Gasification raw material, preparation method of the gasification raw material, and catalytic gasification method adopting the gasification raw material

A raw material and catalyst technology, applied in the raw material field of gasification process, can solve the problems of poor industrial application prospects, small catalyst loading, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

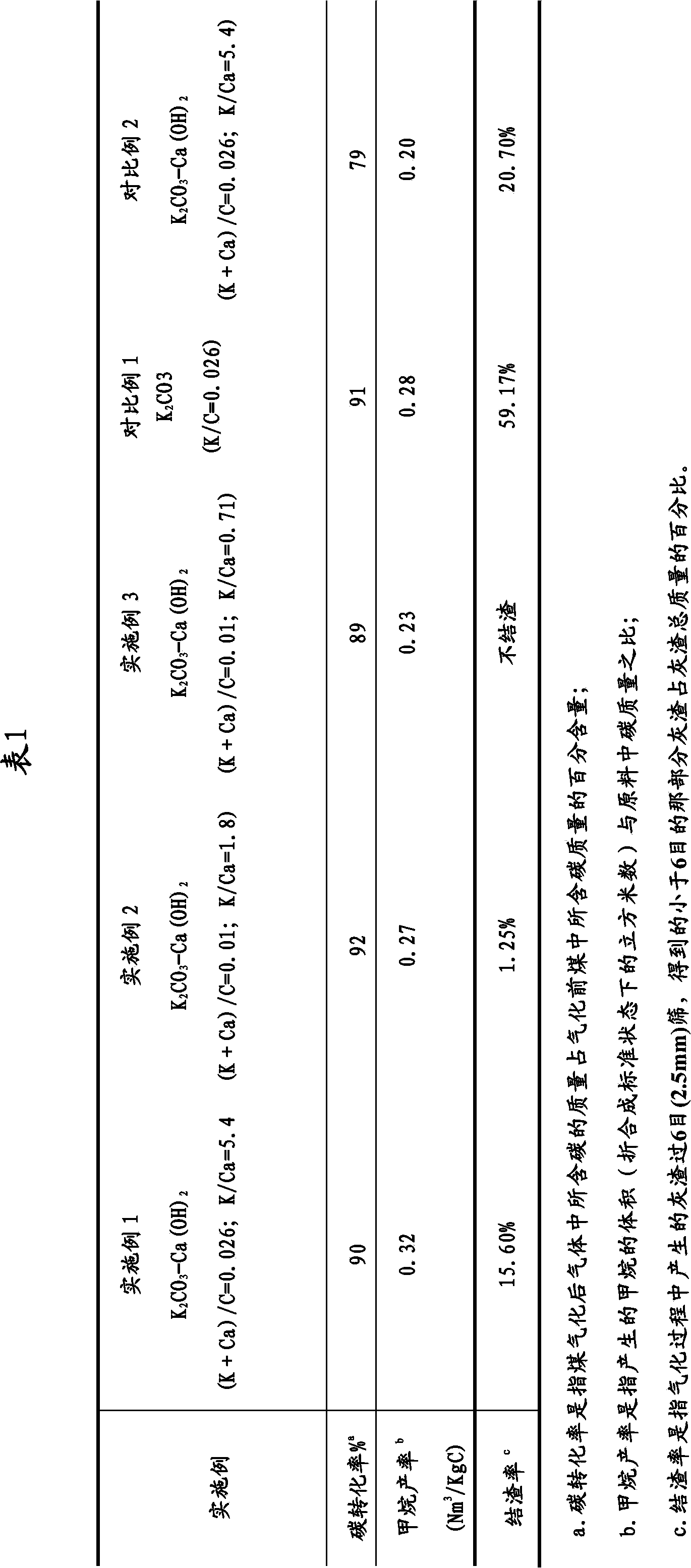

Examples

preparation example Construction

[0027] The method for preparing gasification raw material involved in the second aspect of the present invention comprises the following steps:

[0028] Loading the alkali metal catalyst on the first carbon-containing substance to obtain the first raw material;

[0029] Loading the alkaline earth metal catalyst on the second carbon-containing substance to obtain a second raw material;

[0030] The first raw material and the second raw material are uniformly mixed to obtain a gasification raw material.

[0031] Wherein the selection of the first carbonaceous substance, the second carbonaceous substance, the alkali metal catalyst and the alkaline earth metal catalyst is as described above.

[0032] The "loading" mentioned in the present invention should be understood in a broad sense, including the dispersion step and the drying step, wherein the "dispersion step" generally refers to making a substance (generally referred to as the target substance) in a discrete state A proce...

Embodiment 1

[0042] The selected coal type is Wangjiata bituminous coal (carbon content is about 60%). The raw coal is crushed to a particle size range of 0.25-2.5mm, divided into two parts, loaded with potassium carbonate and calcium hydroxide respectively, dried and mixed , to obtain the gasification raw material, and carry out the coal gasification experiment on the gasification raw material. Divide 100g of Wangjiata bituminous coal into two parts of equal mass, dissolve 7.5g of potassium carbonate in 40ml of deionized water, and then impregnate the obtained potassium carbonate solution on one part of 50g of Wangjiata bituminous coal, and dry it at 105°C to obtain the load Bituminous coal A with potassium carbonate catalyst; dissolve 1.5g of calcium hydroxide in 40ml of deionized water, then impregnate calcium hydroxide onto another 50g of Wangjiata bituminous coal, and dry at 105°C to obtain bituminous coal B with calcium hydroxide catalyst , mix A and B uniformly to obtain the gasific...

Embodiment 2

[0044] The selected coal type is Wangjiata bituminous coal (carbon content is about 60%). The raw coal is crushed to a particle size range of 0.25-2.5mm, divided into two parts, loaded with potassium carbonate and calcium hydroxide respectively, dried and mixed , to obtain the gasification raw material, and carry out the coal gasification experiment on the gasification raw material. Divide 100g of Wangjiata bituminous coal into two parts of equal mass, dissolve 2.5g of potassium carbonate in 40ml of deionized water, and then impregnate the obtained potassium carbonate solution on one part of 50g of Wangjiata bituminous coal, and dry it at 105°C to get the load Bituminous coal A with potassium carbonate catalyst; dissolve 1.5g of calcium hydroxide in 40ml of deionized water, then impregnate calcium hydroxide onto another 50g of Wangjiata bituminous coal, and dry at 105°C to obtain bituminous coal B with calcium hydroxide catalyst , mix A and B uniformly to obtain the gasificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com