Blending method for power station pulverized coal boiler safe burning ramsbottom coke

A pulverized coal boiler and semi-coke technology, which is applied in the blending field of safely burning semi-coke in power station pulverized coal boilers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] According to GB / T 219-2008 "Measurement Method for Fusibility of Coal Ash" and GB / T 465-2007 "Test Method for Scouring Wear Index of Coal", the ash softening temperature ST and scouring wear index of Zhungeer Coal and Blue Coal were respectively measured Ke.

[0033] The ash softening temperature ST of Zhungeer coal is more than 1500 ℃, which belongs to slight slagging coal; the ash softening temperature ST of semi-coal is 1150 ℃, which belongs to serious slagging. The preliminarily determined semi-coke can be blended with 40-50% Zhungeer coal.

[0034] The scour wear index of Zhungeer coal is Ke=3, which belongs to strong wear grade; the scour wear index of semi-coal is Ke=27.7, which belongs to the third extremely strong wear grade. For the boiler equipped with steel ball mill pulverizing system, the scouring wear index Ke of mixed coal is controlled below 15, and the finally determined semi-coke blending ratio is 40%.

Embodiment 2

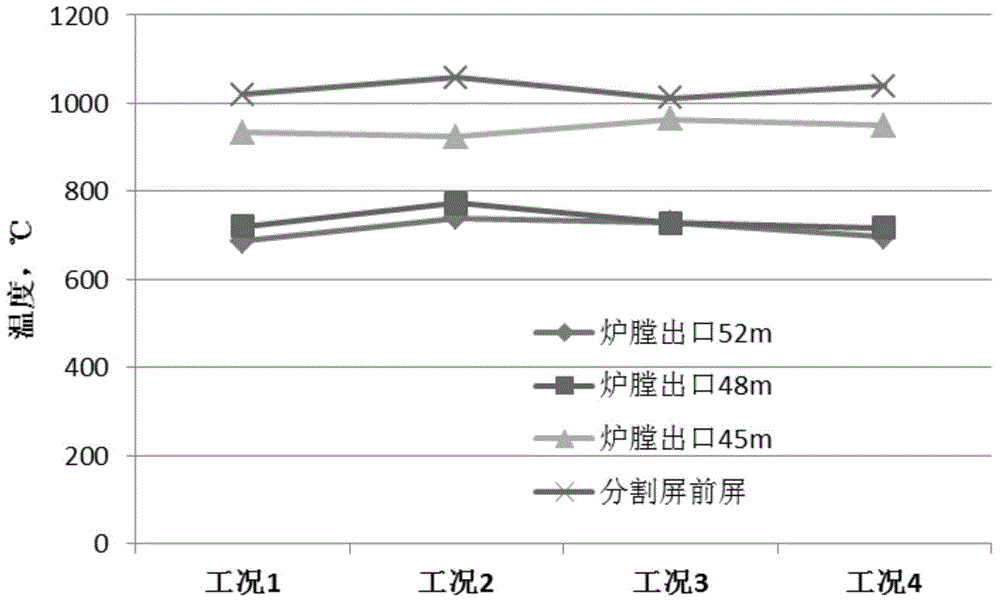

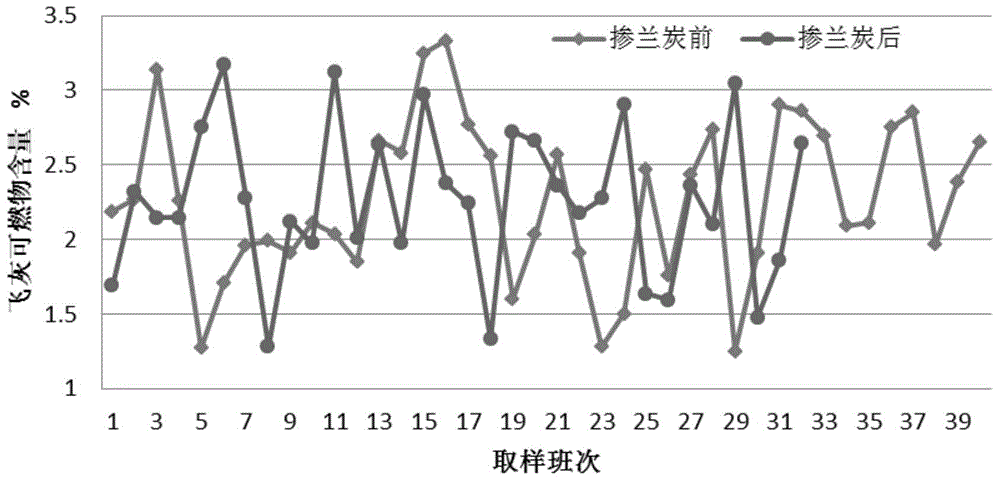

[0036] In this example, a coal blend of quasi-mix 5 (ST > 1500°C, Ke = 3) and semi-coke (ST = 1150°C, Ke = 27.7) is used on the 300MW unit boiler equipped with a steel ball mill pulverizing system. The ratio of blue charcoal blending determined in the present invention is 40%. Such as figure 1 As shown, there is no obvious change in the flue gas temperature at the outlet of the boiler furnace after blending 40% semi-coke, indicating that there is no obvious slagging phenomenon in the boiler furnace. In addition, the steam and water parameters of the boiler are normal, and the boiler can operate safely and stably. Such as figure 2 As shown, there is basically no change in the carbon content of fly ash combustibles in the boiler exhaust before and after blending 40% blue-coke, indicating that the boiler has good adaptability to 40% blue-coke blended coal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com