Method for converter steelmaking by using small-particle grade high-basicity sintered ore

A converter steelmaking and high alkalinity technology, applied in the field of metallurgy, can solve the problems of high cost of sintering process, low utilization rate of sintering machine, impact on sinter quality, etc. The effect of slag and good furnace lining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

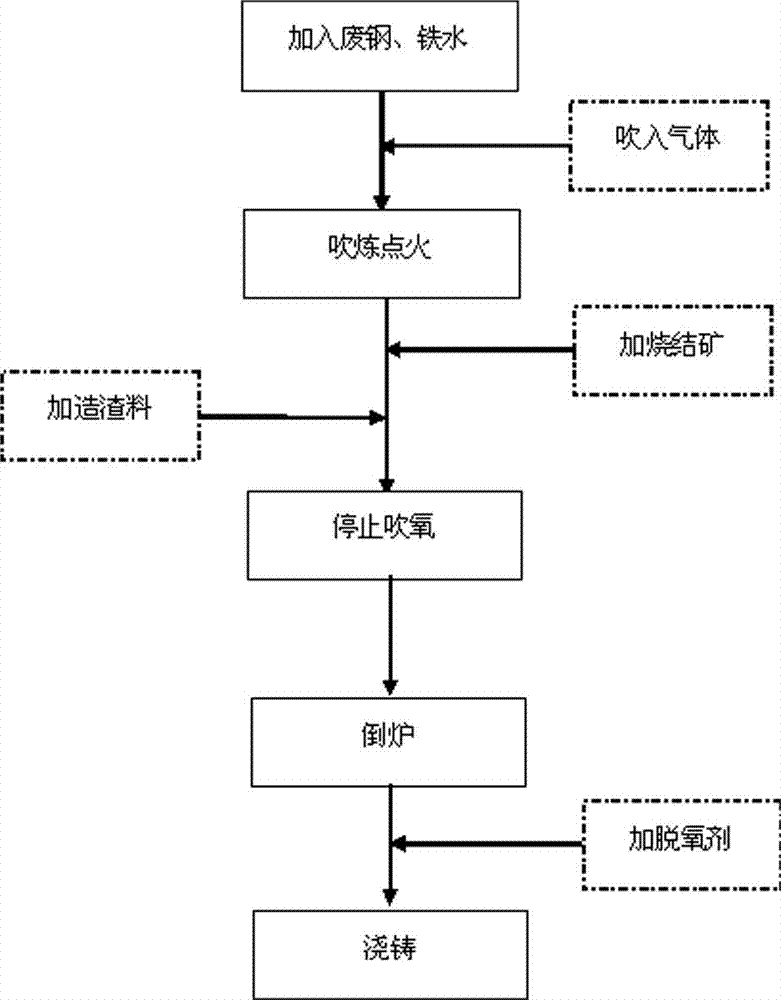

Method used

Image

Examples

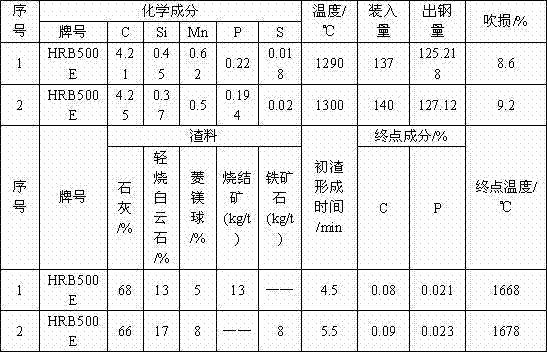

Embodiment 1

[0038] A 120t top-bottom double-blowing converter is used to blow smelt HRB400E steel. Scrap steel is first added to the converter and then molten iron is added. The total charge is 134t. The temperature of the molten iron is 1290°C. The weight percentage of the elements is C: 4.170%, Si: 0.310 %, Mn: 0.560%, S: 0.018%, P: 0.159%. Then blow oxygen into the furnace from the oxygen lance on the top of the converter (the purity of oxygen is ≥99.5%, the oxygen supply pressure is 0.86MPa, and the oxygen supply flow rate is 27000m 3 / h), nitrogen is blown into the bottom of the converter, and after the ignition is successful, lime, 16% of lightly burned dolomite, 8% of magnesite balls and 16% of the total slag are added from the high-level silo with a particle size of 3mm ~ 4mm, high alkalinity sintered ore with a basicity of 2 (the addition amount is 11kg / t), when blowing for 4 minutes, the flame at the furnace mouth softens and retracts, so it can be judged that the primary slag i...

Embodiment 2

[0040] A 120t top-bottom combined blowing converter is used to blow smelt Q235B steel. Scrap steel is first added to the converter and then molten iron is added. The loading capacity is 132t. The temperature of the molten iron is 1305°C. The weight percentage of the elements is C: 4.250%, Si: 0.470% , Mn: 0.530%, S: 0.024%, P: 0.175%. Then blow oxygen into the furnace from the oxygen lance on the top of the converter (the purity of oxygen is ≥99.5%, the oxygen supply pressure is 0.86MPa, and the oxygen supply flow rate is 27000m 3 / h), argon gas is blown into the bottom of the converter, and after the ignition is successful, lime, 30% lightly burned dolomite and 9% high alkalinity sintered ore (addition amount is 8kg / t), at 4.5 minutes of blowing, the flame at the furnace mouth softened and retracted, thus judging the formation of primary slag, controlled by the position of the gun and the addition of slag, the blowing was stable and normal, and the slag was added at 9′45″ F...

Embodiment 3

[0042] A 120t top-bottom double-blowing converter is used to blow smelt HRB500E steel. Scrap steel is first added to the converter and then molten iron is added. The loading capacity is 135t. The temperature of the molten iron is 1280°C. The weight percentage of the elements is C: 4.330%, Si: 0.420% , Mn: 0.590%, S: 0.018%, P: 0.203%. Then blow oxygen into the furnace from the oxygen lance on the top of the converter (the purity of oxygen is ≥99.5%, the oxygen supply pressure is 0.86MPa, and the oxygen supply flow rate is 27000m 3 / h), nitrogen is blown into the bottom of the converter, and after the ignition is successful, lime, 16% of lightly burned dolomite, 5% of magnesite balls and 11% of the particle size of the total slag are added from the high-level silo. 4mm~ 5mm, high alkalinity sintered ore with a basicity of 2.5 (adding amount: 12kg / t), when blowing for 4.5 minutes, the flame at the furnace mouth softens and retracts, so it can be judged that the primary slag is f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com