Method and equipment for winding carbon fiber yarns on annular mandrel

A technology of carbon fiber yarn and ring core, which is applied in the field of winding carbon fiber yarn and its equipment for ring mandrels, can solve the problems that the flatness of the carbon fiber layer cannot be guaranteed, the carbon fiber cloth cannot be recycled and reused, and the waste of materials is large. Uniform and stable rotating speed, guaranteed rigidity and strength, and the effect of overcoming uneven yarn winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

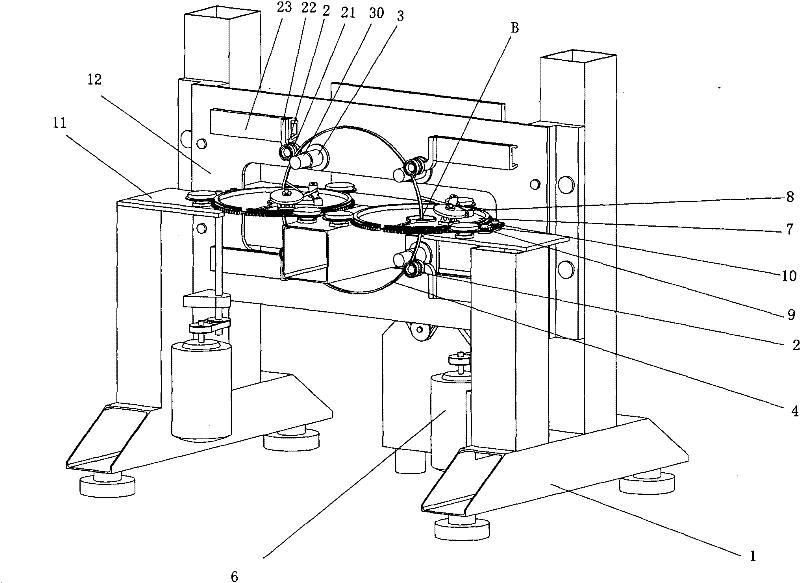

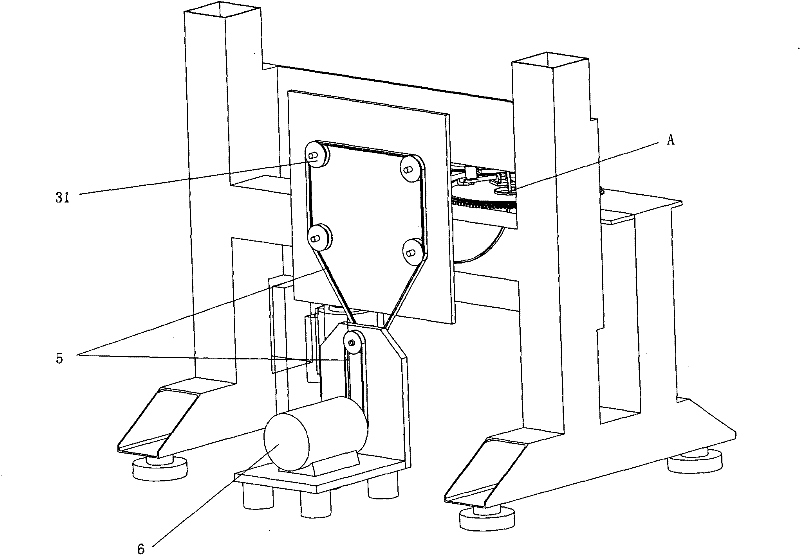

[0037] The technical scheme that the present invention solves its technical problem is: a kind of method for winding carbon fiber yarn to annular mandrel, comprising:

[0038] Step 1: making coiled yarn 8, winding the carbon fiber tape layer by layer on the pin shaft to make coiled yarn 8, the width of the carbon fiber tape is 10cm, the angle is 50 degrees, and the carbon fiber tapes are anti-sticked by plastic tape; The ring-shaped 4-mandrel is rigid and not easily deformed;

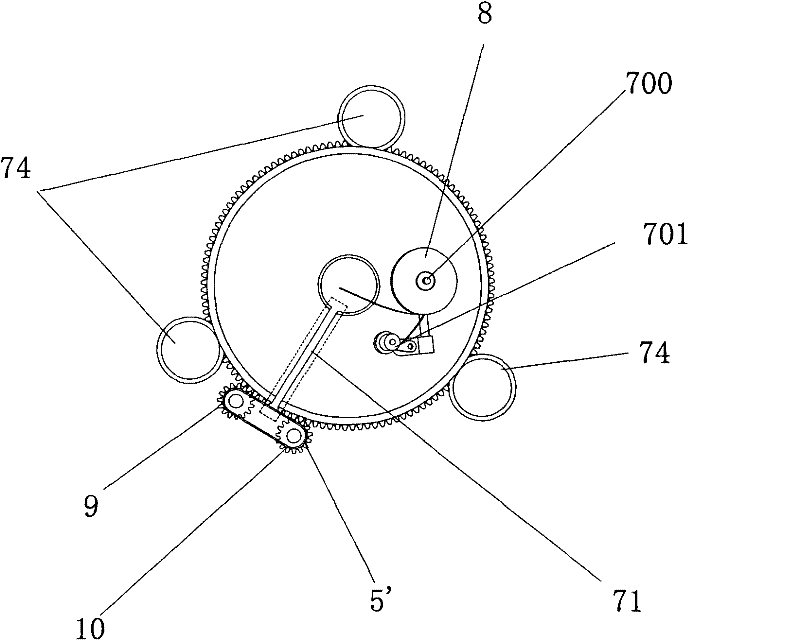

[0039] Step 2: positioning the annular mandrel 4, the power rotor 3 and the positioning rotor 2 are matched to clamp the inner and outer edges of the annular mandrel 4 to suspend and position the annular mandrel 4, so that the annular mandrel 4 cannot move radially or axially;

[0040] Step 3: the ring-shaped mandrel 4 rotates, the power rotor 3 is driven by the motor shaft to rotate, the power rotor 3 presses against the inner edge of the ring-shaped mandrel 4, and drives the ring-shaped mandrel 4 to r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com