Wall type arranged horizontal rich-lean direct current combustion device

A combustion device and horizontal technology, applied in the field of coal-fired boilers, can solve problems such as slagging and high-temperature corrosion, and different gas supply conditions on both sides of the pulverized coal flow, so as to improve gas supply conditions and reduce water wall slagging and high-temperature corrosion , good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

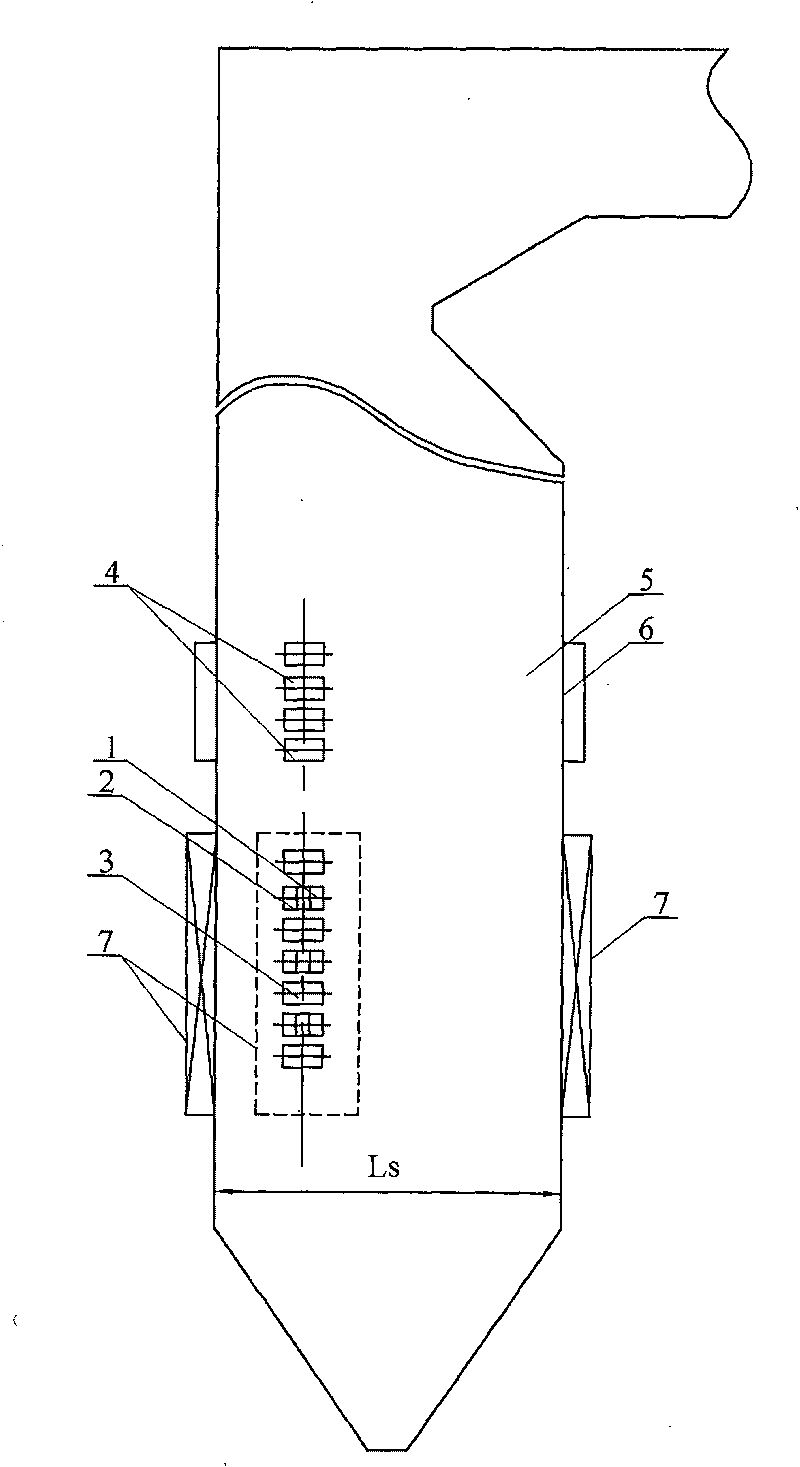

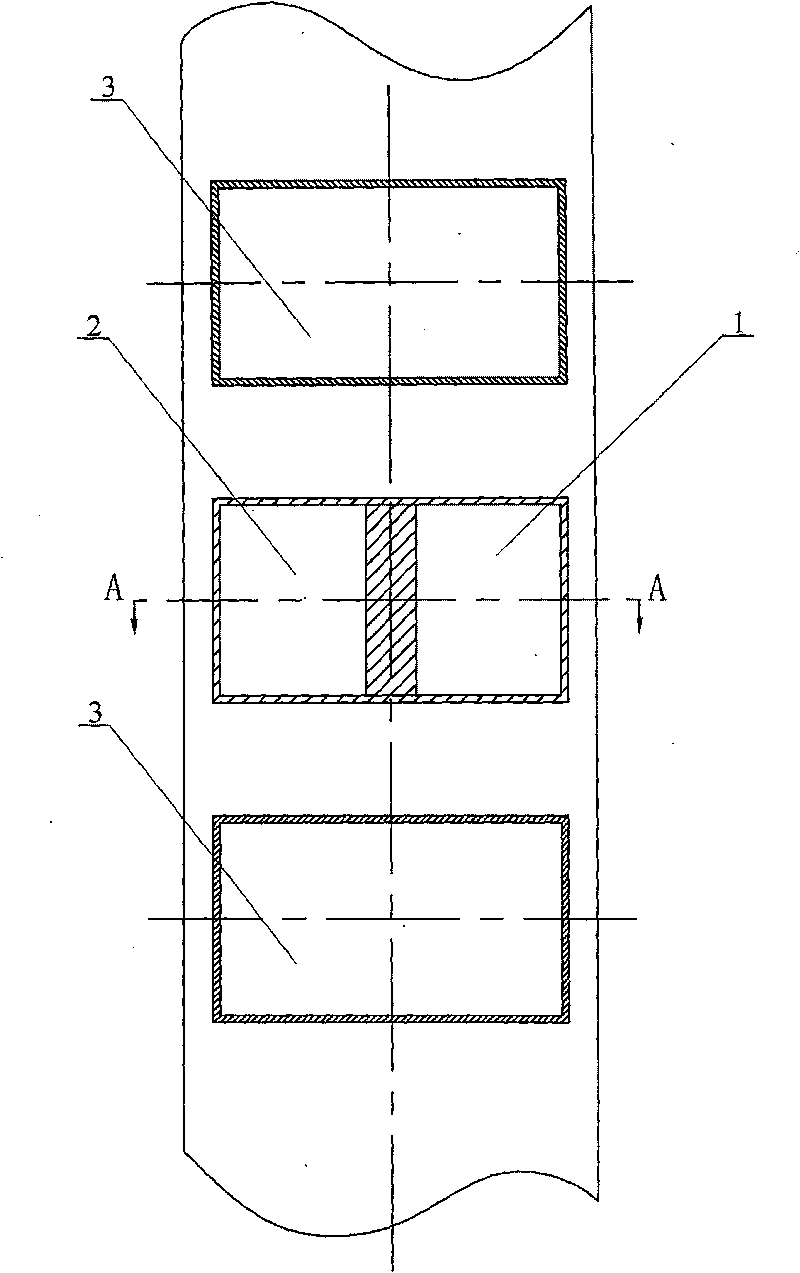

[0009] Specific implementation mode 1: Combination Figure 1~Figure 8 To illustrate this embodiment, this embodiment consists of a furnace 5, a plurality of concentrated primary air nozzles 1, a plurality of weak primary air nozzles 2, a plurality of secondary air nozzles 3, and four sets of burn-out air nozzles 4. The furnace 5 consists of Surrounded by water-cooled walls 6 on all sides, the four-sided water-cooled walls 6 of the furnace 5 are respectively provided with a plurality of concentrated primary air nozzles 1, a plurality of weak primary air nozzles 2 and a plurality of secondary air nozzles 3, each of the water walls The multiple dense primary air nozzles 1, multiple weak primary air nozzles 2 and multiple secondary air nozzles 3 set on 6 are combined to form a set of burners 7. The four sets of burners 7 are respectively arranged on the same horizontal surface, so The secondary air nozzles 3 in each group of burners 7 are alternately arranged up and down with the r...

specific Embodiment approach 2

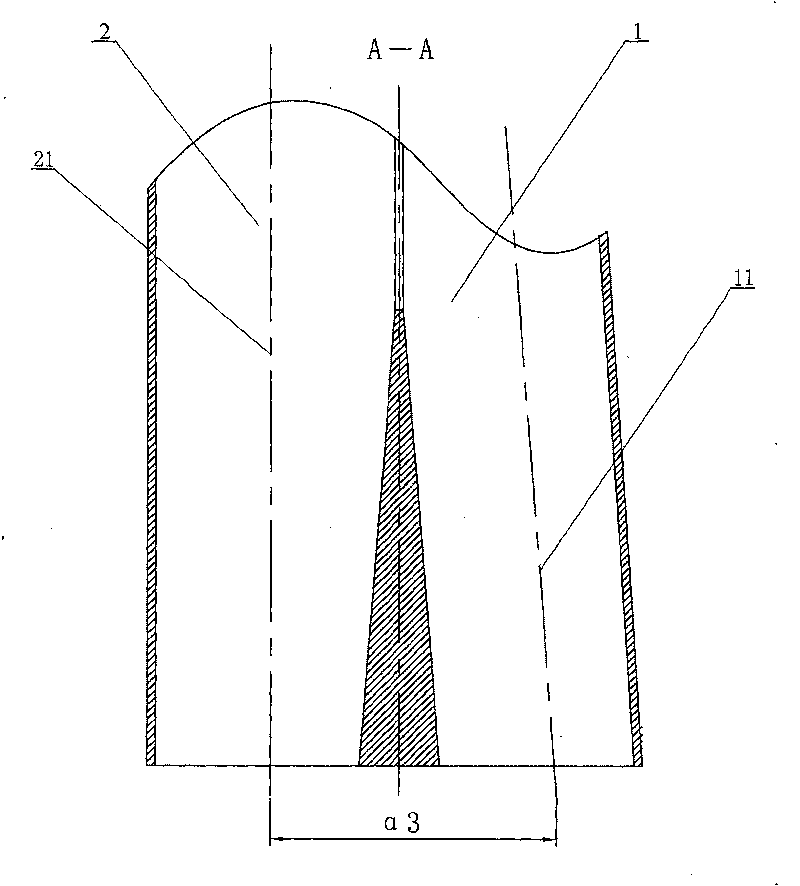

[0012] Specific implementation manner two: combination figure 1 , Figure 4 with Figure 8 To describe this embodiment, the distance between the center line 31 of the secondary air nozzle 3 provided on each water wall 6 and the intersection point on the water wall 6 where it is located is L from the corner of the nearest furnace 5 1 , 1 / 5Lk≤L 1 ≤1 / 2Lk; or 1 / 5Ls≤L 1 ≤1 / 2Ls, the Lk is the width of the furnace, and the Ls is the depth of the furnace. The angle between the center line 31 of the secondary air nozzle 3 in this embodiment and the water wall 6 on the fire side is 54°≤α 1 ≤127°, the angle between the center line 21 of the light primary air nozzle 2 and the water wall 6 on the fire side is 54°≤α 2 ≤127°, the angle between the centerline 11 of the concentrated primary air nozzle 1 and the centerline 21 of the weak primary air nozzle 2 is 0°≤α 3 ≤15°, the concentrated primary wind jet is arranged on the fire side, and the light primary wind jet is arranged on the back fire si...

specific Embodiment approach 3

[0013] Specific implementation mode three: combination Figure 5 To illustrate the present embodiment, the over-burned air nozzle 4 of this embodiment is provided on each corner of the furnace 5. When viewed from above the furnace 5, the center line 41 of the over-fired air nozzle 4 is opposite to it in a clockwise direction. The angle between the adjacent water wall 6 is 20°≤α 4 ≤70°. With this arrangement, the layout of the over-fired air is easy to realize, and the furnace full of the combustion air flow is better. Other components and connection relationships are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com