Device for processing dimethylamine exhaust gas and wastewater

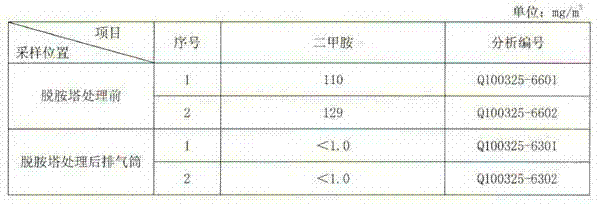

A waste gas treatment device, dimethylamine technology, applied in the direction of degassed water/sewage treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of non-treatment of dimethylamine, environmental pollution, and failure to achieve environmental protection Requirements and other issues to achieve the effect of low content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

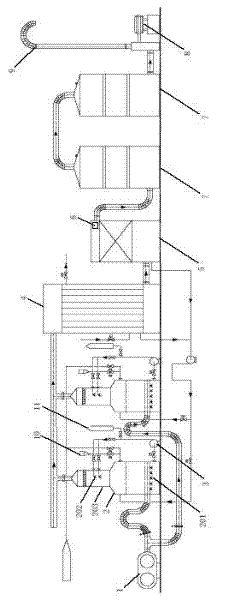

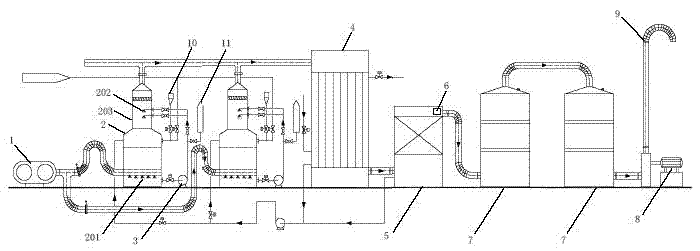

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

[0027] Such as figure 1 As shown, the present invention provides a kind of dimethylamine waste water and exhaust gas treatment device, a Roots blower 1 is respectively connected with hundreds of nozzles 201 evenly distributed at the bottom of two blow-off oxidation tanks 2 through pipelines, and blows off the oxidation tank 2 The water pump 3 is externally connected to the bottom, and the water pump 3 is connected to the atomizing nozzle 202. The atomizing nozzle 202 is in the upper spray tower 203, and the lower part of the blow-off oxidation tank 2 is a dimethylamine solution chamber, and the solution containing dimethylamine is blown by air. After stripping, it is discharged from the top outlet of the stripping oxidation tank 2. After being cooled by the condenser 4 and separated by the water-gas separator 5, the mixed gas enters the low-temperature plasma purifier ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com