Grain screening device

A grain, vertical technology, used in the separation of solids from solids by air flow, solid separation, chemical instruments and methods, etc., can solve the problems of high labor intensity, low screening efficiency, and inability to screen, and achieve high grain density. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

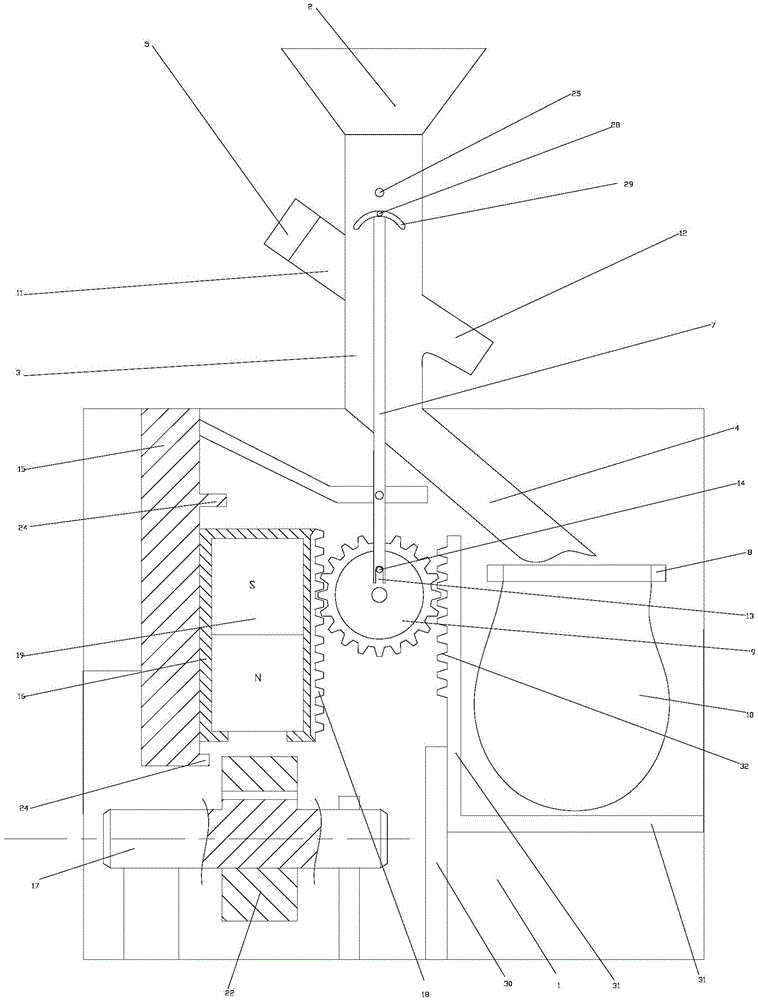

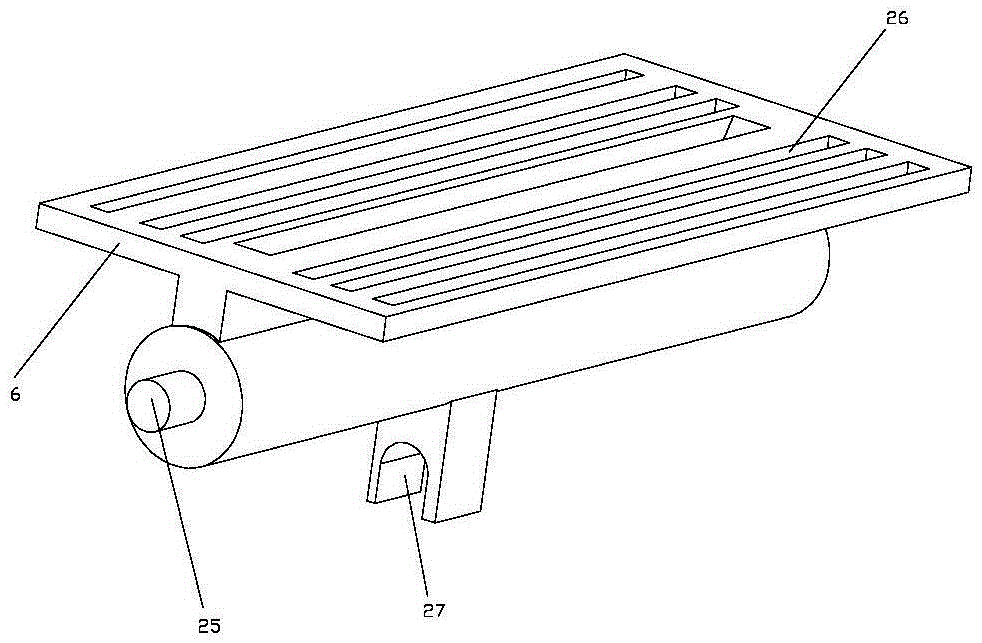

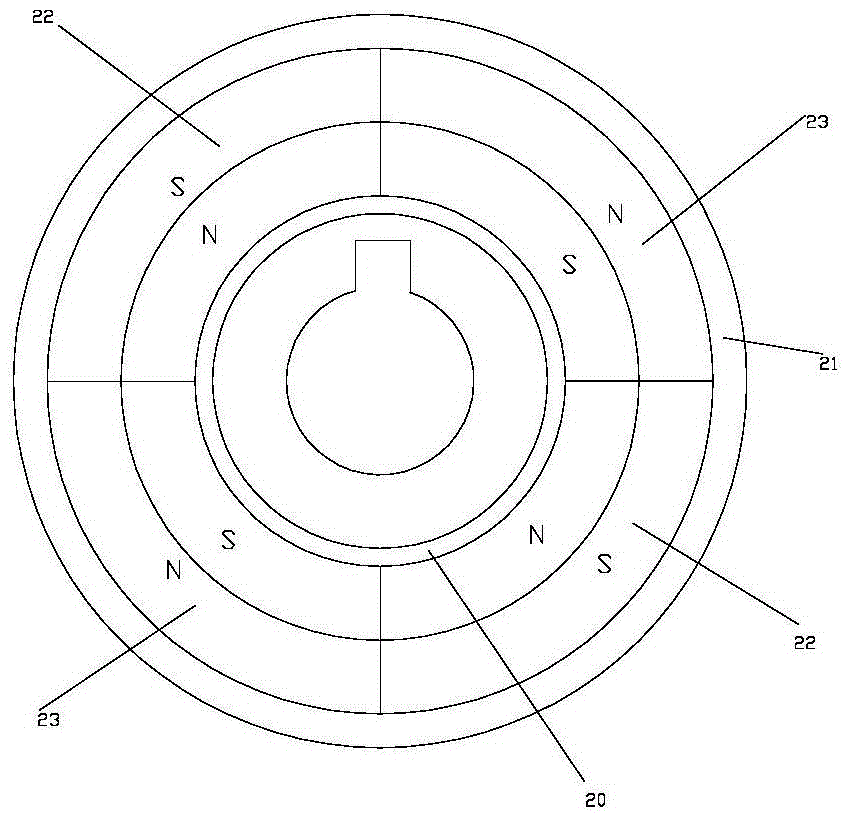

[0021] An embodiment of the driving device: the driving device includes a guide block 15, a housing 16, a first magnet assembly, a second magnet assembly, a rotating shaft 17 and a motor for driving the rotating shaft 17, and the guide block 15 is fixedly connected to the On the base 1, the first magnet assembly is embedded in the casing 16, and the casing 16 is slidably connected to the guide block 15 in the vertical direction, and the casing 16 is provided with a first linear rack for meshing with the transmission gear 9 for transmission. 18; the second magnet assembly is located directly below the first magnet assembly in the vertical direction; the first magnet assembly refers to the bar magnet 19 with the S pole facing up and the N pole facing down; the second magnet assembly includes a lining 20. The outer lining 21, the first arc-shaped magnet 22 and the second arc-shaped magnet 23, the inner lining 20 and the rotating shaft 17 are connected by keys, and the first arc-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com