Seaweed Biomass Rotary Kiln Dry Distillation Oil Production System

A rotary kiln and biomass technology, applied in the fields of biofuels, special forms of dry distillation, direct heating dry distillation, etc., can solve the problems of prolonging the residence time of semi-coke, stable combustion under low load, etc. Good flammability and enhanced mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

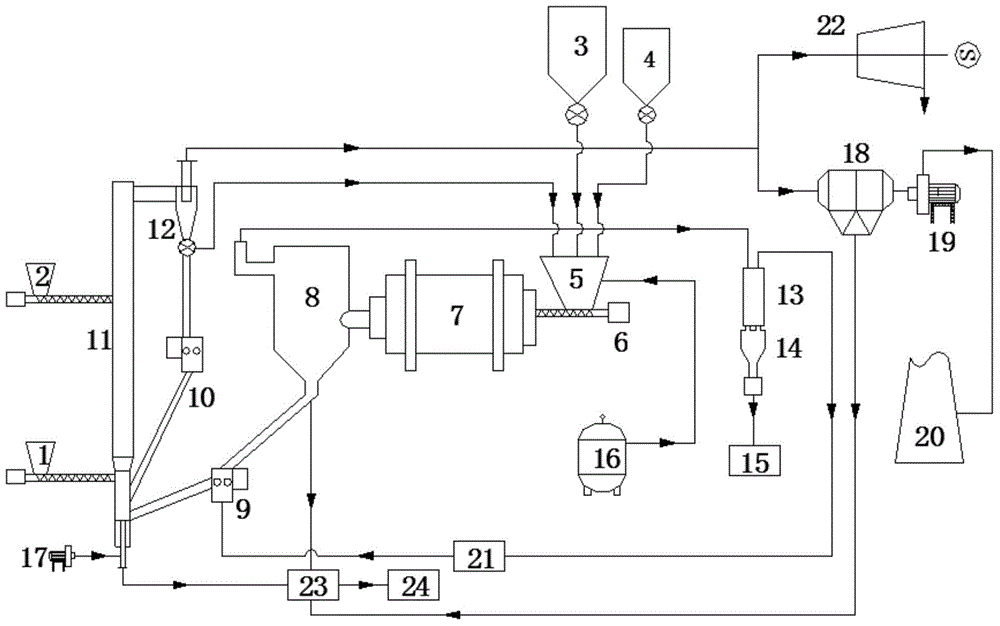

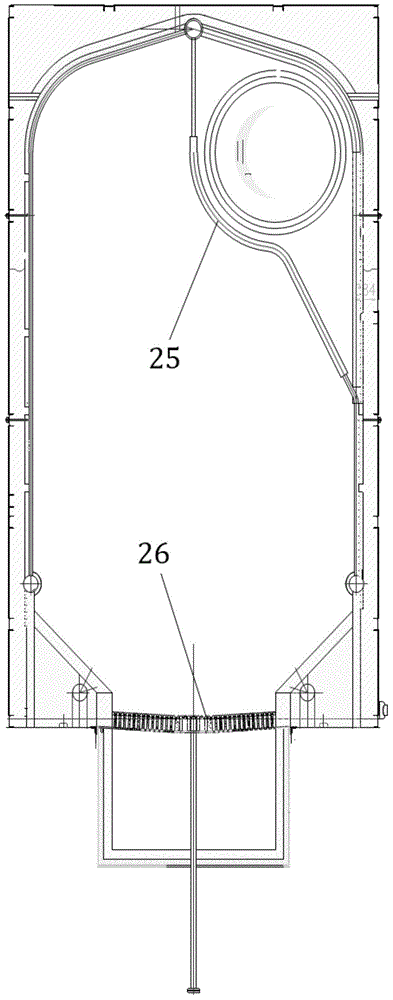

[0022] Such as figure 1 and figure 2 As shown, the present embodiment includes: the input end of the circulating fluidized bed combustion furnace 11 is respectively connected with the output end of the starting fuel feeding device 1, the combustion furnace bed material screw feeder 2, the dry distillation furnace return device 9 and the combustion furnace return The output end of the feeder 10 is connected, and the output end is connected with the combustion furnace cyclone separator 12, and is sent into the fluidization wind by the blower 17, and the first output end of the combustion furnace cyclone separator 12 is connected with the dust collector 18 and the steam turbine 22 respectively, The second output end of the combustion furnace cyclone separator 12 is connected to the input end of the mixer 5 and the input end of the combustion furnace feeder 10 respectively by a star-shaped rotary valve, and the seaweed biomass feed bin 3, the medium bin 4 and the dry distillation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com