Preparation method of low-segregation-degree motor rotor microalloy aluminum of new energy automobile and microalloy aluminum prepared through preparation method

A new energy vehicle and motor rotor technology, applied in the field of micro-alloy aluminum, can solve the problems of different mechanical and physical properties, affecting the working effect and service life of castings, etc., and achieve the effect of improving working conditions, shortening cooling time and stabilizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

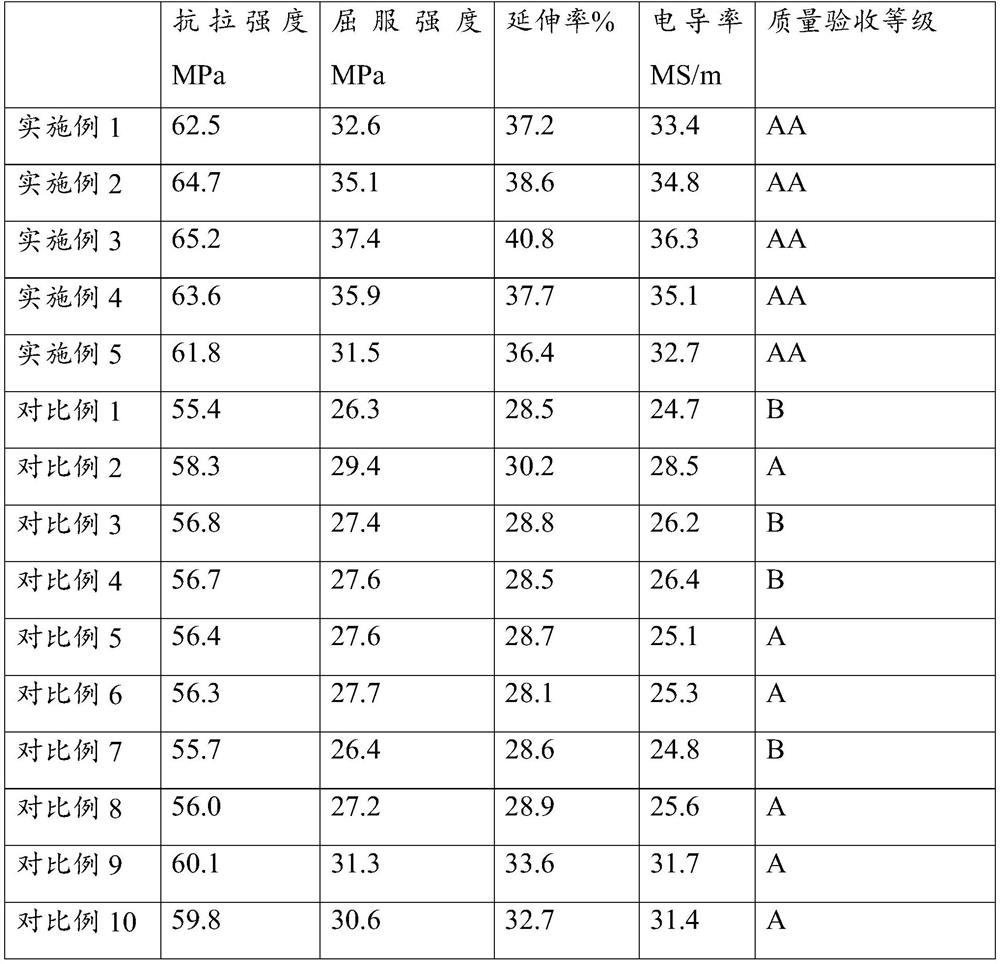

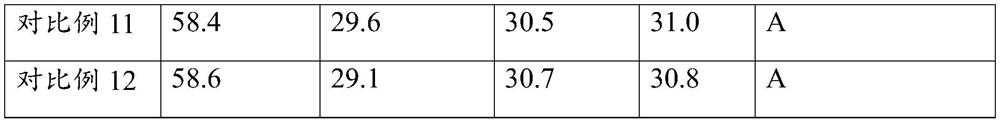

Examples

Embodiment 1

[0029] Method for preparing a new energy vehicle low-sene-segregation motor rotor microalloy aluminum, including the following steps:

[0030] (1) 0.02 wt% titanium, 0.01 wt% boron, <0.1 wt% silicon, <0.2 wt% iron, 0.01 wt% copper, 0.3 wt% magnesium, <0.1 wt% zinc and ≥99.2 wt% aluminum mixture The heat rear furnace is melted, starting from a surface of the mixture after melting 1 wt% cover, and then warmed to 670 ° C;

[0031] (2) After the furnace temperature is stable, 10% by% NAF is added to refine, stand calm the slag to obtain refined melt A;

[0032] (3) Rapidify the refined melt A to 800 ° C, first add 0.03% by weight of lanthanum, heat insulation for 15 min, then add 0.02% by weight, stirring 0.5 wt% cover, and heat the temperature after 10min;

[0033] (4) When the temperature drops to 670 ° C, 5 wt% NAF is added to refine, and the slag is placed to obtain refined melt B;

[0034] (5) The inner spray coating coating, the coating thickness is 0.5 mm, and the refined melt ...

Embodiment 2

[0037] Method for preparing a new energy vehicle low-sene-segregation motor rotor microalloy aluminum, including the following steps:

[0038](1) 0.02 wt% titanium, 0.01 wt% boron, <0.1 wt% silicon, <0.2 wt% iron, 0.03 wt% copper, 0.35 wt% magnesium, <0.1 wt% zinc and ≥99.2 wt% aluminum mixture The heat rear furnace is melted, and the surface of the mixture is placed on the surface of the mixture after melting, then the temperature is raised to 700 ° C;

[0039] (2) After the furnace temperature is stable, 14Wt% KCL is added to refine, stand calm the slag to obtain refined melt A;

[0040] (3) Rapidify the refined melt A to 820 ° C, first add 0.03% by weight of lanthanum, heat insulation for 20 min, then add 0.03% by weight, stirring 0.7 wt% cover, heat insulation for 20min, starting;

[0041] (4) When the temperature drops to 700 ° C, 8% by weight KCl is added to refine, and stand the slag to obtain refined melt B;

[0042] (5) Side spray coating in the mold, the thickness of the...

Embodiment 3

[0045] Method for preparing a new energy vehicle low-sene-segregation motor rotor microalloy aluminum, including the following steps:

[0046] (1) 0.03 wt% titanium, 0.02 wt% boron, <0.1 wt% silicon, <0.2 wt% iron, 0.05 wt% copper, 0.4 wt% magnesium, <0.1 wt% zinc and ≥99.2 wt% aluminum mixture The heat rear furnace is melted, and the surface of the mixture is 1.5 wt% cover after melting, then warmed to 740 ° C;

[0047] (2) After the furnace temperature is stable, add 18% by weight KCL to refine, stand the slag to obtain refined melt A;

[0048] (3) Rapidify the refined melt A to 850 ° C, first add 0.04 wt%, heat insulation for 22min, then add 0.03 wt% 镱, stirred and palate 1 wt% cover, and heat the temperature after 35min;

[0049] (4) When the temperature drops to 740 ° C, 10% by weight KCL is added to refine, and stand on the slag to obtain refined melt B;

[0050] (5) Side spray coating in the mold, the thickness of the coating is 0.8 mm, the refined melt B is cast into the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com