Harmless, recycling and integrated oil sludge treatment method

A treatment method and resource-based technology, applied in the field of oil sludge treatment, can solve the problems of waste water and waste residue, secondary pollutants, incomplete recovery, etc., achieve emission standards, ensure full decomposition, and strengthen the effect of furnace disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

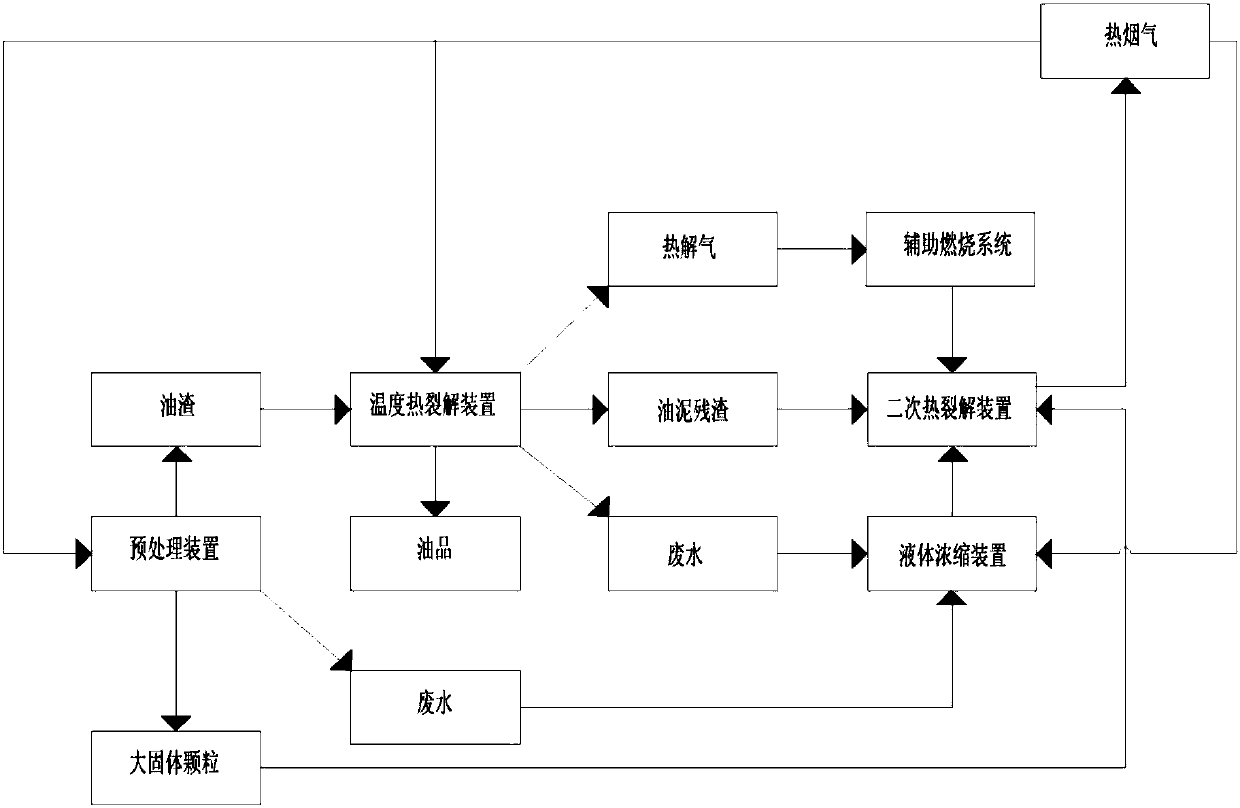

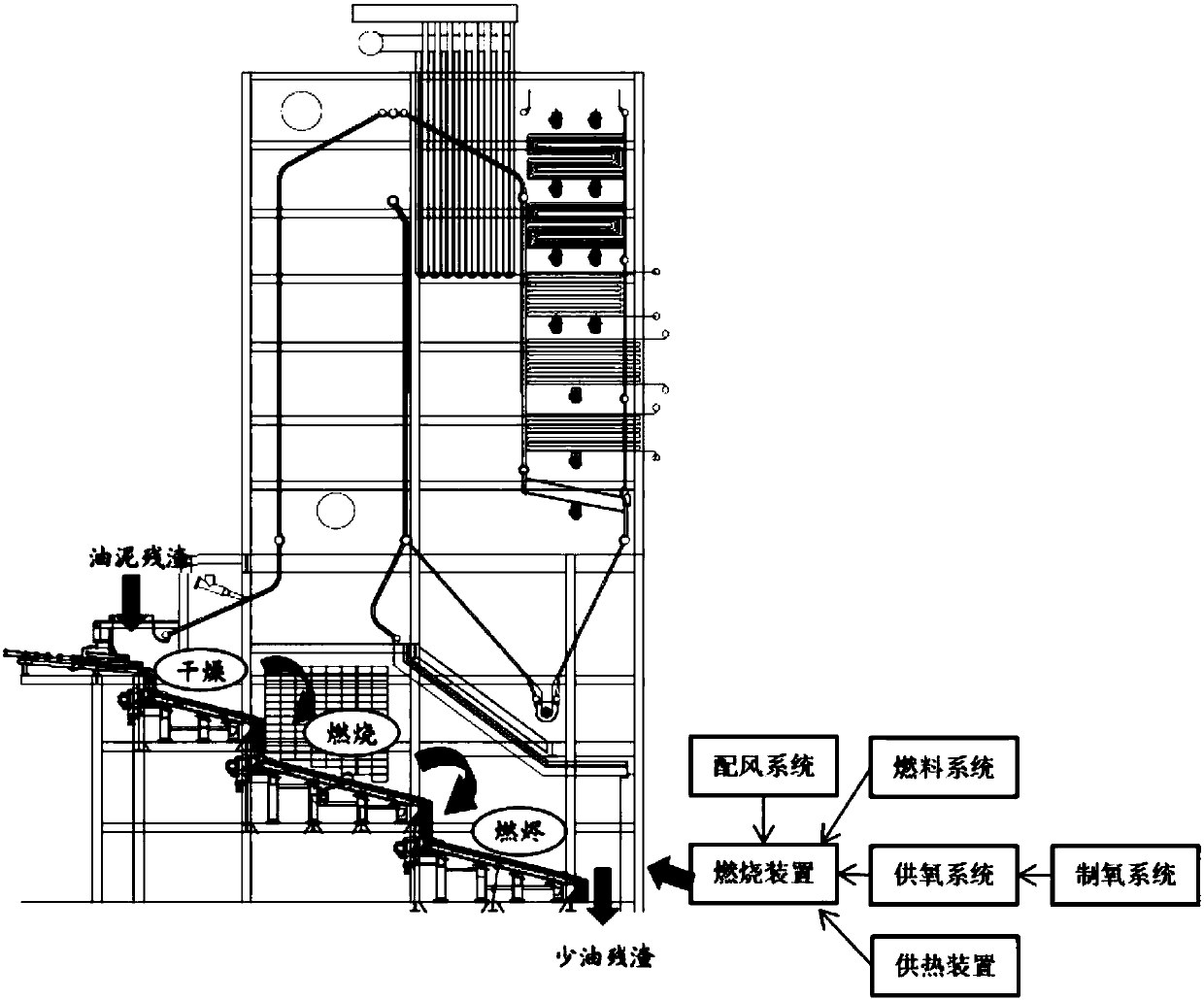

[0051] Embodiment one: if figure 1As shown, a harmless, resourceful, and integrated treatment method for oil sludge. The whole system is composed of a pretreatment device, a temperature thermal cracking device, a wastewater concentration device, a secondary thermal cracking device and a control system according to the process flow. The pyrolysis unit includes a reaction furnace, an auxiliary combustion system, a furnace air distribution system and a hot flue gas system. The auxiliary combustion system includes a combustion device, an air distribution system, a fuel system, a pyrolysis gas system, an oxygen supply system and an oxygen production system; both the fuel system and the pyrolysis gas system can provide combustion energy for the combustion device, and the pyrolysis gas system is preferred As energy supply, the fuel supplied by the fuel system can be coal or gas; the air distribution system is used to provide air distribution for combustion in the auxiliary combustion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com