Biomass granular fuel with high combustion performance and preparation method thereof

A technology of biomass particles and combustion performance, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of difficult to burn completely, high ash content and easy slagging, poor combustion performance, etc., to achieve complete combustion, high burning rate, The effect of improving combustion efficiency and calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A preparation method of high-combustibility biomass particle fuel, comprising the following steps:

[0022] S1. Mix peat and ferric nitrate solution with a concentration of 0.05mol / L at a mass ratio of 1:10, then adjust the pH to 4.5, stir the reaction thoroughly, filter, dry, and heat-preserve and calcinate at 300°C under an inert atmosphere , to obtain peat-iron oxide composite material after cooling;

[0023] S2. Mix the peat-iron oxide composite material described in step S1 with the rosin emulsion having a solid content of 0.5% in a mass ratio of 1:8, then dry and pulverize to obtain a rosin-modified peat-iron oxide composite material;

[0024] S3. Mix the main biomass material, rosin modified peat-iron oxide composite material, and calcium carbonate in a mass ratio of 80:10:2, extrude and granulate under the conditions of 60MPa and 70°C to obtain a high-combustibility product. Material pellet fuel; wherein, the main biomass material is composed of wheat straw, pe...

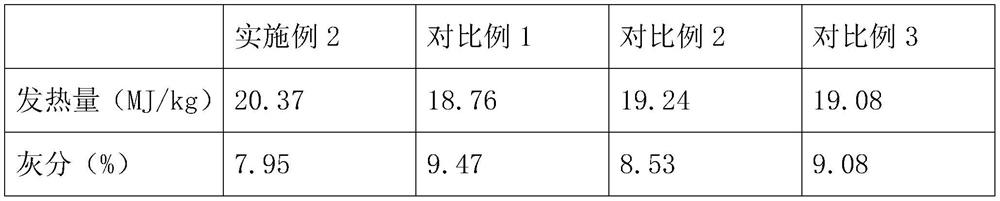

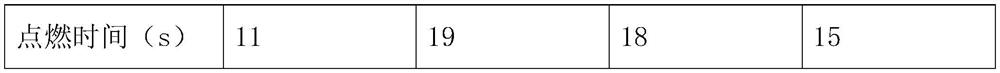

Embodiment 2

[0026] A preparation method of high-combustibility biomass particle fuel, comprising the following steps:

[0027] S1. Mix peat and ferric nitrate solution with a concentration of 0.06mol / L in a mass ratio of 1:15, then adjust the pH to 5, stir the reaction thoroughly, filter, dry, and heat-preserve and calcinate at 320°C under an inert atmosphere , to obtain peat-iron oxide composite material after cooling;

[0028] S2. Mix the peat-iron oxide composite material described in step S1 with the rosin emulsion having a solid content of 0.8% in a mass ratio of 1:9, then dry and pulverize to obtain a rosin-modified peat-iron oxide composite material;

[0029] S3. Mix the main biomass material, rosin modified peat-iron oxide composite material, and calcium carbonate at a mass ratio of 85:12:3, extrude and granulate at 70MPa and 80°C to obtain a high-combustibility product. Material pellet fuel; among them, the main biomass material is composed of wheat straw, peanut shells and sawd...

Embodiment 3

[0031] A preparation method of high-combustibility biomass particle fuel, comprising the following steps:

[0032] S1. Mix peat and 0.1mol / L ferric nitrate aqueous solution evenly in a mass ratio of 1:20, then adjust the pH to 5.5, fully stir the reaction, filter, dry, and heat-preserve and calcinate at 350°C under an inert atmosphere , to obtain peat-iron oxide composite material after cooling;

[0033] S2. Mix the peat-iron oxide composite material described in step S1 with the rosin emulsion having a solid content of 1% in a mass ratio of 1:10, then dry and pulverize to obtain a rosin-modified peat-iron oxide composite material;

[0034] S3. Mix the main biomass material, rosin modified peat-iron oxide composite material, and calcium carbonate at a mass ratio of 100:20:5, extrude and granulate at 80MPa and 100°C to obtain a high-combustibility product. Material pellet fuel; wherein, the main biomass material is composed of wheat straw, peanut shells and sawdust in a mass r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com