Clean pulverized coal combustion industrial boiler device

A pulverized coal combustion and industrial boiler technology, applied in the direction of burners, combustion chambers, combustion methods, etc., can solve problems such as unsatisfactory organizational combustion effects, and achieve the effects of good coal type adaptability, strong disturbance, and good load regulation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

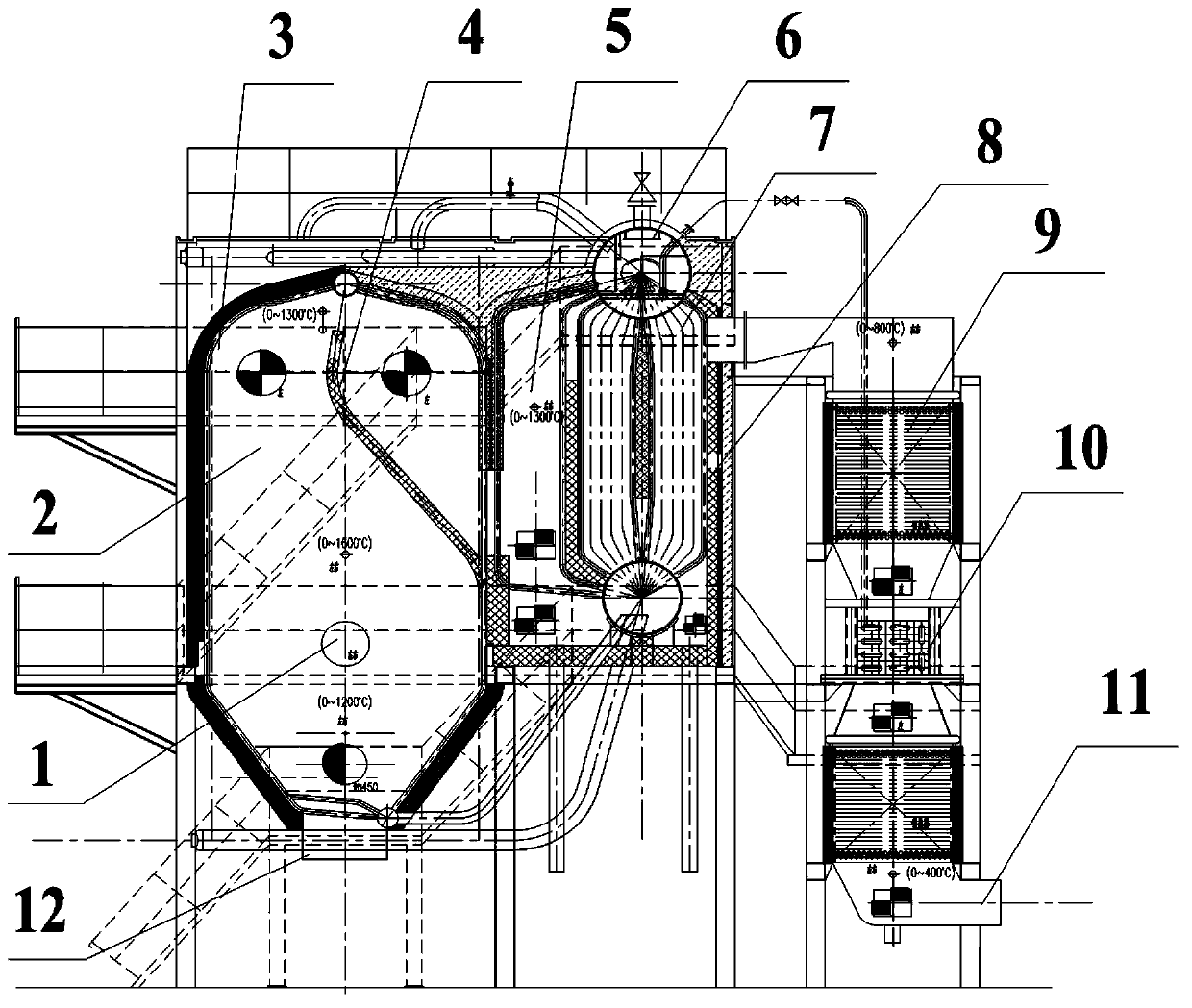

[0027] Such as figure 1 As shown, the present invention includes: a furnace 2, a swirl pulverized coal burner 1, a high-temperature vortex burnout device 4, a transition chamber 5, a convection flue 8 and a tail flue 11, wherein: the upper outlet of the furnace 2 is provided with a high-temperature vortex burner As far as the device 4 is concerned, the front and rear walls or the left and right walls of the lower part are provided with the flow pulverized coal burner 1 in a counter-positioned manner to realize the counter-powdered coal combustion, ensure good flame fullness, strong disturbance, and make the furnace smoke temperature and speed evenly distributed, which is beneficial to heating Protect your face. A transition chamber 5 is provided at the rear of the high-temperature vortex burnout device 4, the entrance of the convection flue 8 is connected to the rear of the transition chamber 5, and the outlet is connected to the tail flue 11;

[0028] The water-cooled wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com