Composite additive

A compound additive and additive technology, applied in the fields of energy, environmental protection, and chemical industry, can solve problems such as pollution of the environment, and achieve the effects of reducing emissions, inhibiting the production of NOx, and reducing the production and emission of NOx.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

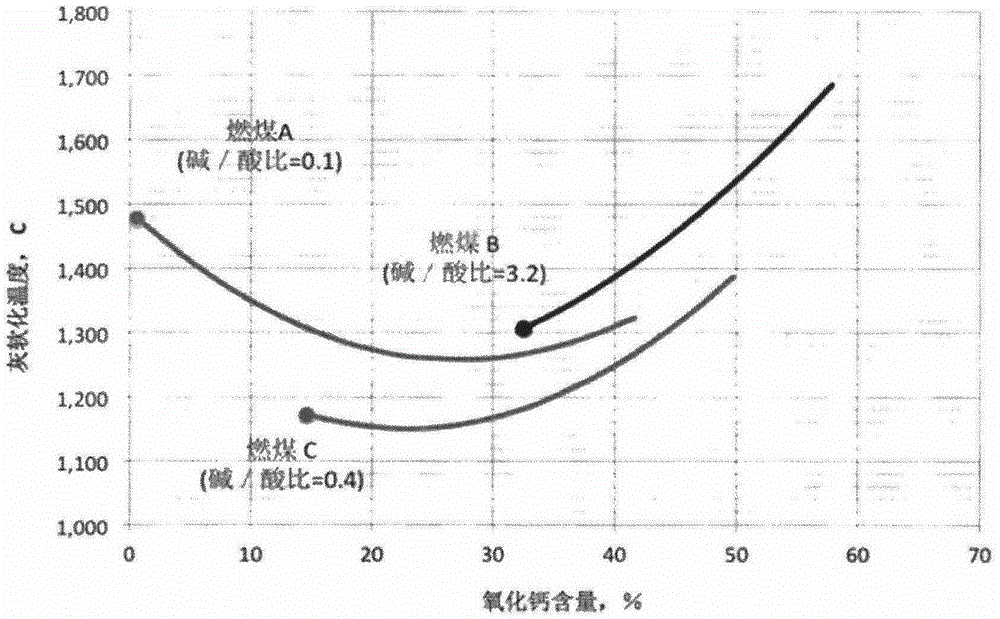

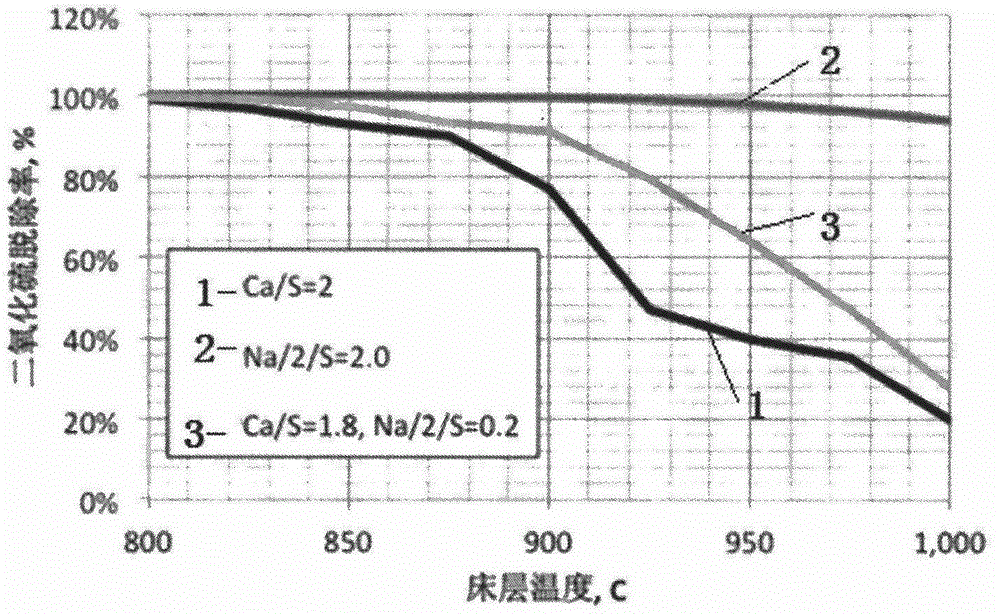

[0067] The embodiment of the present invention provides a composite additive, including calcium-based additives and sodium-based additives, the calcium-based additives include but not limited to inorganic calcium compounds, such as limestone powder (CaCO 3 ), slaked lime powder (Ca(OH) 2 ), lime (CaO) and dolomite (CaCO 3 MgCO 3 ), etc., and organic calcium compounds, such as calcium propionate, calcium magnesium acetate, etc.; the sodium-based additives include but are not limited to baking soda powder (NaHCO 3 ), soda ash (Na 2 CO 3 ) or caustic soda (NaOH). In this embodiment and subsequent embodiments, the calcium-based additive and the sodium-based additive may also include all wastes containing calcium or sodium, such as egg shells, shells, carbide slag or spent caustic soda.

[0068] In the composite additive comprising calcium-based additives and sodium-based additives provided in the embodiments of the present invention, after the calcium-based additives and sodi...

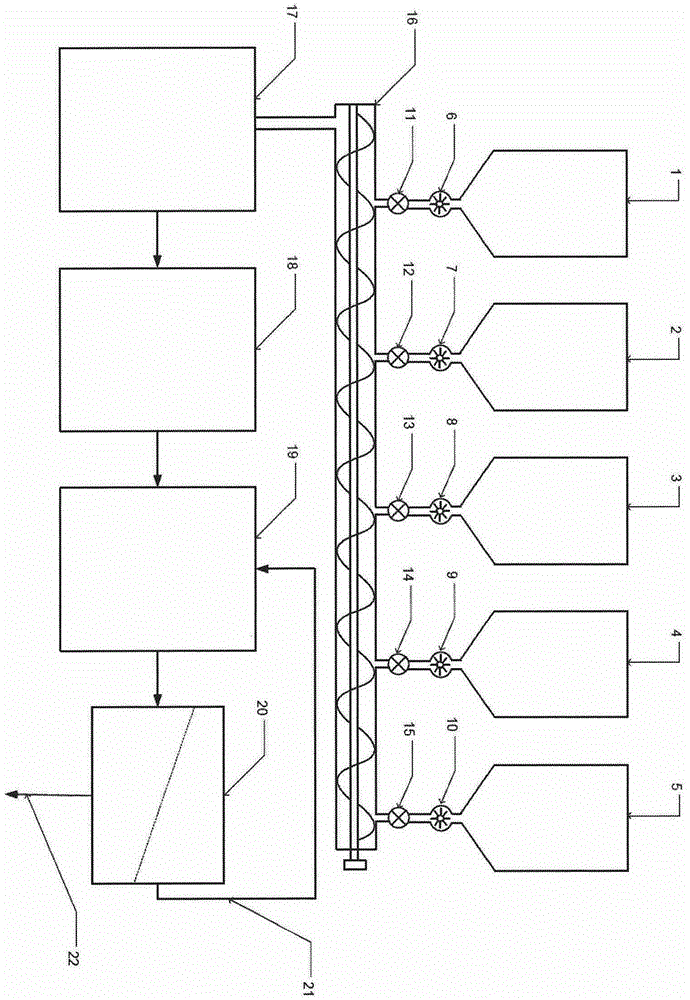

Embodiment 2

[0085] The composite additive provided in the embodiment of the present invention is based on the composite additive provided in Example 1 and then mixed with an amino additive, the amino additive includes but not limited to urea, ammonia water, ammonia sulfide, etc. After adding the amino additive in the composite additive , can remove the nitrate produced in the combustion process of coal powder.

[0086] In an embodiment of the present invention, the amount of amino additive added in the composite additive is based on the NOx pollutant generation and removal requirements of the coal to be mixed with the composite additive in the combustion process and the temperature and atmosphere (oxidizing atmosphere or reducing atmosphere) of the composite additive. Atmosphere) and selected and determined, in a preferred scheme, the molar ratio of the amino additive to the amount of NOx generated is in the range of 1 to 3, in a more preferred scheme, the molar ratio of the amino additive...

Embodiment 3

[0090] The composite additives provided in the embodiments of the present invention are based on the composite additives provided in Embodiment 1 or Embodiment 2 and then mixed with halogen additives. The halogen additives include calcium bromide, sodium bromide, calcium chloride, chloride Sodium etc. Halogen additives can remove heavy metal elements, such as mercury, that appear in pulverized coal during combustion. Mercury can exist in the air in the form of 0 valence, but 0 valence mercury is insoluble in water, only the divalent mercury oxide can dissolve in water or be condensed and adsorbed by fly ash to be removed. Halogen is a strong oxidizing agent, which can oxidize the zero-valent mercury produced by the combustion of coal powder into divalent mercury oxide, which can be dissolved in water or attached to coal ash to be removed.

[0091] In the embodiment of the present invention, the addition amount of the above-mentioned halogen additive is selected and determined...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com