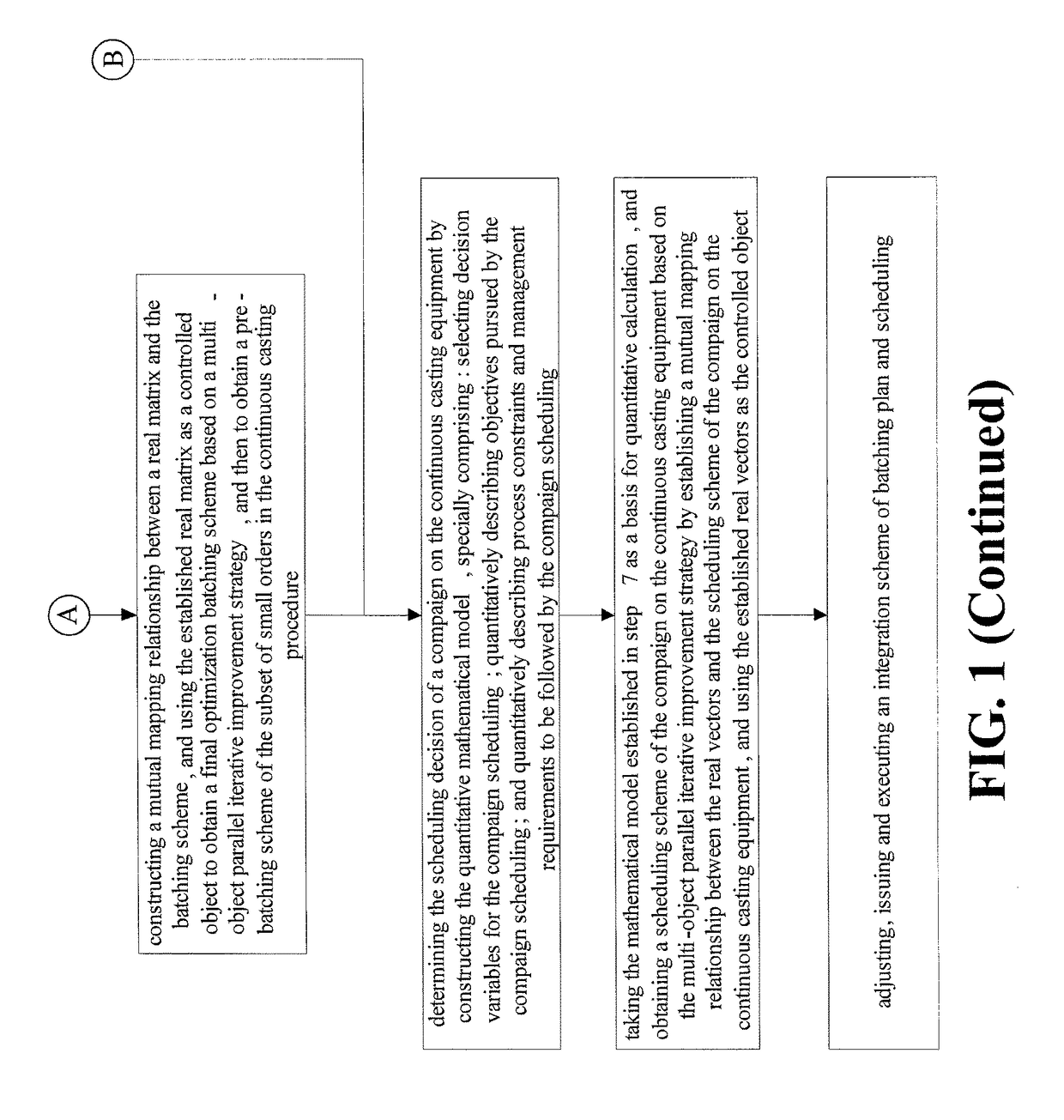

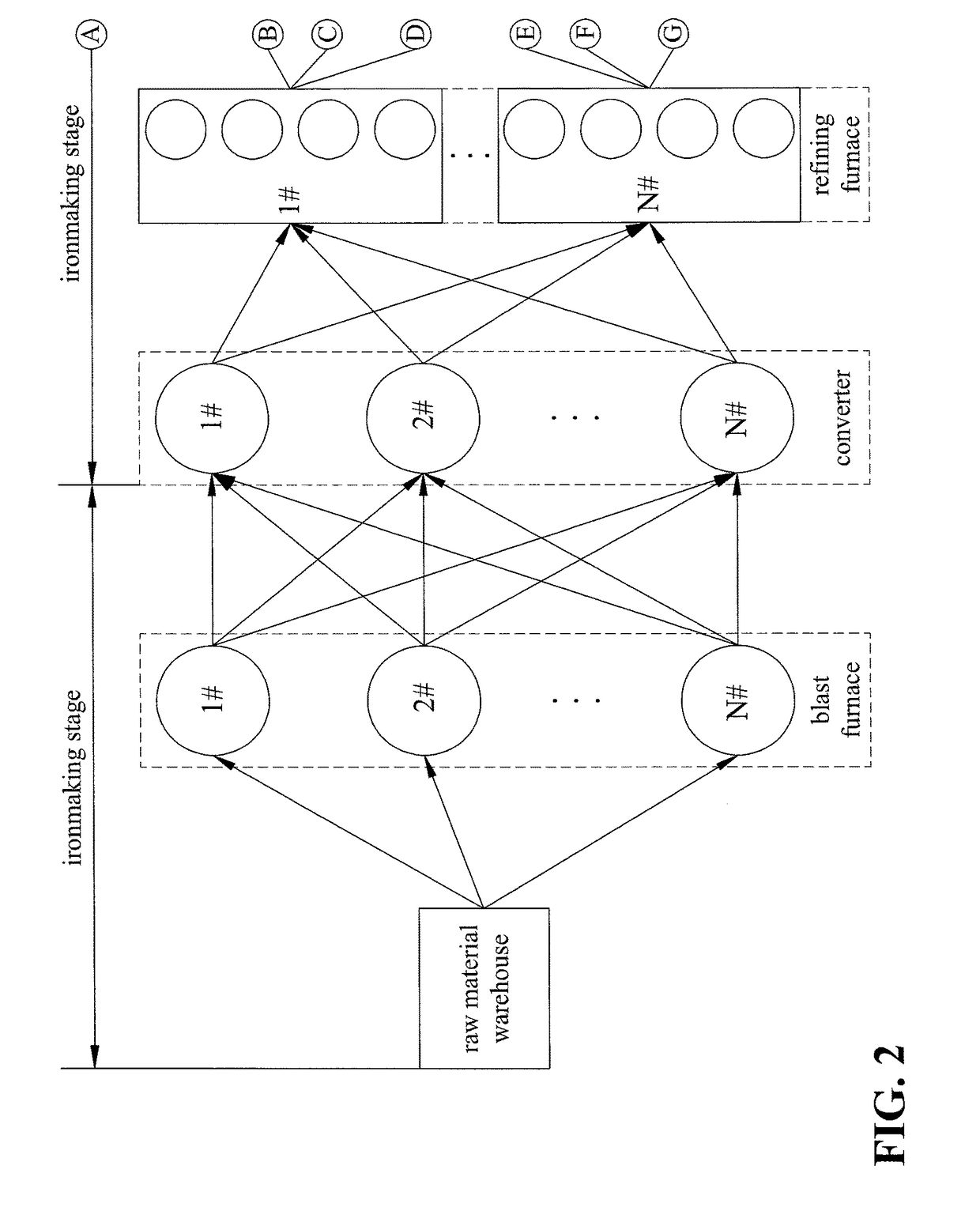

Method of batching and scheduling for steelmaking production with plant-wide process consideration

ActiveUS20170316131A1Improve product qualityImprove material yieldHot-dipping/immersion processesData processing applicationsSteelmakingLogistics management

Provided is a method of batching and scheduling for steelmaking production with plant-wide process consideration, including the steps of: establishing a mathematical model for quantitatively describing the decision problem of batching on steelmaking and continuous casting procedures; starting from the production capacity balance between parallel equipment of the same procedure, and material flow convergence between upstream and downstream procedures, establishing a model for the assignment and sequencing of batches on continuous casting equipment and the time dimension; integrating the batching plan and the production scheduling scheme, issuing the batching plan and the production scheduling scheme integrated to all production and manufacturing units at the steelmaking stage. The present invention improves product quality, increases the material yield, resource utilization rate and equipment operation efficiency, realizes load balance on parallel equipment and smooth material linkage between serial equipment, and reduces the material flow transportation jam, downstream equipment waiting time and inventory.

Owner:NORTHEASTERN UNIV

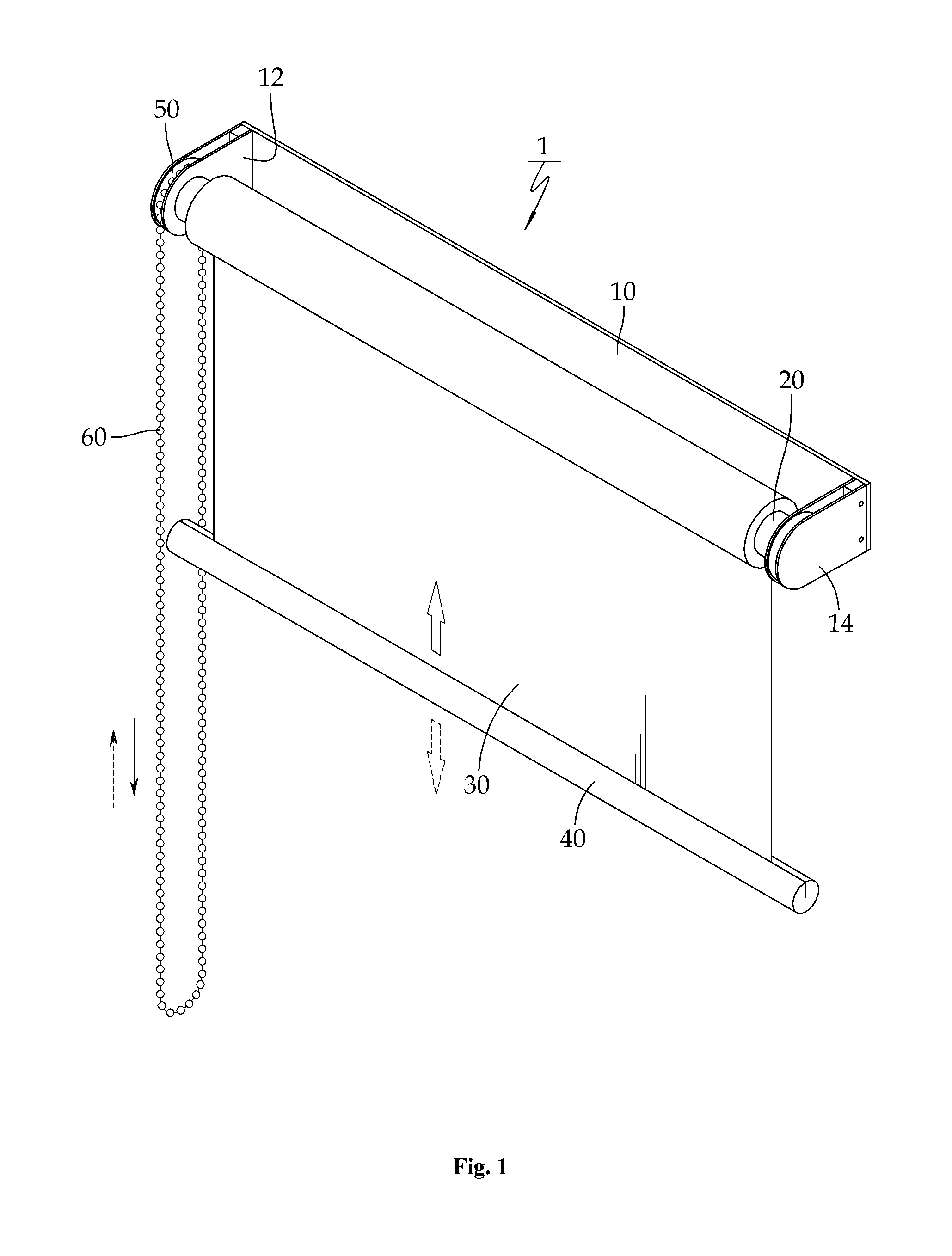

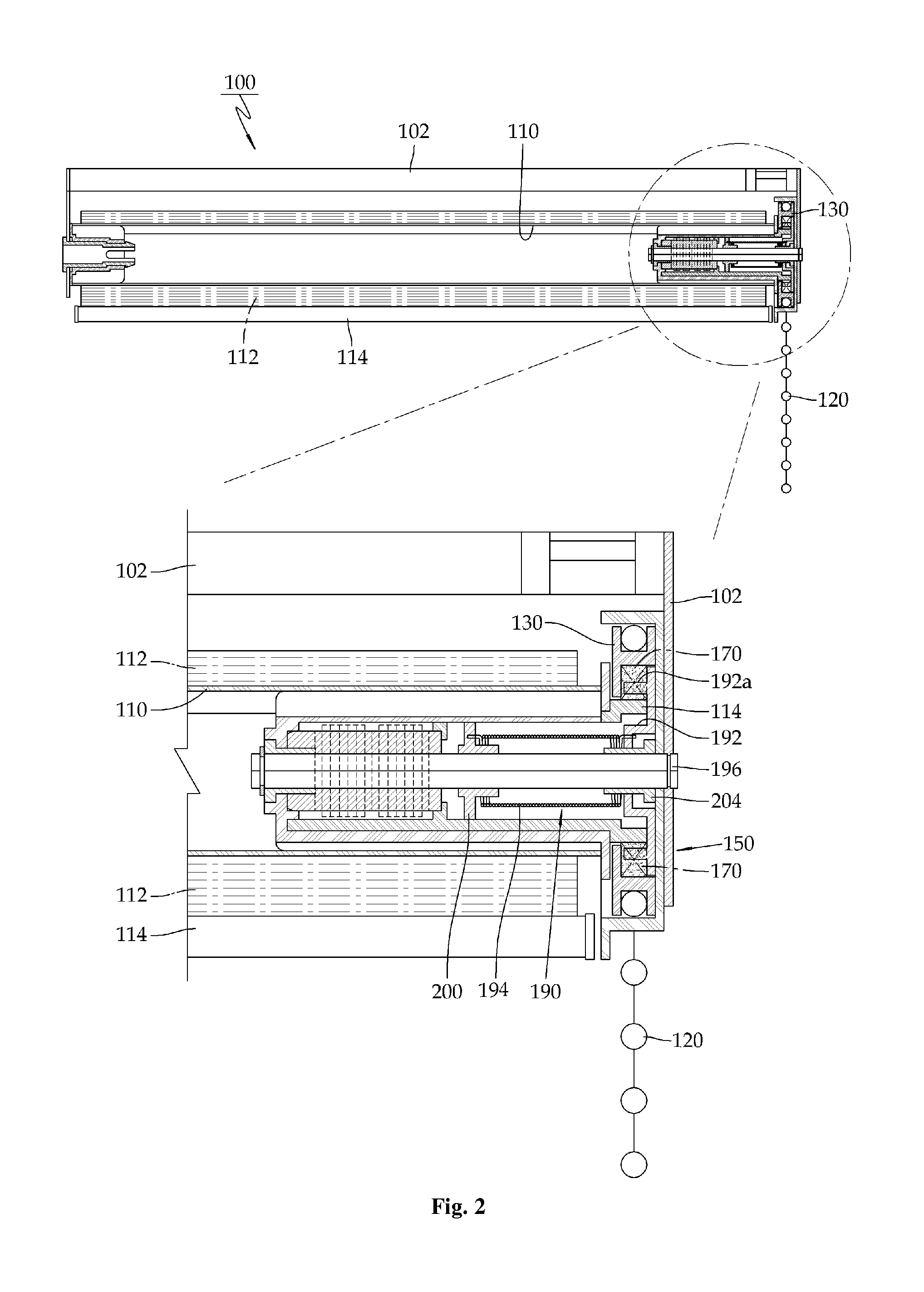

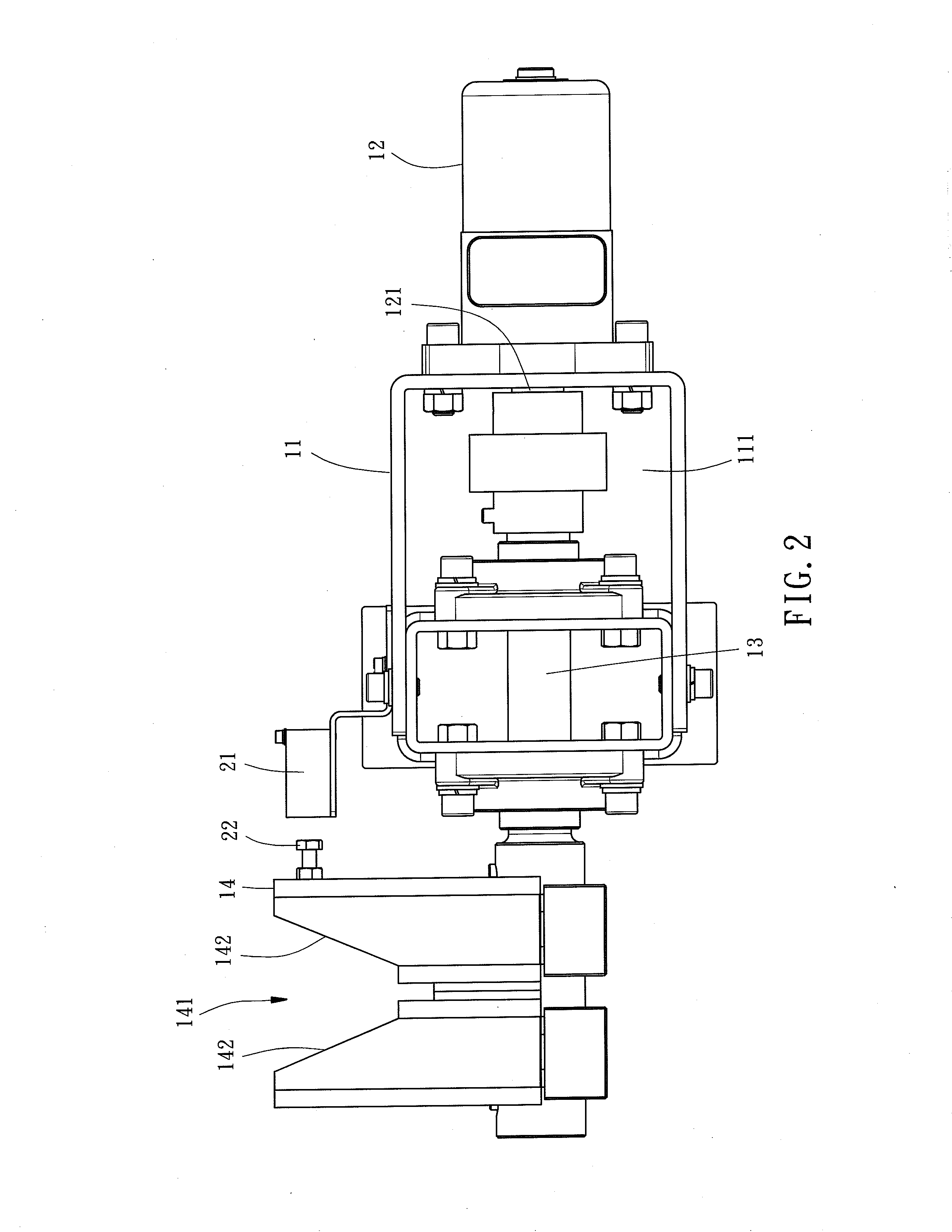

Roll blind having noiseless bidirectional clutch

InactiveUS20130255894A1Shorten the lengthSmooth materialScreensShutters/ movable grillesDrive shaftSprocket

A roll blind includes: a safety cord connected to and wound around a chain pulley adapted to rotate the winding rod, the safety cord having a separated lower end so that one side defines a lowering cord for pulling down the blind material and the other side defines a raising cord for rolling up the blind material; a bidirectional clutch unit adapted to raise / lower the blind material, the bidirectional clutch unit being positioned between the chain pulley and a driving shaft of the winding rod, the bidirectional clutch unit having bidirectional protrusions formed on an inner peripheral surface of the chain pulley at an identical interval in a circumferential direction so that, when the lowering or raising cord is pulled, the winding rod rotates together with the chain pulley, the bidirectional clutch unit having a number of rollers positioned between respective bidirectional protrusions on an outer peripheral surface of the driving shaft of the winding rod at an identical interval in the circumferential direction; and a return operation unit having an elastic restoration member adapted to accumulate elastic restoration force, when pulling of the lowering or raising cord rotates the chain pulley, through a return pulley rotating together with the chain pulley, the return pulley rotating the chain pulley backwards around the driving shaft of the winding rod, when the lowering or raising cord is released from the pulled condition, using the elastic restoration force accumulated in the elastic restoration member so that, without displacement of the blind material, the safety cord returns to the original position.

Owner:KIM JUNG MIN

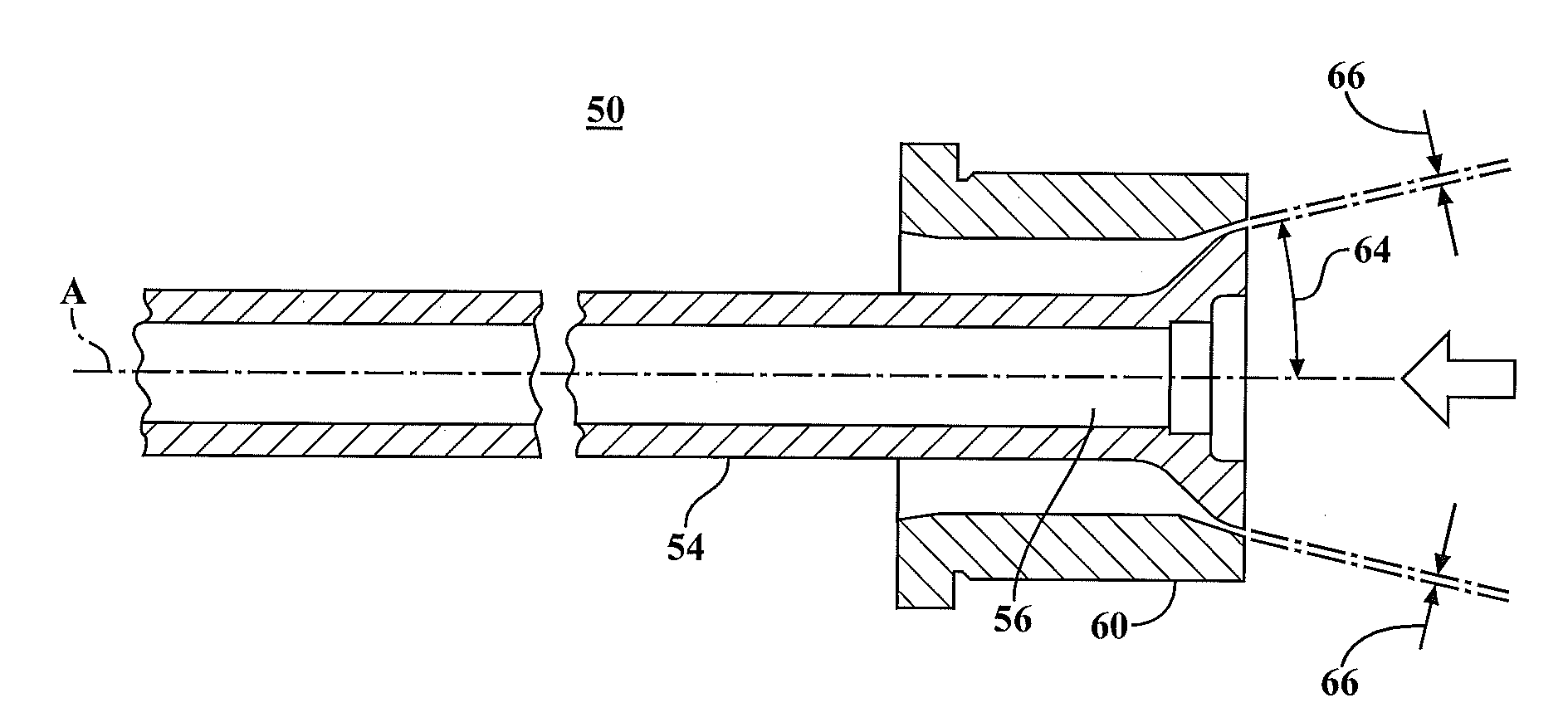

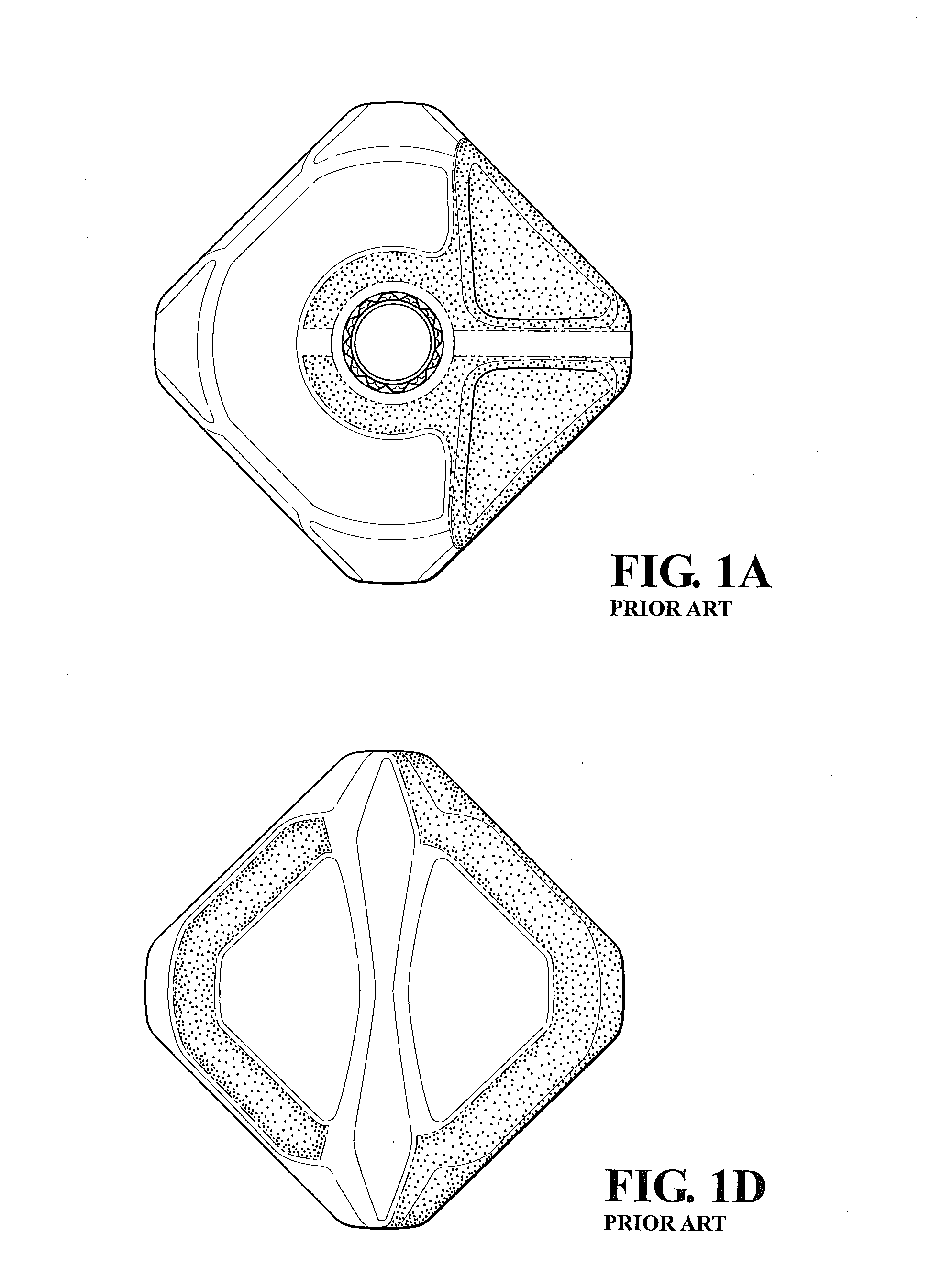

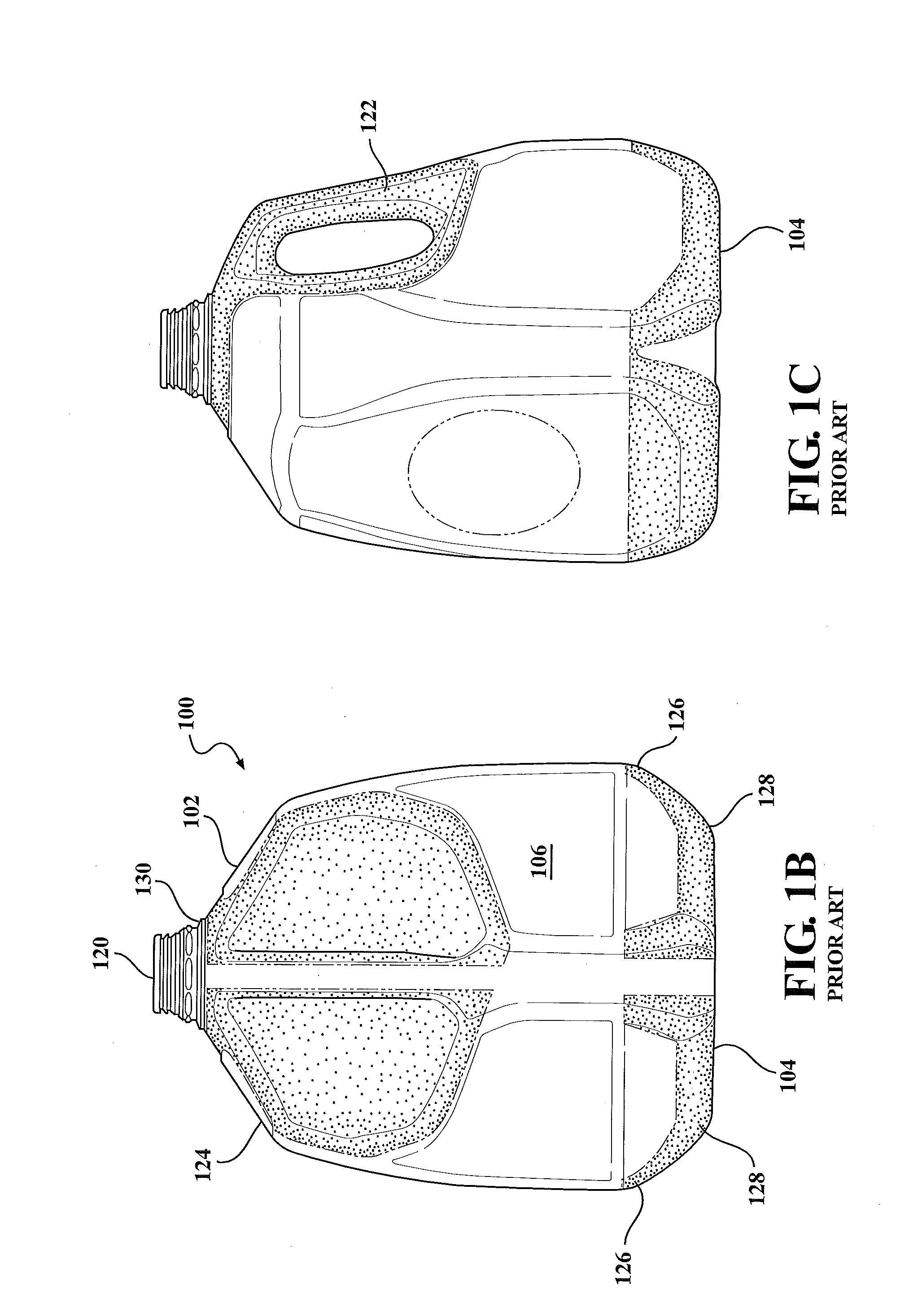

Method and apparatus for making a light weight container

ActiveUS8535599B1Smooth materialEffective distributionBottlesDomestic articlesEngineeringMechanical engineering

Owner:MID AMERICA MACHINING

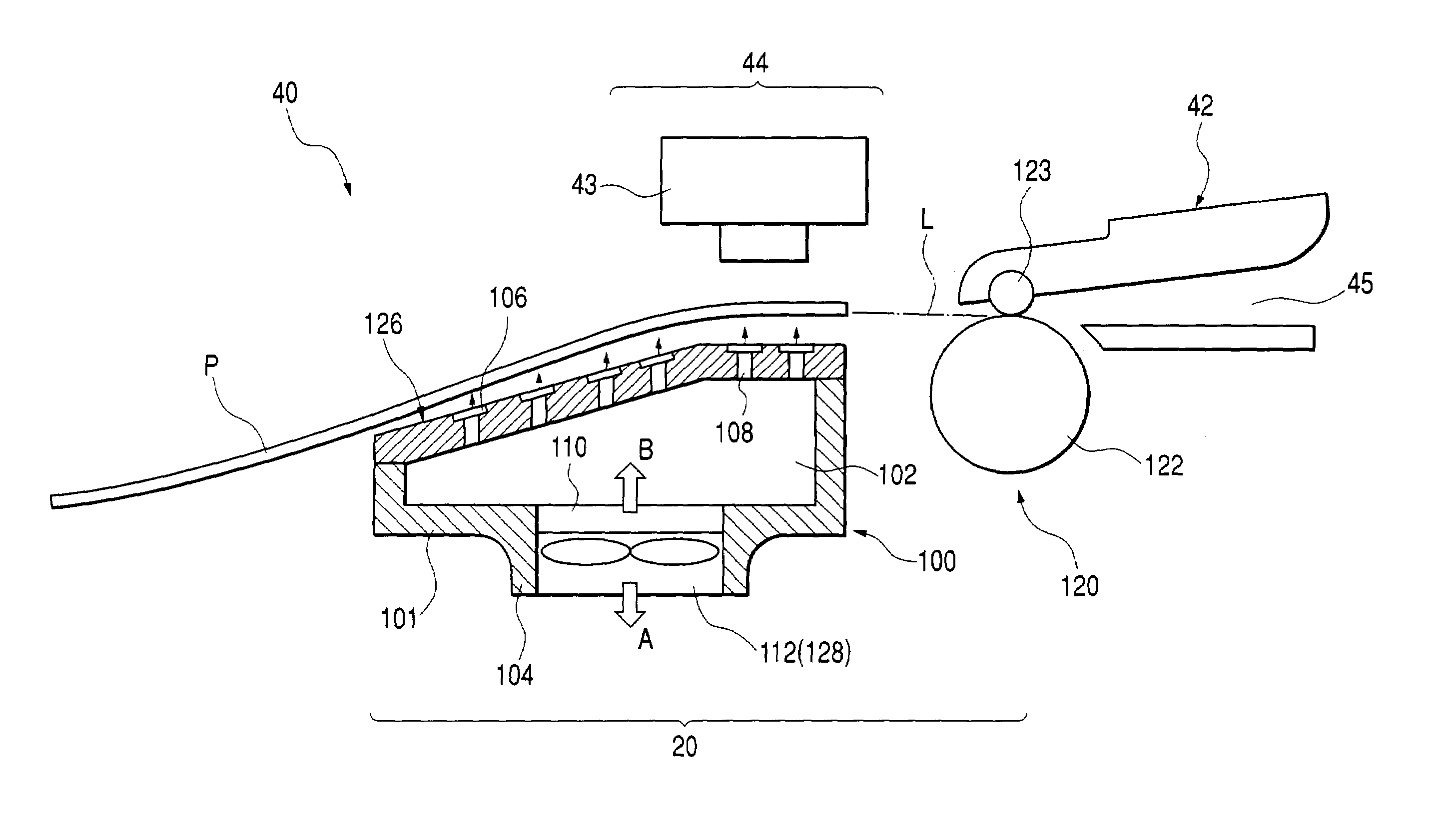

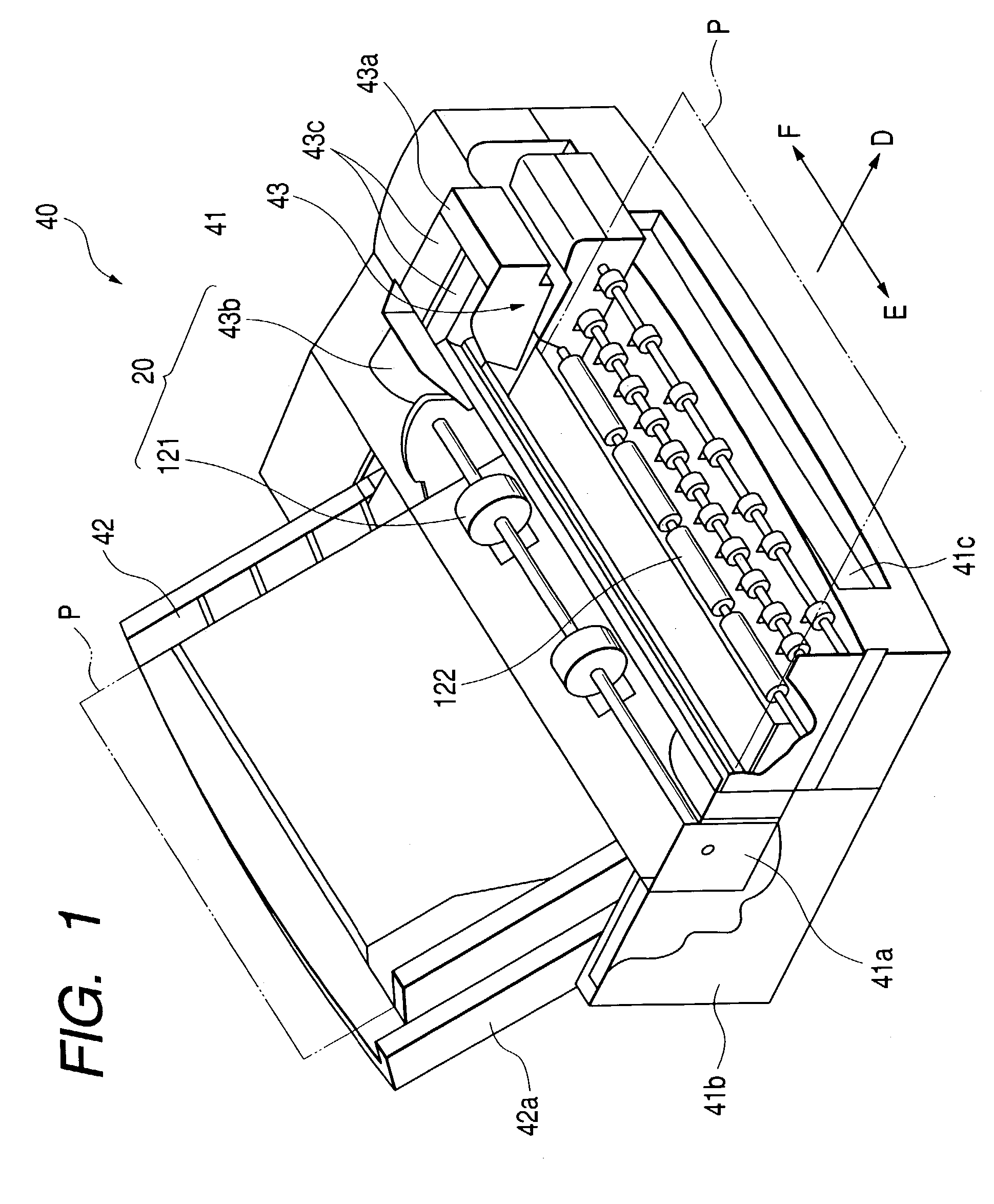

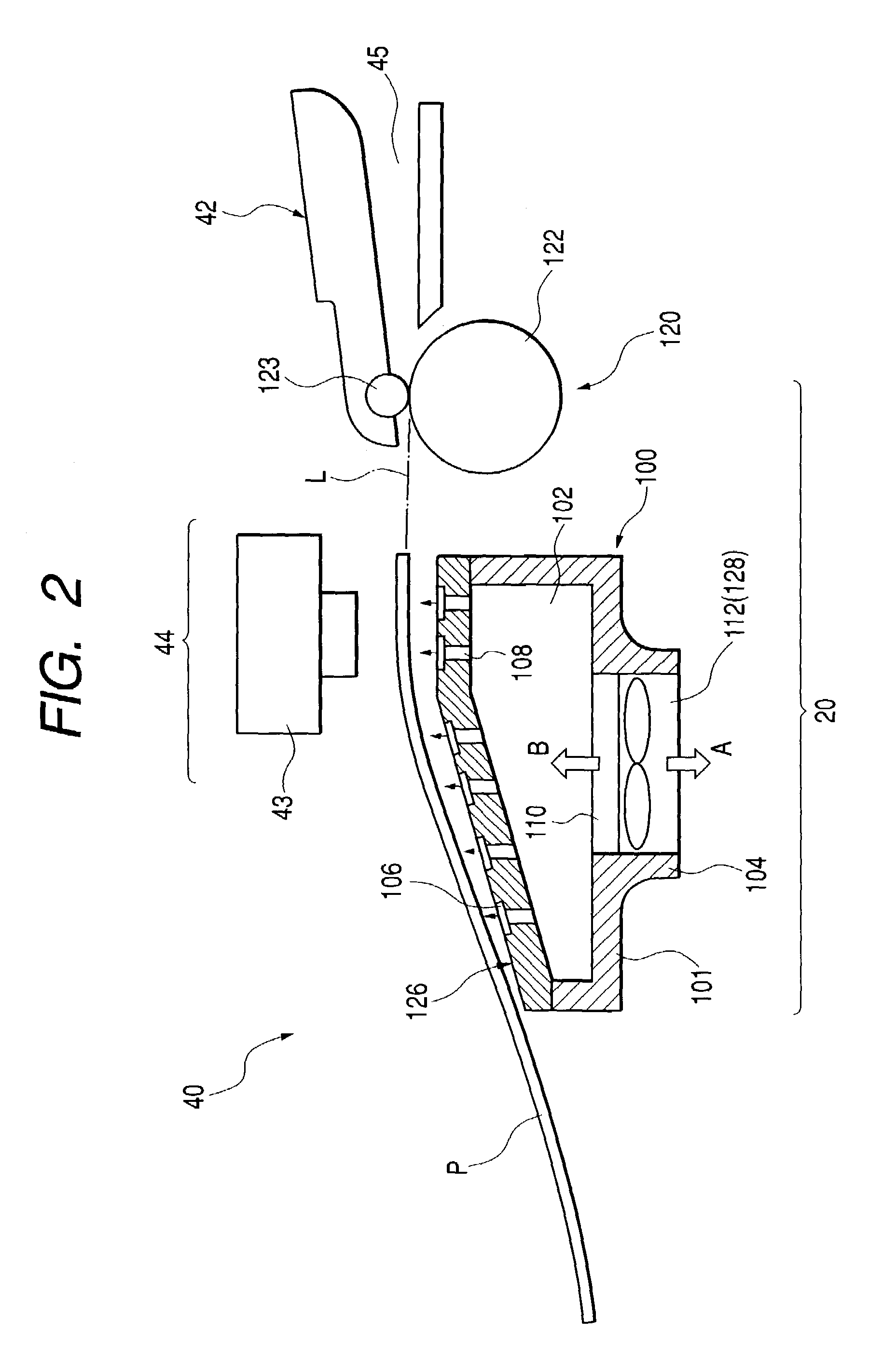

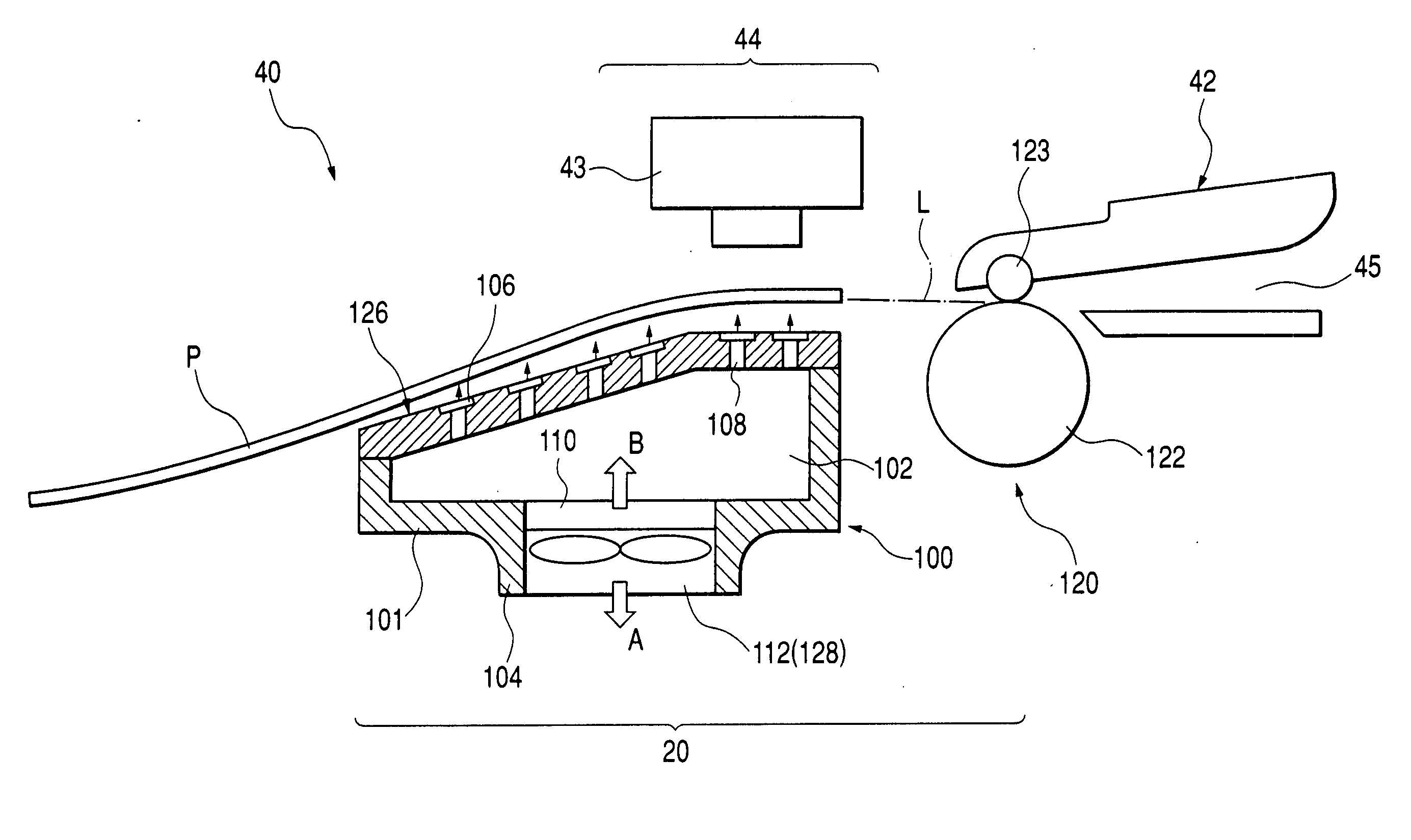

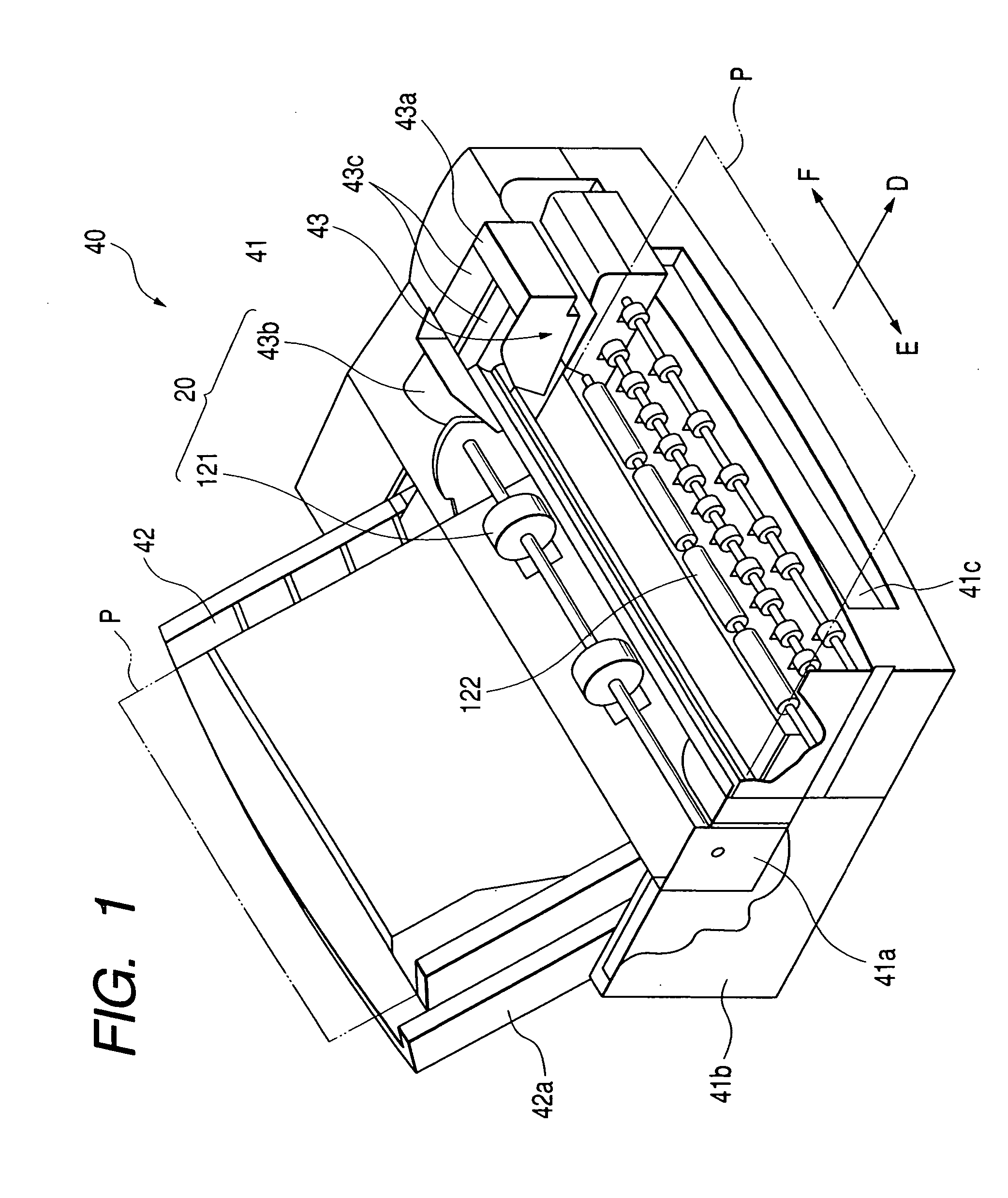

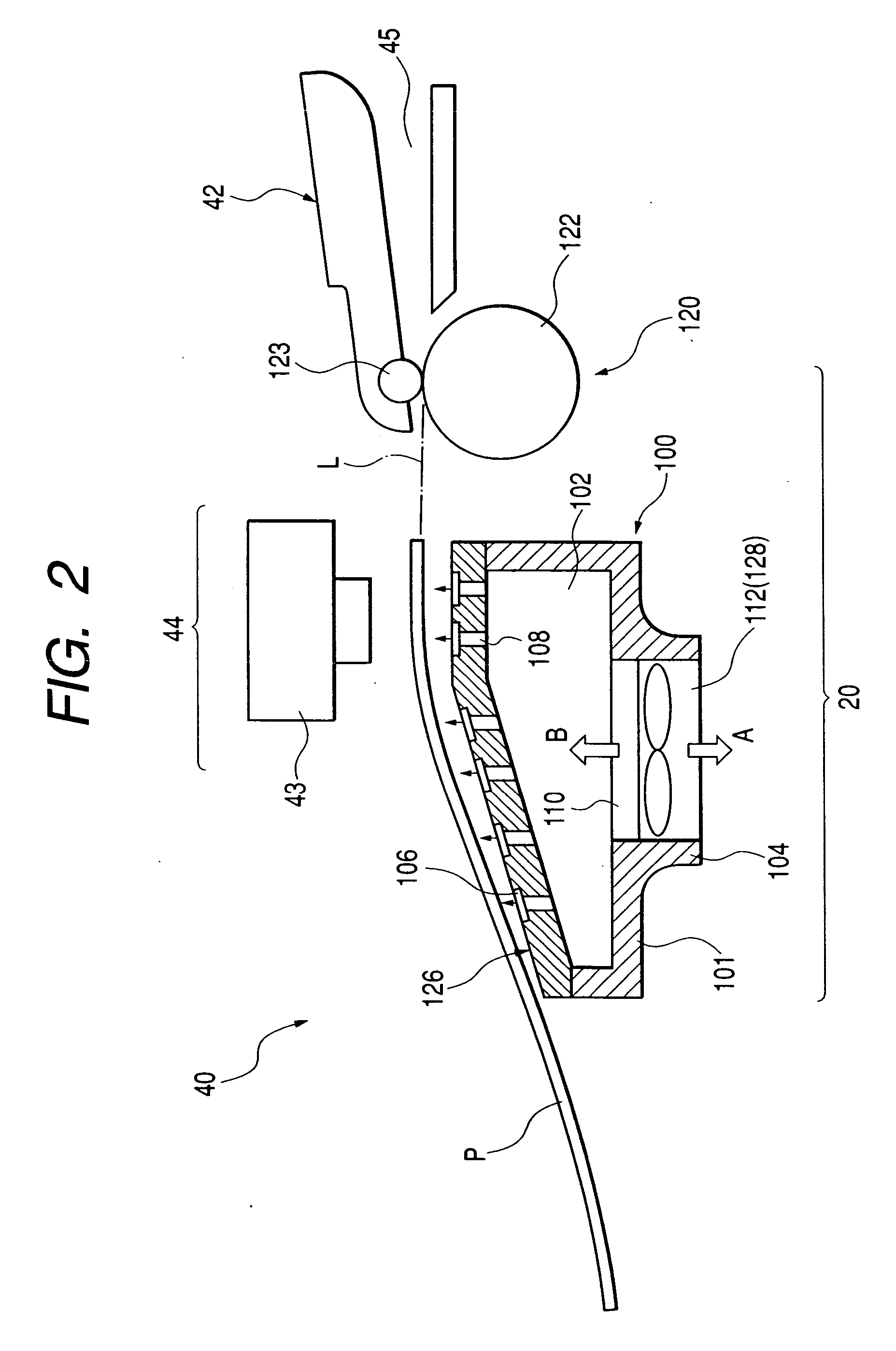

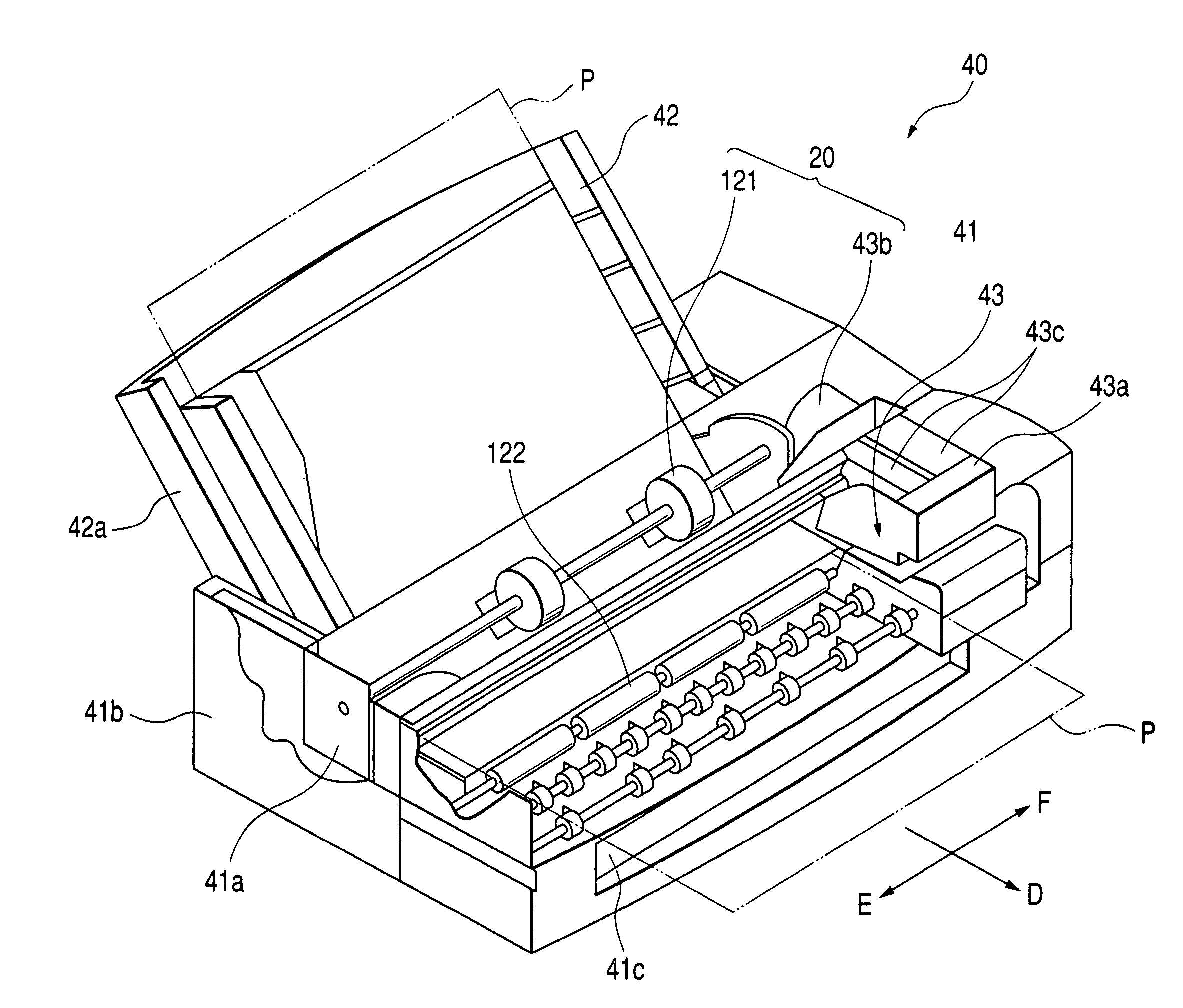

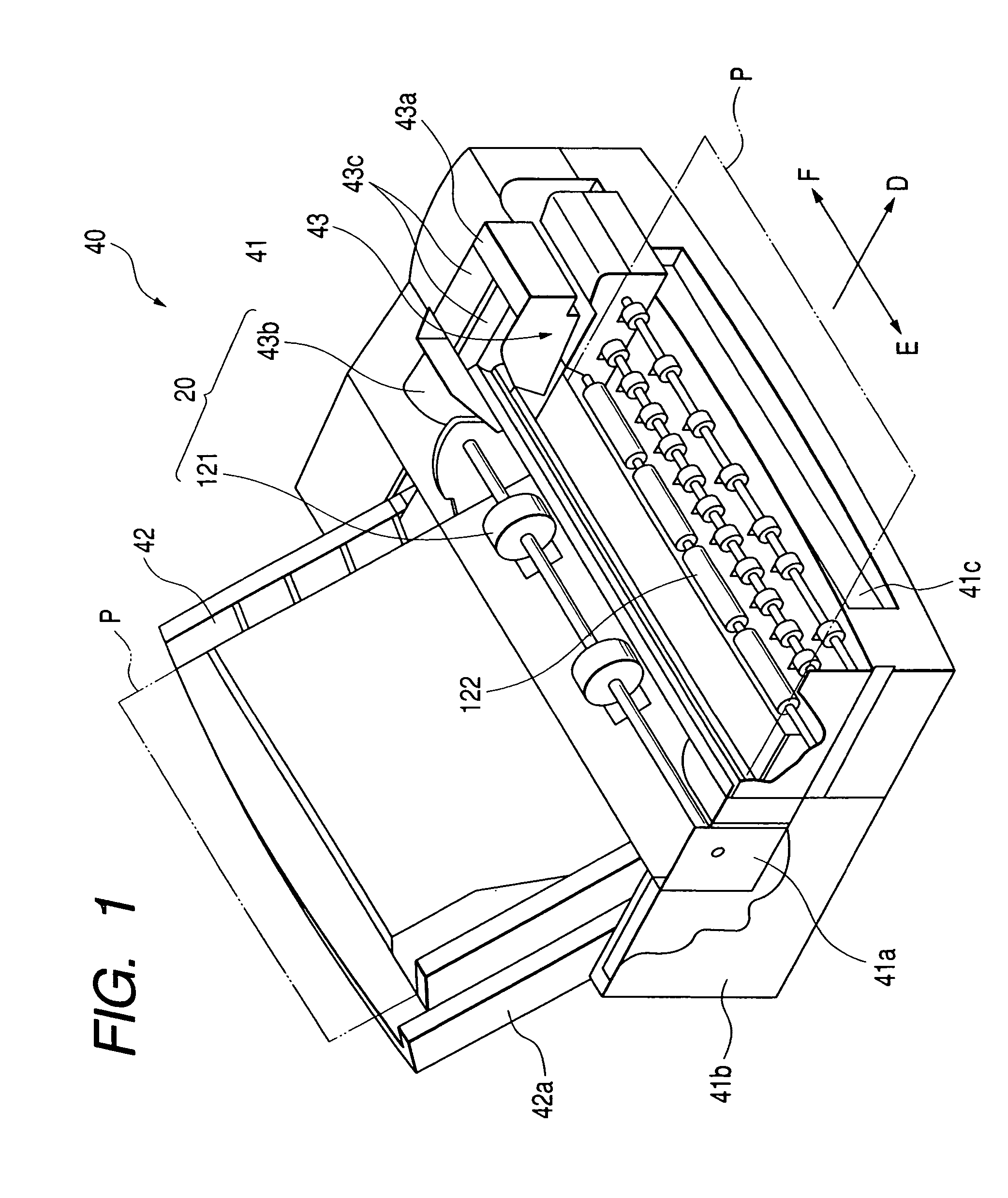

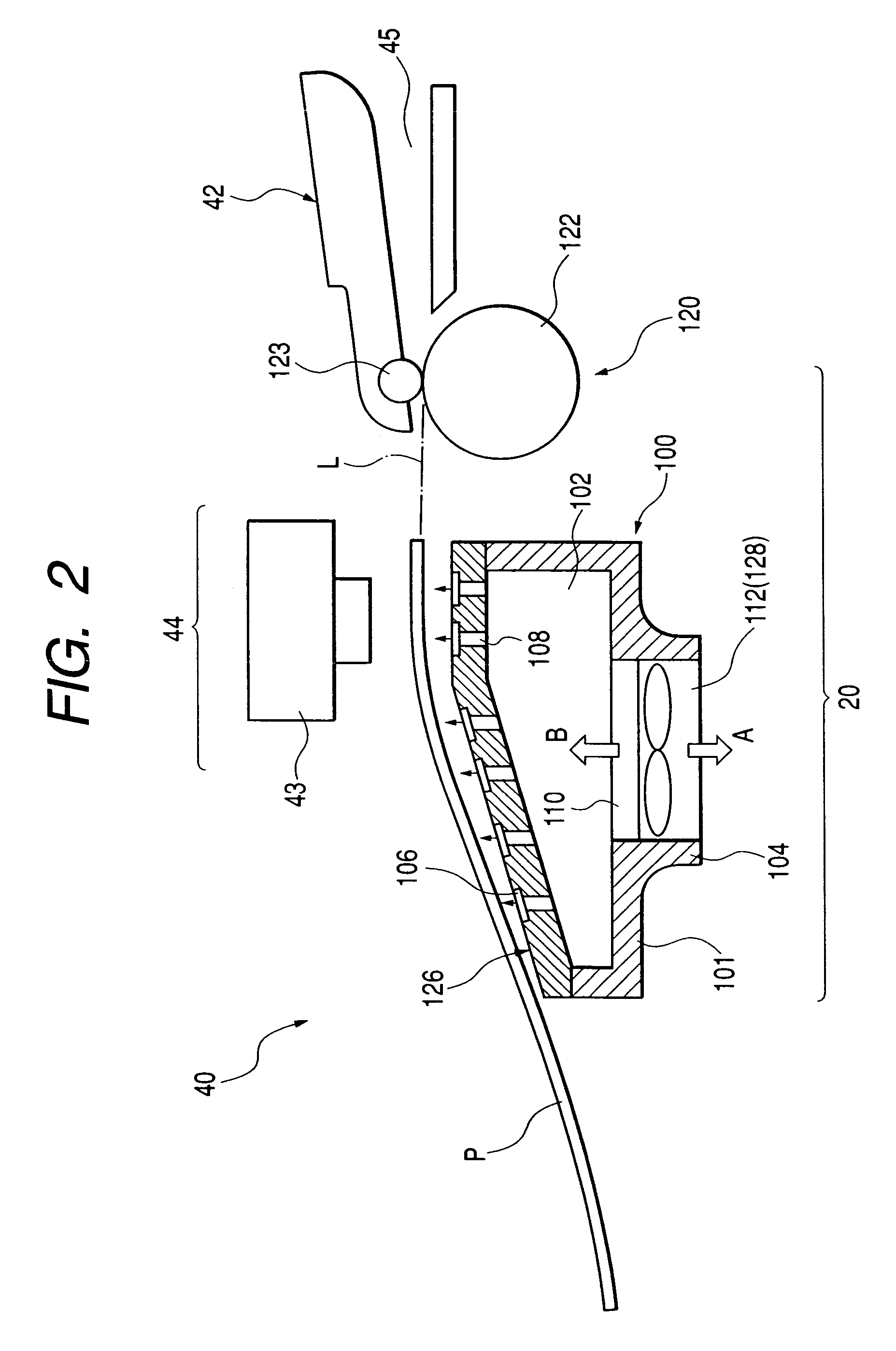

Fixed material transportation apparatus, fixed material discharging apparatus, method for discharging the fixed material, and liquid fixing apparatus

InactiveUS7093931B2Smooth materialShort working hoursOther printing apparatusDecompression chamberWaste management

The present invention involves a sucking device having a fixed material transportation surface including plural sucking holes, a decompression chamber connecting to the plural sucking holes, and a sucking device sucking air in the decompression chamber. The fixed material is fed on the fixed material transportation surface of the sucking device by the delivering device, and is stuck on the fixed material transportation surface through the sucking holes by the sucking device. The fixed material is fixed by a fixing head at the state of being stuck and is transported gradually to a downstream side by the delivering device on the fixed material transportation surface. When fixing is finished, the fixed material separates from the surface of the fixed material transportation surface and rises slightly by blowing air from the sucking holes by a blowing device so as to move to a discharging direction.

Owner:SEIKO EPSON CORP

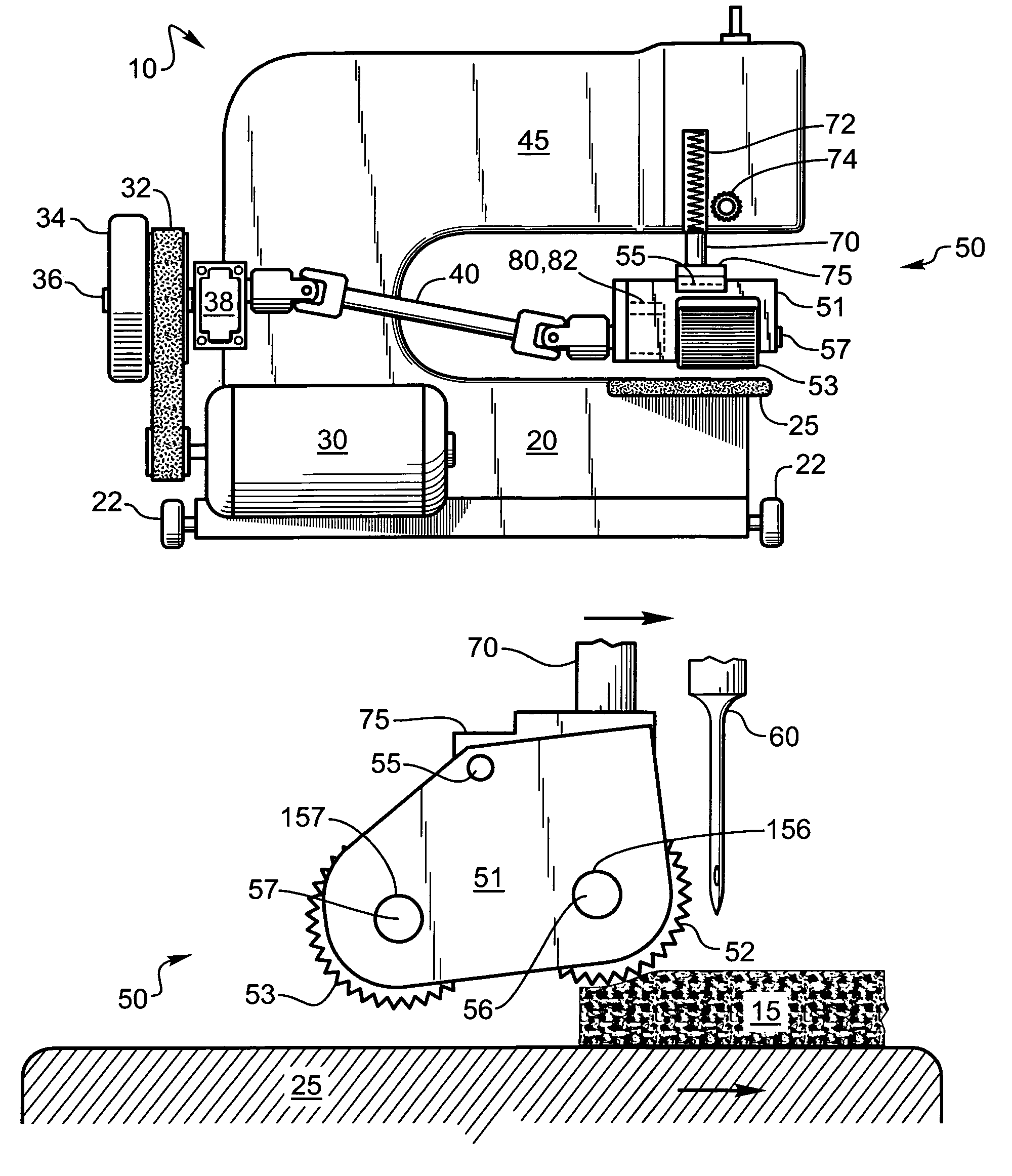

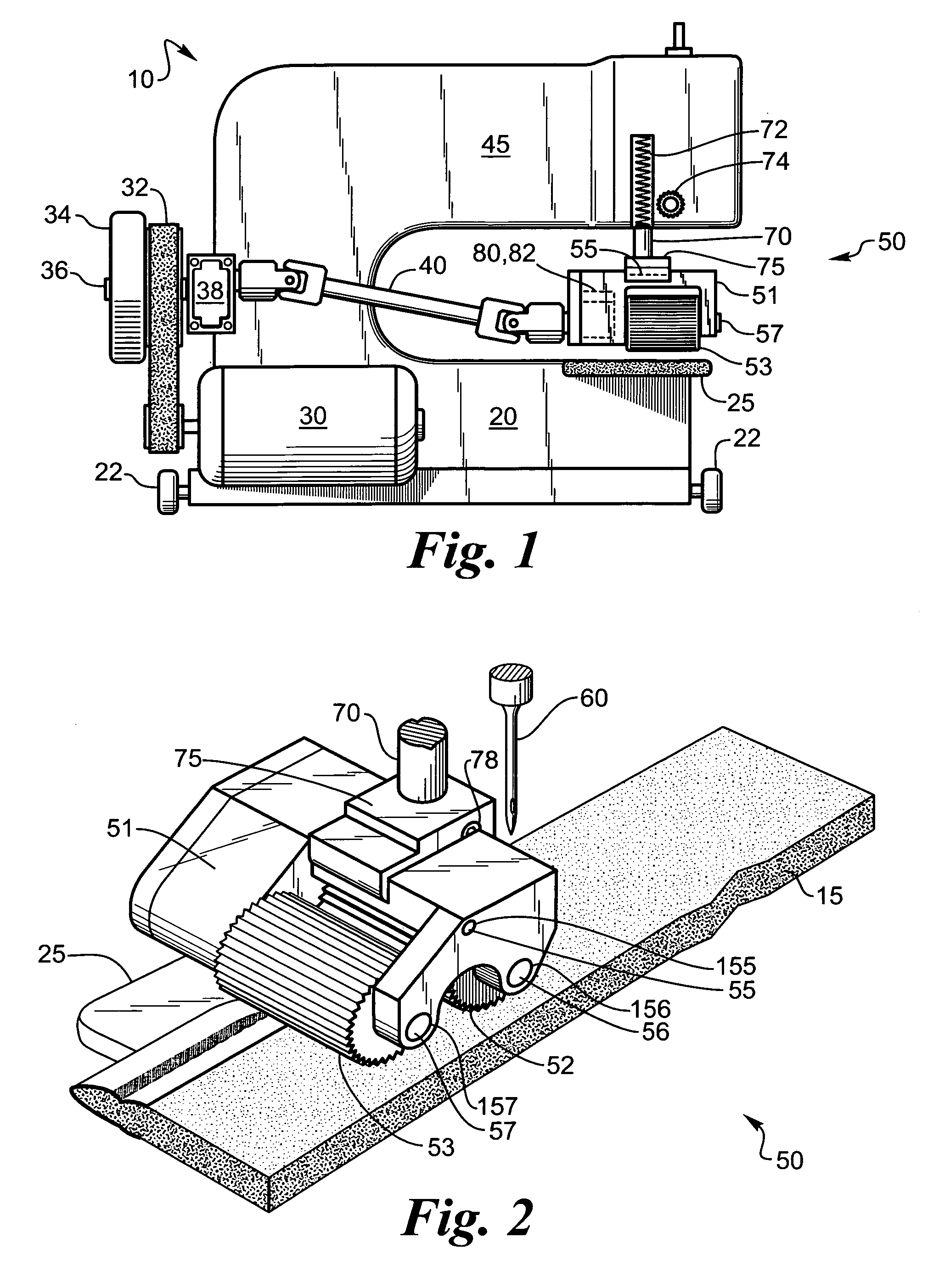

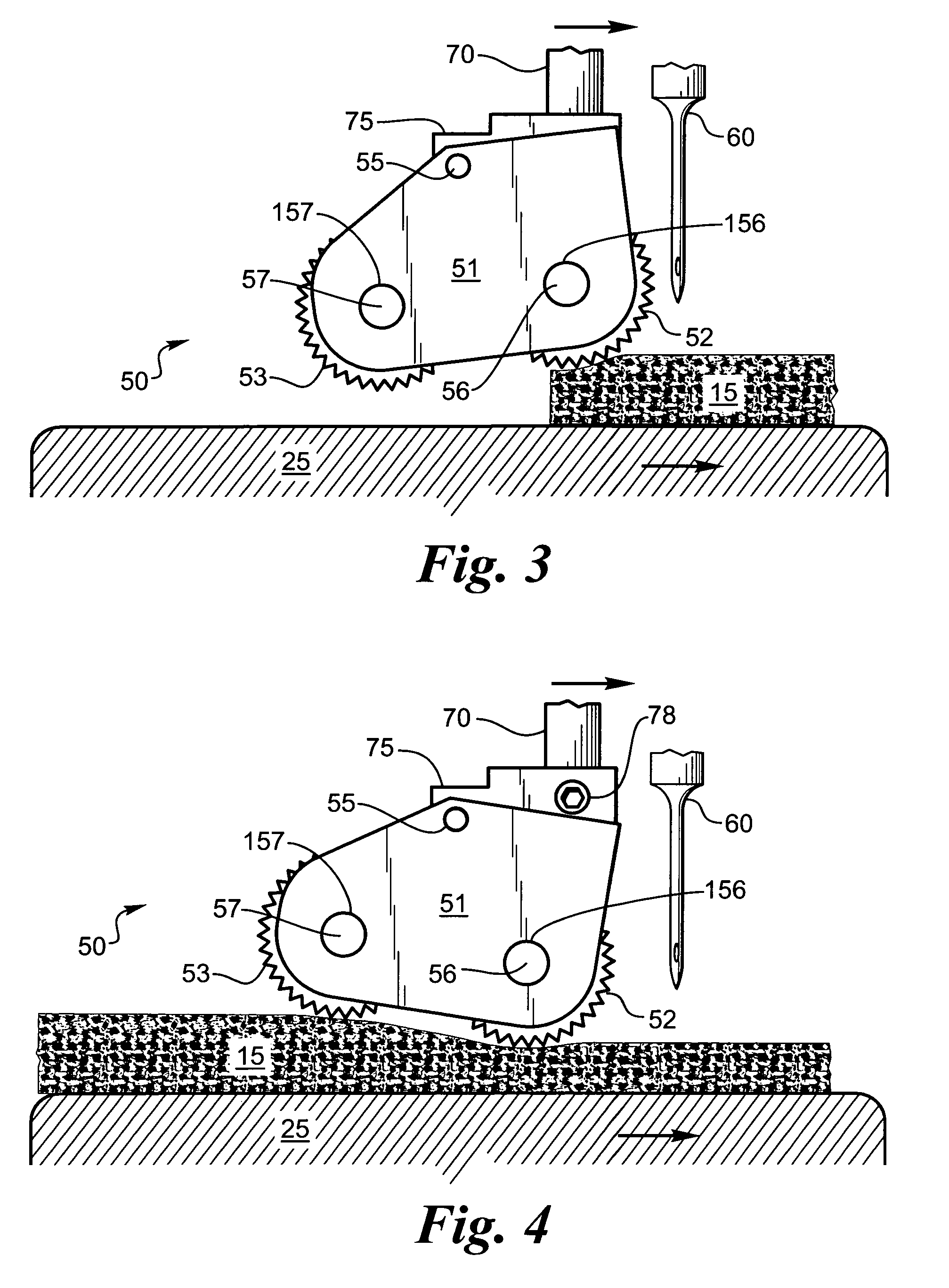

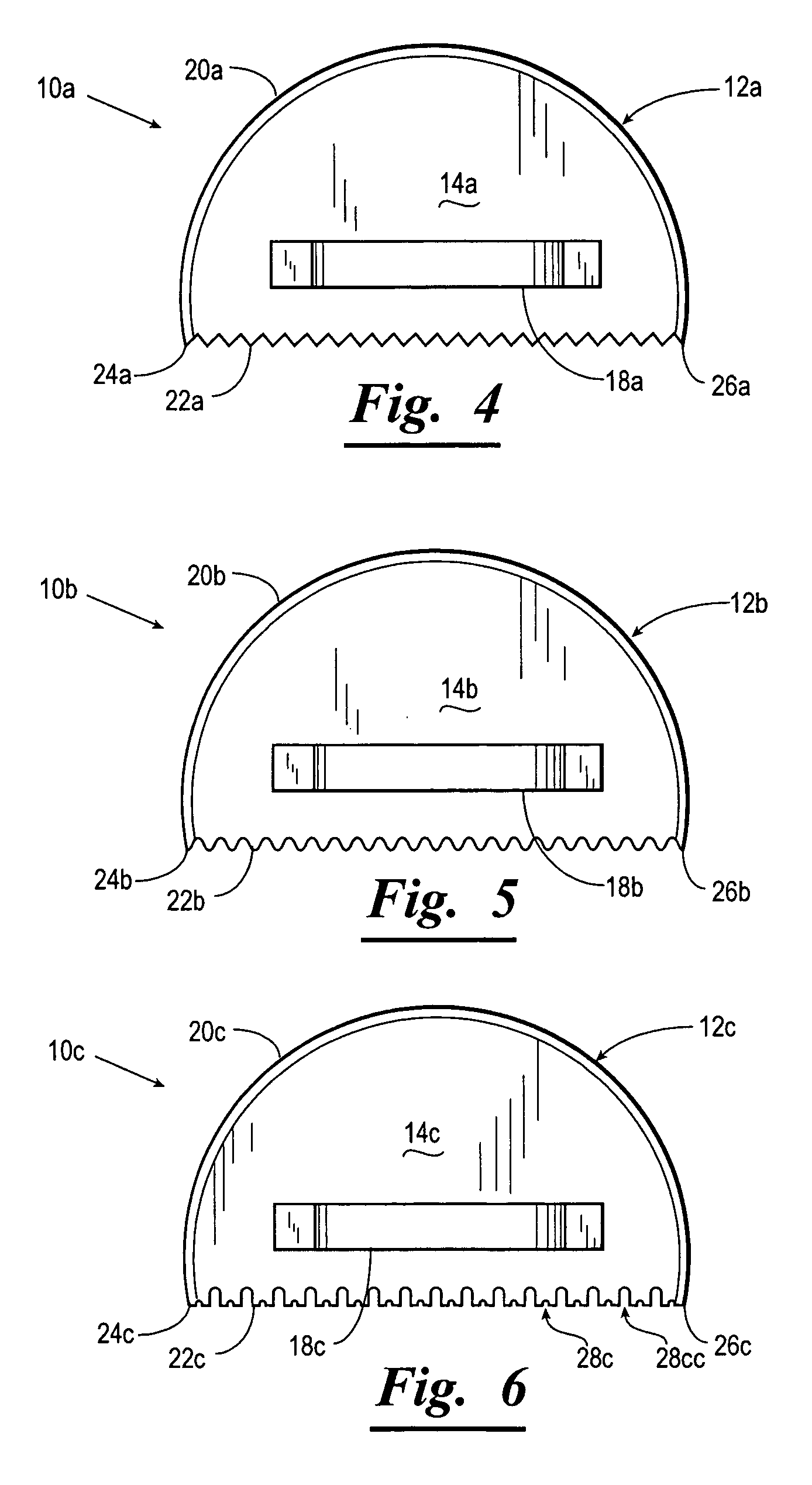

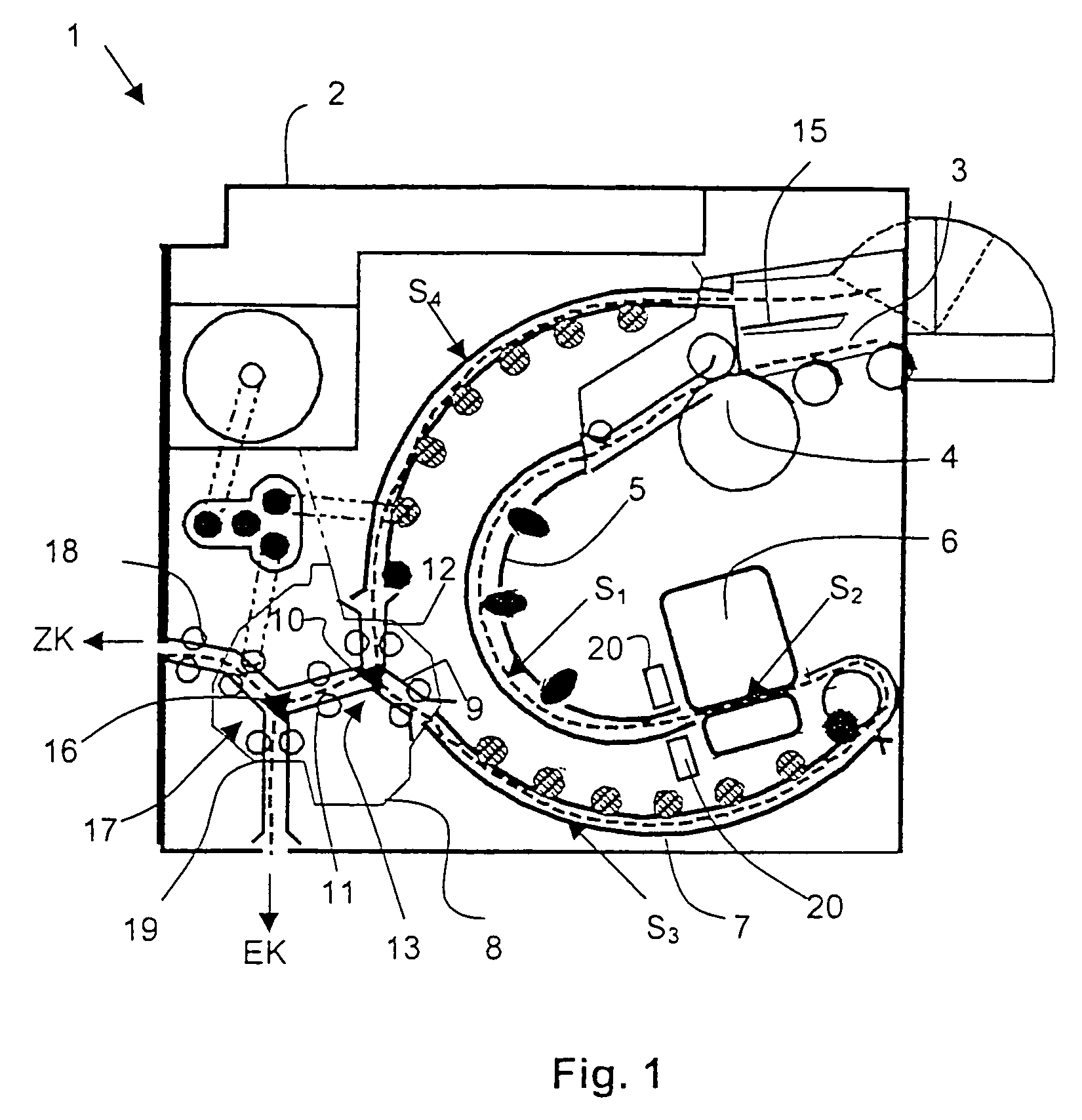

Pivoting feed roller

InactiveUS7080605B1Prevent floatingReduce maintenance costsWork-feeding meansCarpetsSewing machineEngineering

A pivoting twin roller for feeding a material to a sewing machine is disclosed. The twin rollers grip the material with serrated rollers, which rotate at the same rate for uniformly moving the material relative the sewing machine. The twin rollers press down on the material with equal force due to the central pivot point, which improves the feed of the material. The pivoting twin rollers also allow for automatic feeding of material to the sewing machine. A spring loading on the housing for the pivoting twin rollers applies downward pressure on the material being sewn for a sure grip thereon. The downward pressure also insures that the rollers will press down with equal force on uneven height materials since the pivot adjusts the height of the rollers to the height of the materials and thus prevents floating which can lead to jamming of the sewing machine.

Owner:NAT FLOORING EQUIP INC

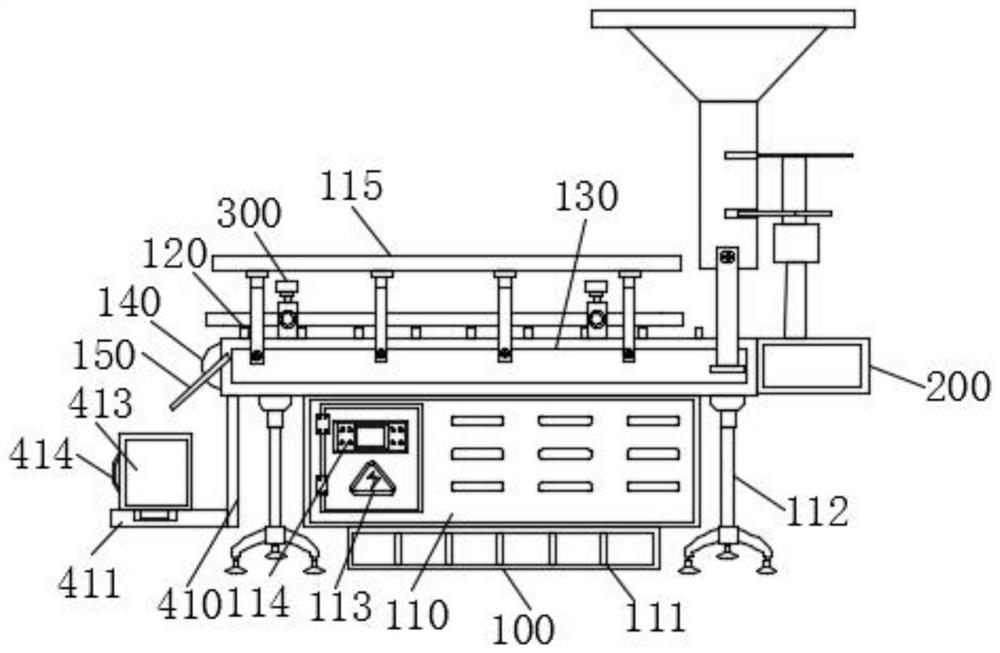

Kiwifruit cleaning dehairing device

The invention discloses a kiwifruit cleaning dehairing device. The device comprises a base, a box body, a first gear and a hopper; a supporting post is arranged on the base; the top of the supportingpost is provided with a first air bag; the hopper passes through the first gear and extends into the box body; a plurality of baffles are connected to the bottom of the first gear; the baffles are rotatably connected to the box body; the inner side of the baffles are provided with a plurality of second air bags with brushes; the first gear engages with a half gear; the half gear is fixed with a rotating shaft which is rotatably connected to a frame; the other side of the half gear is provided with a second gear; the second gear is fixed with a gear shaft which is rotatably connected to the frame; the gear shaft is connected to a first bevel gear; the first bevel gear engages with a second bevel gear; the second bevel gear drives a transmission mechanism through a tensioning shaft; and a cleaning device is arranged above the hopper, and a water pump supplies the cleaning device with water. The device can carry out automatic dehairing and cleaning on kiwifruits, and reduce the intensityof manual operation.

Owner:务川自治县绿一果农业开发有限公司

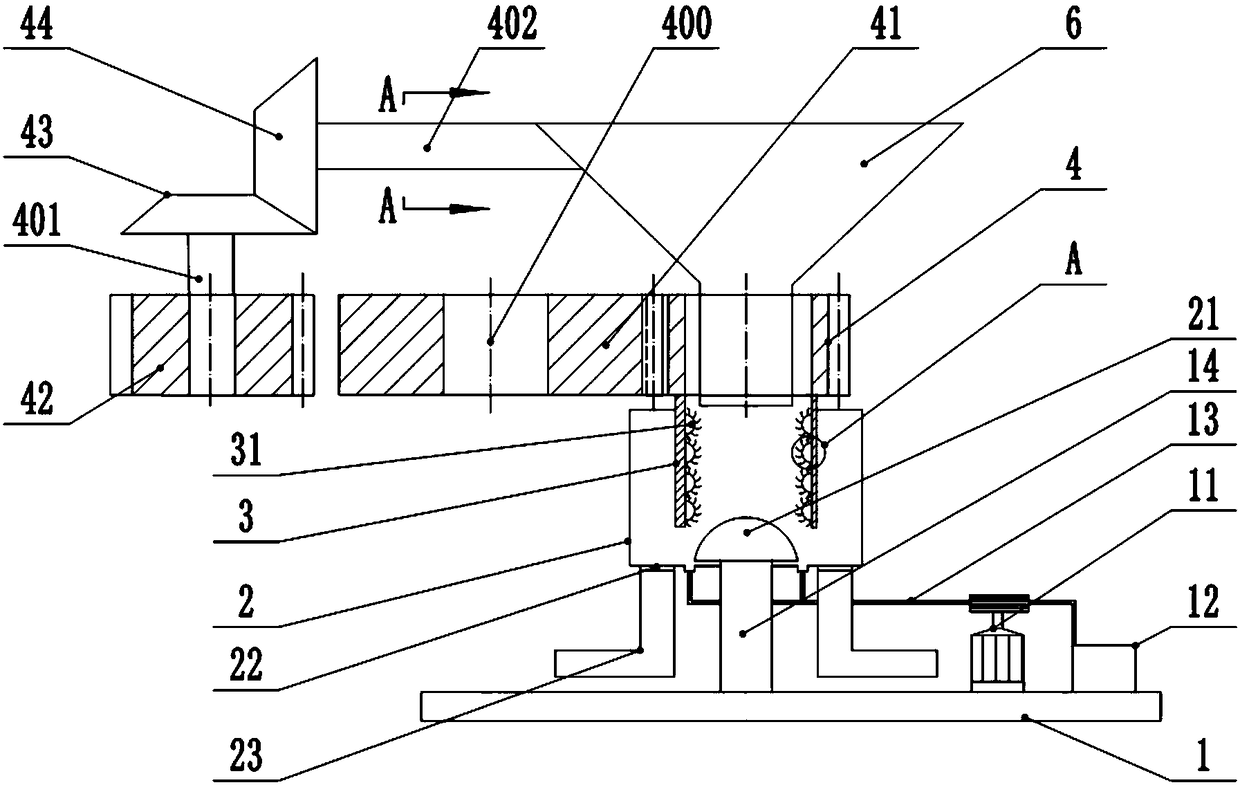

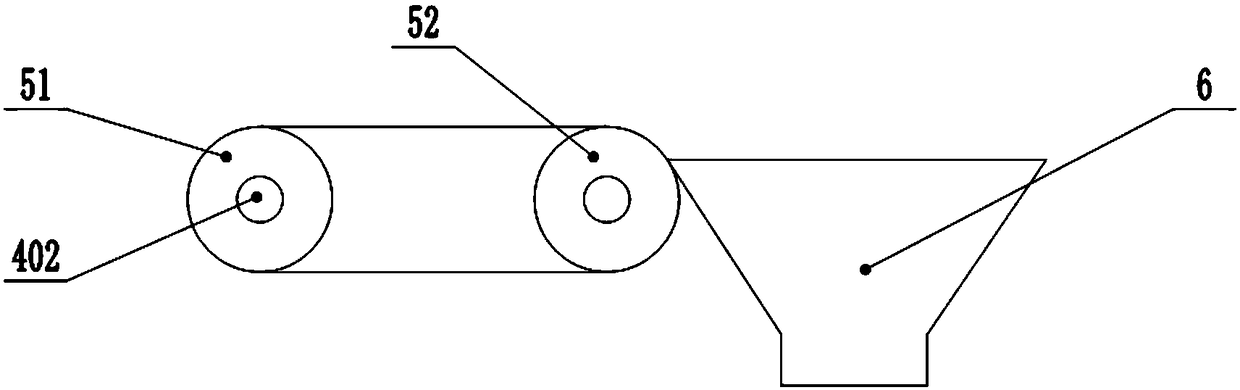

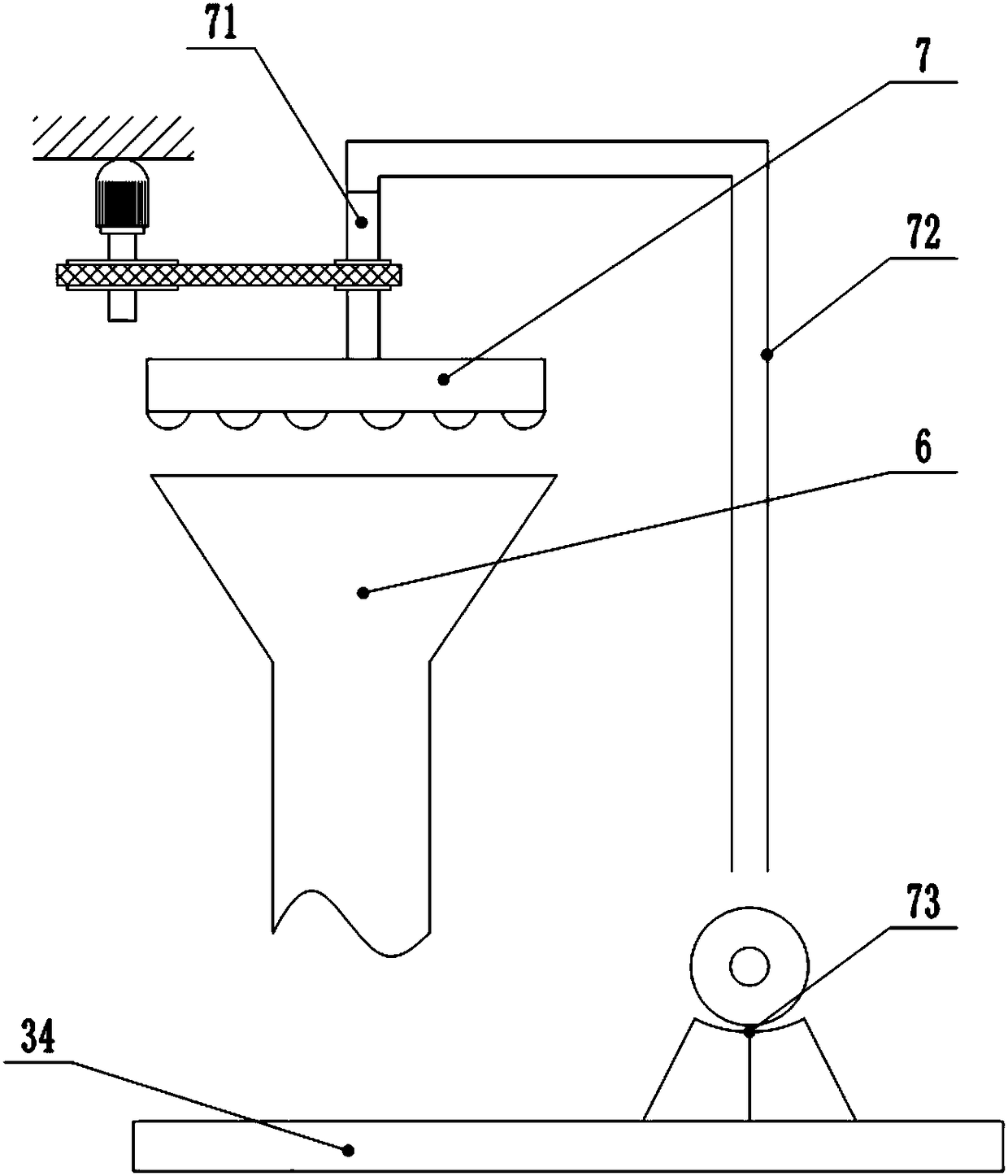

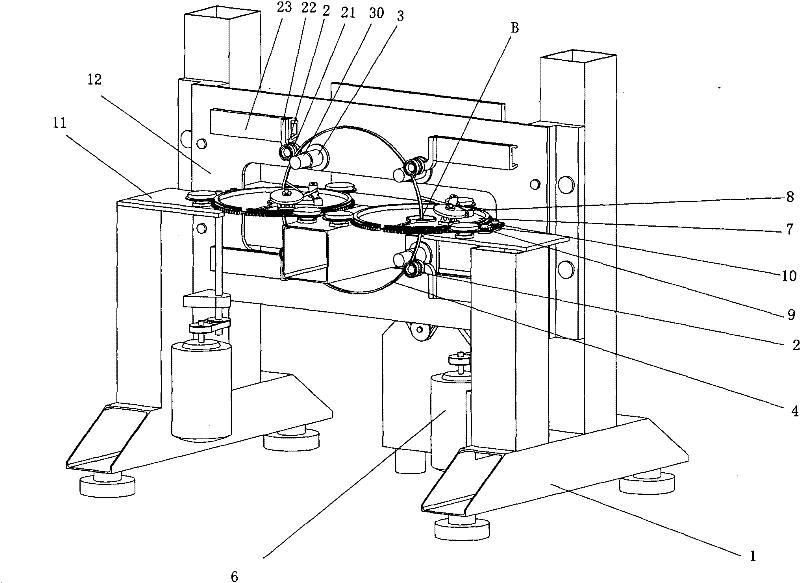

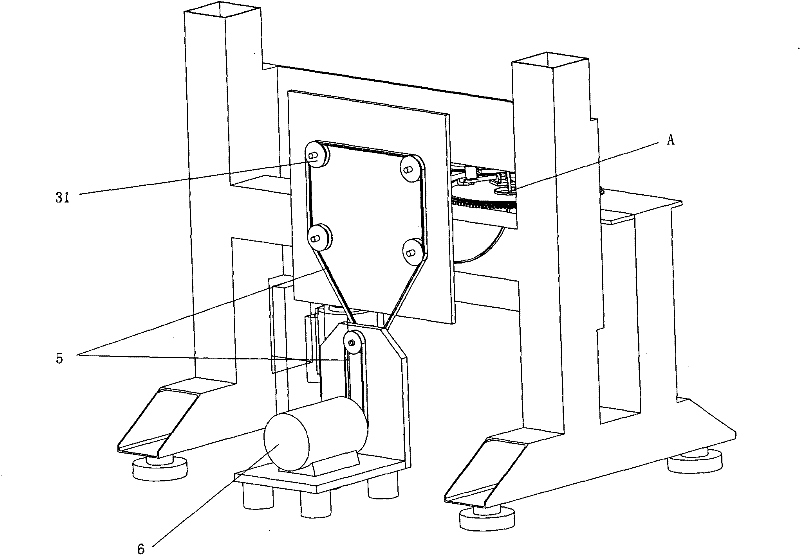

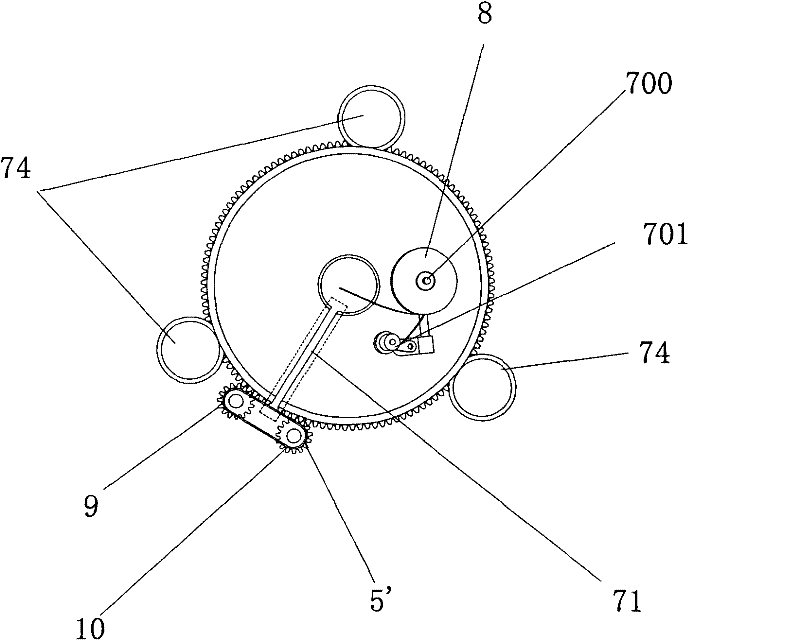

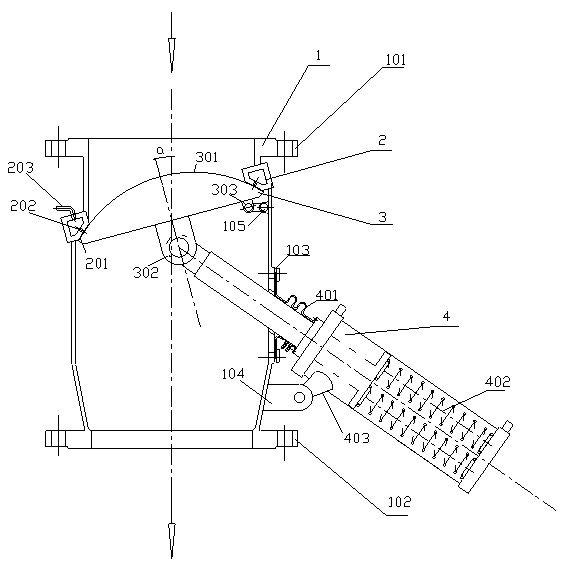

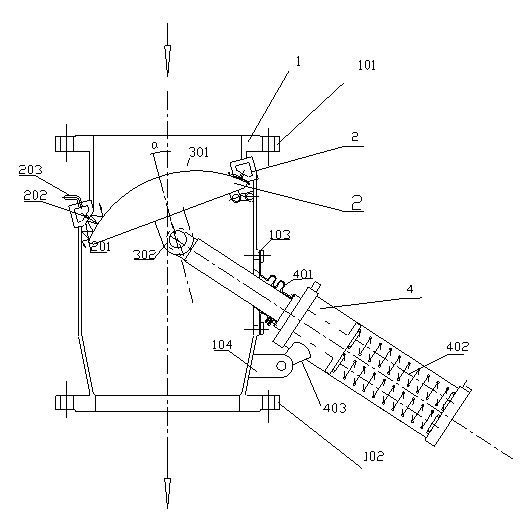

Method and equipment for winding carbon fiber yarns on annular mandrel

The invention discloses a method and special equipment for winding carbon fiber yarns on an annular mandrel, which comprise coiled yarn manufacture, positioning of the annular mandrel, self-rotation of the mandrel, a winding method and the special equipment for the method. After the invention is adopted, yarns can be continuously wound, the manufacturing process of products is simple and convenient, the manpower and the time of manual yarn winding are reduced, and the production efficiency is improved; the rotary speed of a machine platform is uniform and stable, and the strength and the spacing of yarn winding are uniform, so that the rigidity and the strength of molded products are ensured, the rejection rate is reduced, the carbon fiber layers of the products are smooth, and have uniform wall thicknesses and are not deformed, and the sizes of the products can be effectively controlled; the products are continuously wound to be molded, and the inside and outside of the whole pipe wall have uniform materials, and an overlapping phenomenon does not occur, so that the carbon fiber layers of the products are smooth, and have uniform wall thicknesses and are not deformed; the whole carbon fiber tapes are whole tapes, and so the carbon fiber layers do not need to be cut always, so that raw materials are simplified and saved; the rotating speed of the mandrel is changed, and the angle between the yarns and the mandrel, and the staggered angle between the two adjacent yarn layers are variable, so that the performances of various products are met.

Owner:王景山

Fixed material transportation apparatus, fixed material discharging apparatus, method for discharging the fixed material, liquid fixing apparatus

InactiveUS20050225621A1Smooth materialShort working hoursOther printing apparatusDecompression chamberWaste management

A sucking device having a fixed material transportation surface including plural sucking holes, a decompression chamber connecting to the plural sucking holes, and a sucking device sucking air in the decompression chamber is set at discharging side of the fixed material. The fixed material is fed on the fixed material transportation surface of the sucking device by the delivering device, and is stuck on the fixed material transportation surface through the sucking holes by the sucking device. The fixed material is fixed by a fixing head at the state being stuck and is transported gradually to a downstream side from an upstream side by the delivering device on the fixed material transportation surface. After that, when fixing is finished, the fixed material separates from surface of the fixed material transportation surface and rises slightly by blowing air from the sucking holes by a blowing device so as to move to discharging direction, that is, the downstream side by an auxiliary transporting device. Thus, since the fixed material is discharge smoothly, the prior discharging serrated roller is unnecessary so that spur mark run over caused by the discharging serrated roller does not remain on the fixed material at discharging.

Owner:SEIKO EPSON CORP

Construction method of integrally-poured building house

ActiveCN110952585AAvoid uneven concrete massReasonable designFoundation engineeringEarthquake resistantPlant roots

The invention discloses a construction method of an integrally-poured building house. The method comprises the following steps of S1, drawing design, wherein according to the terrain and size data ofa construction location, a building construction drawing is designed; S2, impurity cleaning, wherein remaining building waste on the construction location is cleaned, and plant root stocks are dug andcleaned; S3, foundation exploration, wherein the construction location is subjected to terrain detection, and it is determined that no holes are formed in the construction location; S4, preparation before construction, wherein the construction ground is leveled, and then is flattened and compacted; and S5, foundation building, wherein according to the building construction drawing, the foundationposition and size information are determined, and are marked on the corresponding position, then, a constructor carries out digging work on the ground according to the corresponding size information.The method is reasonable in design, a building formwork can be conveniently constructed on a foundation and a wall supporting beam part, and is good in seal and high in stability and facilitates concrete injection, a house frame part can be integrally poured, the frame is more steady, and the house anti-vibration capacity is improved.

Owner:金匠建设集团有限公司

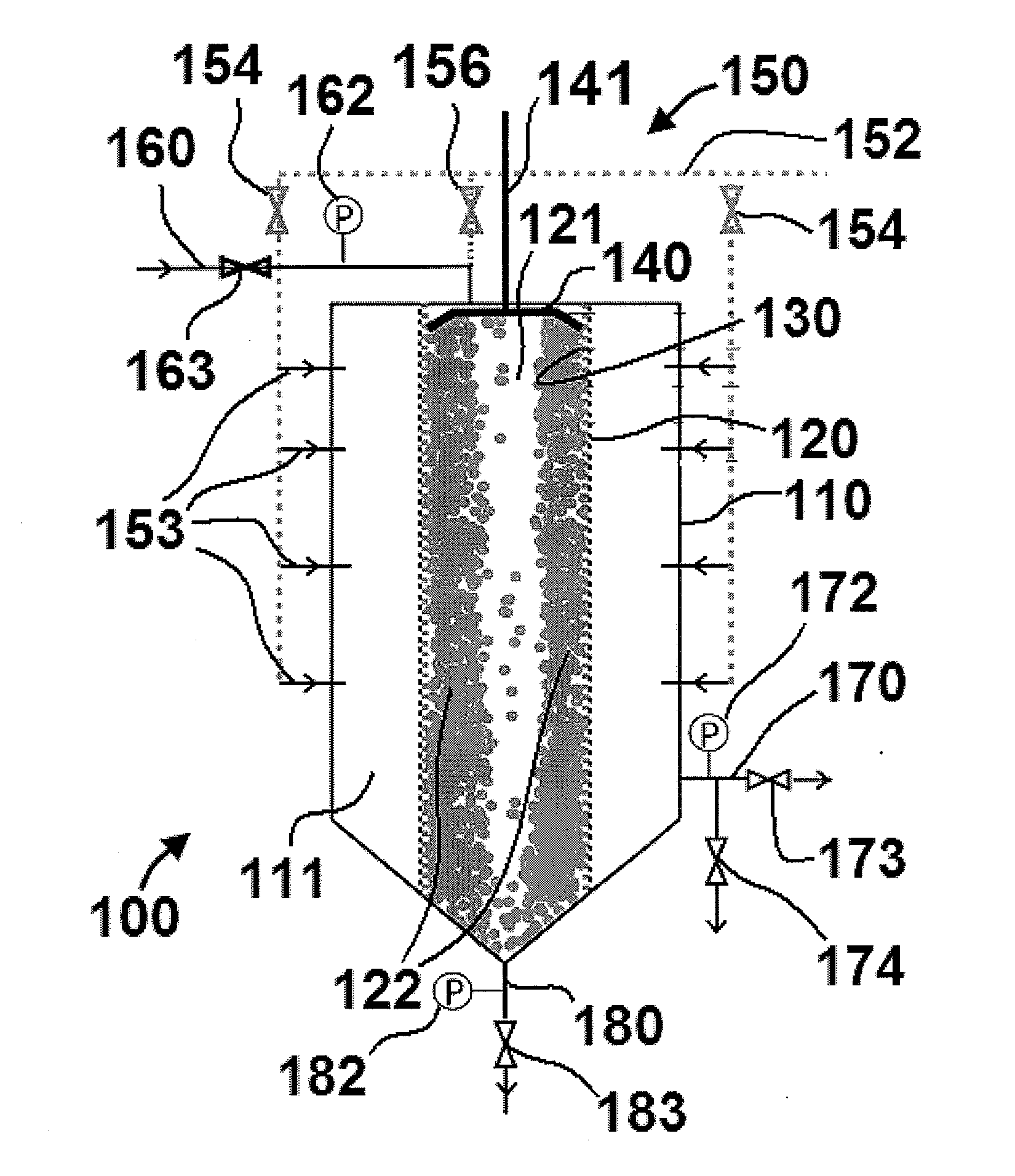

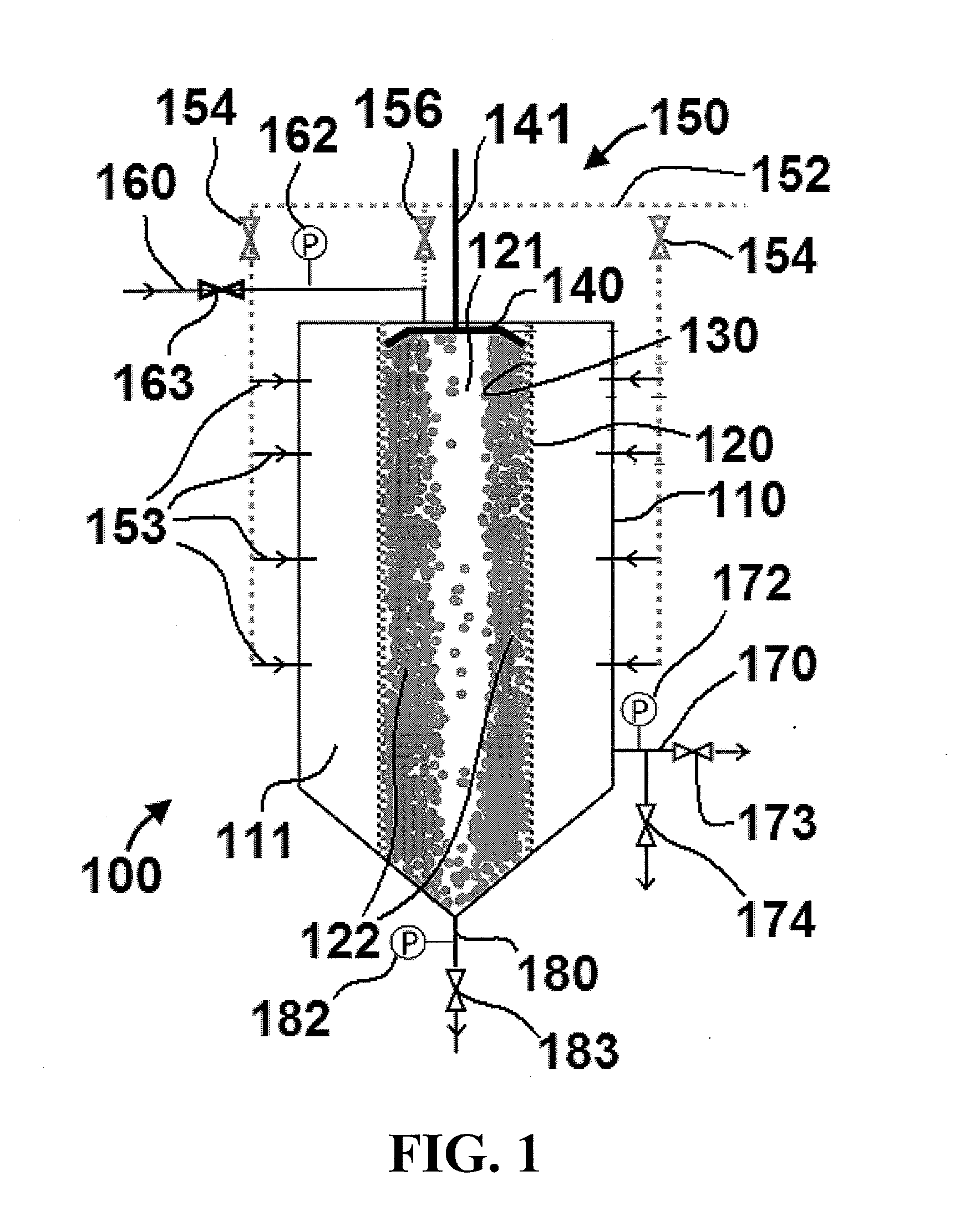

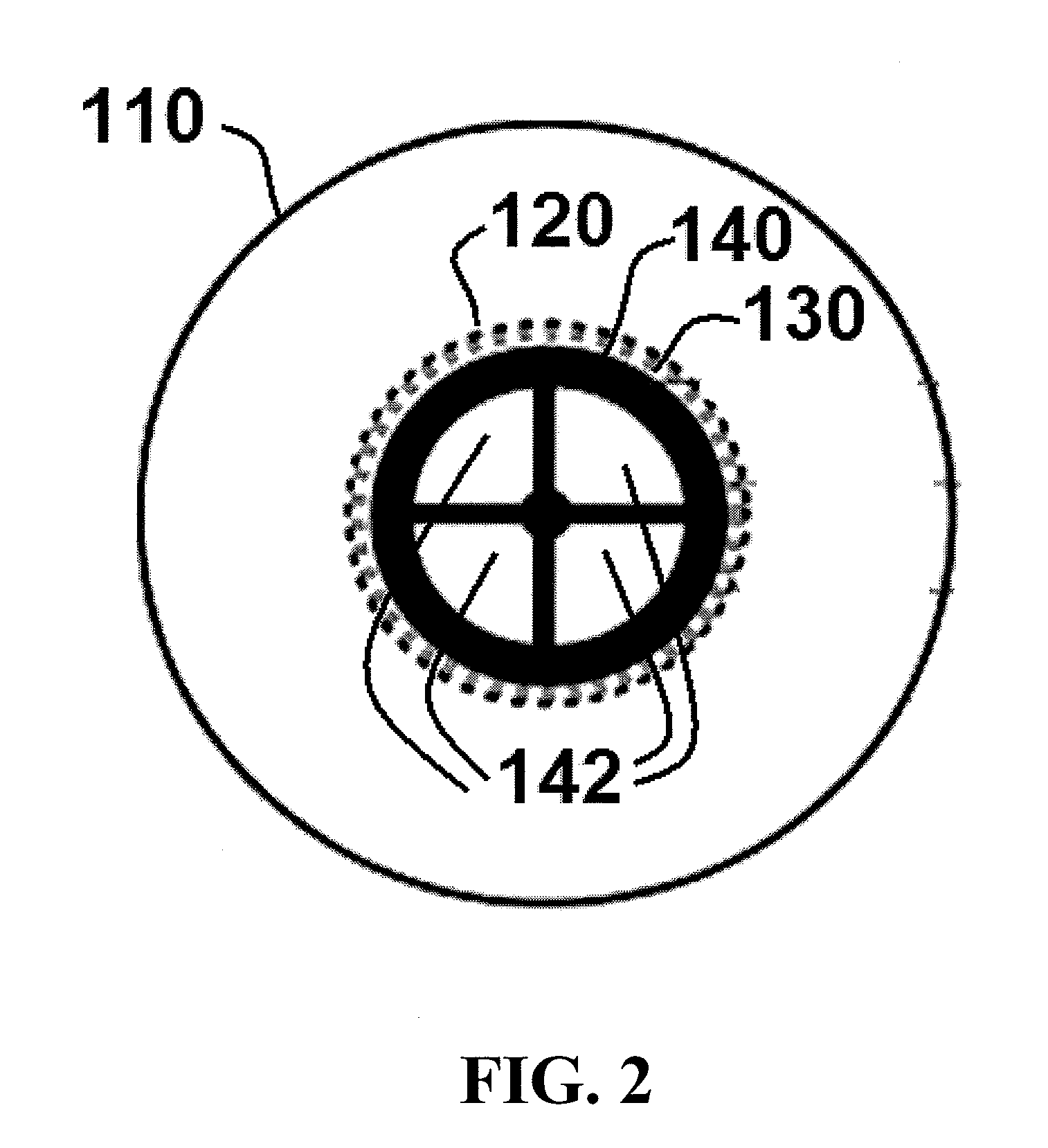

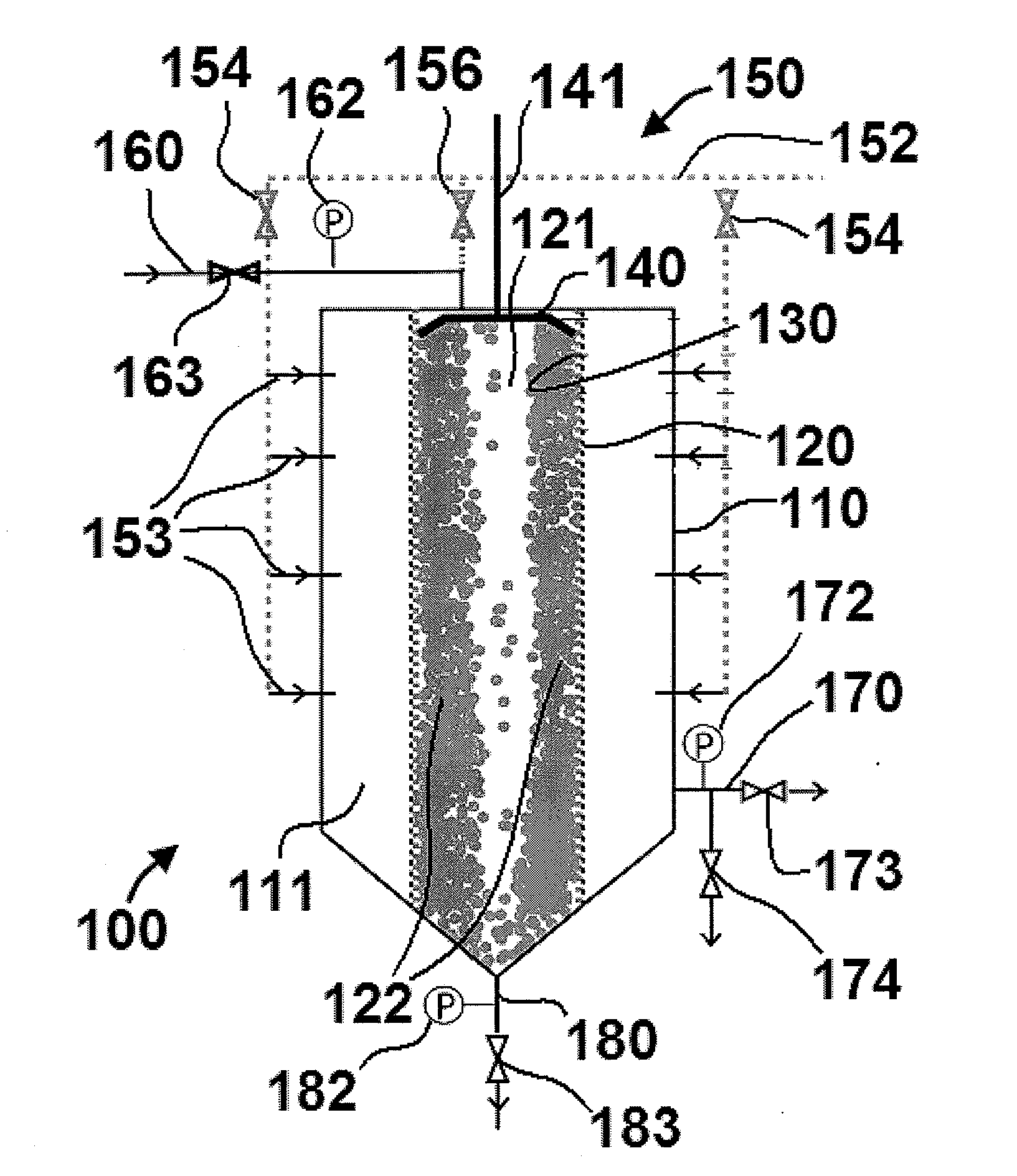

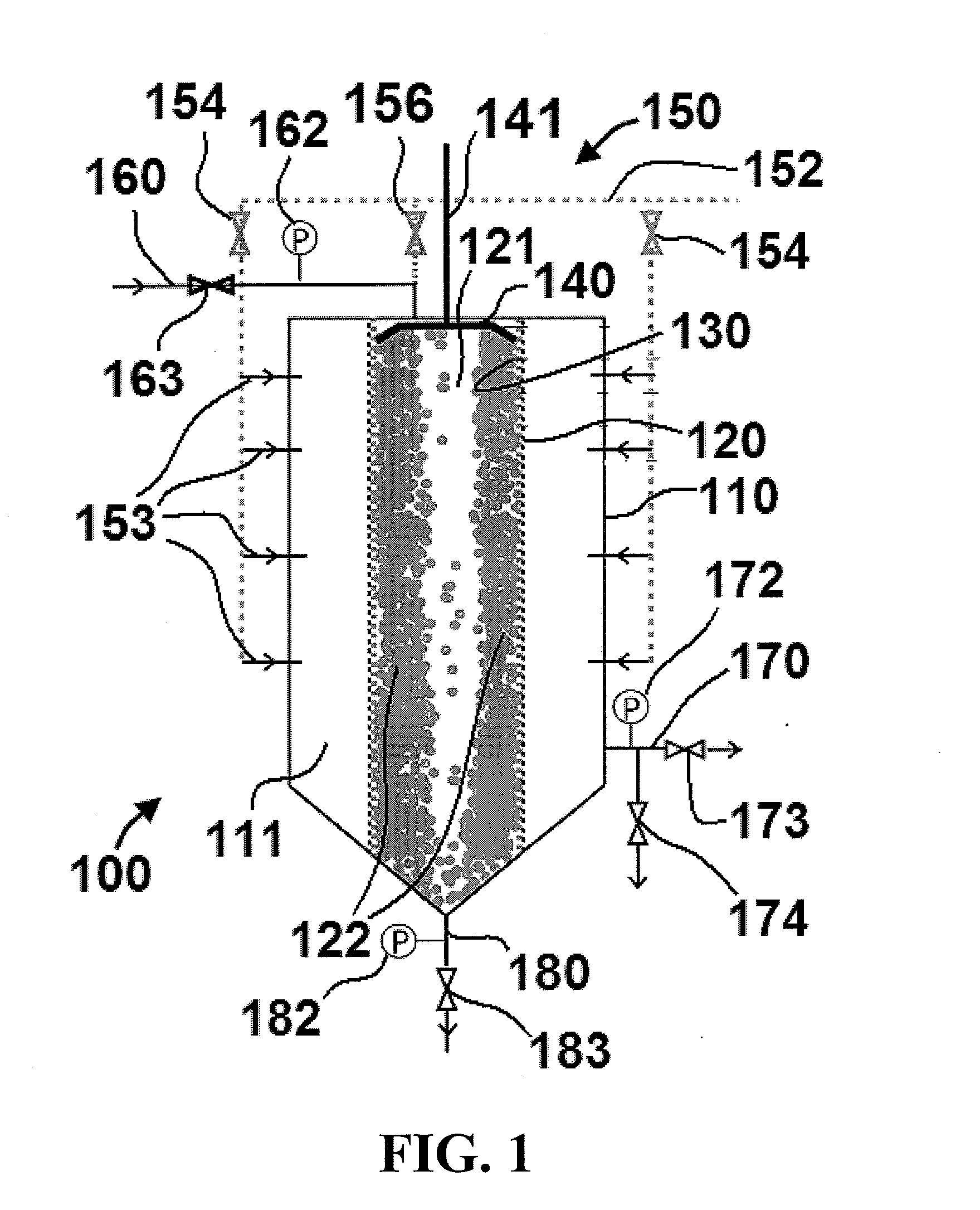

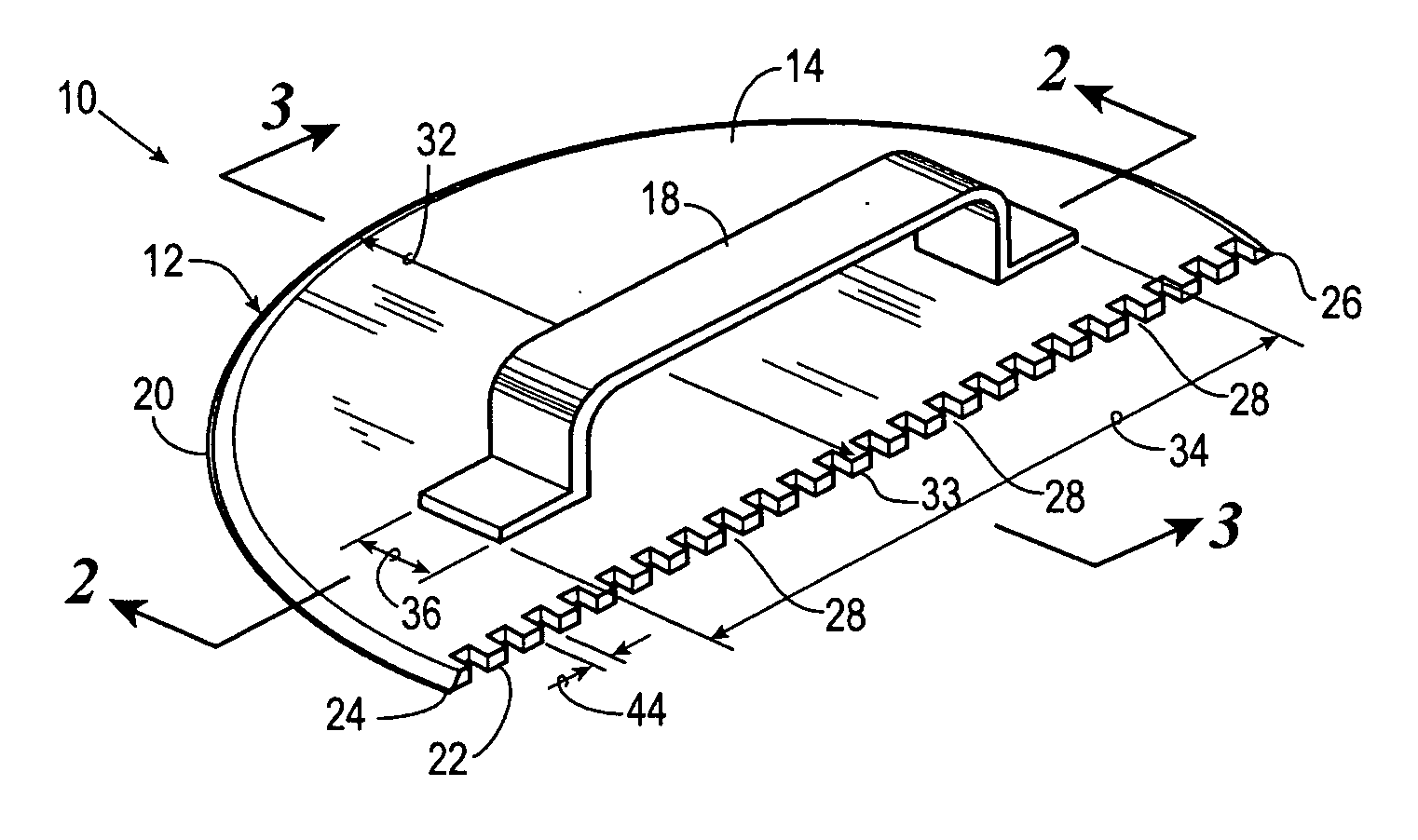

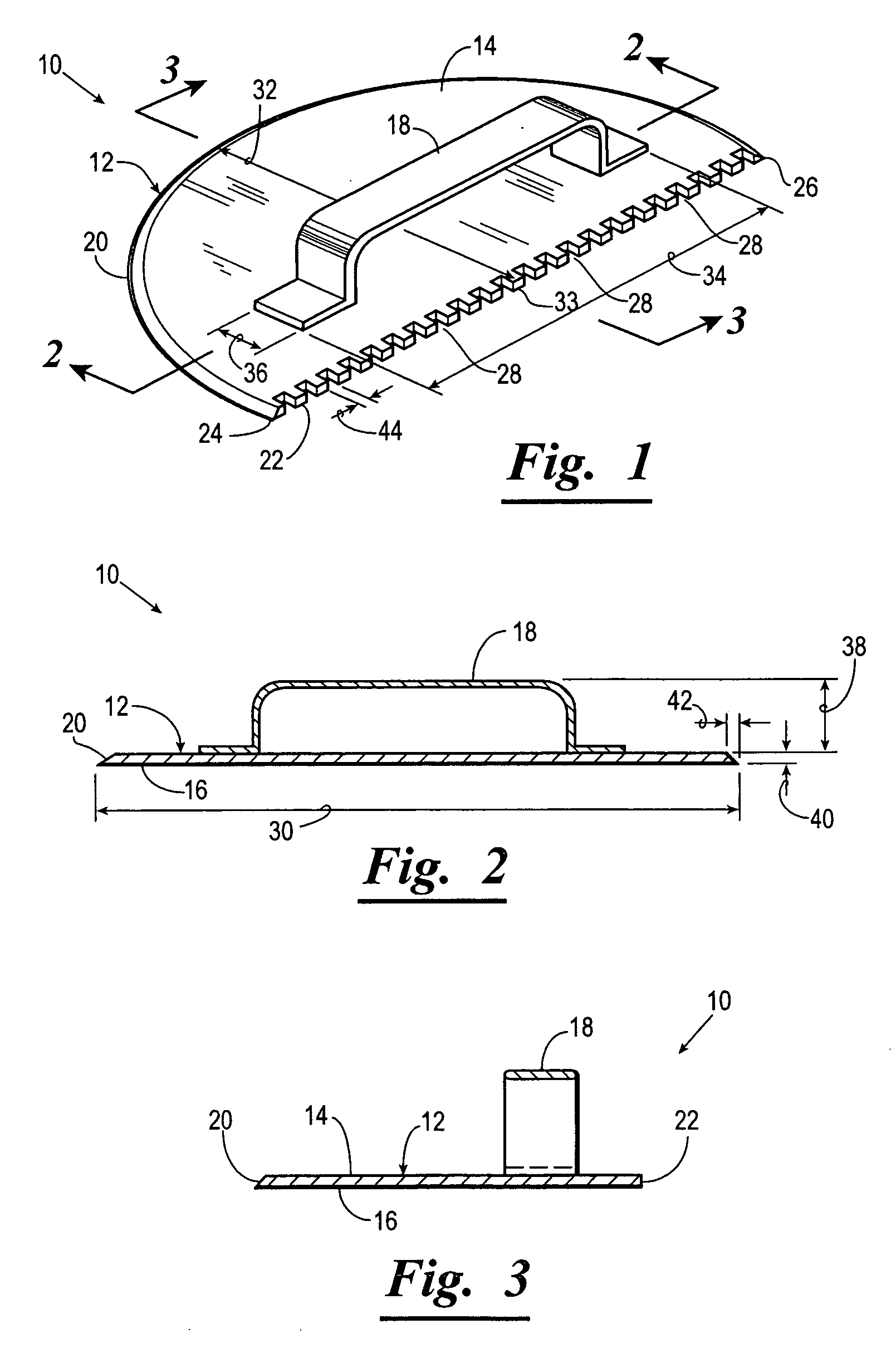

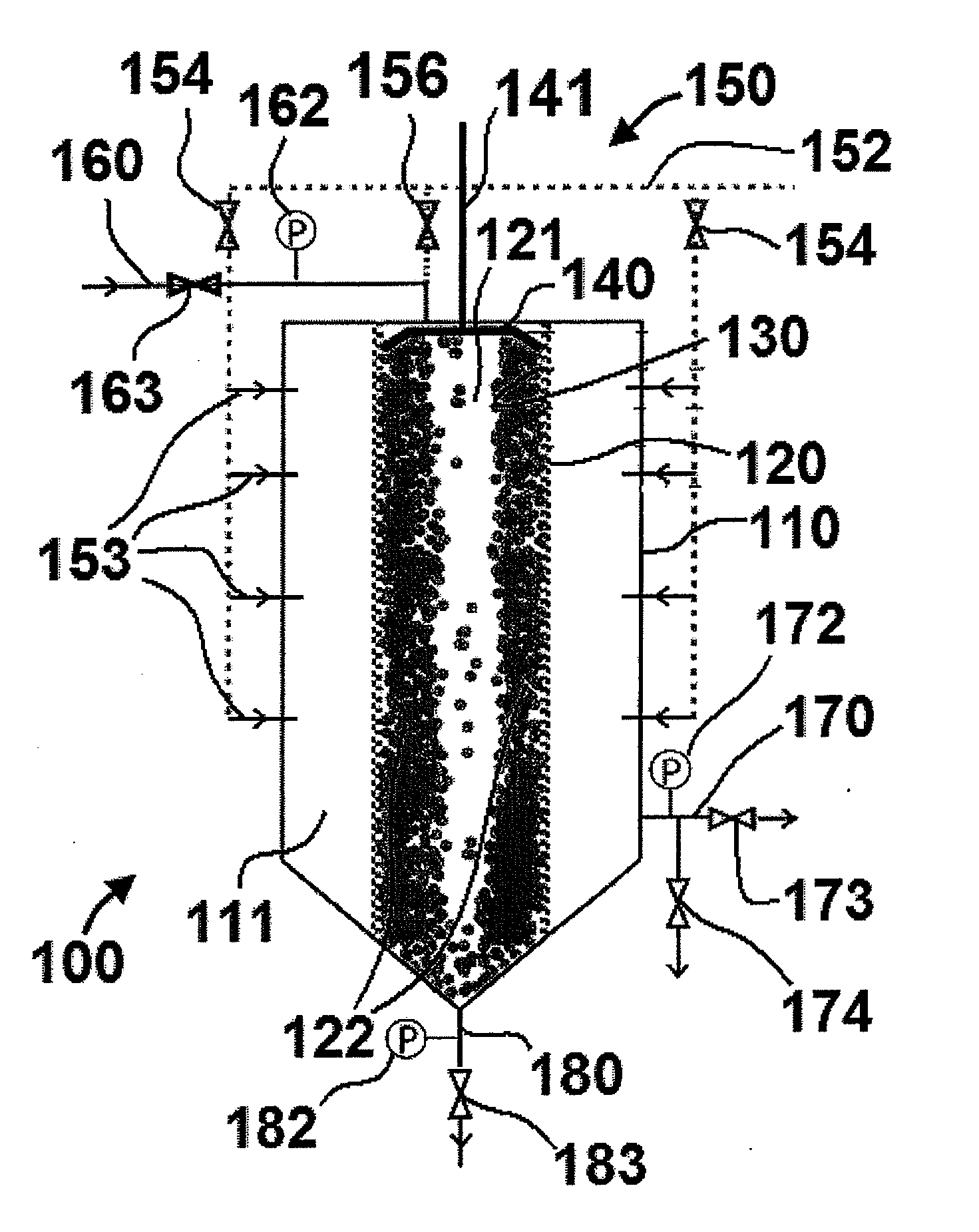

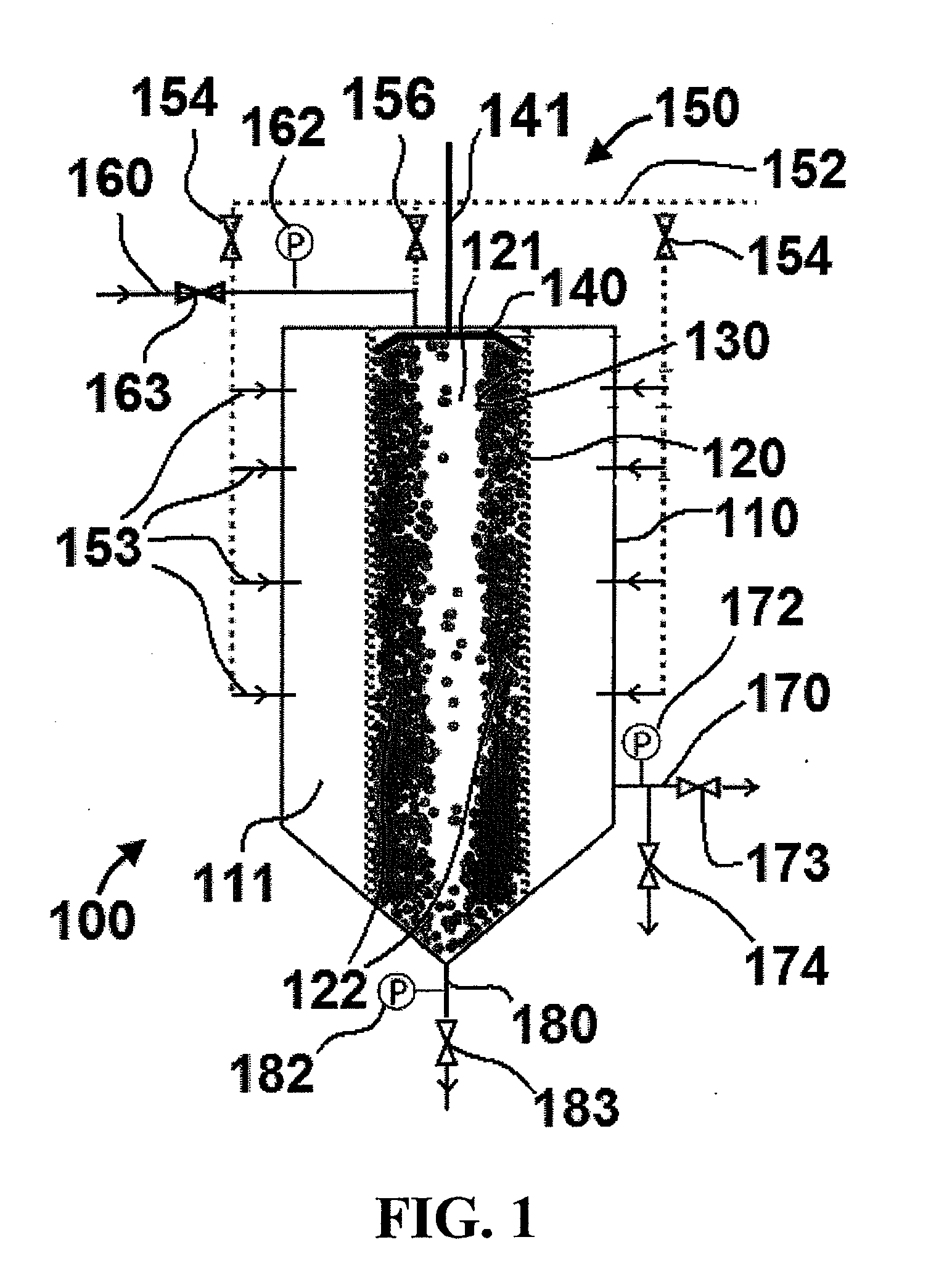

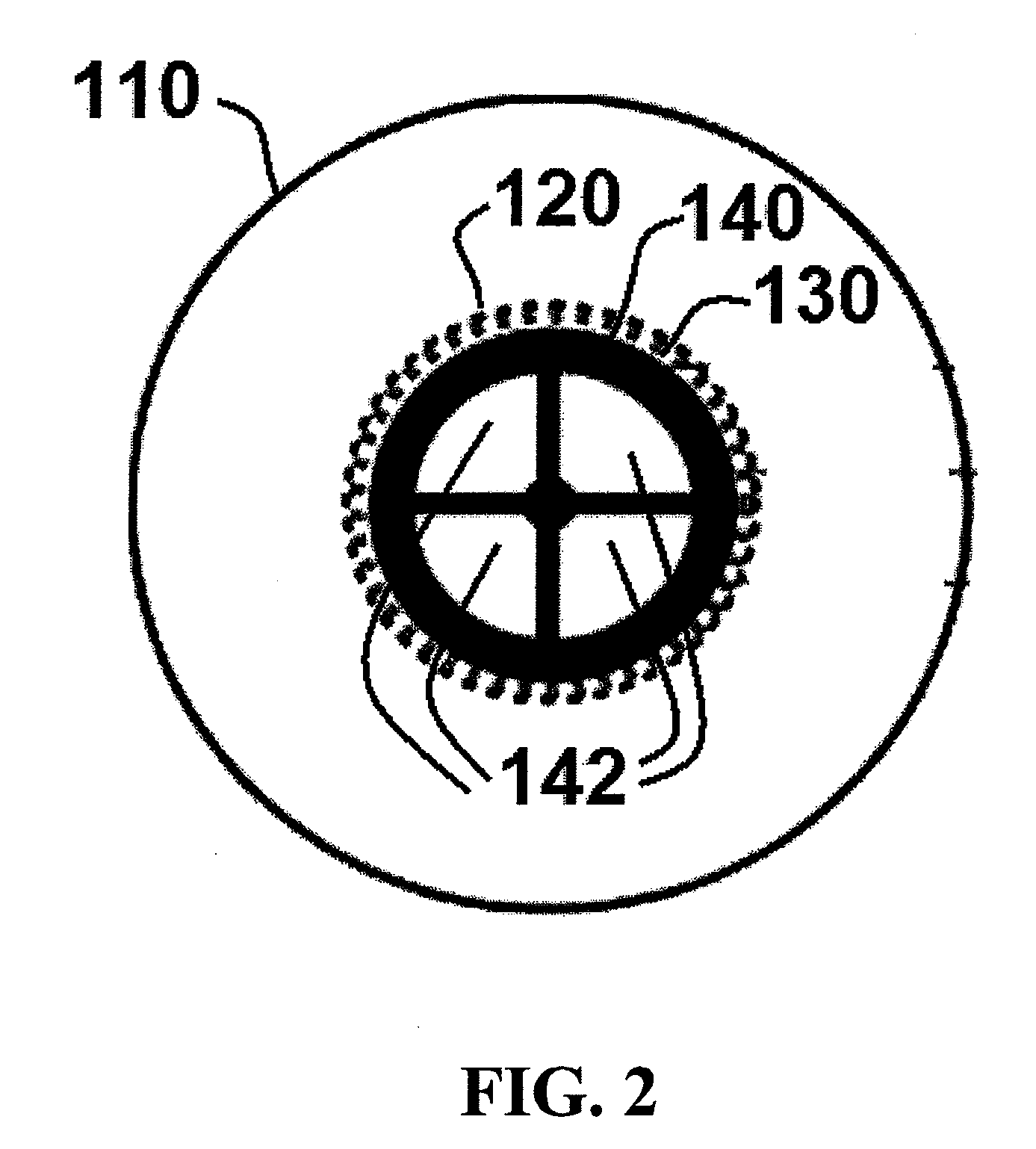

Algae filtration systems and methods

InactiveUS20110253605A1Easy scrapingEasy to removeSemi-permeable membranesAlgae productsFiltrationPiston

Owner:ARIZONA STATE UNIVERSITY

Algae filtration systems and methods

InactiveUS20110253646A1Easily scraped and removed easilyCorrosion resistanceWater/sewage treatmentMembrane filtersFiltrationAlgae

Owner:ARIZONA STATE UNIVERSITY

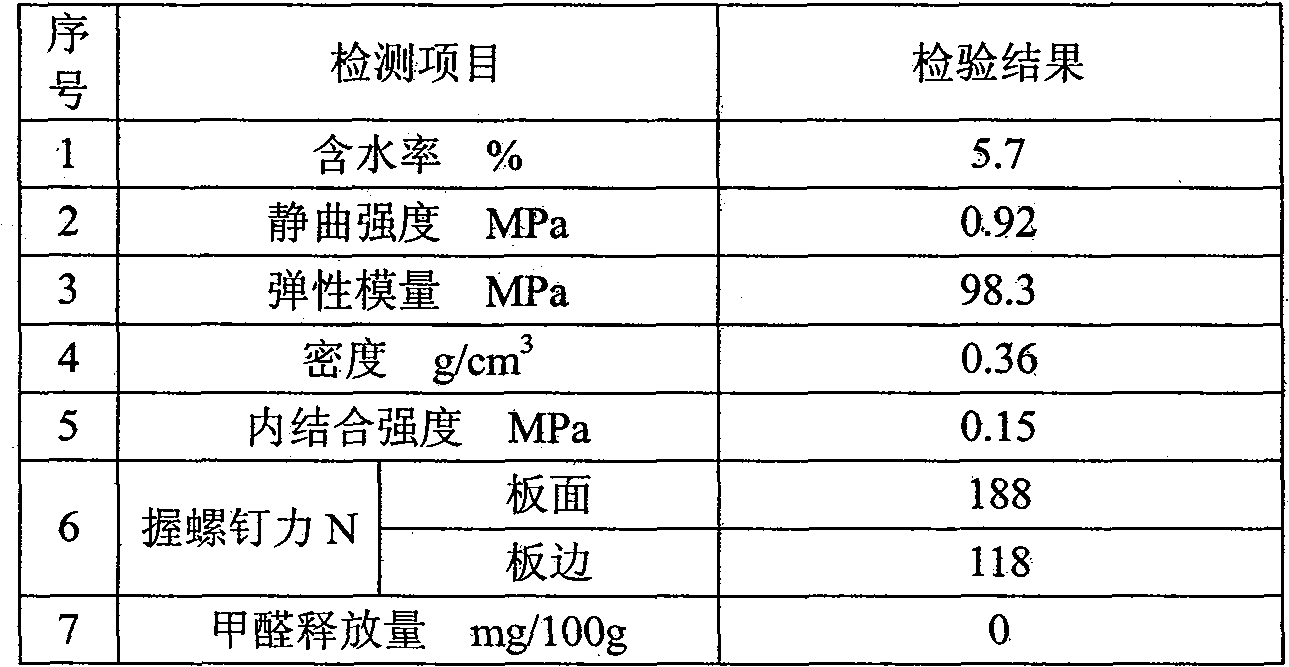

Method for preparing sheets from potatoes or potato residues and discarded vegetable fibers

InactiveCN101967289AUniform materialSmooth materialWood working apparatusDomestic articlesVegetable fibersMaterials science

The invention discloses a method for preparing sheets from potatoes or potato residues and discarded vegetable fibers. The method comprises the following steps of mixing cooked potatoes or potato residues and discarded vegetable fiber powder uniformly, putting the mixture into a die, and forming, polishing, demoulding and drying to obtain sheets. The sheets of the invention have the characteristics of light weight, no toxicity, low cost, simple preparation process, and recycle waste, and contribute to environmental protection, and can be widely applied in fields of decoration, packaging and the like.

Owner:INNER MONGOLIA UNIVERSITY

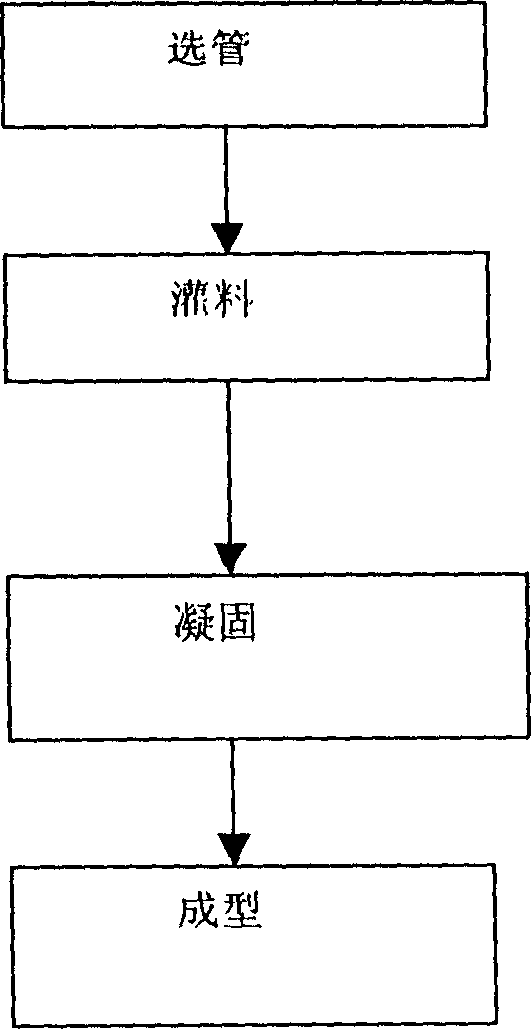

High-strength composite material skeleton for green house and its forming process

InactiveCN1436748AHigh strengthExtended service lifeCeramic shaping apparatusGreenhouseHigh intensity

The high-strength plastic house skeleton of composite material has the material composition of: magnesite powder in 100 weight portions, baume degree 20-35 magnesium chloride solution 80-95 weight portions and modifier 0.1-1.0 weight portions. The plastic house skeleton produced with the material and through solidification has high strength, long service life and low cost. The forming technological process is also disclosed.

Owner:李学术

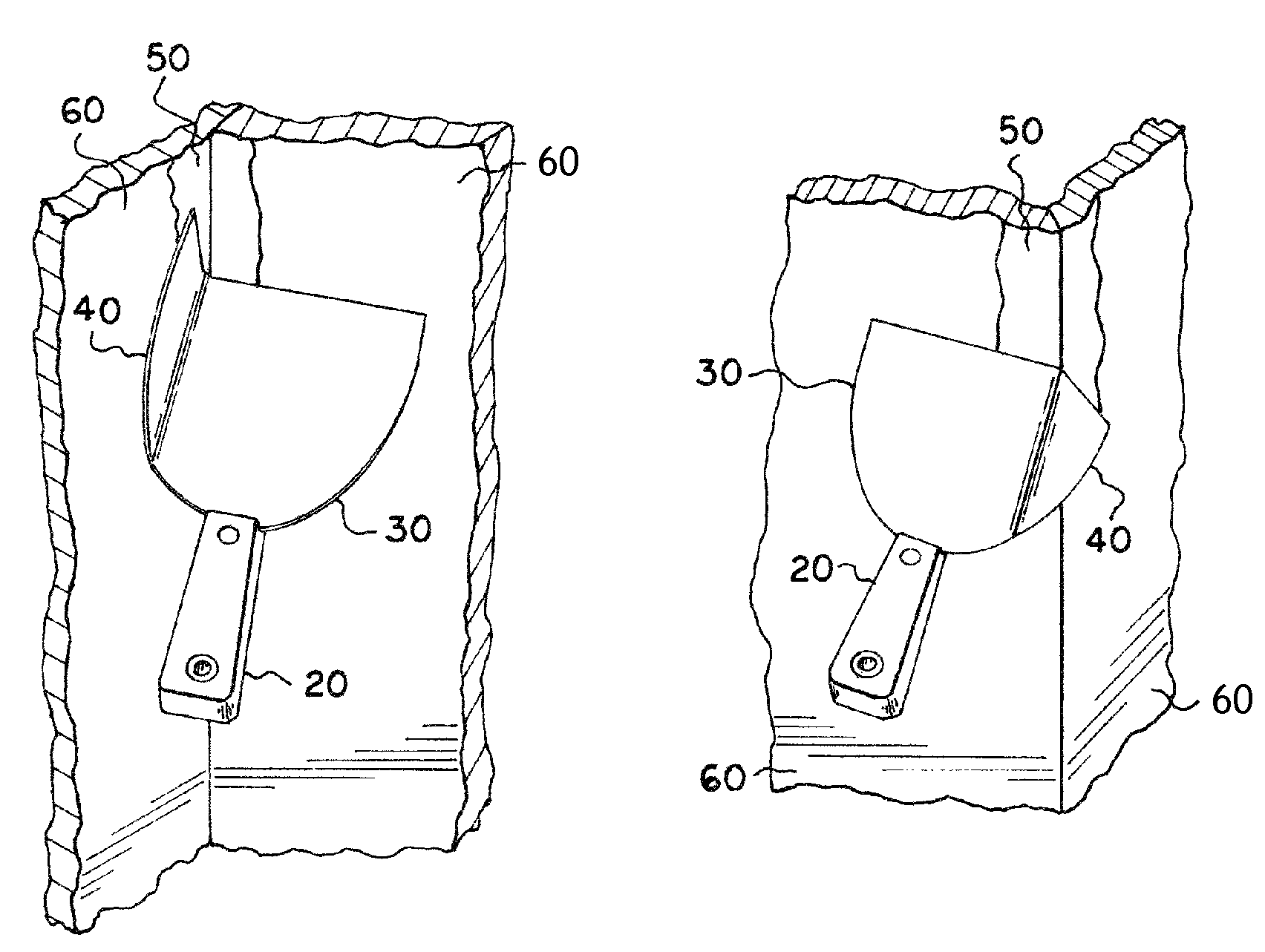

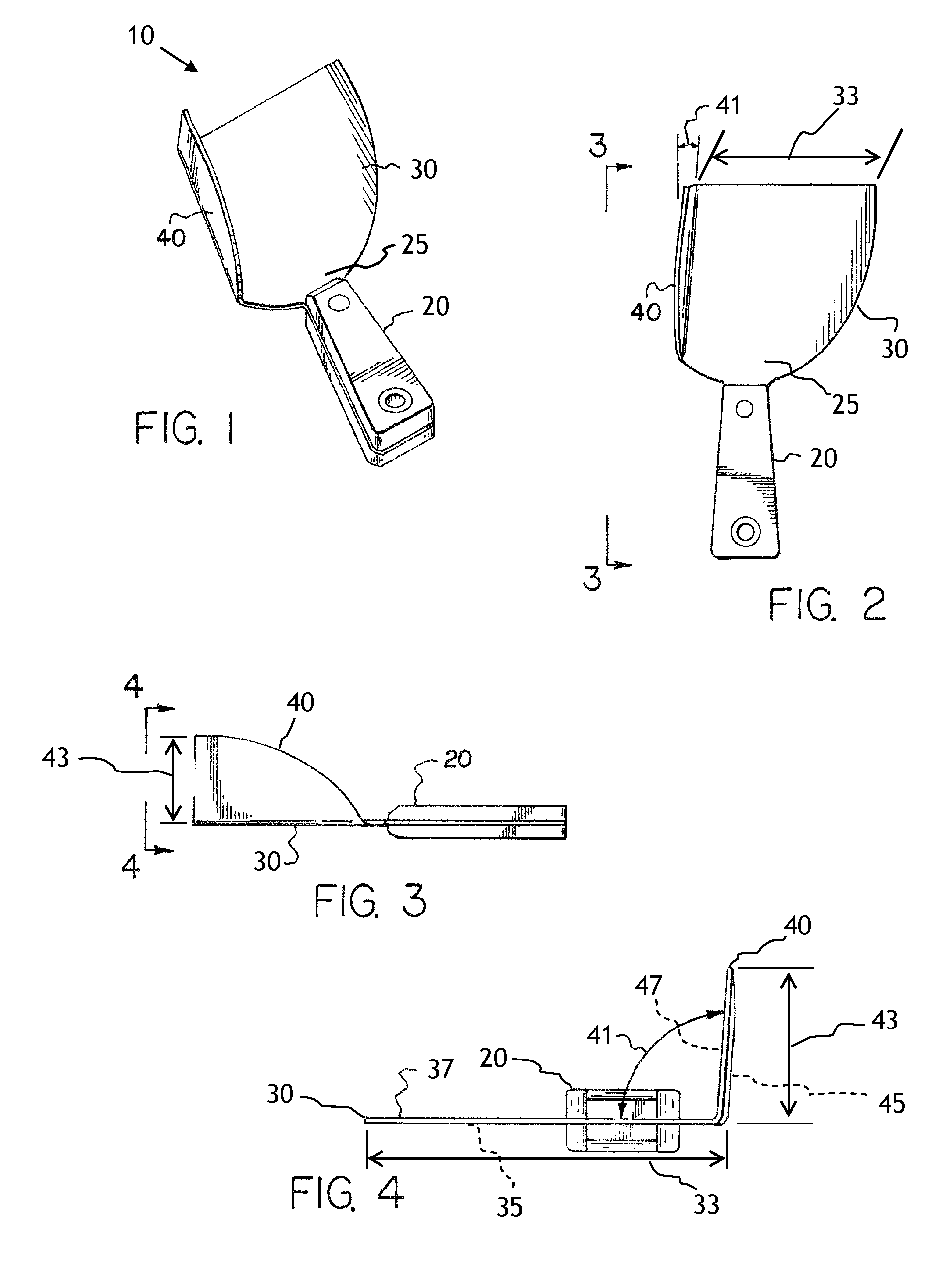

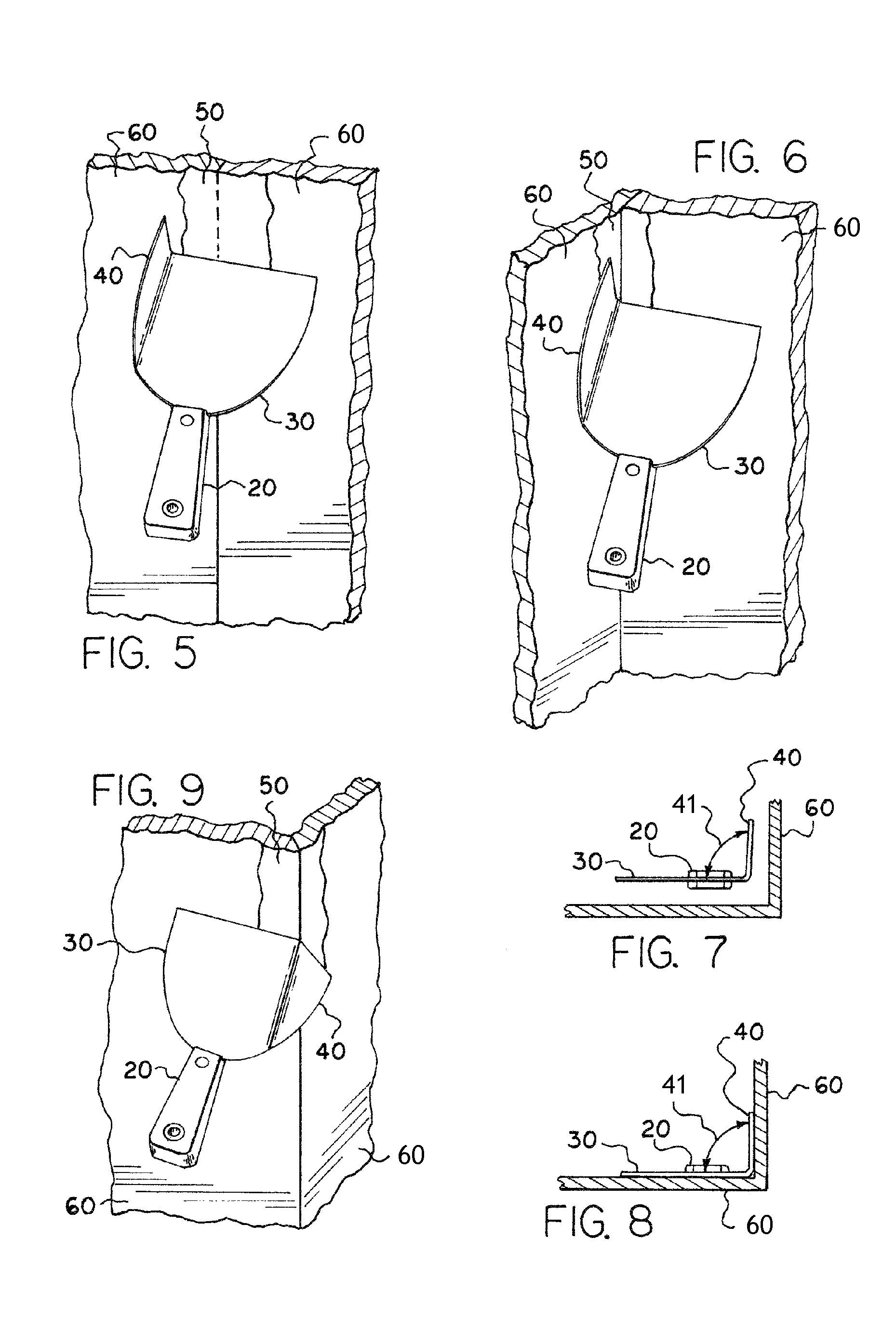

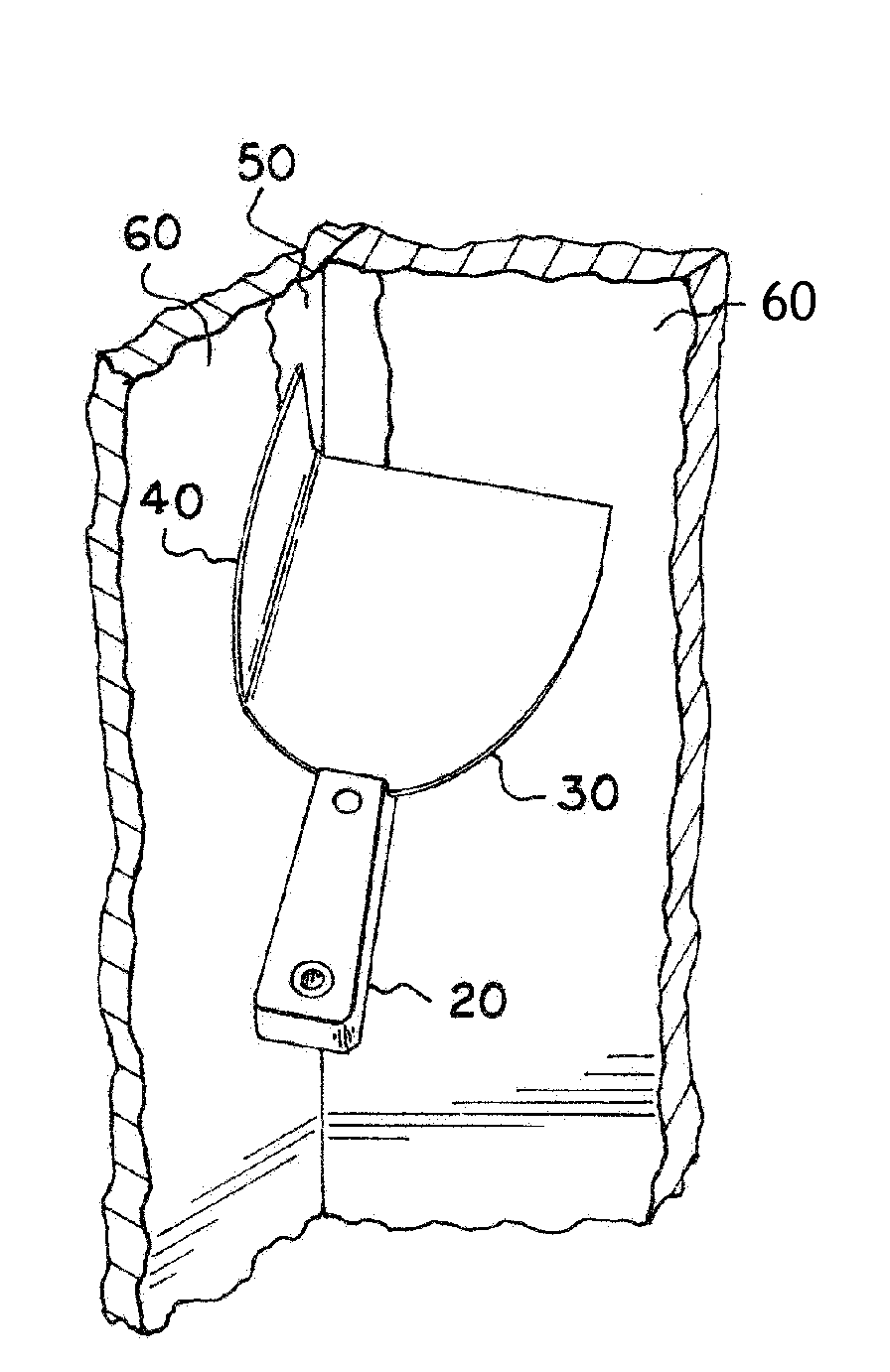

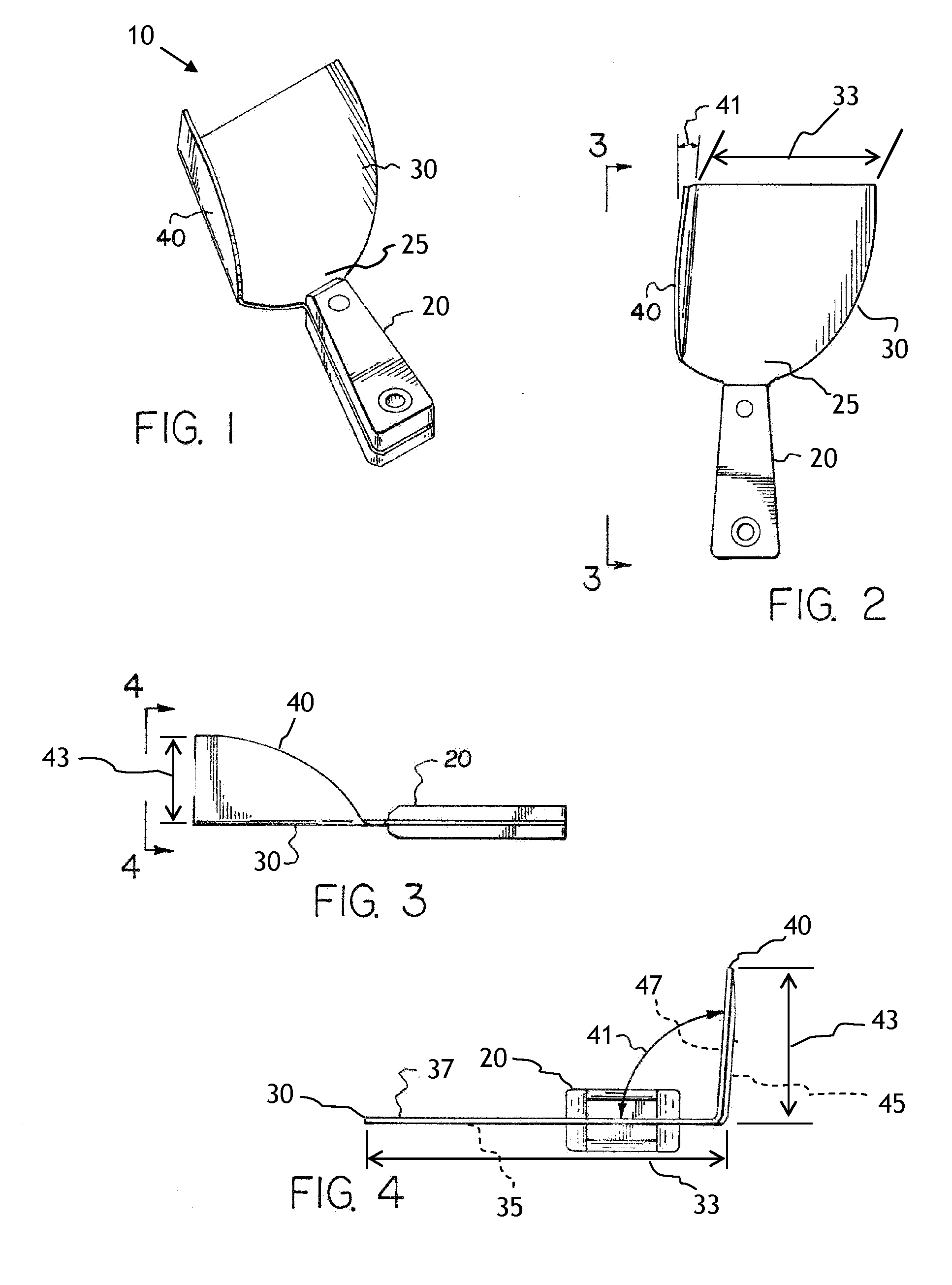

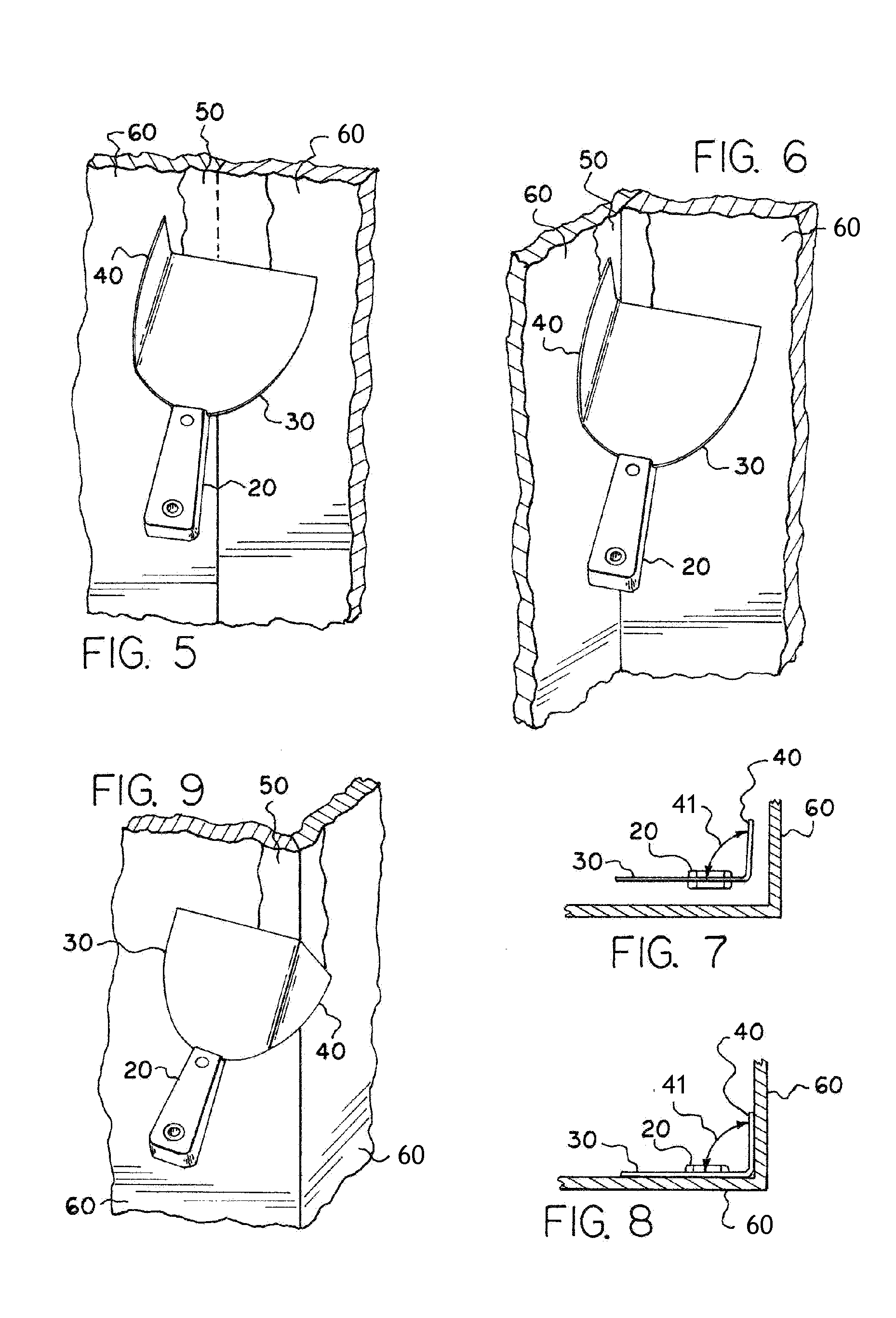

Drywall trowel

InactiveUS8151405B2Apply evenlyEasy to manufactureLiquid surface applicatorsConfectioneryDrywallViscous material

A tool for spreading viscous material comprising a sheet of resilient material having a inner face and an outer face, a handle attachment edge and a forward edge. The sheet being bent from the outer face toward the inner face along a bend line to form a V-shaped point to shape an offset corner blade and at least one substantially flat surface blade from the forward edge, and a handle for gripping the tool attached to the handle attachment edge of the sheet distal distally from the bend line.

Owner:GIANNANTONIO NICHOLAS

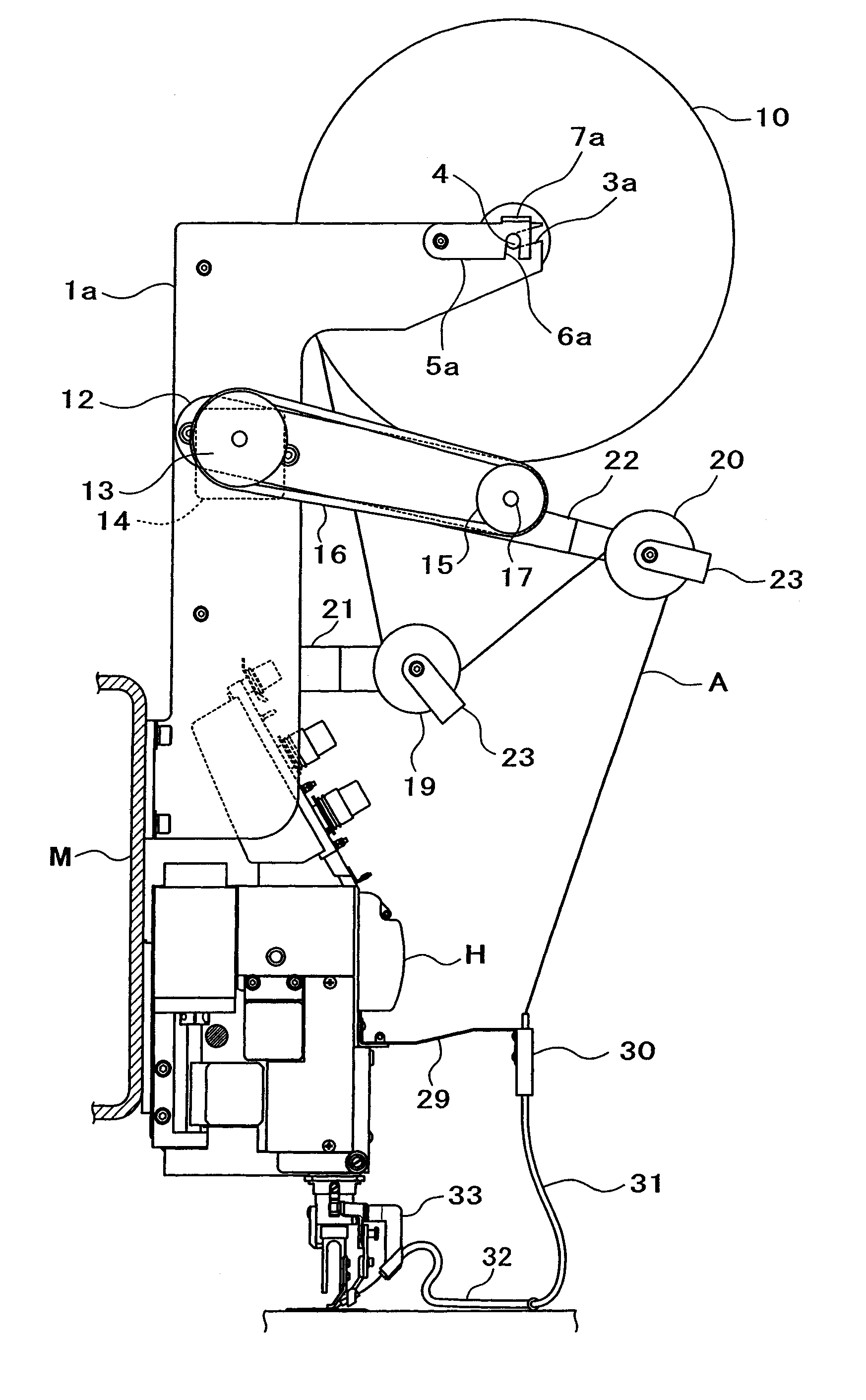

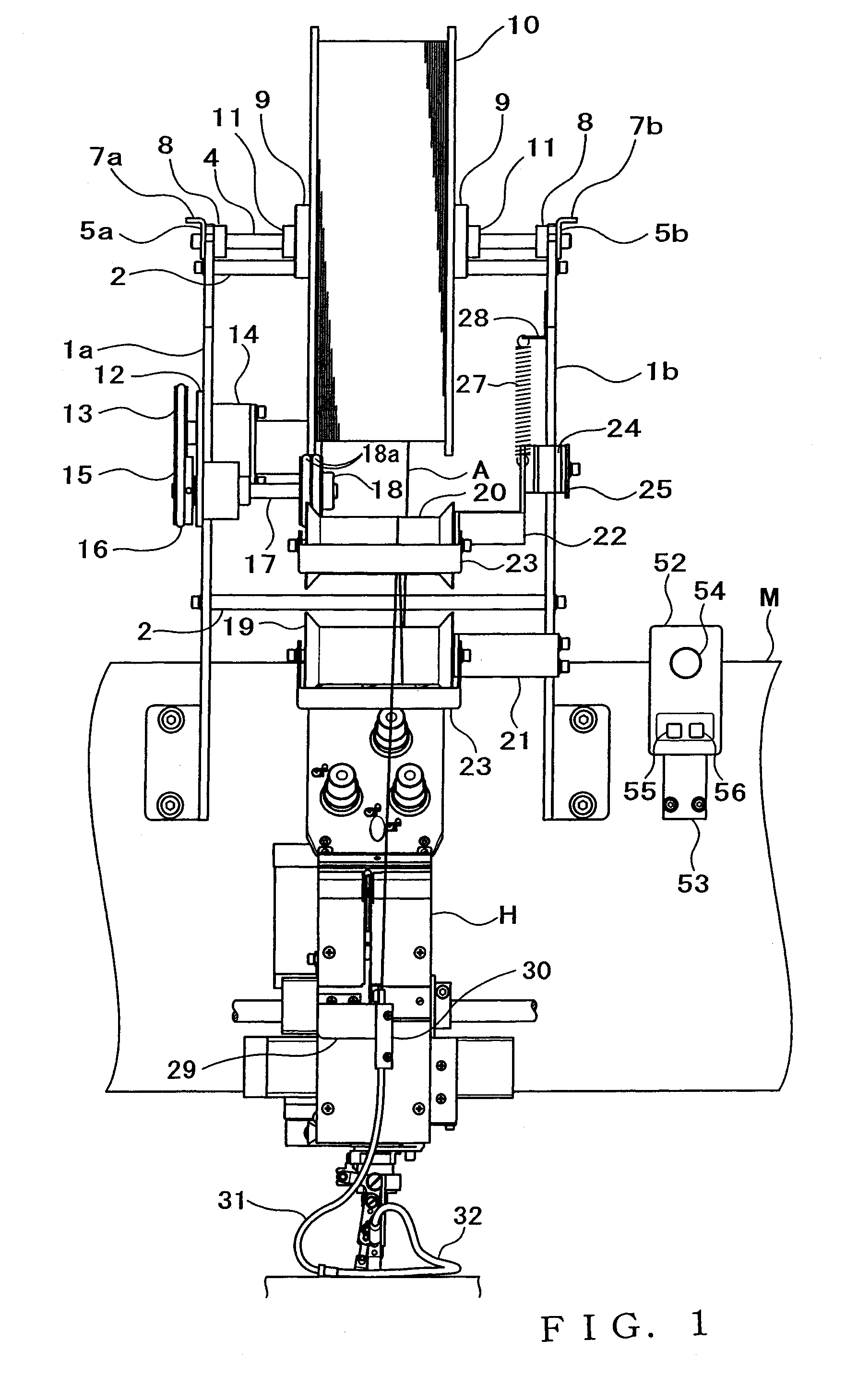

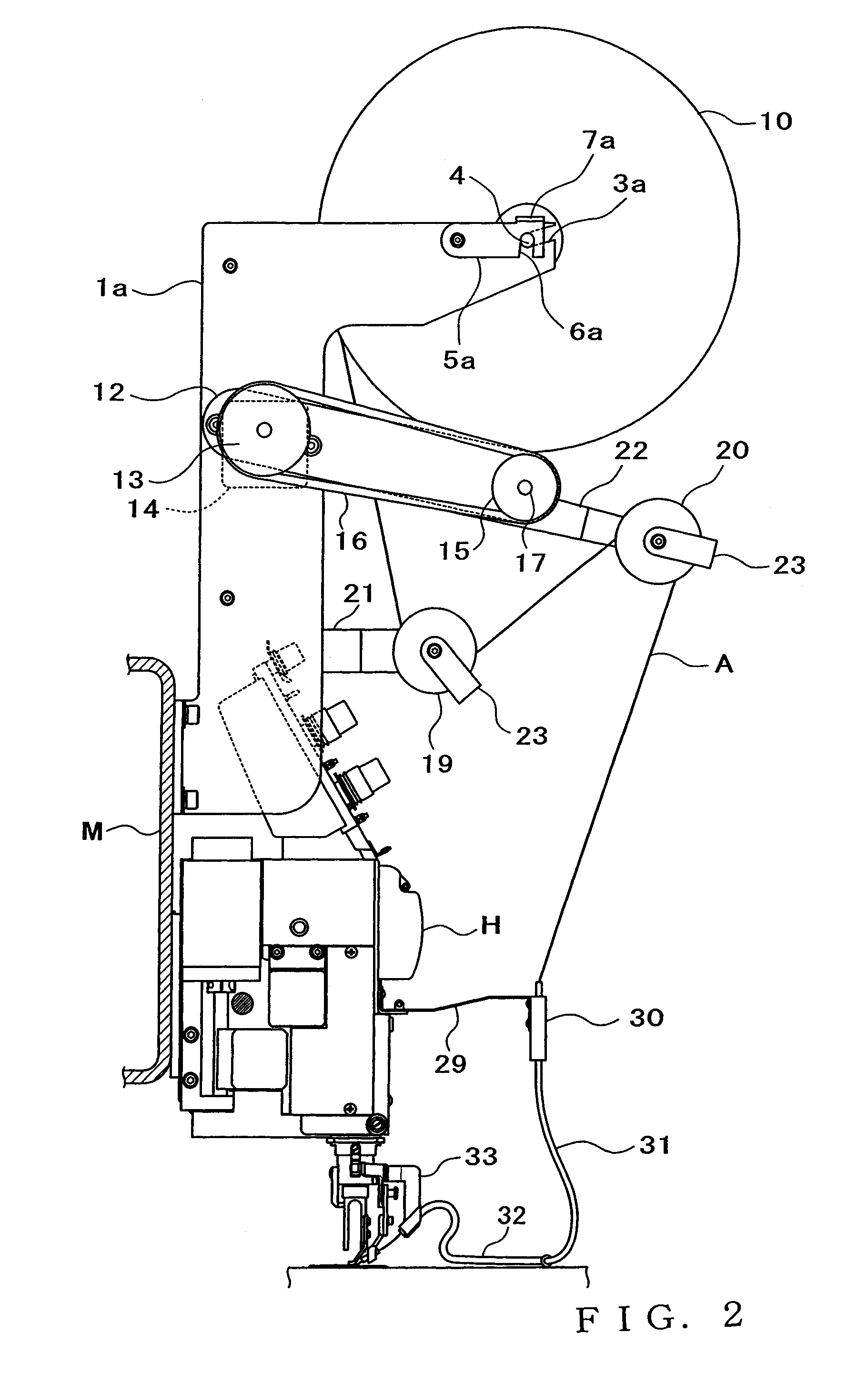

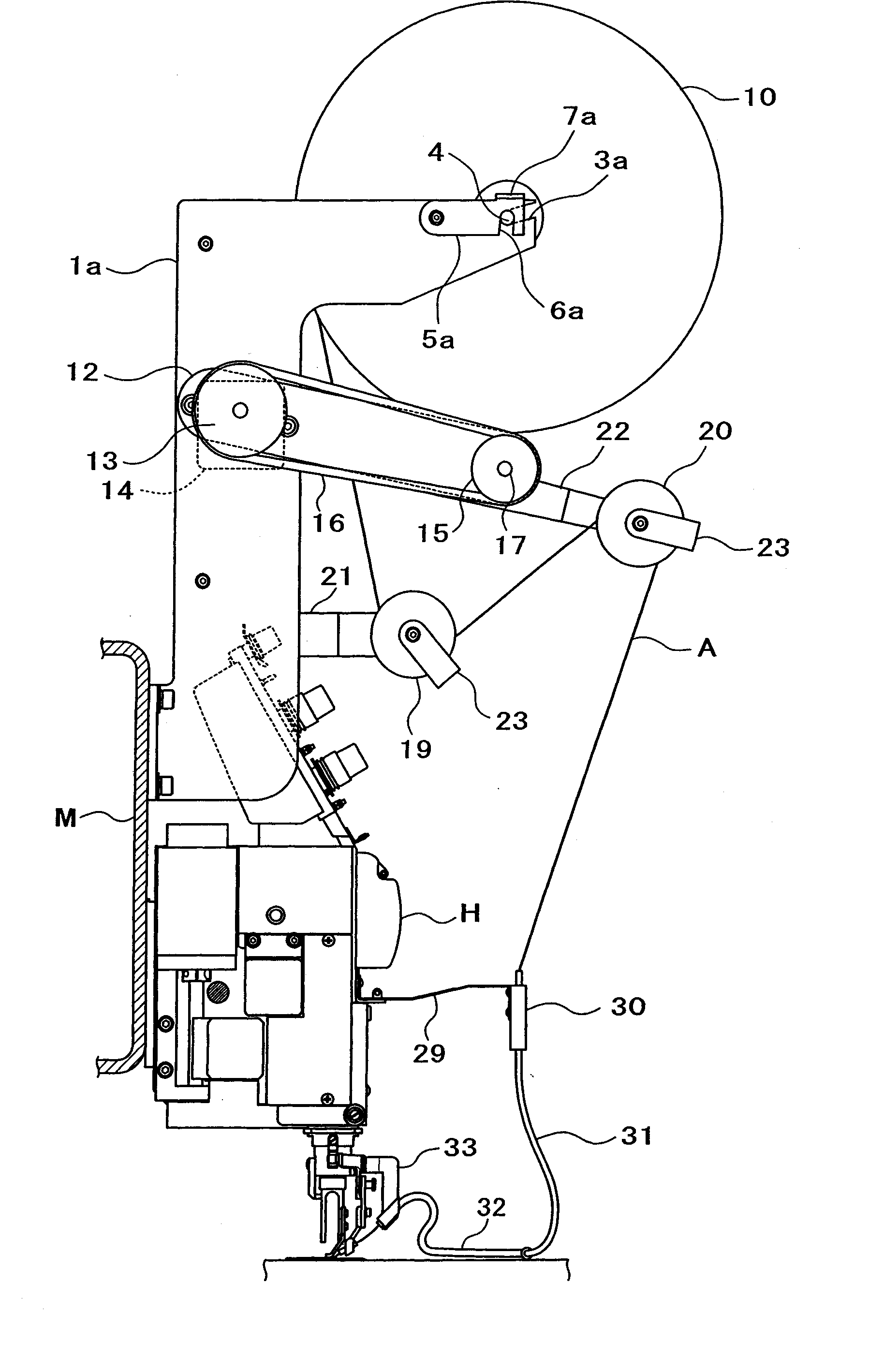

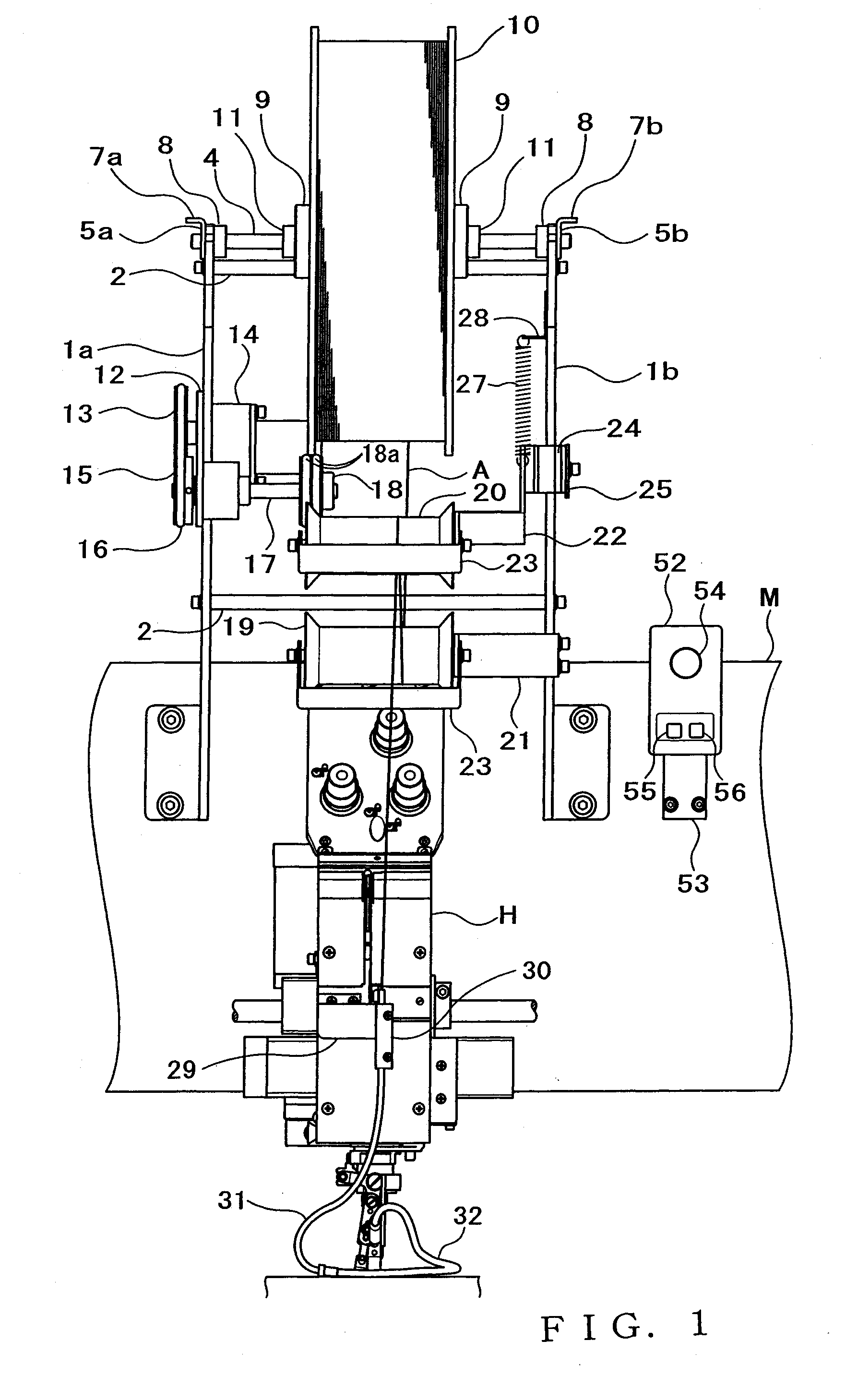

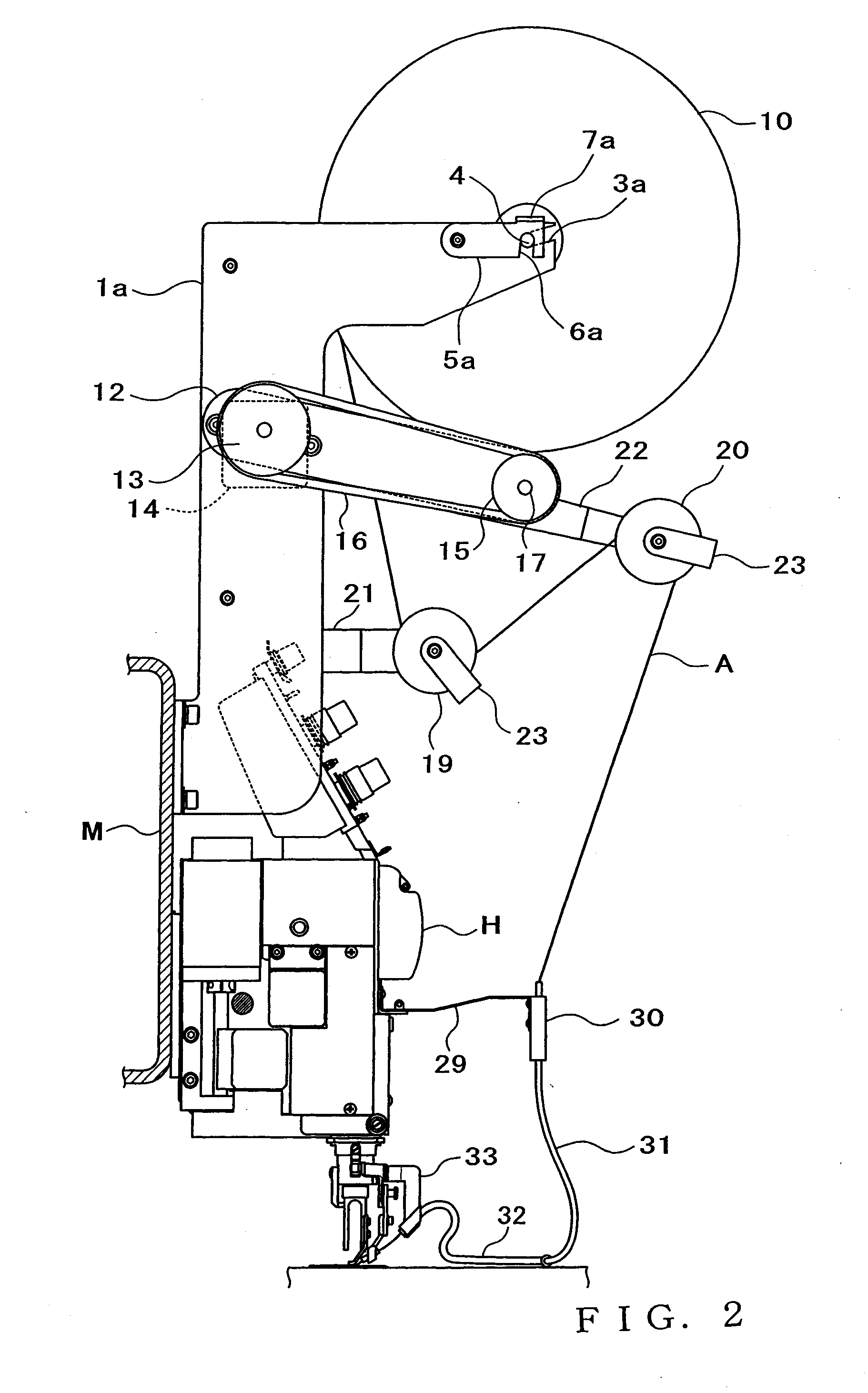

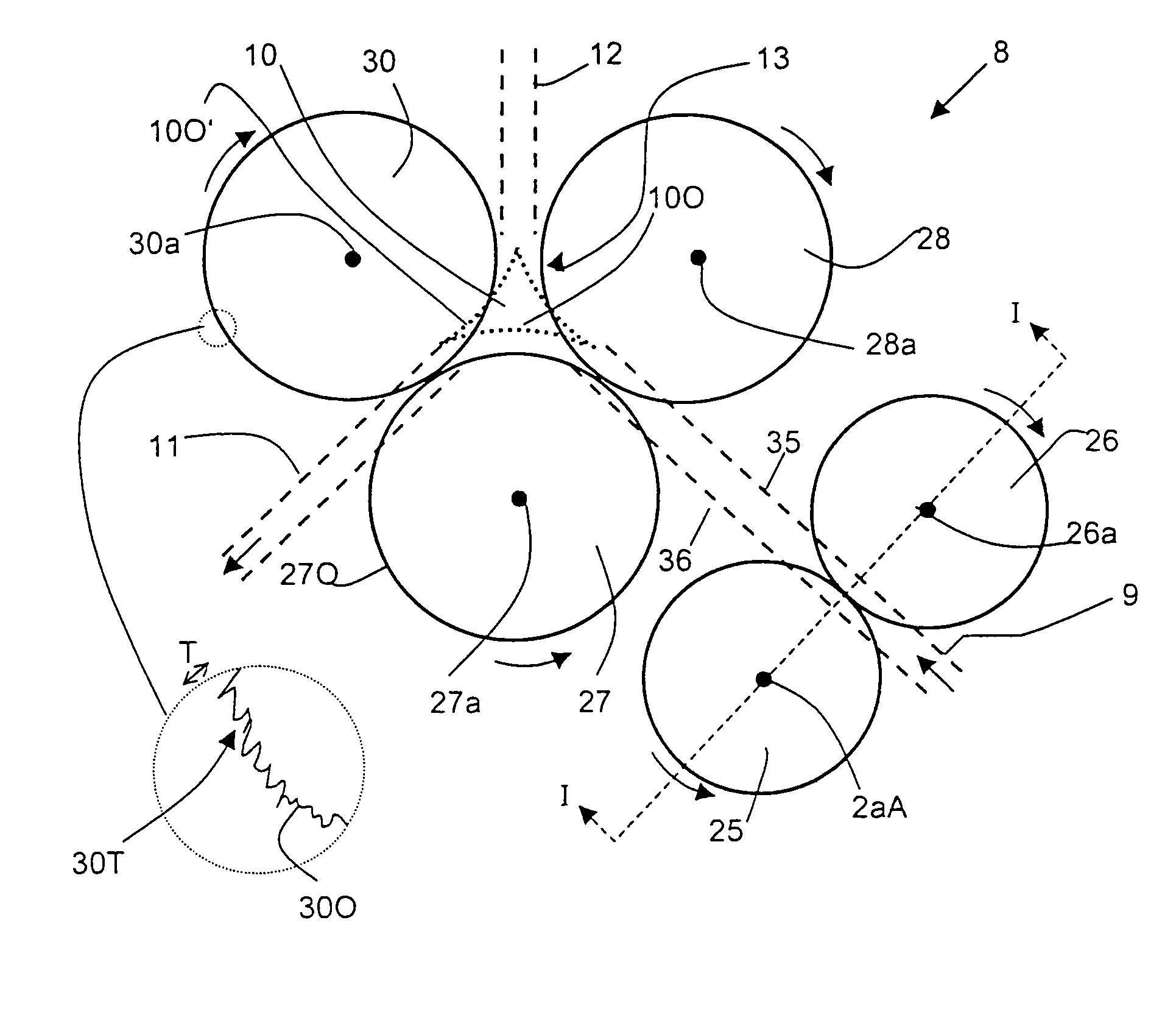

Sewing machine

InactiveUS7370592B2Heavy weightSmoothly paid outWork-feeding meansSewing-machine control devicesIncrease sizeEngineering

Sewing machine includes a tension detection section (26) for detecting tension acting on a sewn material (A) paid out from a rotary holder member, and a drive section for driving the rotary holder member, and the driving operation of the drive section (14) is controlled on the basis of the detection by the tension detection section. Once the tension acting on the sewn material has increased, the rotary holder member is driven to rotate by the drive section, so that the sewn material can be paid out smoothly from the rotary holder member. The sewing machine is particularly useful in a case where the rotary holder member is constructed into an increased size so that an increased amount of the sewn material can be wound thereon.

Owner:TOKAI IND SEWING MACH CO LTD

Drywall trowel

InactiveUS20110041277A1Apply evenlyEasy to manufactureLiquid surface applicatorsConfectioneryEngineeringDrywall

A tool for spreading viscous material comprising a sheet of resilient material having a inner face and an outer face, a handle attachment edge and a forward edge. The sheet being bent from the outer face toward the inner face along a bend line to form a V-shaped point to shape an offset corner blade and at least one substantially flat surface blade from the forward edge, and a handle for gripping the tool attached to the handle attachment edge of the sheet distal distally from the bend line.

Owner:GIANNANTONIO NICHOLAS

Combination squeegee and hand trowel tool

InactiveUS20060272117A1Efficient removalSmooth materialLiquid surface applicatorsCarpet cleanersEngineeringKnife blades

Owner:CRISSWELL CARL

Sewing machine

InactiveUS20070137540A1Heavy weightSmoothly paid outWork-feeding meansSewing-machine control devicesIncrease sizeEngineering

Sewing machine includes a tension detection section (26) for detecting tension acting on a sewn material (A) paid out from a rotary holder member, and a drive section for driving the rotary holder member, and the driving operation of the drive section (14) is controlled on the basis of the detection by the tension detection section. Once the tension acting on the sewn material has increased, the rotary holder member is driven to rotate by the drive section, so that the sewn material can be paid out smoothly from the rotary holder member. The sewing machine is particularly useful in a case where the rotary holder member is constructed into an increased size so that an increased amount of the sewn material can be wound thereon.

Owner:TOKAI IND SEWING MACH CO LTD

Powder sealing valve

InactiveCN102042417AGuaranteed cleanlinessSolve the sticky problemCleaning using gasesLift valveEngineeringNitrogen gas

The invention discloses a powder sealing valve comprising a valve body, a sweeping mechanism, a valve core and an executing mechanism; the valve core is arranged in the valve body to open and close the valve under the effect of the executing mechanism; the sweeping mechanism is an annular gas chamber; the annular gas chamber is also arranged in the valve body; the valve core is in sealed contact with the gas chamber; the sealing surfaces of the valve core and the gas chamber are both spherical surfaces; the annular gas chamber is provided with a gas inlet and a gas outlet; and the gas outlet is arranged on the sealing surfaces of the gas chamber and the valve core. In the invention, the annular gas chamber is arranged in the valve body, the gas inlet is arranged outside the gas chamber, the gas outlet is arranged on the sealing surfaces of the interior of the gas chamber and the valve core, and dry gas (compressed gases of air and nitrogen can be selected according to conditions for use) is injected between the sealing surfaces to keep the sealing surfaces clean by means of the sweeping of gas flow, thereby solving the problem of material sticking, realizing reliable sealing and achieving zero leakage.

Owner:LIMIN CHEM CO LTD

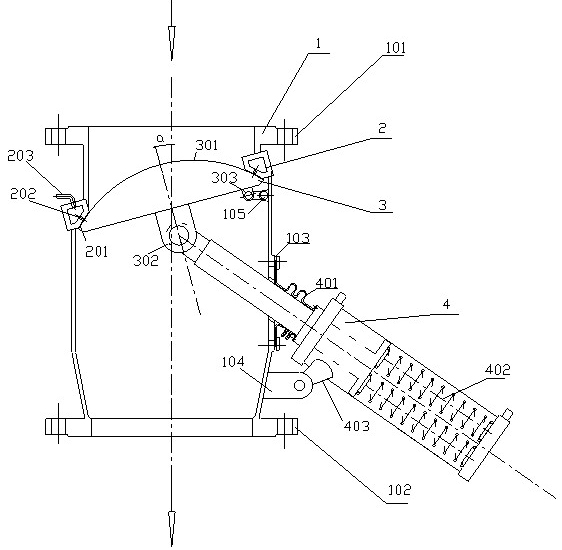

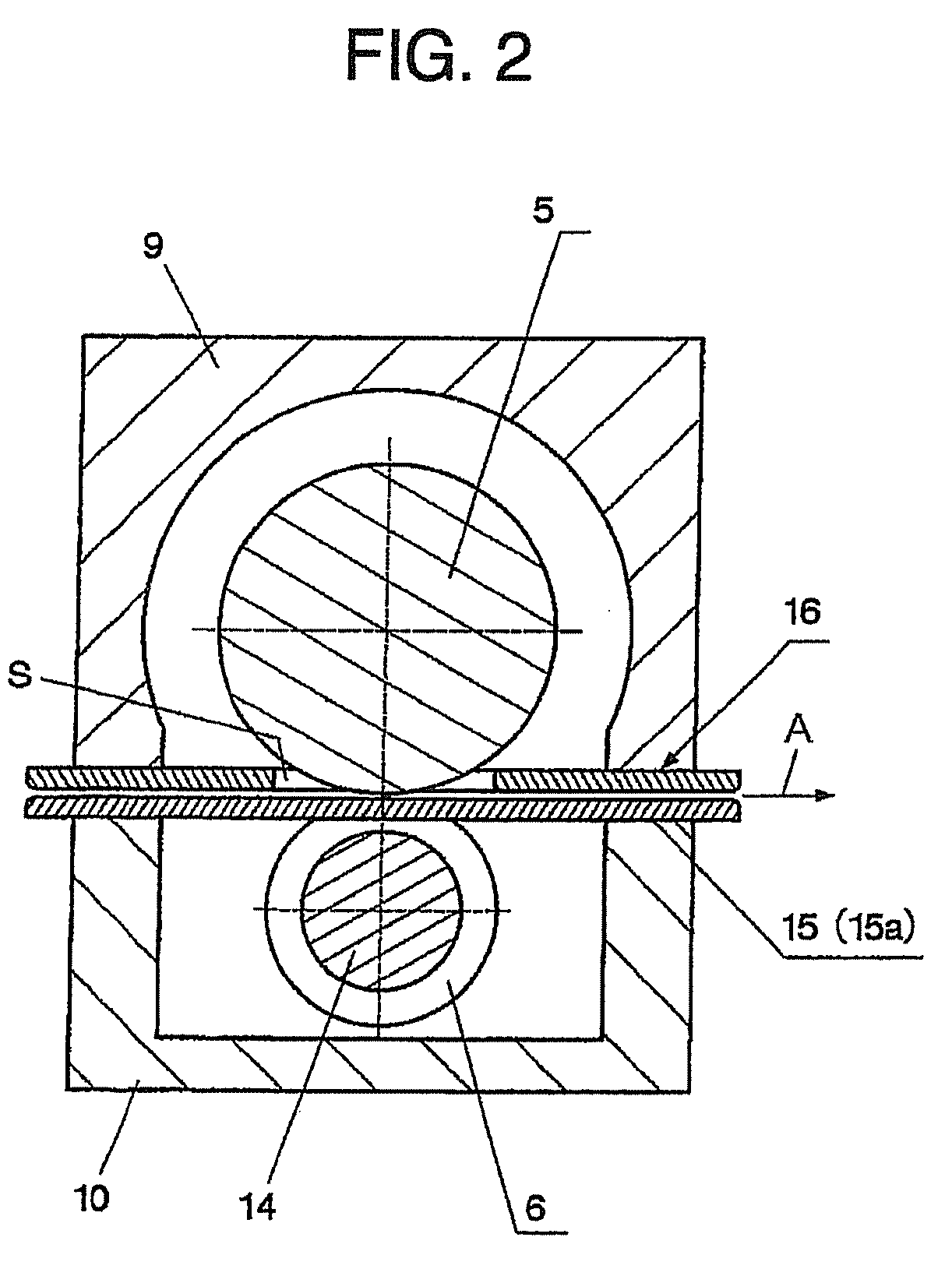

Sheet material feeding apparatus

ActiveUS20090108521A1Stable of sheet materialSmooth materialMetal working apparatusArticle feedersEngineeringSheet material

A sheet material feeding apparatus capable of favorably guiding a sheet material to perform smooth feeding comprises a pair of rolls and first and second guide members and permits a sheet material to pass between the first guide member and the second guide member. One of the rolls has a plurality of circumferential grooves arranged between both ends of a sheet material feeding surface in an axial direction and spaced from one another in the axial direction, and the first guide member includes guide portions passing through the respective circumferential grooves and extending continuously to a downstream side from an upstream side between the pair of rolls in a sheet-material conveyance direction.

Owner:SANKYO SEISAKUSHO

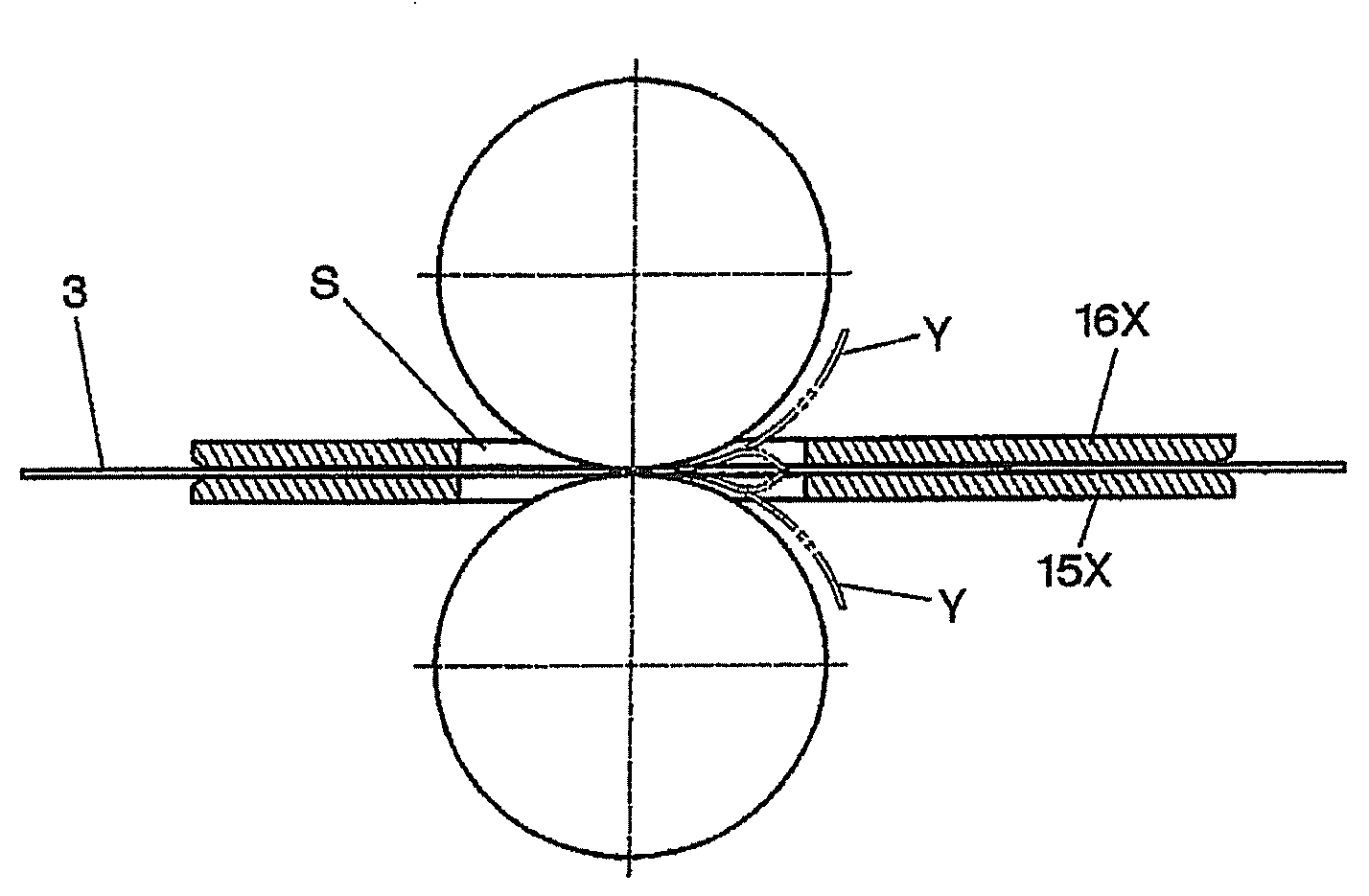

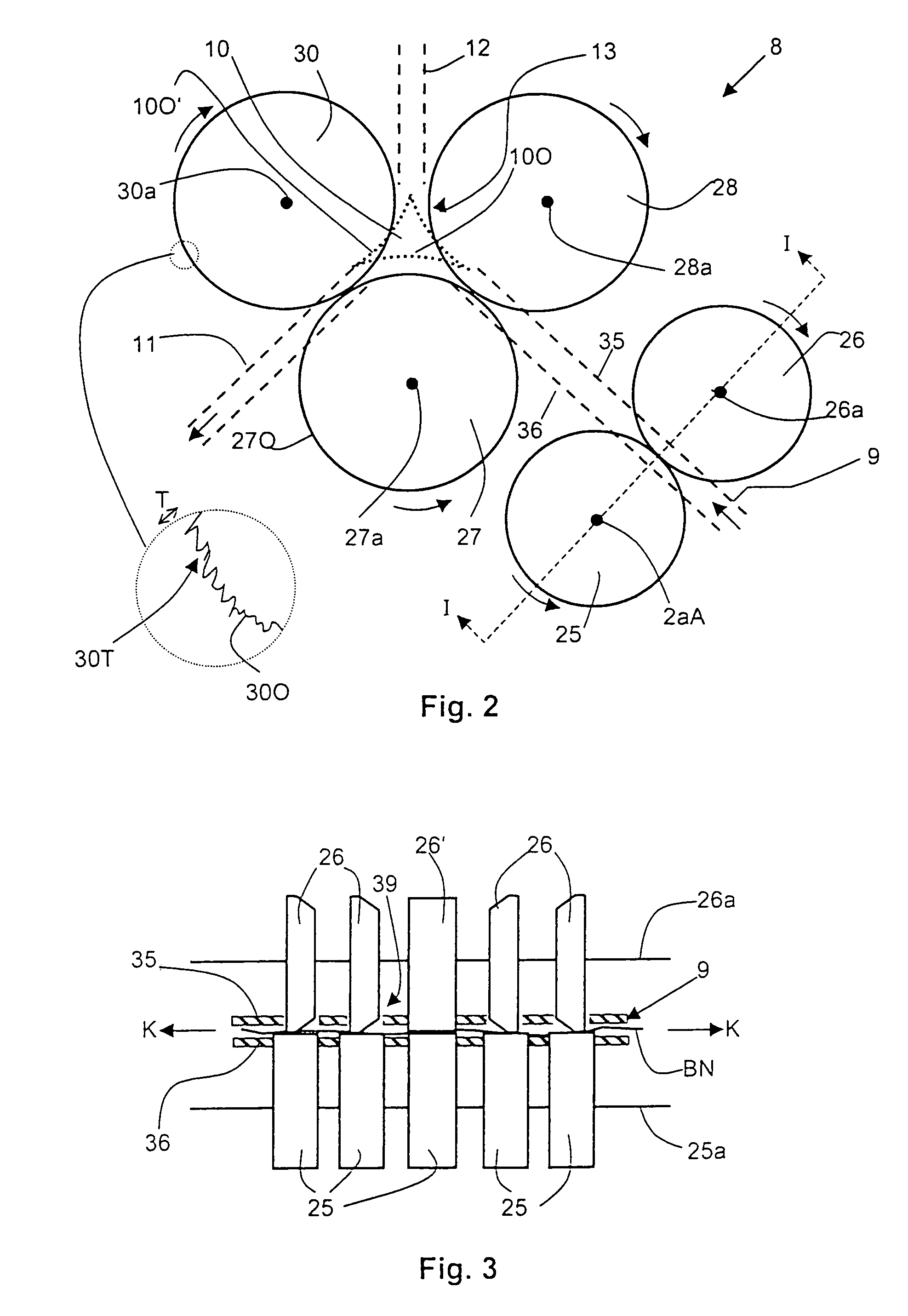

Apparatuses for processing sheet material

InactiveUS7624982B2Reduce incidenceSmooth materialPaper-money testing devicesCoin/currency accepting devicesEngineeringSheet material

An apparatus for processing sheet material includes a transport device for transporting single sheets of the sheet material. The transport device includes a diverting device for diverting the transport direction of the single sheets having one or more opposite first and second diverting elements between which the sheets are transported through for diversion. One of the diverting elements has a roughened surface with depressions of at least 1 mm. The apparatus further includes a smoothing device arranged so as to pull apart the sheet material in a direction perpendicular to the transport direction immediately before diversion in the diverting device.

Owner:GIESECKE & DEVRIENT GMBH

Fixed material transportation apparatus, fixed material discharging apparatus, method for discharging the fixed material, liquid fixing apparatus

InactiveUS7367668B2Smooth materialShort working hoursOther printing apparatusReciprocating motionDecompression chamber

A fixed material transportation apparatus having a reciprocating stage, plural sucking holes, a decompression chamber connecting to the plural sucking holes, and a sucking device sucking air in the decompression chamber set at a discharging side of the fixed material. The fixed material is fed on the fixed material transportation surface of the sucking device by the delivering device, and is stuck on the fixed material transportation surface through the sucking holes by the sucking device. The fixed material is transported gradually to a downstream side from an upstream side by the delivering device on the fixed material transportation surface. The fixed material then separates from a surface of the fixed material transportation surface and rises slightly by blowing air from the sucking holes so as to move to discharging direction, that is, the downstream side.

Owner:SEIKO EPSON CORP

Conveying device with thread clamping prevention structure for textile machining

InactiveCN112777262APrevent pulling outAvoid pinchingConveyorsControl devices for conveyorsSpinningElectric machinery

The invention relates to the technical field of textile conveying devices, in particular to a conveying device with a thread clamping prevention structure for textile machining. The conveying device comprises a textile conveying device main body and a motor, wherein the textile conveying device main body comprises a control box shell main body, and a control panel is fixedly arranged on the front surface of the control box shell main body. By arranging anti-deviation mechanisms, threaded grooves can freely slide in a rectangular empty box, the positions of the threaded grooves can be adjusted, the position of a supporting rod is fixed by rotating bolts and clamping the threads of the bolts into the appropriate threaded grooves, the supporting rod cannot freely move, the threaded grooves enable a spinning bobbin to be blocked by cylindrical rods at the two sides, the spinning bobbins cannot slide to a gap between a conveyor belt and a conveying stainless steel shell body, the thread clamping phenomenon is avoided, nuts prevent the supporting rod from being pulled out of the rectangular empty box in the adjusting process, the surfaces of the cylindrical rods are smooth, and thread hooking cannot be caused when the position of the spinning bobbin is adjusted.

Owner:蔡柳飞

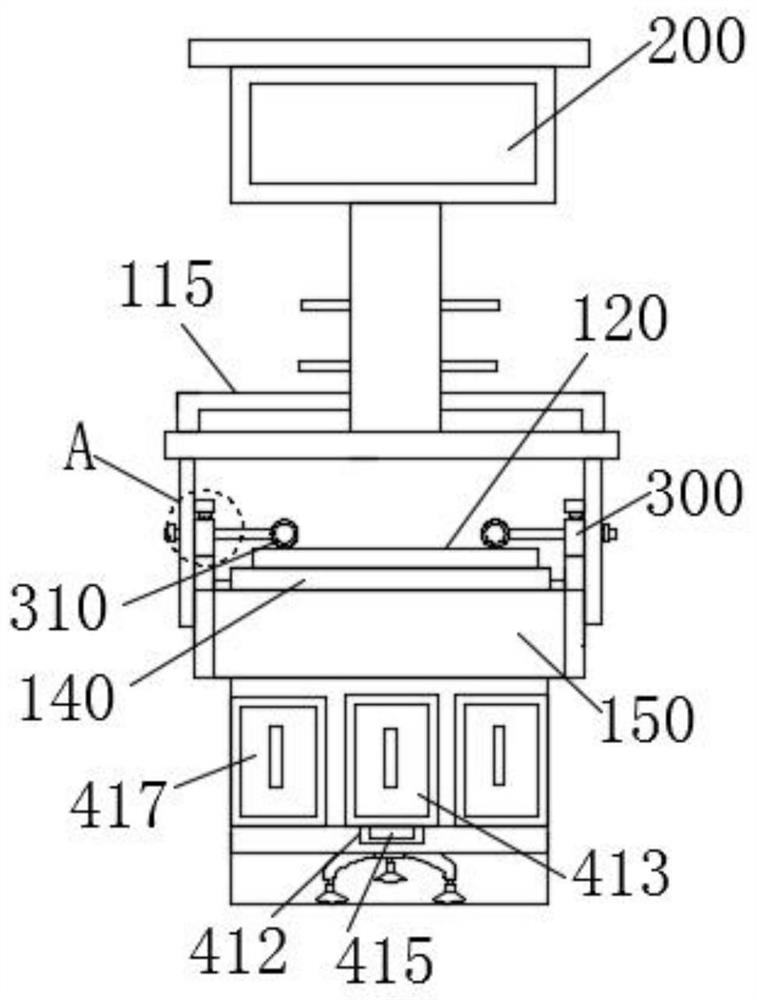

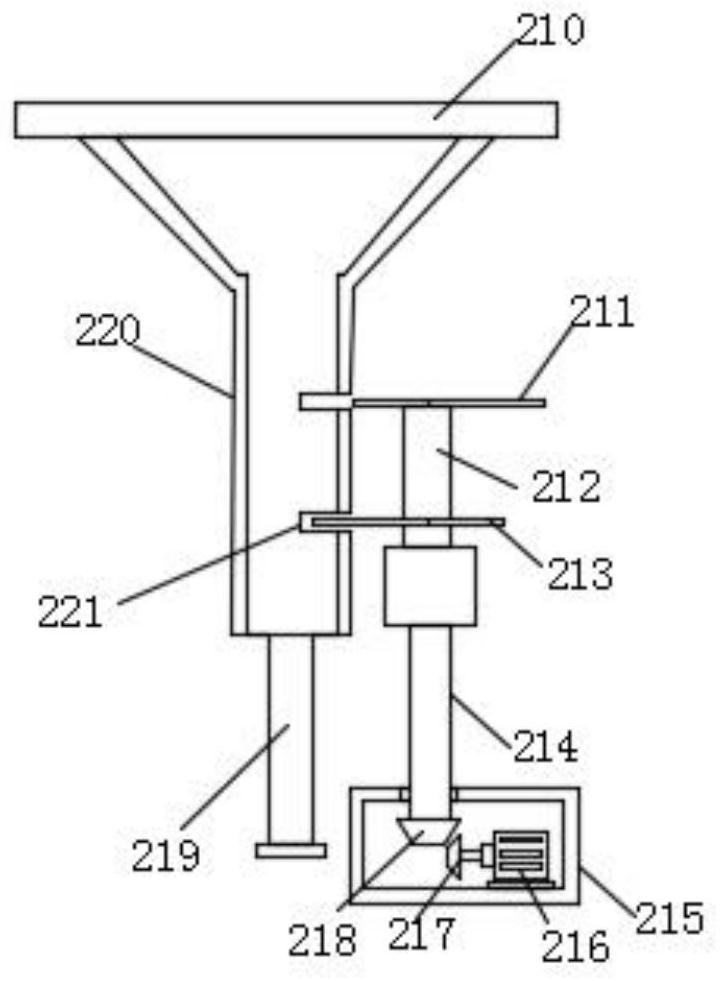

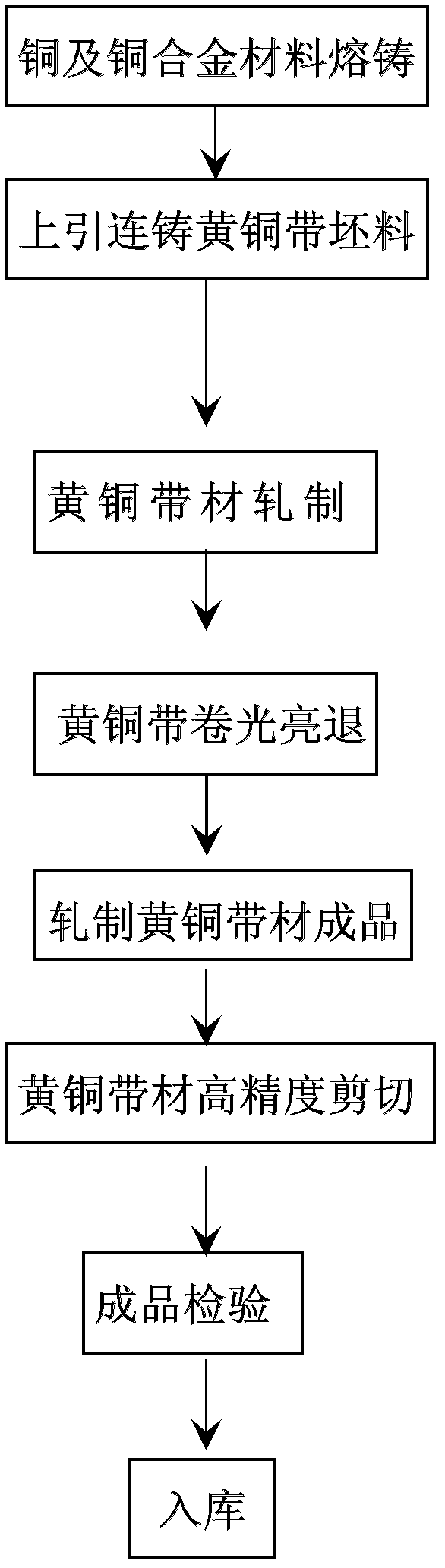

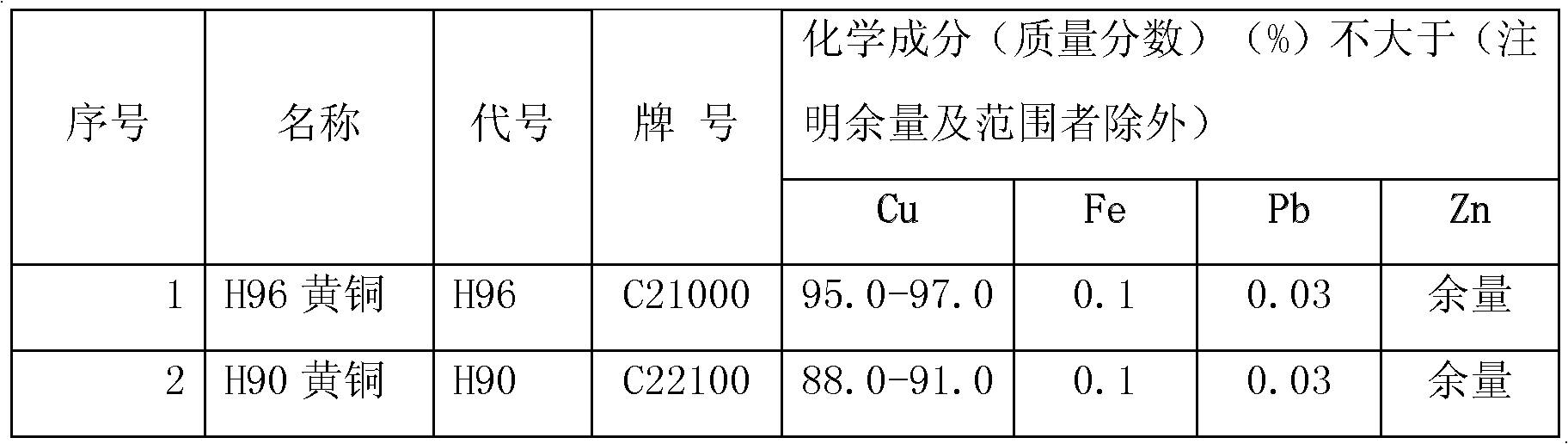

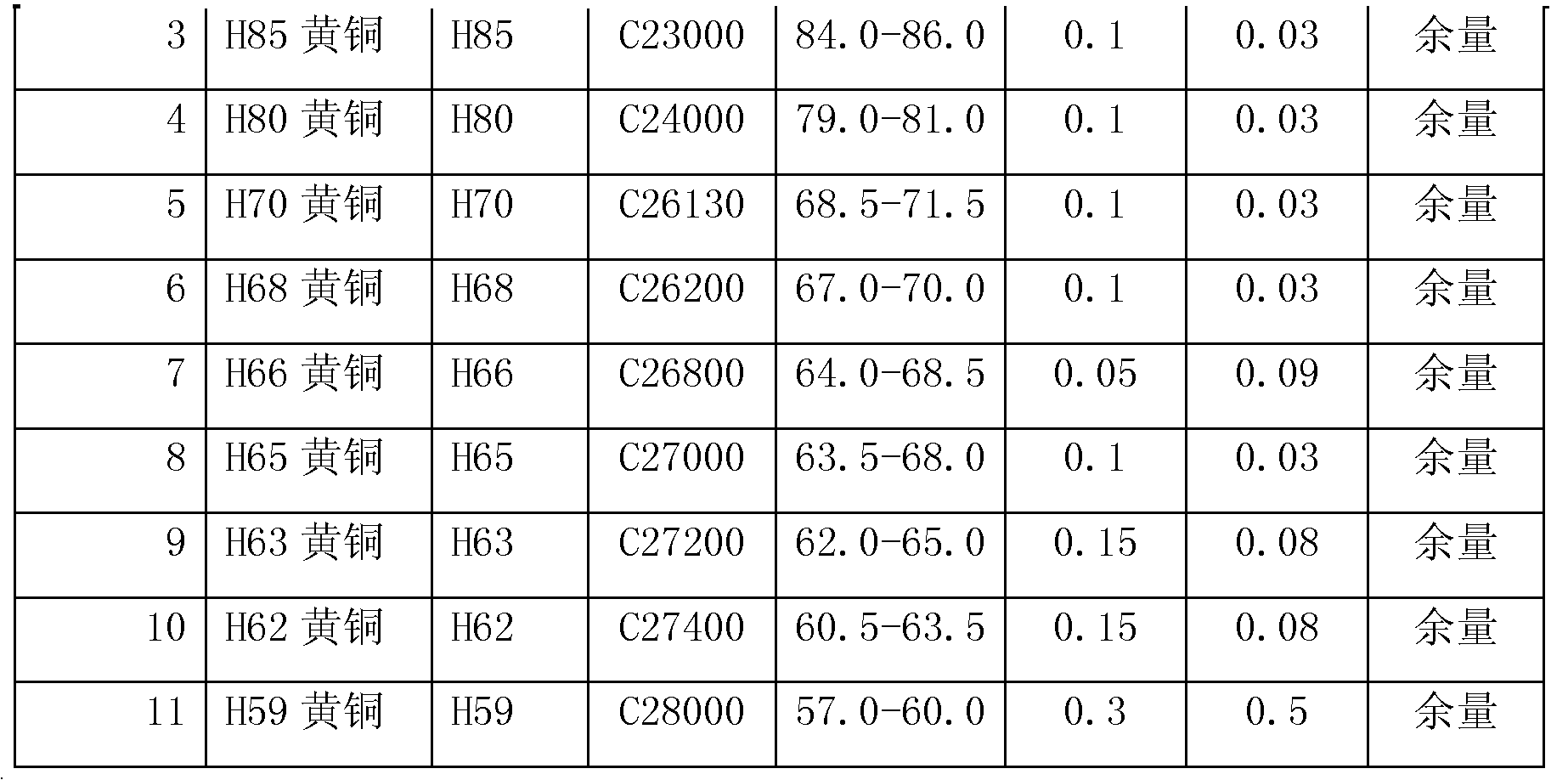

A processing method for producing brass strip

A processing method for producing brass strips, comprising the following steps: smelting, casting, high-precision rolling, bright annealing, finished product rolling, and finished product shearing, characterized in that the casting adopts upward continuous casting to prepare billets, and The circular crystallizer tooling equipped with graphite moulds, which was used for wire rod production by upward continuous casting, was transformed into a designed cross-section crystallizer tooling for strip production. Compared with the original brass strip processing method, it has the characteristics of low manufacturing cost and cheap tooling and molds. The surface of the blank obtained by the invention is bright, the crystal texture is uniform, and the surface milling is not required in the subsequent processing. At the same time, the method has low energy consumption, and is a high-efficiency, low-cost brass strip blank production method.

Owner:赤峰京铜铜业有限公司 +1

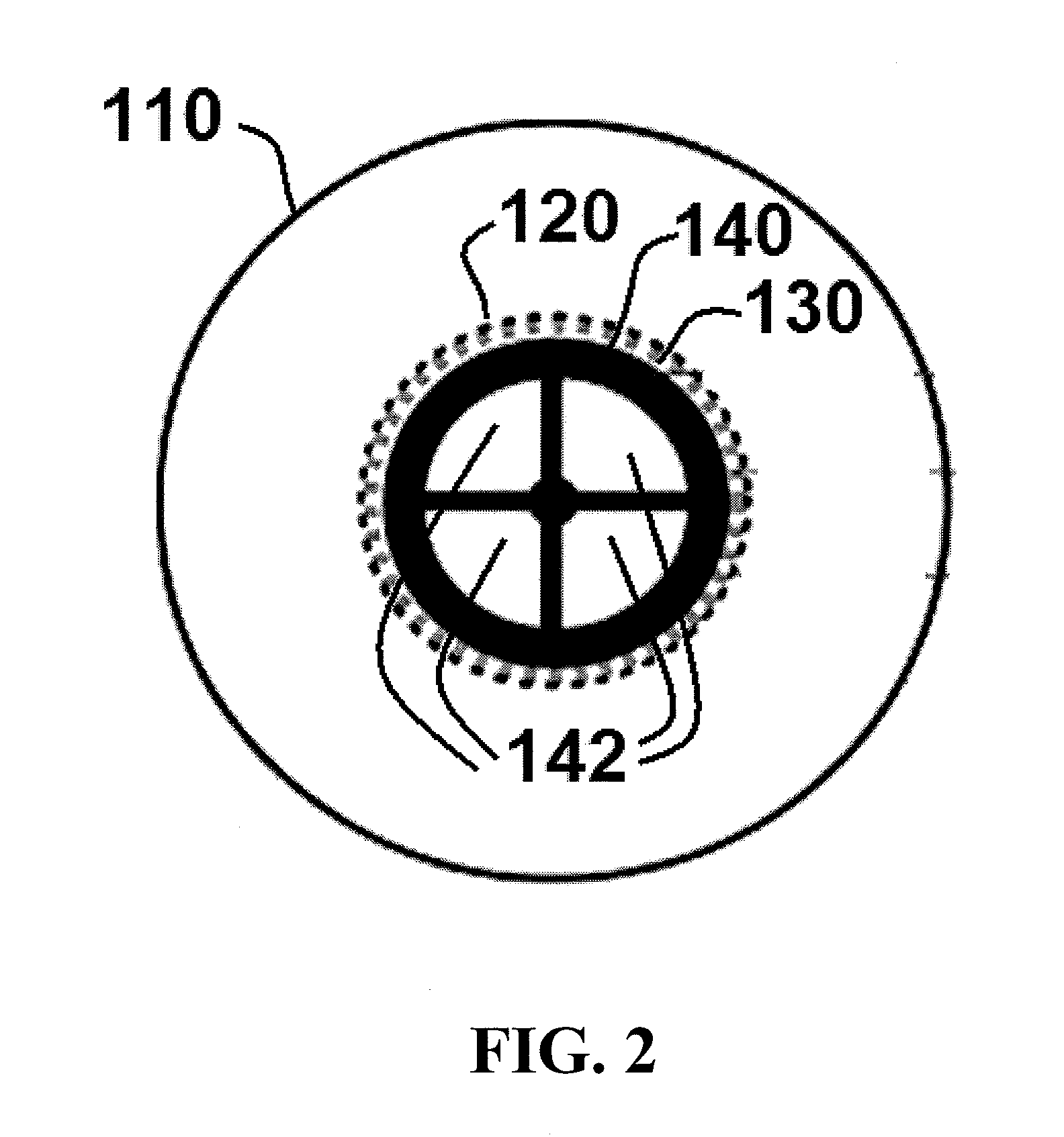

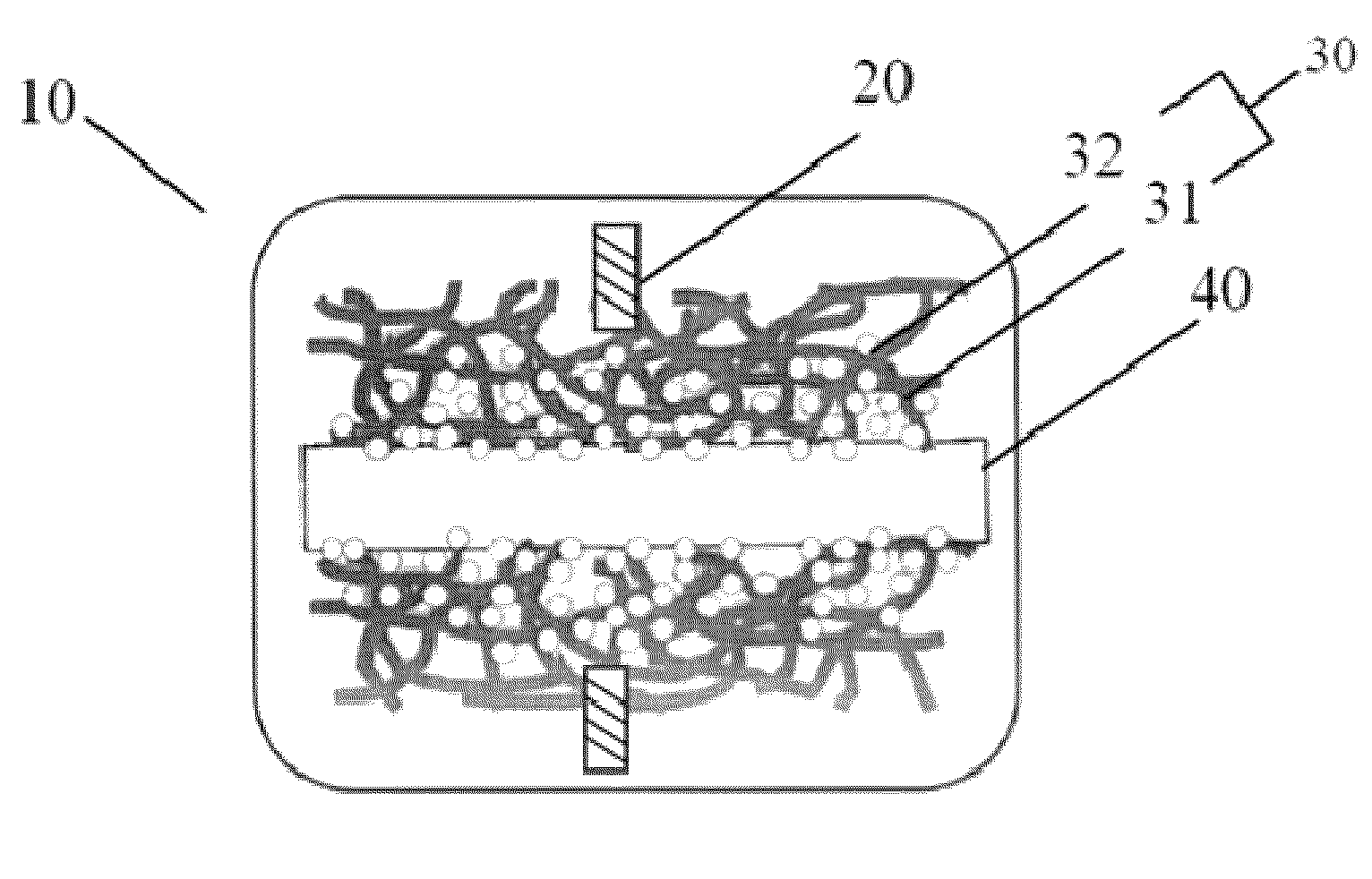

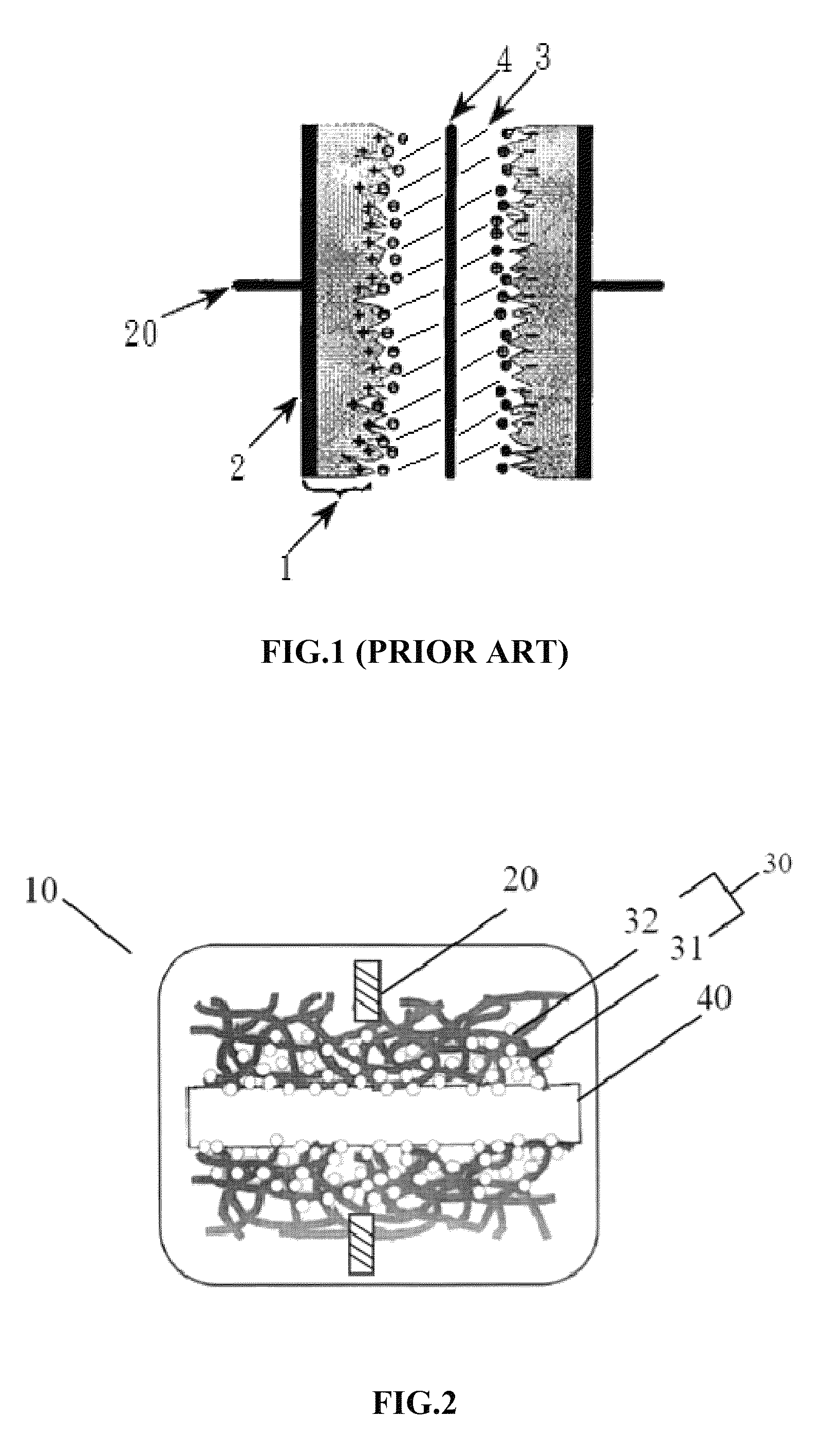

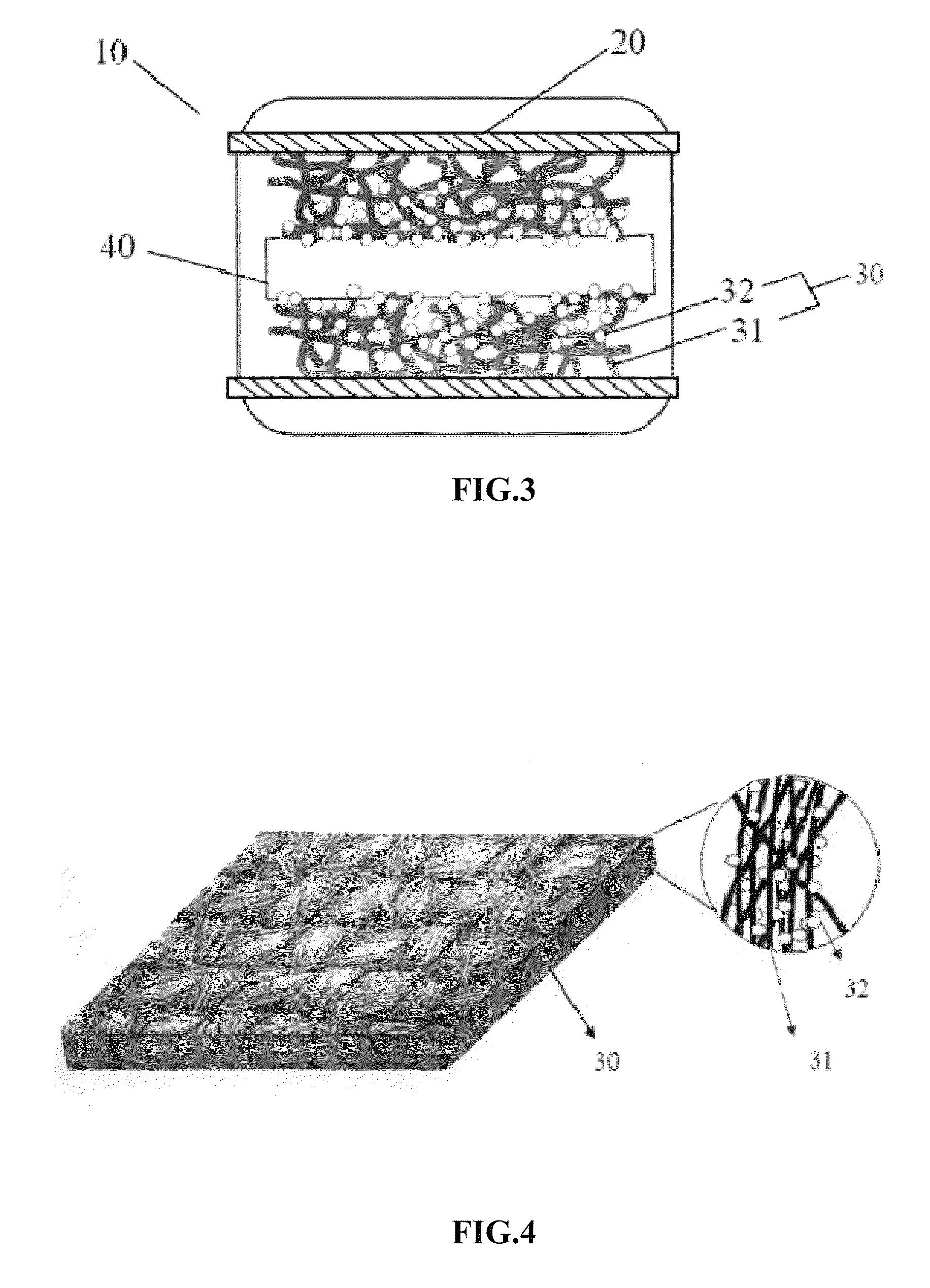

Super capacitor structure and the manufacture thereof

InactiveUS8947853B2The production process is simpleLow toxicityElectrolytic capacitorsHybrid capacitor electrodesSandwich likeBULK ACTIVE INGREDIENT

Disclosed is a super capacitor and method of manufacture thereof. This invention relates to a solid state super capacitor comprising a solid state polymer electrolyte and a modified carbonaceous electrode. Said modified carbonaceous electrode comprises a conductive carbonaceous material covered with active ingredients. Said modified carbonaceous electrode and said solid state polymer electrolyte are layered on top of each other to form a sandwich-like structure. Said super capacitor performs much better than known super capacitor comprising liquid or gel-form electrolytes. Said super capacitor has higher conductivity, therefore can be manufactured without a current collector. Since said super capacitor contains solid state polymer electrolyte, the method of manufacturing said super capacitor is more environmentally friendly and has a higher safety level.

Owner:FENG CHIA UNIVERSITY

Antibacterial dustproof copy paper and preparation method thereof

InactiveCN109024064AEasy to prepareHigh static bending strengthReinforcing agents additionPaper/cardboardChemistryChitin

The invention discloses an antibacterial dustproof copy paper and a preparation method thereof. The antibacterial dustproof copy paper comprises the following raw materials (by weight): 124-148 partsof bleached softwood pulp, 100-380 parts of artificial fiber, 305-380 parts of kaolin, 189-210 parts of starch, 10-15 parts of an antifoaming agent, 2-9 parts of nano-titanium oxide, 2-10 parts of nano-zinc oxide, 40-70 parts of an antibacterial agent, 1-5 parts of lemon essential oil, 30-60 parts of cationic polyacrylamide, 60-70 parts of seaweed powder, 25-45 parts of an antioxidant, and 10-30 parts of a surfactant. The antibacterial agent is composed of the following materials (by weight): 10-15 parts of N-(4-hydroxy-3-methoxybenzyl)acrylamide, 5-20 parts of chitin, and 7-15 parts of pomegranate peel. The copy paper of the invention has small deformation when printed or copied, has strong antibacterial property, is non-toxic and harmless and is green and environmentally-friendly, and has smooth surface, which can avoid the accumulation of dust. The raw materials are easily available, and the preparation cost is low. Thus, the copy paper is good for industrial production.

Owner:枣庄市天龙纸业有限公司

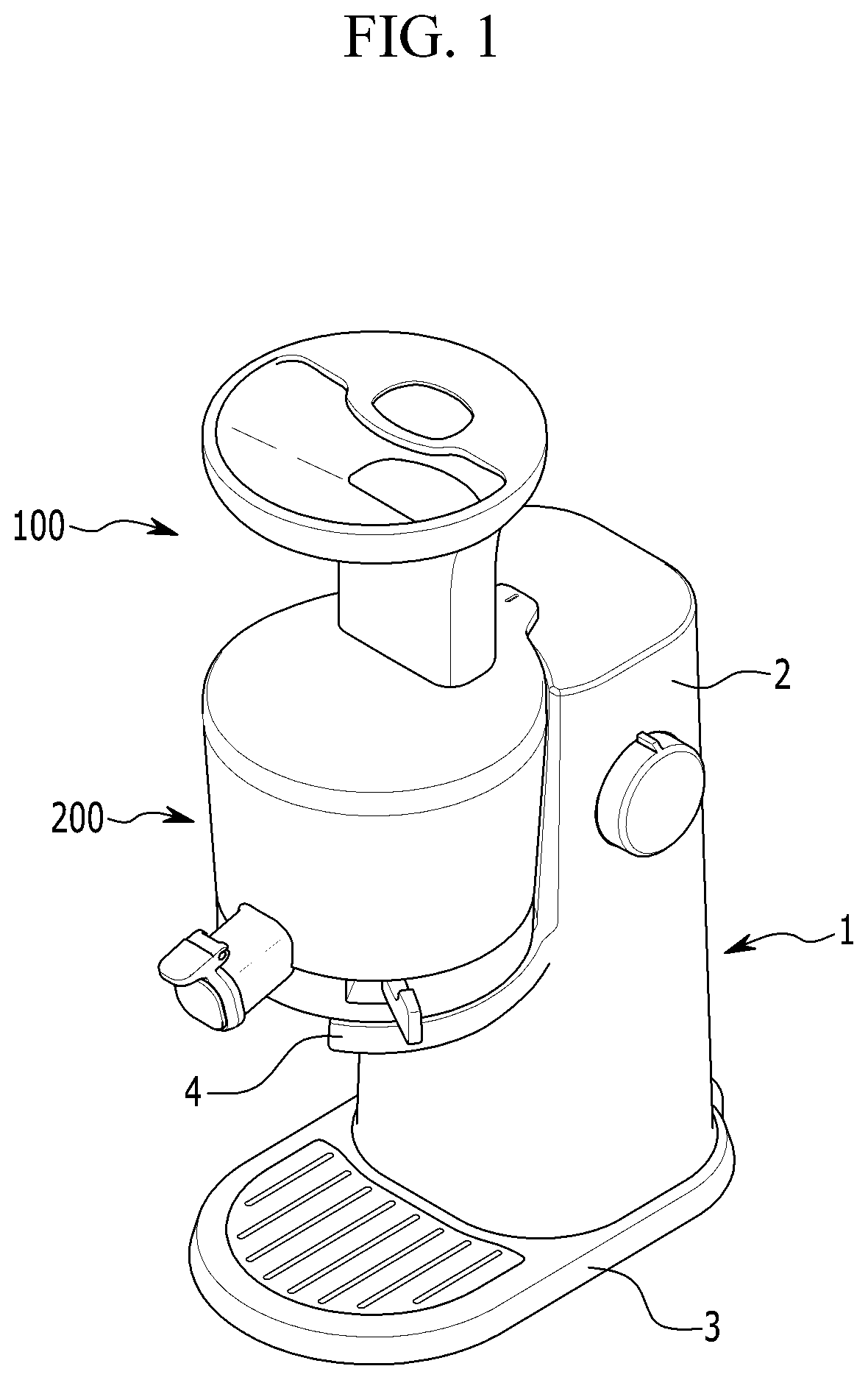

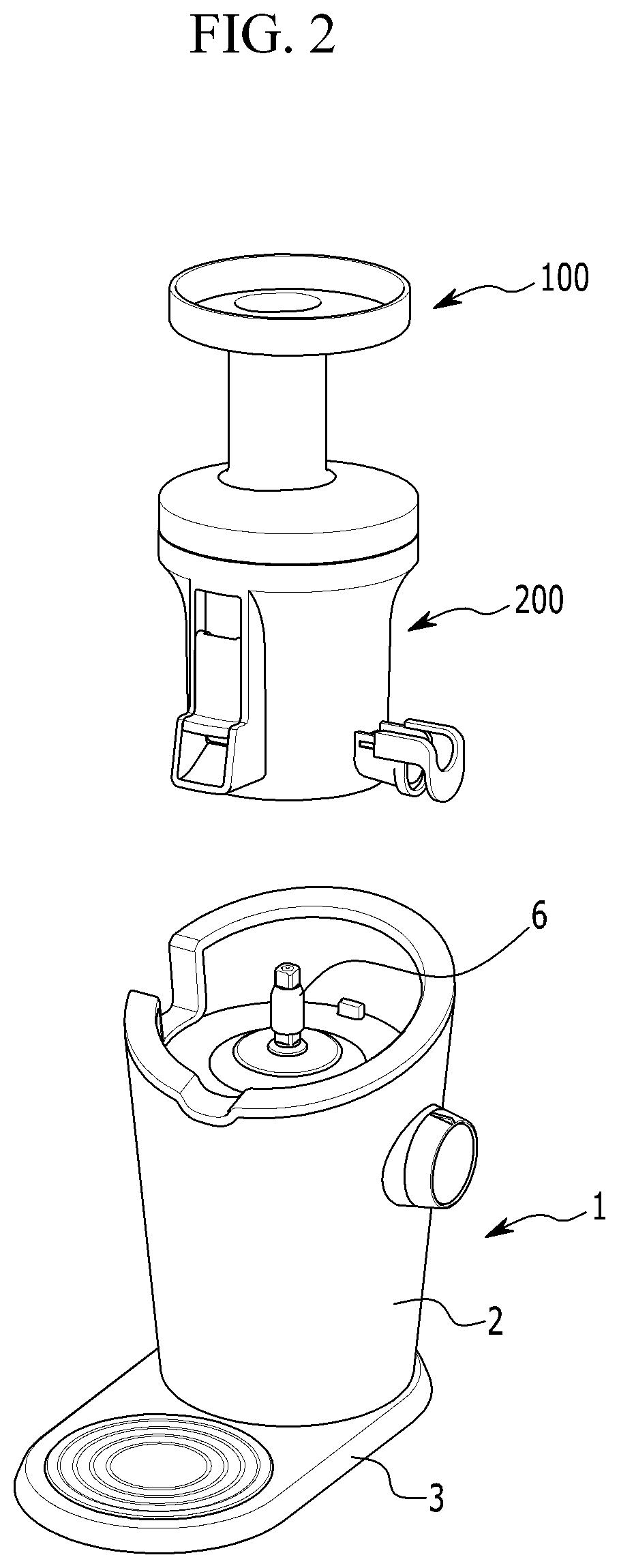

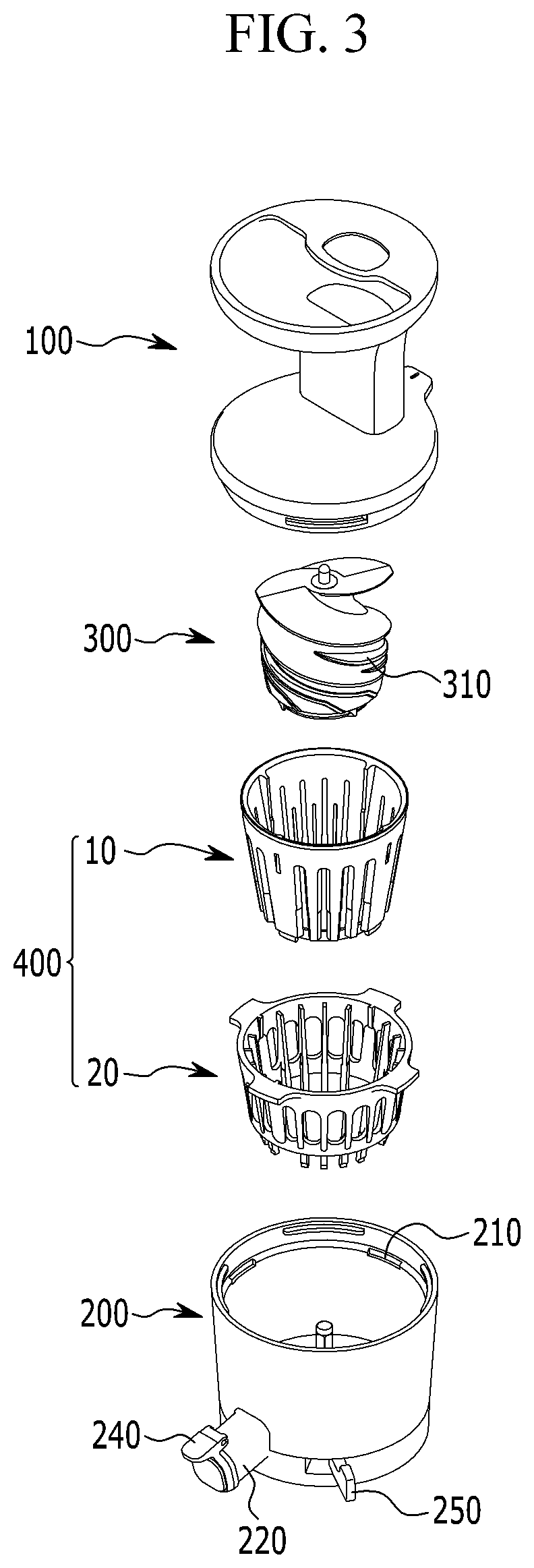

Juice extraction drum and juicer

PendingUS20210120995A1Easy to disassembleEasy to manufacturePressesStrainersHelical bladeEngineering

A juice-extracting drum includes a screw rotating inside. An inner module includes a hollow cylinder with an upper portion having the screw. A plurality of slits are formed as penetration holes having both lateral sides, an upper surface, and a lower surface along an interior circumference. An outer module is detachably coupled to the inner module, and includes a rib protruding in a radially interior direction on an interior circumference. The rib is inserted into the slit of the inner module when the outer module surrounds and combines the inner module. A predetermined fixed gap discharging juice extracted by the screw is formed lengthily in an up and down direction between the lateral side of the slit of the inner module and a lateral side of the rib of the outer module. The fixed gap is formed in a direction intersecting the screw blade.

Owner:HUROM CO LTD

Algae harvesting devices and methods

InactiveUS20120031858A1Easily scraped and removed easilyCorrosion resistanceSettling tanks feed/dischargeWater/sewage treatmentEnvironmental engineeringAlgae

Owner:ARIZONA STATE UNIVERSITY

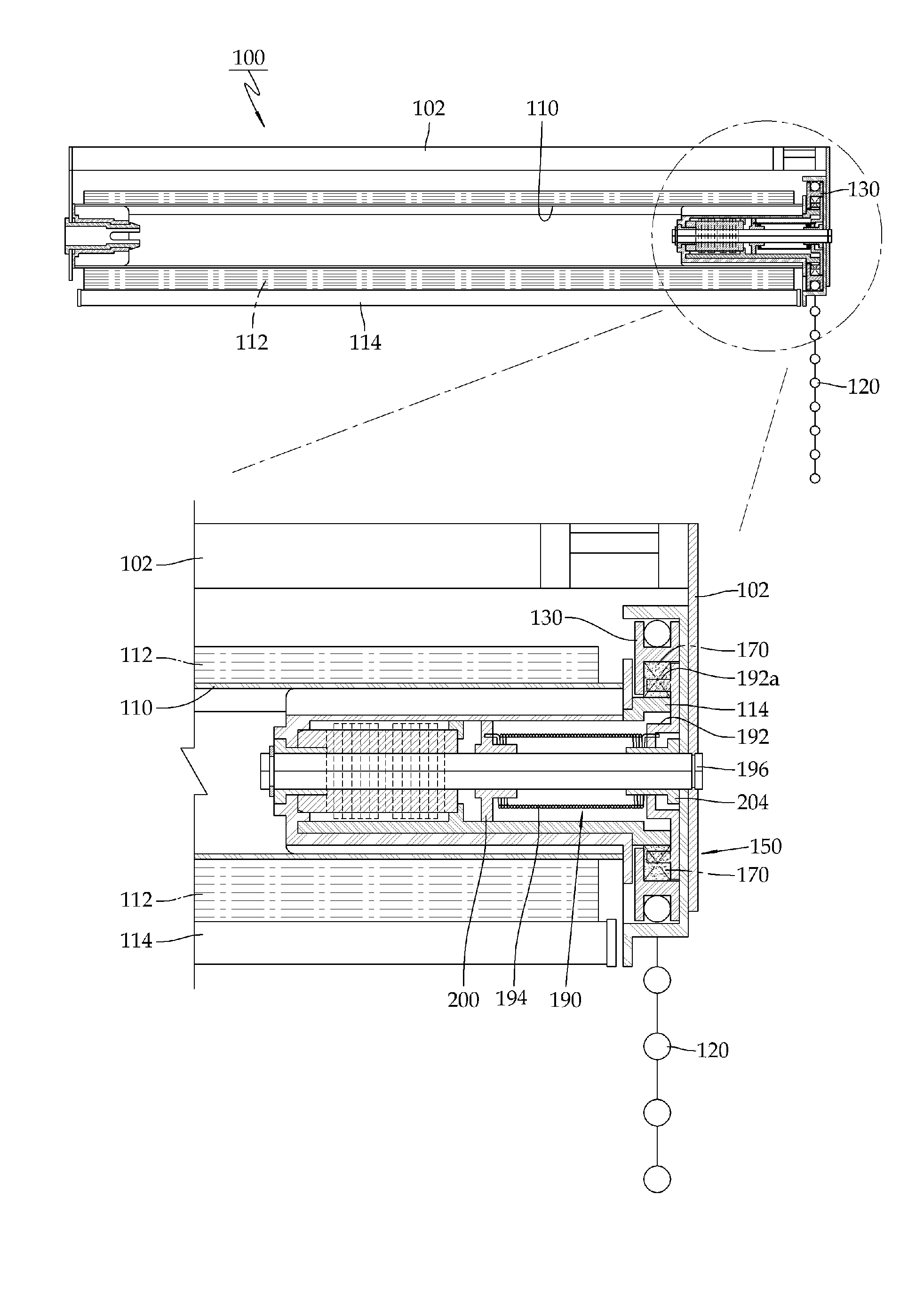

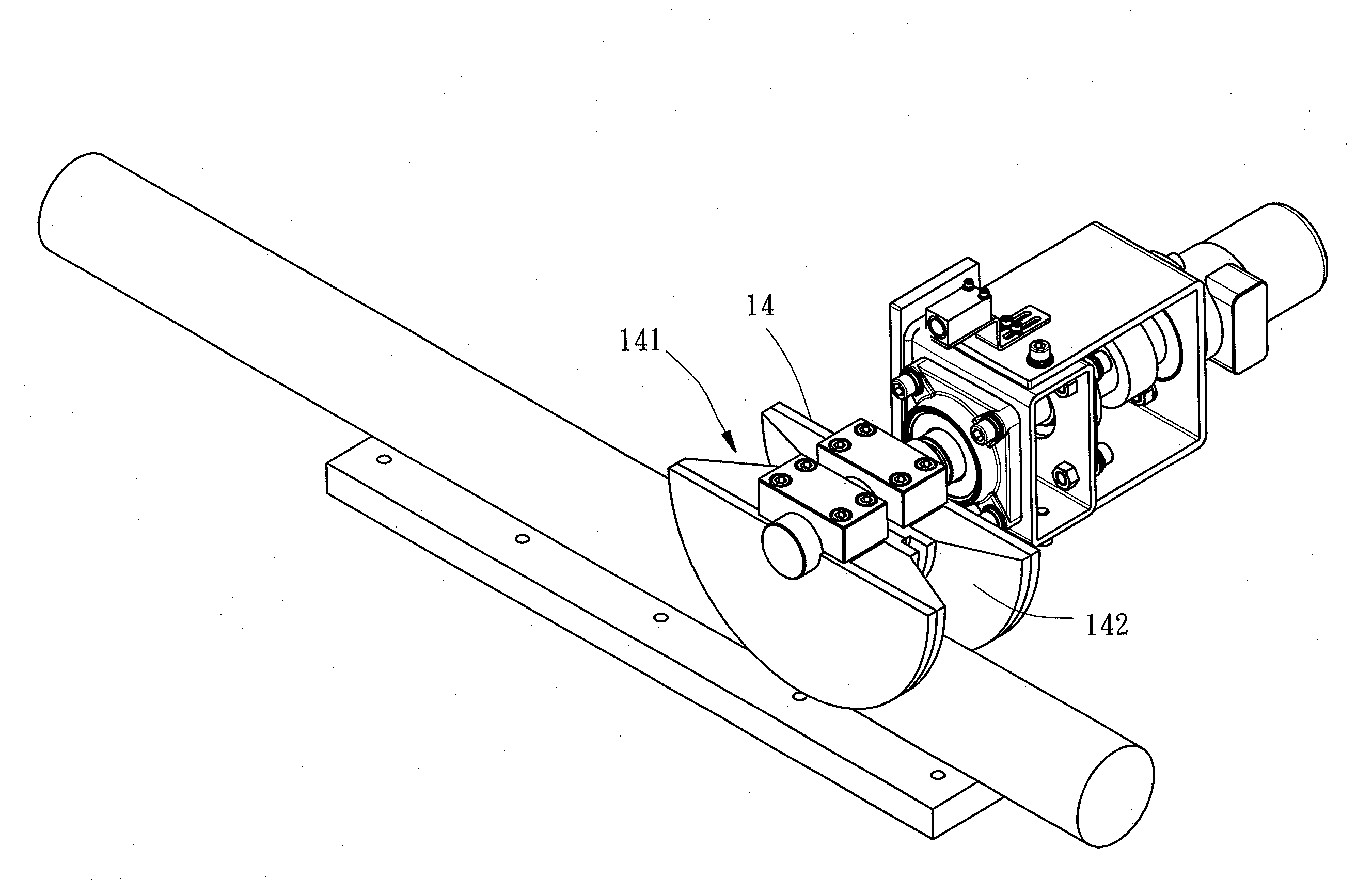

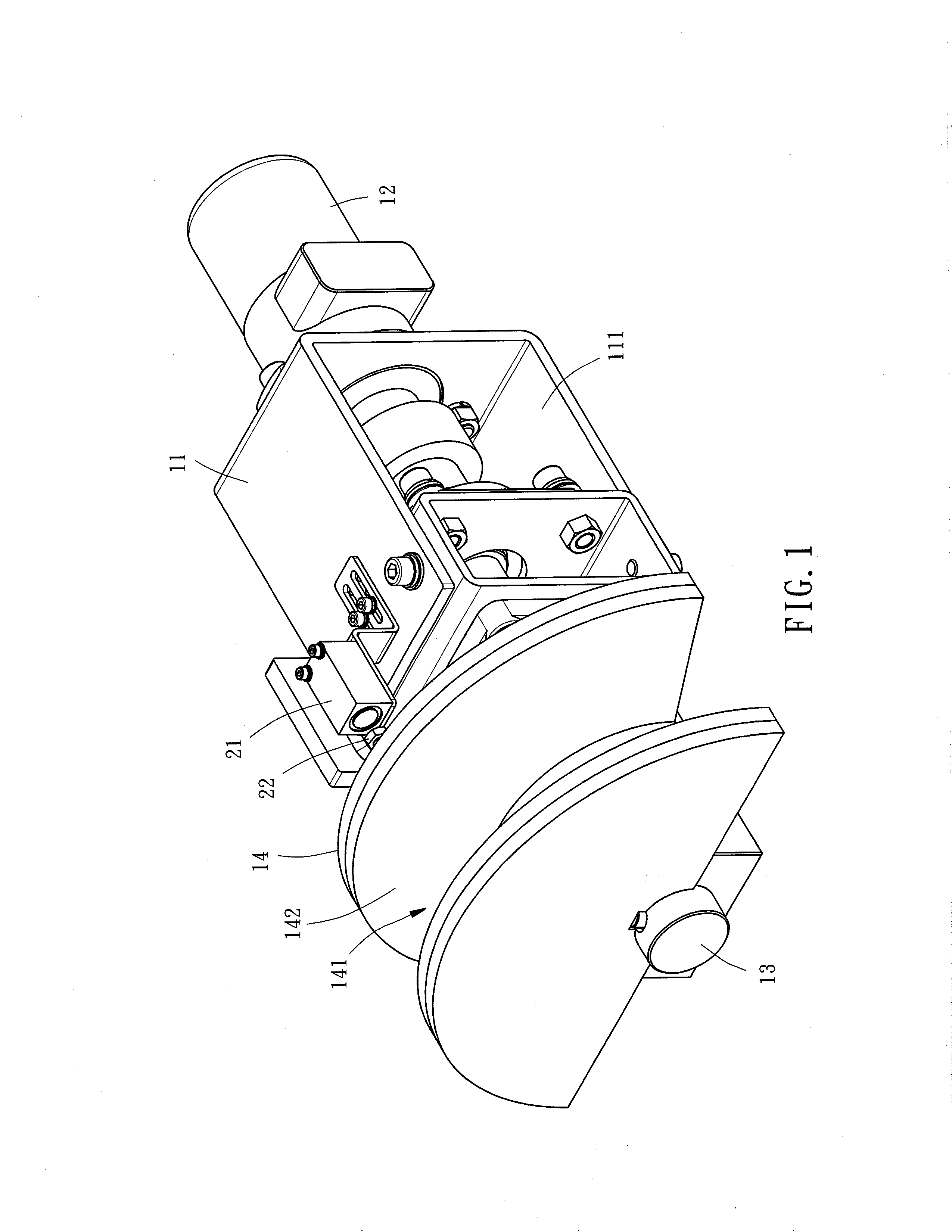

Feeding device

InactiveUS20130313302A1Small overall deformationEliminate limitationsProjector film strip handlingMetal-working feeding devicesMotor driveDrive shaft

A feeding device includes a fixing base. A motor is fixed to the fixing base. The motor has an output axle. A transmission axle is fixedly connected to the output axle. The feeding device further includes a feeding block having a side fixedly connected to the transmission axle. The feeding block has a feeding notch. The feeding notch is formed around the transmission axle circumferentially. Hence, once a slender material enters the rotational space of the feeding block, the motor drives the feeding block to rotate, whereas the slender material is pressed by the feeding notch of the feeding block and sent out as a result of the continuous rotation of the feeding block. Hence, the feeding device not only enables continuous material conveyance but also allows the slender material to be conveyed smoothly even when the slender material is slightly bent or deformed.

Owner:HIWIN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com