Converter steelmaking fluoride-free composite fluxing medium

A compound slagging agent and converter steelmaking technology, which is applied in the manufacture of converters and the improvement of process efficiency, can solve the problems of high slag viscosity, polluted air, poor fluidity, etc., and achieve obvious economic benefits, good slagging, and low price cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

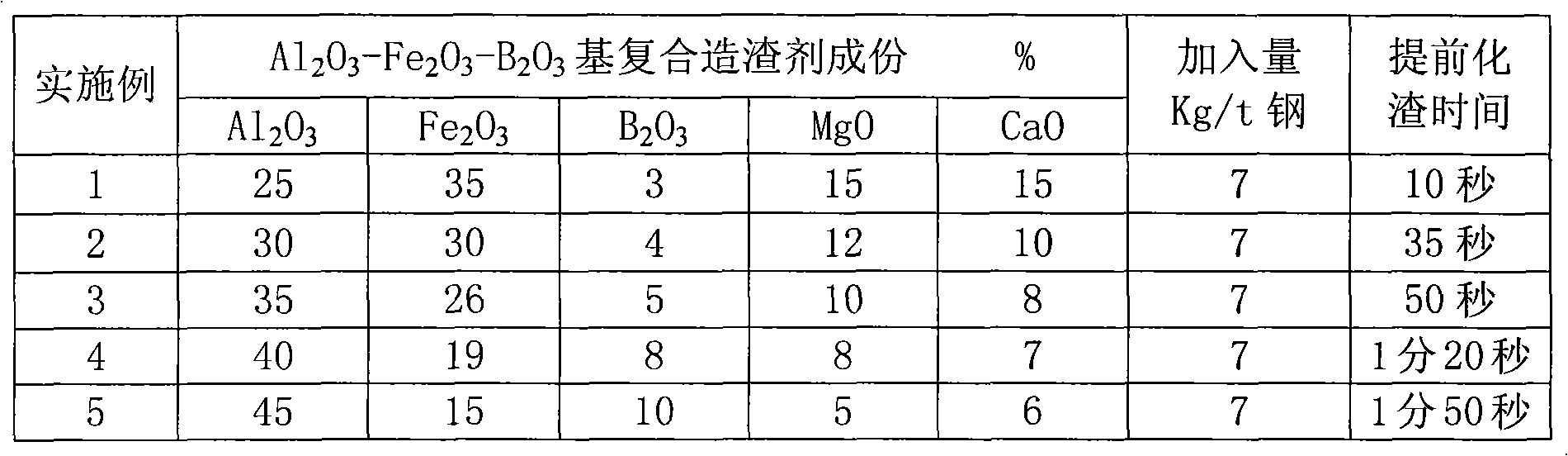

[0021] The raw materials are processed, crushed into granules / powders, and each component is weighed and compounded according to the specified weight percentage - adding binder - mixing - granulating - drying - cooling - bagging. Made into granular pellets with a particle size of Φ30-60mm. The 50-ton converter smelting steel grades are 35K and 40Cr, and the amount of compound slagging agent added is 6-8Kg / t, about 330Kg per furnace. Add into the converter in two batches: the first batch of composite slagging agent is added together with the first batch of slag material during blowing, and the quantity is 2 / 3 of the total amount; the second batch of balance is added at about 30% of the blowing. The slagging agent components are listed in the table by weight percentage (%) and the slagging time in advance.

Embodiment 2

[0023] Preparation and application were carried out according to the method of Example 1, and the weight percentage of each component and the advanced slagging time are listed in Table 1.

Embodiment 3

[0025] Preparation and application were carried out according to the method of Example 1, and the weight percentage of each component and the advanced slagging time were listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com