Desulfurization, denitrification and decarbonization integrated system for ship waste gas

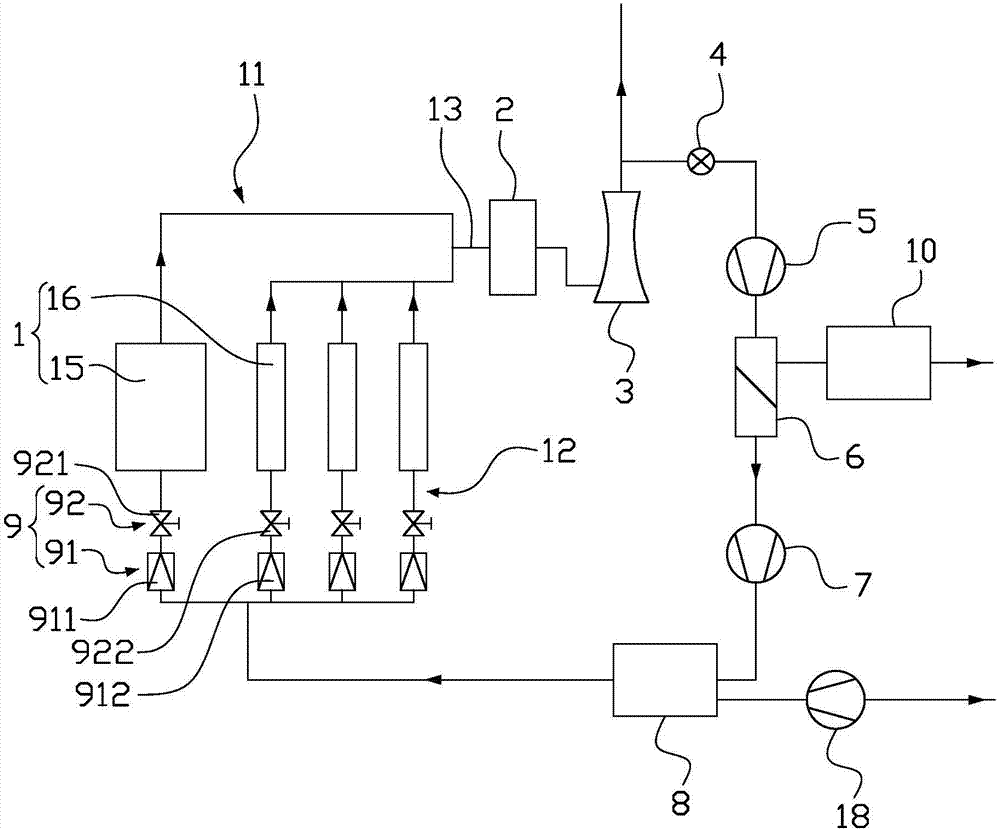

A technology for desulfurization of waste gas and ships. It is applied in the charging system, waste gas recirculation, exhaust device and other directions. It can solve the problems of restricting the handling of dangerous situations, reducing the speed and power of ships, and limiting the carrying capacity of ships. Effects achieved by emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The induced draft fan introduces 10% desulfurized waste gas into the first air compressor, and separates the carbon dioxide gas through the carbon dioxide membrane separation device, and presses the separated carbon dioxide gas into the carbon dioxide storage tank by the second air compressor for storage. When the control system receives the signal of the ship entering the ECA area, the corresponding intake valve in the intake valve group opens, and adjusts the opening of the intake valve according to the power signal of the main engine or auxiliary engine, and controls the intake of carbon dioxide to be the normal diesel engine scavenging volume. 5%. At this time, the weight value of nitrogen oxide emission under the four load points of 25%, 50%, 75%, and 100% is 3.1g / kwh, which meets the requirements of the IMO Convention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com