Method for separating methanol-containing organic solvent binary azeotrope

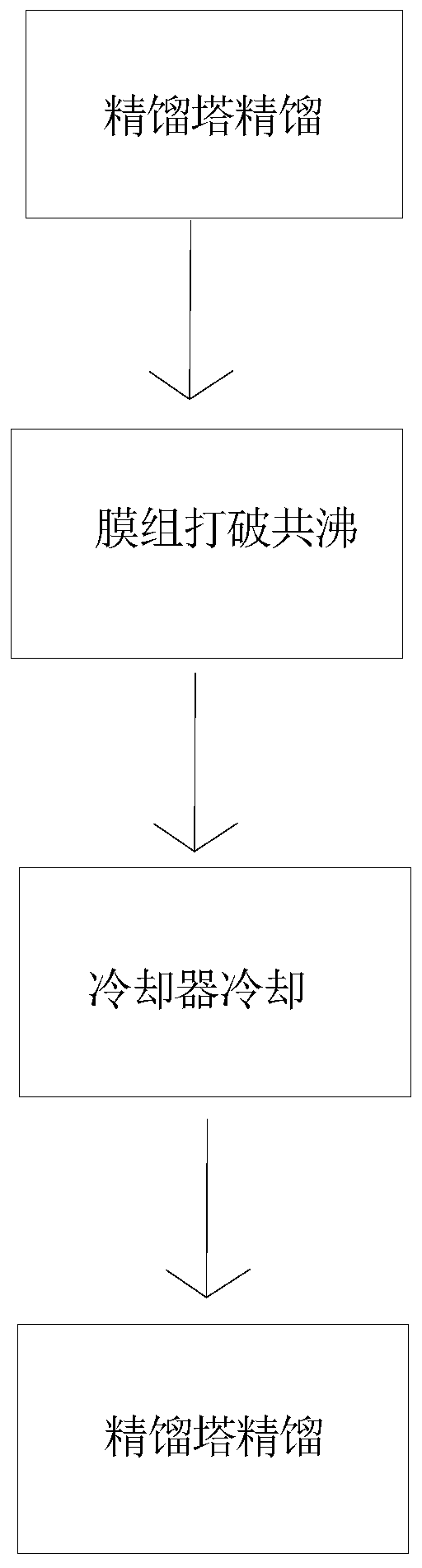

A binary azeotrope and organic solvent technology, applied in the field of methanol-containing organic solvent binary azeotrope separation method, can solve the problems of complex separation and purification process, low purity of methanol and organic solvent, cumbersome process flow, etc. Achieve the effects of reducing condensation conditions, small footprint, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

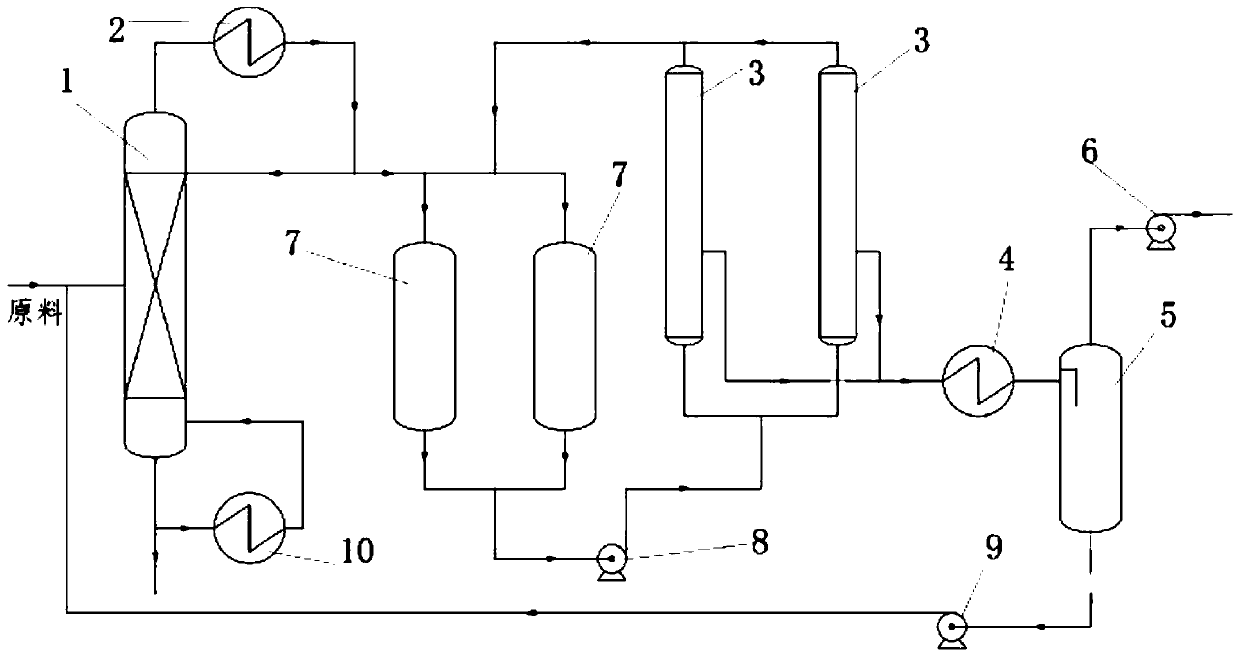

Embodiment 1

[0054] The ethyl acetate mixture material containing 60% methanol is transported to the rectification tower 1, and the ethyl acetate solution with a methanol content of 45% is obtained after the impurity removal and concentration of the rectification tower 1, and the methanol-containing organic solvent azeotropic material enters the infiltration In the circulation tank 7 of the vaporization membrane group 3, the heater heats the mixed material of ethyl acetate and methanol, and at the same time, the circulation pump 8 is turned on to heat the material evenly until the temperature reaches 120°C, and the vacuum pump 6 is turned on so that the vacuum degree of the permeate side is 10KPa; When the ethyl acetate and methanol materials reach a suitable operating temperature, increase the circulation rate so that the Reynolds number in the pervaporation membrane group 3 reaches about 13,000, and the system starts to repeatedly cycle out methanol and obtain ethyl acetate products with a...

Embodiment 2

[0056] Transport the toluene mixture material containing 80% methanol to the rectification tower 1, and obtain a toluene solution with a methanol content of 70% after the rectification tower 1 removes impurities and concentrates, and the azeotropic material of toluene and methanol enters the pervaporation membrane In the circulation tank of group 3, the heater heats the mixed material of toluene and methanol, and at the same time, the circulation pump 8 is turned on to heat the material evenly until the temperature reaches 130°C, and the vacuum pump 6 is turned on to make the vacuum degree reach 30KPa; when the toluene and methanol material reaches a suitable 130 ℃, increase the circulation rate, so that the Reynolds number in the pervaporation membrane group 3 reaches about 18,000, and the membrane system starts to repeatedly cycle out methanol and obtain a product with a methanol content of <0.5% toluene; when one of the circulation tanks starts to work, the other One circula...

Embodiment 3

[0058] The tetrahydrofuran mixture material containing 50% methanol is transported to the rectification tower one 1, and the tetrahydrofuran solution with a methanol content of 35% is obtained after the rectification tower one 1 removes impurities and concentrates, and the azeotropic material containing tetrahydrofuran and methanol enters the pervaporation After the ring tank of the membrane group 3, the heater heats the mixture of THF and methanol, and at the same time, the circulation pump 8 is turned on to heat the material evenly until the temperature reaches 120°C, and the vacuum pump 6 is turned on to make the vacuum reach 15KPa; when the ethyl acetate and methanol materials When the temperature reaches 120°C, increase the circulation rate so that the Reynolds number entering the pervaporation membrane group 3 reaches about 15,000, and the membrane system begins to repeatedly cycle out water and methanol and obtain a product containing methanol <0.5% THF; when one of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com