A processing method for producing brass strip

A processing method and technology for brass strips, applied in the field of non-ferrous metal processing, can solve problems such as unfavorable development of national industry, high equipment manufacturing cost, inflexible operation, etc., and achieve easy electroplating or coating, improved material utilization, and physical properties. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

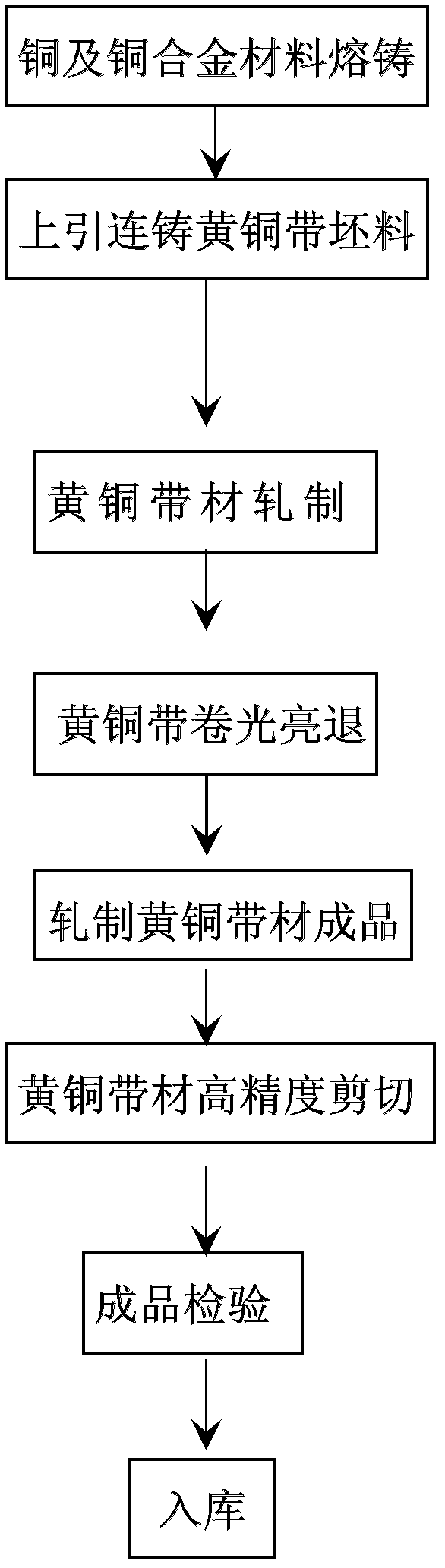

[0022] This embodiment requires that the material of the high-precision finished brass strip is H65, the thickness of the finished product is 1.5 ± 0.02mm, and the width is 61.5 ± 0.1mm. The physical properties of the finished product require a semi-hard state (HV=106), and the tensile strength (Rm / MPa) is 355--460Mpa, and the elongation rate after breaking (A11.3 / %) reaches 25%; the weight of each roll is ≥120Kg, and its production process is as follows figure 1 Shown; In the finished rolling process or the final high-precision shearing process, the intermediate material is divided into the required reel weight, 120-300Kg / reel.

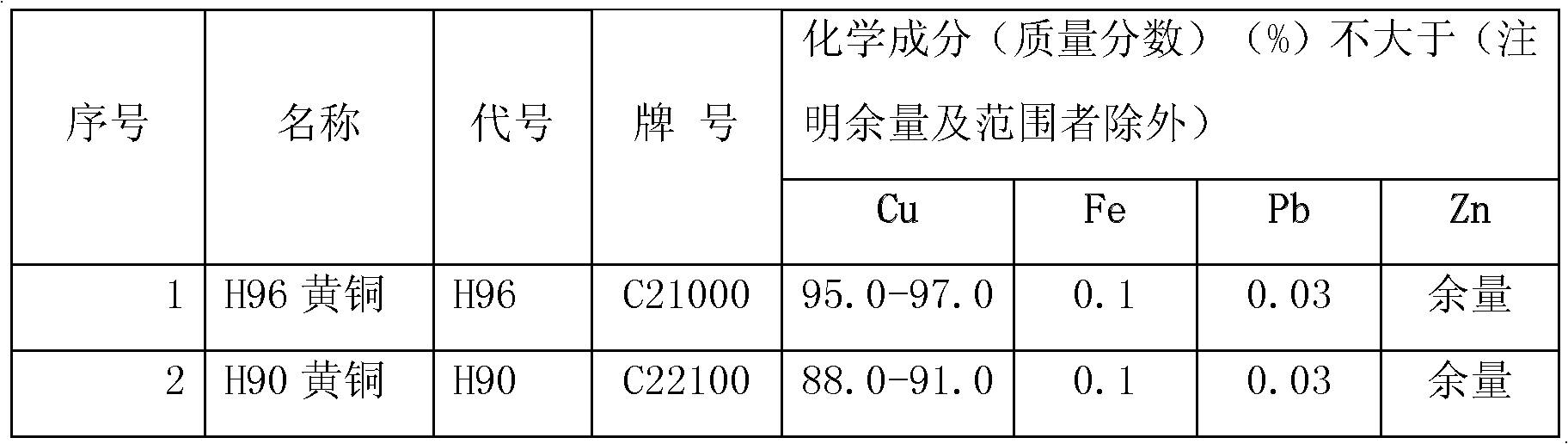

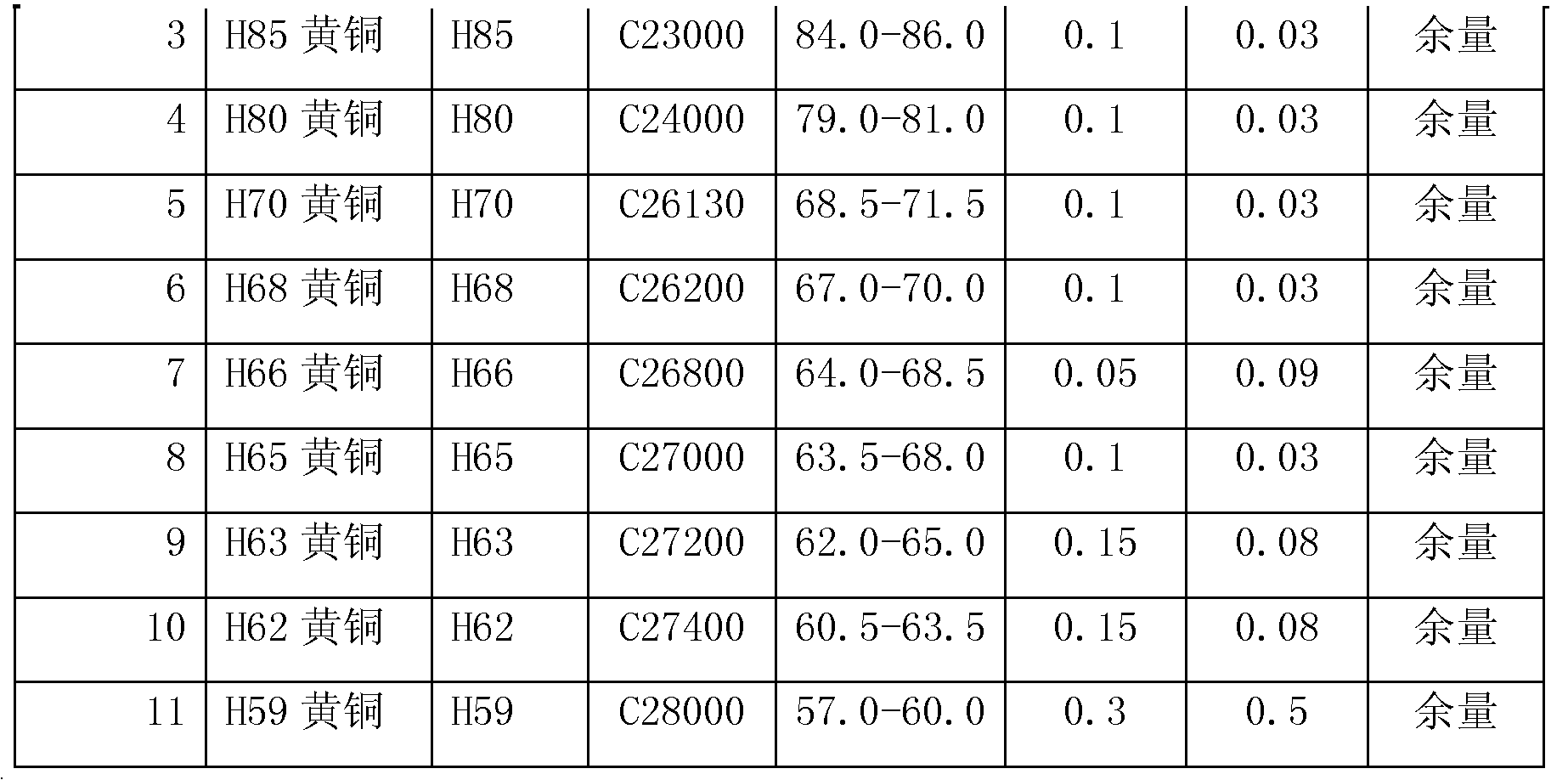

[0023] 1. Smelting: Strictly follow the chemical composition requirements of H65. Adding materials: Cu 63.5--68wt% Zn 32-36.5wt%; the total of P BiSb Fe Pb should be ≤0.3wt%; H65 scrap can be used in the production process; use intermediate frequency The melting efficiency of induction melting furnace and power frequency induction holding furnace is...

Embodiment 2

[0032] This embodiment requires that the material of the high-precision finished brass strip is H90, the thickness of the finished product is 0.8 ± 0.01mm, and the width is 48 ± 0.05mm. The physical properties of the finished product require a tensile strength Rm (N / mm 2 ) is ≥390Mpa, and the elongation rate A11.3 after breaking reaches 3%; the weight of each roll is ≥100Kg, and its production process is as follows figure 1 Shown; In the finished rolling process or the final high-precision shearing process, the intermediate material is divided into the required reel weight, 90-110Kg / reel.

[0033] 1. Smelting: Strictly follow the chemical composition requirements of H90. Adding materials: Cu 88.0-91.0wt% Zn 9-12wt%; the total of P Bi SbFe Pb should be ≤0.3wt%; H65 scrap can be used in the production process; use medium frequency induction The melting efficiency of the melting furnace and the power frequency induction holding furnace is 0.75 tons / hour.

[0034] 2. Upward conti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com